Miniaturization of Heat Engines Using Nitinol Elements

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nitinol Heat Engines: Background and Objectives

Nitinol, an alloy of nickel and titanium, has emerged as a revolutionary material in the field of heat engine miniaturization. This shape memory alloy, discovered in the 1960s, possesses unique properties that make it ideal for creating compact and efficient heat engines. The development of Nitinol-based heat engines represents a significant advancement in the quest for more sustainable and versatile energy solutions.

The primary objective of miniaturizing heat engines using Nitinol elements is to harness thermal energy more efficiently in compact devices. This technology aims to convert low-grade heat, often wasted in industrial processes or available from renewable sources, into useful mechanical work. By leveraging Nitinol's shape memory effect and superelasticity, researchers seek to create heat engines that can operate with small temperature differentials, making them suitable for a wide range of applications.

The evolution of Nitinol heat engines can be traced back to the early experiments with shape memory alloys in the 1970s. Initially, the focus was on understanding the material's unique properties and exploring potential applications. As research progressed, the potential for creating thermally-driven actuators became apparent, leading to the concept of Nitinol-based heat engines.

In recent years, the drive towards miniaturization has gained momentum, fueled by the increasing demand for portable and efficient energy harvesting devices. This trend aligns with the broader goals of developing sustainable energy solutions and improving energy efficiency across various sectors. The miniaturization of Nitinol heat engines holds promise for applications in wearable technology, remote sensing, and micro-robotics.

The technical challenges in this field primarily revolve around optimizing the thermomechanical properties of Nitinol for specific operating conditions. Researchers are working on enhancing the material's fatigue resistance, improving its response time to temperature changes, and increasing the overall energy conversion efficiency. Additionally, efforts are being made to develop novel designs that maximize the power output of these miniature heat engines while minimizing their size and weight.

As the technology continues to evolve, the focus is shifting towards integrating Nitinol heat engines into practical devices and systems. This includes exploring hybrid designs that combine Nitinol elements with other materials or energy conversion mechanisms to create more versatile and efficient energy harvesting solutions. The ultimate goal is to develop compact, reliable, and cost-effective heat engines that can tap into previously unutilized heat sources, contributing to a more sustainable energy landscape.

The primary objective of miniaturizing heat engines using Nitinol elements is to harness thermal energy more efficiently in compact devices. This technology aims to convert low-grade heat, often wasted in industrial processes or available from renewable sources, into useful mechanical work. By leveraging Nitinol's shape memory effect and superelasticity, researchers seek to create heat engines that can operate with small temperature differentials, making them suitable for a wide range of applications.

The evolution of Nitinol heat engines can be traced back to the early experiments with shape memory alloys in the 1970s. Initially, the focus was on understanding the material's unique properties and exploring potential applications. As research progressed, the potential for creating thermally-driven actuators became apparent, leading to the concept of Nitinol-based heat engines.

In recent years, the drive towards miniaturization has gained momentum, fueled by the increasing demand for portable and efficient energy harvesting devices. This trend aligns with the broader goals of developing sustainable energy solutions and improving energy efficiency across various sectors. The miniaturization of Nitinol heat engines holds promise for applications in wearable technology, remote sensing, and micro-robotics.

The technical challenges in this field primarily revolve around optimizing the thermomechanical properties of Nitinol for specific operating conditions. Researchers are working on enhancing the material's fatigue resistance, improving its response time to temperature changes, and increasing the overall energy conversion efficiency. Additionally, efforts are being made to develop novel designs that maximize the power output of these miniature heat engines while minimizing their size and weight.

As the technology continues to evolve, the focus is shifting towards integrating Nitinol heat engines into practical devices and systems. This includes exploring hybrid designs that combine Nitinol elements with other materials or energy conversion mechanisms to create more versatile and efficient energy harvesting solutions. The ultimate goal is to develop compact, reliable, and cost-effective heat engines that can tap into previously unutilized heat sources, contributing to a more sustainable energy landscape.

Market Analysis for Miniature Heat Engines

The market for miniature heat engines utilizing Nitinol elements is experiencing significant growth and attracting attention across various industries. This emerging technology offers promising applications in sectors such as medical devices, aerospace, robotics, and energy harvesting. The global market for shape memory alloys, including Nitinol, is projected to reach several billion dollars by 2025, with a compound annual growth rate exceeding 10%.

In the medical device industry, miniature heat engines based on Nitinol are finding applications in minimally invasive surgical tools, drug delivery systems, and implantable devices. The ability of these engines to operate at body temperature and their biocompatibility make them particularly attractive for medical applications. The growing demand for less invasive medical procedures and the increasing prevalence of chronic diseases are driving the adoption of Nitinol-based miniature heat engines in this sector.

The aerospace industry is another key market for miniature heat engines using Nitinol elements. These engines offer potential weight savings and improved efficiency in aircraft systems, such as actuators for control surfaces and thermal management systems. As the aerospace industry continues to focus on fuel efficiency and reducing environmental impact, the demand for lightweight and energy-efficient components is expected to drive the adoption of Nitinol-based miniature heat engines.

In the field of robotics, miniature heat engines utilizing Nitinol elements are being explored for use in micro-robotics and soft robotics applications. The ability of these engines to provide controlled, silent actuation with a high power-to-weight ratio makes them attractive for developing small-scale robotic systems. As the robotics industry continues to expand into new applications, including healthcare, manufacturing, and exploration, the demand for miniature heat engines is expected to grow.

Energy harvesting is another promising market for miniature heat engines based on Nitinol. These engines can convert low-grade waste heat into useful mechanical or electrical energy, offering potential applications in wearable devices, industrial sensors, and remote monitoring systems. The increasing focus on energy efficiency and sustainability across industries is driving interest in this technology for recovering and utilizing waste heat.

While the market for miniature heat engines using Nitinol elements shows significant potential, there are challenges to widespread adoption. These include the need for further research and development to improve efficiency and reliability, as well as the relatively high cost of Nitinol compared to conventional materials. However, as manufacturing processes improve and economies of scale are achieved, the cost of Nitinol-based components is expected to decrease, further driving market growth.

In the medical device industry, miniature heat engines based on Nitinol are finding applications in minimally invasive surgical tools, drug delivery systems, and implantable devices. The ability of these engines to operate at body temperature and their biocompatibility make them particularly attractive for medical applications. The growing demand for less invasive medical procedures and the increasing prevalence of chronic diseases are driving the adoption of Nitinol-based miniature heat engines in this sector.

The aerospace industry is another key market for miniature heat engines using Nitinol elements. These engines offer potential weight savings and improved efficiency in aircraft systems, such as actuators for control surfaces and thermal management systems. As the aerospace industry continues to focus on fuel efficiency and reducing environmental impact, the demand for lightweight and energy-efficient components is expected to drive the adoption of Nitinol-based miniature heat engines.

In the field of robotics, miniature heat engines utilizing Nitinol elements are being explored for use in micro-robotics and soft robotics applications. The ability of these engines to provide controlled, silent actuation with a high power-to-weight ratio makes them attractive for developing small-scale robotic systems. As the robotics industry continues to expand into new applications, including healthcare, manufacturing, and exploration, the demand for miniature heat engines is expected to grow.

Energy harvesting is another promising market for miniature heat engines based on Nitinol. These engines can convert low-grade waste heat into useful mechanical or electrical energy, offering potential applications in wearable devices, industrial sensors, and remote monitoring systems. The increasing focus on energy efficiency and sustainability across industries is driving interest in this technology for recovering and utilizing waste heat.

While the market for miniature heat engines using Nitinol elements shows significant potential, there are challenges to widespread adoption. These include the need for further research and development to improve efficiency and reliability, as well as the relatively high cost of Nitinol compared to conventional materials. However, as manufacturing processes improve and economies of scale are achieved, the cost of Nitinol-based components is expected to decrease, further driving market growth.

Current Challenges in Nitinol-based Heat Engine Miniaturization

The miniaturization of heat engines using Nitinol elements faces several significant challenges that hinder widespread adoption and commercialization. One of the primary obstacles is the limited energy density of Nitinol-based systems. While Nitinol exhibits remarkable shape memory and superelastic properties, the amount of work it can produce per unit volume is relatively low compared to conventional heat engines. This limitation necessitates larger Nitinol elements to generate sufficient power, conflicting with the goal of miniaturization.

Another critical challenge lies in the thermal management of Nitinol-based heat engines. Efficient heat transfer is crucial for optimal performance, but as the size of the engine decreases, maintaining effective heating and cooling cycles becomes increasingly difficult. The reduced surface area-to-volume ratio in miniaturized systems impedes rapid heat exchange, potentially leading to slower response times and reduced overall efficiency.

The fatigue life of Nitinol elements presents a significant hurdle in developing long-lasting, miniaturized heat engines. Repeated thermal cycling and shape changes can lead to material degradation over time, affecting the reliability and longevity of the engine. Addressing this issue requires advanced material engineering and design strategies to enhance the durability of Nitinol components without compromising their functional properties.

Control and precision in actuation pose another challenge in miniaturization efforts. As the scale of Nitinol elements decreases, achieving precise control over their shape-changing behavior becomes more complex. This is particularly crucial in applications requiring fine-tuned movements or specific power outputs, where even small variations can significantly impact performance.

The integration of Nitinol elements with other components in a miniaturized heat engine system presents additional challenges. Ensuring compatibility between Nitinol and other materials, as well as designing compact and efficient mechanical interfaces, requires innovative engineering solutions. This integration must be achieved while maintaining the overall miniature form factor and without compromising the engine's functionality.

Cost-effectiveness remains a substantial barrier to the widespread adoption of miniaturized Nitinol-based heat engines. The production of high-quality Nitinol with consistent properties can be expensive, especially when considering the specialized processing required for small-scale applications. Balancing the cost of materials and manufacturing with the performance benefits of Nitinol-based systems is crucial for commercial viability.

Lastly, the development of standardized design and manufacturing processes for miniaturized Nitinol heat engines is still in its infancy. The lack of established protocols and industry standards makes it challenging to scale production and ensure consistent quality across different applications and manufacturers. Overcoming this challenge requires collaborative efforts within the industry to develop and implement standardized practices for the design, production, and testing of miniaturized Nitinol-based heat engines.

Another critical challenge lies in the thermal management of Nitinol-based heat engines. Efficient heat transfer is crucial for optimal performance, but as the size of the engine decreases, maintaining effective heating and cooling cycles becomes increasingly difficult. The reduced surface area-to-volume ratio in miniaturized systems impedes rapid heat exchange, potentially leading to slower response times and reduced overall efficiency.

The fatigue life of Nitinol elements presents a significant hurdle in developing long-lasting, miniaturized heat engines. Repeated thermal cycling and shape changes can lead to material degradation over time, affecting the reliability and longevity of the engine. Addressing this issue requires advanced material engineering and design strategies to enhance the durability of Nitinol components without compromising their functional properties.

Control and precision in actuation pose another challenge in miniaturization efforts. As the scale of Nitinol elements decreases, achieving precise control over their shape-changing behavior becomes more complex. This is particularly crucial in applications requiring fine-tuned movements or specific power outputs, where even small variations can significantly impact performance.

The integration of Nitinol elements with other components in a miniaturized heat engine system presents additional challenges. Ensuring compatibility between Nitinol and other materials, as well as designing compact and efficient mechanical interfaces, requires innovative engineering solutions. This integration must be achieved while maintaining the overall miniature form factor and without compromising the engine's functionality.

Cost-effectiveness remains a substantial barrier to the widespread adoption of miniaturized Nitinol-based heat engines. The production of high-quality Nitinol with consistent properties can be expensive, especially when considering the specialized processing required for small-scale applications. Balancing the cost of materials and manufacturing with the performance benefits of Nitinol-based systems is crucial for commercial viability.

Lastly, the development of standardized design and manufacturing processes for miniaturized Nitinol heat engines is still in its infancy. The lack of established protocols and industry standards makes it challenging to scale production and ensure consistent quality across different applications and manufacturers. Overcoming this challenge requires collaborative efforts within the industry to develop and implement standardized practices for the design, production, and testing of miniaturized Nitinol-based heat engines.

Existing Miniaturization Techniques for Nitinol Heat Engines

01 Nitinol wire size and configuration in heat engines

The size and configuration of Nitinol wires play a crucial role in heat engine performance. Different wire diameters and arrangements can affect the engine's efficiency and power output. Optimizing these parameters is essential for maximizing the energy conversion from thermal to mechanical energy in Nitinol-based heat engines.- Nitinol element size and configuration in heat engines: The size and configuration of Nitinol elements play a crucial role in heat engine design. Optimizing the dimensions and arrangement of Nitinol wires or sheets can significantly impact the engine's efficiency and power output. Factors such as element thickness, length, and surface area are considered to maximize the heat transfer and shape memory effect of the Nitinol material.

- Temperature control and cycling of Nitinol elements: Effective temperature control and cycling of Nitinol elements are essential for heat engine operation. This involves precise heating and cooling mechanisms to exploit the shape memory properties of Nitinol. The size of heating and cooling components, as well as the overall engine design, must be optimized to ensure efficient temperature cycling and energy conversion.

- Integration of Nitinol elements with other engine components: The integration of Nitinol elements with other engine components is critical for overall performance. This includes designing appropriate interfaces between Nitinol elements and mechanical parts such as pistons, crankshafts, or turbines. The size and arrangement of these components must be carefully considered to maximize energy transfer and minimize losses.

- Scaling and miniaturization of Nitinol-based heat engines: Research focuses on scaling and miniaturizing Nitinol-based heat engines for various applications. This involves developing compact designs that maintain efficiency while reducing overall size. Challenges include managing heat transfer and mechanical stress in smaller Nitinol elements, as well as optimizing power output relative to engine dimensions.

- Material composition and treatment of Nitinol elements: The material composition and treatment of Nitinol elements significantly influence their performance in heat engines. This includes adjusting the nickel-titanium ratio, incorporating additional alloying elements, and applying specific heat treatments. These factors can affect the transformation temperatures, mechanical properties, and overall efficiency of the Nitinol elements, impacting the size and design of the heat engine.

02 Compact design of Nitinol-based heat engines

Developing compact and efficient Nitinol-based heat engines is a key focus area. These designs aim to minimize the overall size of the engine while maintaining or improving performance. Compact designs can lead to more practical applications and easier integration into various systems.Expand Specific Solutions03 Scaling of Nitinol elements for different power outputs

The scaling of Nitinol elements is crucial for achieving different power outputs in heat engines. By adjusting the size and number of Nitinol elements, engineers can design engines for various applications, from small-scale power generation to larger industrial uses. This scalability allows for flexibility in meeting diverse energy needs.Expand Specific Solutions04 Optimization of heat transfer surface area

The size and shape of Nitinol elements affect the heat transfer surface area, which is critical for the efficiency of heat engines. Optimizing this surface area through various element configurations can enhance the engine's performance by improving heat absorption and release cycles.Expand Specific Solutions05 Integration of Nitinol elements in micro-scale devices

Incorporating Nitinol elements into micro-scale heat engines presents unique challenges and opportunities. The size reduction of these elements allows for the development of miniature power generation devices, potentially leading to applications in microelectronics and medical implants.Expand Specific Solutions

Key Players in Nitinol and Miniature Heat Engine Industry

The miniaturization of heat engines using Nitinol elements is an emerging technology in the early stages of development, with a growing but still limited market. The competitive landscape is characterized by a mix of established industrial players and research institutions exploring potential applications. Companies like Shin-Etsu Chemical, Abbott Laboratories, and Honeywell are leveraging their materials expertise to advance Nitinol-based technologies. Universities such as Hunan University and Nanchang University are conducting fundamental research. The technology's maturity is still evolving, with ongoing efforts to optimize performance and scalability for practical applications in sectors like aerospace, medical devices, and energy harvesting.

Shin-Etsu Chemical Co., Ltd.

Technical Solution: Shin-Etsu Chemical has developed advanced Nitinol alloys with precise composition control, enabling the creation of miniaturized heat engines. Their approach involves fine-tuning the nickel-titanium ratio to optimize the shape memory effect and superelasticity of Nitinol elements. The company has implemented a proprietary heat treatment process that enhances the fatigue resistance of Nitinol, allowing for prolonged cyclic operation in miniature heat engines[1]. Additionally, Shin-Etsu has developed a novel surface treatment technique that improves the biocompatibility of Nitinol, expanding its potential applications in biomedical miniature devices[3].

Strengths: Precise composition control, enhanced fatigue resistance, and improved biocompatibility. Weaknesses: Potentially higher production costs due to specialized processes.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has pioneered the integration of Nitinol elements into miniaturized heat engines for aerospace applications. Their approach focuses on leveraging the high power density of Nitinol-based actuators to create compact, lightweight thermal energy harvesting systems. Honeywell has developed a proprietary Nitinol wire configuration that maximizes the energy conversion efficiency in small-scale heat engines[2]. The company has also implemented advanced control algorithms to optimize the phase transformation timing of Nitinol elements, resulting in improved overall system performance[4]. Furthermore, Honeywell has successfully miniaturized supporting components, such as heat exchangers and electrical generators, to create fully integrated micro-scale heat engine systems.

Strengths: Expertise in aerospace applications, high energy conversion efficiency, and integrated system design. Weaknesses: Potentially limited to high-end applications due to complexity and cost.

Core Innovations in Nitinol-based Heat Engine Design

Nitinol alloy for with good mechanical stability and a good superelastic operating window

PatentWO2006081011A3

Innovation

- Development of a nickel-titanium alloy with an additional element (e.g., platinum, palladium, manganese) to achieve a large superelastic operating temperature window.

- Establishment of a mathematical relationship between temperature and upper plateau stress for the alloy, expressed as UP=(0.66ksi/°C)(T)+s0, with R2=0.98.

- Optimization of heat treatment and area reduction steps to enhance the alloy's superelastic properties and mechanical stability.

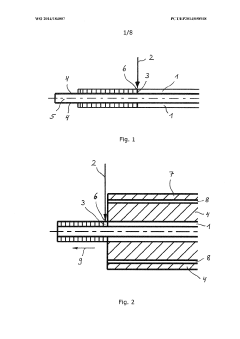

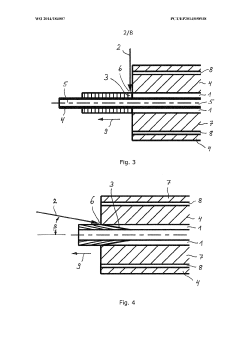

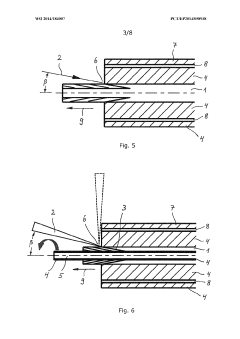

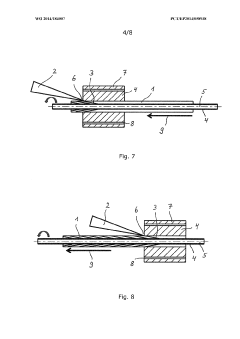

Method and device for remelting and/or remelt-alloying metallic materials, in particular nitinol

PatentWO2014184007A1

Innovation

- A method involving high-energy, focused radiation to selectively melt and rapidly solidify nitinol using a melting capillary, where heat is extracted through a cooled heat sink with good thermal conductivity, allowing for a high cooling rate that prevents the formation of inclusions by rapidly solidifying the molten material.

Thermal Management Strategies for Miniature Heat Engines

Thermal management is a critical aspect of miniaturizing heat engines using Nitinol elements. As these engines become smaller, the challenges of efficiently dissipating heat and maintaining optimal operating temperatures become more pronounced. Effective thermal management strategies are essential to ensure the performance, reliability, and longevity of miniature heat engines.

One key approach to thermal management in miniature heat engines is the implementation of advanced heat sink designs. These heat sinks are engineered to maximize surface area for heat dissipation while minimizing overall size. Micro-channel heat sinks, for instance, utilize intricate networks of small channels to increase cooling efficiency. Additionally, the integration of phase-change materials (PCMs) into heat sink structures can provide temporary heat storage and help regulate temperature fluctuations during operation.

Another important strategy involves the optimization of thermal interfaces between components. In miniature heat engines, even small thermal resistances can significantly impact overall performance. The use of high-performance thermal interface materials, such as graphene-based compounds or liquid metal alloys, can greatly enhance heat transfer between Nitinol elements and other engine components. Furthermore, advanced bonding techniques, like diffusion bonding or laser welding, can be employed to create more efficient thermal pathways.

Active cooling systems, despite the challenges of miniaturization, play a crucial role in thermal management for these engines. Micro-scale thermoelectric coolers (TECs) can be integrated to provide localized cooling at critical points. Similarly, miniature heat pipes or loop heat pipes can be utilized to transport heat away from sensitive areas more efficiently than traditional conduction methods.

The strategic placement of thermal sensors and the implementation of intelligent thermal management systems are also vital. By continuously monitoring temperature distributions across the engine, these systems can dynamically adjust cooling parameters to maintain optimal operating conditions. This approach not only enhances performance but also contributes to the overall efficiency and lifespan of the miniature heat engine.

Lastly, the development of novel materials with enhanced thermal properties is an ongoing area of research that holds promise for improving thermal management in miniature heat engines. For instance, nanostructured materials with tailored thermal conductivity or innovative composites that combine high thermal conductivity with low thermal expansion could revolutionize heat dissipation in these compact systems.

One key approach to thermal management in miniature heat engines is the implementation of advanced heat sink designs. These heat sinks are engineered to maximize surface area for heat dissipation while minimizing overall size. Micro-channel heat sinks, for instance, utilize intricate networks of small channels to increase cooling efficiency. Additionally, the integration of phase-change materials (PCMs) into heat sink structures can provide temporary heat storage and help regulate temperature fluctuations during operation.

Another important strategy involves the optimization of thermal interfaces between components. In miniature heat engines, even small thermal resistances can significantly impact overall performance. The use of high-performance thermal interface materials, such as graphene-based compounds or liquid metal alloys, can greatly enhance heat transfer between Nitinol elements and other engine components. Furthermore, advanced bonding techniques, like diffusion bonding or laser welding, can be employed to create more efficient thermal pathways.

Active cooling systems, despite the challenges of miniaturization, play a crucial role in thermal management for these engines. Micro-scale thermoelectric coolers (TECs) can be integrated to provide localized cooling at critical points. Similarly, miniature heat pipes or loop heat pipes can be utilized to transport heat away from sensitive areas more efficiently than traditional conduction methods.

The strategic placement of thermal sensors and the implementation of intelligent thermal management systems are also vital. By continuously monitoring temperature distributions across the engine, these systems can dynamically adjust cooling parameters to maintain optimal operating conditions. This approach not only enhances performance but also contributes to the overall efficiency and lifespan of the miniature heat engine.

Lastly, the development of novel materials with enhanced thermal properties is an ongoing area of research that holds promise for improving thermal management in miniature heat engines. For instance, nanostructured materials with tailored thermal conductivity or innovative composites that combine high thermal conductivity with low thermal expansion could revolutionize heat dissipation in these compact systems.

Environmental Impact of Nitinol-based Miniature Heat Engines

The environmental impact of Nitinol-based miniature heat engines is a crucial aspect to consider as this technology advances. These engines, while offering potential benefits in terms of energy efficiency and compact design, also present unique environmental challenges throughout their lifecycle.

The production of Nitinol, a nickel-titanium alloy, involves energy-intensive processes and the extraction of raw materials. Mining and refining nickel and titanium can lead to habitat disruption, soil erosion, and water pollution if not properly managed. Additionally, the manufacturing process of Nitinol requires high temperatures and precise control, potentially resulting in significant energy consumption and associated greenhouse gas emissions.

During the operational phase, Nitinol-based miniature heat engines offer several environmental advantages. Their high efficiency in converting low-grade heat into mechanical work can lead to reduced fossil fuel consumption and lower carbon emissions compared to traditional heat engines. The compact size of these engines also means less material usage and potentially reduced transportation-related emissions.

However, the long-term environmental effects of widespread adoption of these engines must be carefully evaluated. The durability and lifespan of Nitinol components in repeated thermal cycling conditions need to be assessed to determine the frequency of replacement and associated waste generation. Proper disposal and recycling protocols for Nitinol-based devices are essential to minimize environmental impact at the end of their lifecycle.

The potential for Nitinol to leach nickel into the environment, particularly in aquatic ecosystems, is a concern that requires further study. While Nitinol is generally considered biocompatible, the long-term effects of its degradation products on various ecosystems are not yet fully understood.

On a broader scale, the implementation of Nitinol-based miniature heat engines could contribute to more efficient energy recovery systems, potentially reducing overall energy consumption and associated environmental impacts. This technology could play a role in harnessing waste heat from industrial processes or natural sources, thereby indirectly contributing to reduced reliance on fossil fuels.

As research and development in this field progress, it is crucial to conduct comprehensive life cycle assessments to fully understand and mitigate the environmental impacts of Nitinol-based miniature heat engines. This should include considerations for sustainable sourcing of raw materials, energy-efficient manufacturing processes, optimized operational efficiency, and responsible end-of-life management.

The production of Nitinol, a nickel-titanium alloy, involves energy-intensive processes and the extraction of raw materials. Mining and refining nickel and titanium can lead to habitat disruption, soil erosion, and water pollution if not properly managed. Additionally, the manufacturing process of Nitinol requires high temperatures and precise control, potentially resulting in significant energy consumption and associated greenhouse gas emissions.

During the operational phase, Nitinol-based miniature heat engines offer several environmental advantages. Their high efficiency in converting low-grade heat into mechanical work can lead to reduced fossil fuel consumption and lower carbon emissions compared to traditional heat engines. The compact size of these engines also means less material usage and potentially reduced transportation-related emissions.

However, the long-term environmental effects of widespread adoption of these engines must be carefully evaluated. The durability and lifespan of Nitinol components in repeated thermal cycling conditions need to be assessed to determine the frequency of replacement and associated waste generation. Proper disposal and recycling protocols for Nitinol-based devices are essential to minimize environmental impact at the end of their lifecycle.

The potential for Nitinol to leach nickel into the environment, particularly in aquatic ecosystems, is a concern that requires further study. While Nitinol is generally considered biocompatible, the long-term effects of its degradation products on various ecosystems are not yet fully understood.

On a broader scale, the implementation of Nitinol-based miniature heat engines could contribute to more efficient energy recovery systems, potentially reducing overall energy consumption and associated environmental impacts. This technology could play a role in harnessing waste heat from industrial processes or natural sources, thereby indirectly contributing to reduced reliance on fossil fuels.

As research and development in this field progress, it is crucial to conduct comprehensive life cycle assessments to fully understand and mitigate the environmental impacts of Nitinol-based miniature heat engines. This should include considerations for sustainable sourcing of raw materials, energy-efficient manufacturing processes, optimized operational efficiency, and responsible end-of-life management.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!