Nitinol Influence in Small-Scale Energy Harvesting Devices

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nitinol in Energy Harvesting: Background and Objectives

Nitinol, an alloy of nickel and titanium, has emerged as a promising material in the field of small-scale energy harvesting devices. This shape memory alloy (SMA) possesses unique properties that make it particularly suitable for converting thermal and mechanical energy into electrical energy at miniature scales. The development of Nitinol-based energy harvesting technologies has gained significant momentum over the past decade, driven by the increasing demand for self-powered microelectronic devices and wireless sensor networks.

The primary objective of exploring Nitinol in energy harvesting is to harness its shape memory effect and superelasticity to create efficient, compact, and durable energy conversion systems. These properties allow Nitinol to undergo reversible phase transformations in response to temperature changes or mechanical stress, enabling the material to generate electrical energy from ambient thermal and mechanical sources.

The evolution of Nitinol in energy harvesting can be traced back to its discovery in the 1960s at the Naval Ordnance Laboratory. Initially utilized in aerospace and medical applications, researchers began to recognize its potential for energy harvesting in the early 2000s. Since then, significant advancements have been made in understanding the material's behavior at small scales and optimizing its performance for energy conversion.

Current research focuses on developing novel device architectures and improving the energy conversion efficiency of Nitinol-based harvesters. Key areas of investigation include enhancing the material's fatigue resistance, increasing its power output, and broadening the range of operating temperatures. Additionally, efforts are being made to integrate Nitinol with other smart materials and microelectronic components to create hybrid energy harvesting systems.

The potential applications of Nitinol in small-scale energy harvesting are vast and diverse. These include powering wearable electronics, implantable medical devices, structural health monitoring sensors, and Internet of Things (IoT) nodes. The ability to scavenge energy from ambient sources offers the promise of extended device lifetimes, reduced maintenance requirements, and deployment in remote or inaccessible locations.

As we look towards the future, the continued development of Nitinol-based energy harvesting technologies is expected to play a crucial role in enabling self-sustaining microelectronic systems. The integration of these devices with emerging technologies such as flexible electronics and nanotechnology presents exciting opportunities for innovation and advancement in the field of small-scale energy harvesting.

The primary objective of exploring Nitinol in energy harvesting is to harness its shape memory effect and superelasticity to create efficient, compact, and durable energy conversion systems. These properties allow Nitinol to undergo reversible phase transformations in response to temperature changes or mechanical stress, enabling the material to generate electrical energy from ambient thermal and mechanical sources.

The evolution of Nitinol in energy harvesting can be traced back to its discovery in the 1960s at the Naval Ordnance Laboratory. Initially utilized in aerospace and medical applications, researchers began to recognize its potential for energy harvesting in the early 2000s. Since then, significant advancements have been made in understanding the material's behavior at small scales and optimizing its performance for energy conversion.

Current research focuses on developing novel device architectures and improving the energy conversion efficiency of Nitinol-based harvesters. Key areas of investigation include enhancing the material's fatigue resistance, increasing its power output, and broadening the range of operating temperatures. Additionally, efforts are being made to integrate Nitinol with other smart materials and microelectronic components to create hybrid energy harvesting systems.

The potential applications of Nitinol in small-scale energy harvesting are vast and diverse. These include powering wearable electronics, implantable medical devices, structural health monitoring sensors, and Internet of Things (IoT) nodes. The ability to scavenge energy from ambient sources offers the promise of extended device lifetimes, reduced maintenance requirements, and deployment in remote or inaccessible locations.

As we look towards the future, the continued development of Nitinol-based energy harvesting technologies is expected to play a crucial role in enabling self-sustaining microelectronic systems. The integration of these devices with emerging technologies such as flexible electronics and nanotechnology presents exciting opportunities for innovation and advancement in the field of small-scale energy harvesting.

Market Analysis for Nitinol-based Energy Harvesters

The market for Nitinol-based energy harvesters is experiencing significant growth, driven by the increasing demand for small-scale energy harvesting devices across various industries. Nitinol, a shape memory alloy with unique properties, has emerged as a promising material for energy harvesting applications due to its ability to convert thermal energy into mechanical work.

The global market for energy harvesting devices is projected to reach substantial value in the coming years, with Nitinol-based solutions expected to capture a significant share. This growth is primarily fueled by the rising adoption of Internet of Things (IoT) devices, wearable technologies, and autonomous sensors in industries such as healthcare, automotive, aerospace, and consumer electronics.

In the healthcare sector, Nitinol-based energy harvesters are finding applications in implantable medical devices and wearable health monitors. These devices can harness body heat to power sensors and transmitters, reducing the need for battery replacements and improving patient comfort. The automotive industry is also exploring Nitinol-based solutions for harvesting waste heat from engines and exhaust systems, contributing to improved fuel efficiency and reduced emissions.

The aerospace sector presents another promising market for Nitinol-based energy harvesters. These devices can be used to power wireless sensors in aircraft structures, enabling real-time monitoring of structural health and reducing maintenance costs. In the consumer electronics market, Nitinol-based energy harvesters are being developed for wearable devices and smart home applications, offering a sustainable power source for low-power electronics.

Market trends indicate a growing preference for self-powered and maintenance-free devices, particularly in remote or hard-to-reach locations. This trend aligns well with the capabilities of Nitinol-based energy harvesters, which can operate autonomously by converting ambient thermal energy into usable electricity. Additionally, the increasing focus on sustainability and energy efficiency is driving the adoption of energy harvesting technologies across industries.

However, the market for Nitinol-based energy harvesters also faces challenges. The relatively high cost of Nitinol and the complexity of manufacturing shape memory alloys at scale may limit widespread adoption in cost-sensitive applications. Furthermore, competition from other energy harvesting technologies, such as piezoelectric and thermoelectric materials, may impact market growth.

Despite these challenges, the unique properties of Nitinol and its potential for miniaturization make it an attractive option for small-scale energy harvesting devices. As research and development efforts continue to improve the efficiency and cost-effectiveness of Nitinol-based solutions, the market is expected to expand further, offering significant opportunities for manufacturers and suppliers in the coming years.

The global market for energy harvesting devices is projected to reach substantial value in the coming years, with Nitinol-based solutions expected to capture a significant share. This growth is primarily fueled by the rising adoption of Internet of Things (IoT) devices, wearable technologies, and autonomous sensors in industries such as healthcare, automotive, aerospace, and consumer electronics.

In the healthcare sector, Nitinol-based energy harvesters are finding applications in implantable medical devices and wearable health monitors. These devices can harness body heat to power sensors and transmitters, reducing the need for battery replacements and improving patient comfort. The automotive industry is also exploring Nitinol-based solutions for harvesting waste heat from engines and exhaust systems, contributing to improved fuel efficiency and reduced emissions.

The aerospace sector presents another promising market for Nitinol-based energy harvesters. These devices can be used to power wireless sensors in aircraft structures, enabling real-time monitoring of structural health and reducing maintenance costs. In the consumer electronics market, Nitinol-based energy harvesters are being developed for wearable devices and smart home applications, offering a sustainable power source for low-power electronics.

Market trends indicate a growing preference for self-powered and maintenance-free devices, particularly in remote or hard-to-reach locations. This trend aligns well with the capabilities of Nitinol-based energy harvesters, which can operate autonomously by converting ambient thermal energy into usable electricity. Additionally, the increasing focus on sustainability and energy efficiency is driving the adoption of energy harvesting technologies across industries.

However, the market for Nitinol-based energy harvesters also faces challenges. The relatively high cost of Nitinol and the complexity of manufacturing shape memory alloys at scale may limit widespread adoption in cost-sensitive applications. Furthermore, competition from other energy harvesting technologies, such as piezoelectric and thermoelectric materials, may impact market growth.

Despite these challenges, the unique properties of Nitinol and its potential for miniaturization make it an attractive option for small-scale energy harvesting devices. As research and development efforts continue to improve the efficiency and cost-effectiveness of Nitinol-based solutions, the market is expected to expand further, offering significant opportunities for manufacturers and suppliers in the coming years.

Current Challenges in Nitinol Energy Harvesting

Despite the promising potential of Nitinol in small-scale energy harvesting devices, several significant challenges currently hinder its widespread adoption and optimal performance. One of the primary obstacles is the complex thermomechanical behavior of Nitinol, which makes it difficult to predict and control its performance in energy harvesting applications. The material's phase transformation characteristics, crucial for energy conversion, are highly sensitive to temperature variations and mechanical stress, leading to inconsistent output in real-world conditions.

Another major challenge lies in the fabrication and processing of Nitinol for energy harvesting devices. The material's unique properties require specialized manufacturing techniques, which can be costly and challenging to scale up for mass production. Achieving the precise composition and microstructure necessary for optimal energy harvesting performance often involves complex heat treatments and processing steps, limiting the material's accessibility for widespread use in small-scale devices.

The fatigue life and long-term stability of Nitinol in energy harvesting applications also present significant concerns. Repeated cycling through phase transformations can lead to material degradation over time, potentially reducing the efficiency and lifespan of energy harvesting devices. This issue is particularly critical for applications requiring sustained performance over extended periods, such as in wearable technologies or remote sensing devices.

Furthermore, the energy conversion efficiency of Nitinol-based harvesters remains a challenge. While the material exhibits impressive shape memory and superelastic properties, translating these characteristics into high-efficiency energy conversion mechanisms for small-scale devices is an ongoing area of research. Current designs often struggle to achieve the power output levels necessary for practical applications, especially when compared to other energy harvesting technologies.

Integration challenges also persist in incorporating Nitinol into functional energy harvesting systems. The material's unique properties often require specialized interfacing with other components, such as electrical circuits and energy storage devices. Developing robust and efficient systems that can effectively capture, convert, and store the energy generated by Nitinol elements remains a complex engineering task.

Lastly, the cost-effectiveness of Nitinol-based energy harvesting solutions poses a significant barrier to widespread adoption. The material itself is relatively expensive compared to conventional alternatives, and the additional processing and manufacturing costs further increase the overall expense of Nitinol-based devices. Balancing the material's performance benefits against its economic viability remains a crucial challenge for researchers and engineers in the field.

Another major challenge lies in the fabrication and processing of Nitinol for energy harvesting devices. The material's unique properties require specialized manufacturing techniques, which can be costly and challenging to scale up for mass production. Achieving the precise composition and microstructure necessary for optimal energy harvesting performance often involves complex heat treatments and processing steps, limiting the material's accessibility for widespread use in small-scale devices.

The fatigue life and long-term stability of Nitinol in energy harvesting applications also present significant concerns. Repeated cycling through phase transformations can lead to material degradation over time, potentially reducing the efficiency and lifespan of energy harvesting devices. This issue is particularly critical for applications requiring sustained performance over extended periods, such as in wearable technologies or remote sensing devices.

Furthermore, the energy conversion efficiency of Nitinol-based harvesters remains a challenge. While the material exhibits impressive shape memory and superelastic properties, translating these characteristics into high-efficiency energy conversion mechanisms for small-scale devices is an ongoing area of research. Current designs often struggle to achieve the power output levels necessary for practical applications, especially when compared to other energy harvesting technologies.

Integration challenges also persist in incorporating Nitinol into functional energy harvesting systems. The material's unique properties often require specialized interfacing with other components, such as electrical circuits and energy storage devices. Developing robust and efficient systems that can effectively capture, convert, and store the energy generated by Nitinol elements remains a complex engineering task.

Lastly, the cost-effectiveness of Nitinol-based energy harvesting solutions poses a significant barrier to widespread adoption. The material itself is relatively expensive compared to conventional alternatives, and the additional processing and manufacturing costs further increase the overall expense of Nitinol-based devices. Balancing the material's performance benefits against its economic viability remains a crucial challenge for researchers and engineers in the field.

Existing Nitinol-based Energy Harvesting Solutions

01 Nitinol-based energy harvesting devices

Energy harvesting devices utilizing Nitinol's shape memory and superelastic properties to convert thermal or mechanical energy into electrical energy. These devices can capture ambient energy from temperature fluctuations or mechanical vibrations, providing a sustainable power source for various applications.- Nitinol-based energy harvesting devices: Energy harvesting devices utilizing Nitinol's shape memory and superelastic properties to convert thermal or mechanical energy into electrical energy. These devices can capture energy from temperature fluctuations or mechanical vibrations in the environment, offering potential applications in self-powered sensors and wearable technology.

- Thermal energy harvesting with Nitinol: Systems and methods for harvesting thermal energy using Nitinol alloys. These approaches leverage Nitinol's temperature-dependent phase transformation to generate electricity from temperature gradients or fluctuations, potentially enabling energy recovery from waste heat in industrial processes or natural temperature variations.

- Mechanical energy harvesting using Nitinol: Techniques for harvesting mechanical energy through Nitinol-based systems. These methods utilize Nitinol's superelastic properties to convert mechanical stress or strain into electrical energy, with potential applications in vibration energy harvesting for powering wireless sensor networks or IoT devices.

- Hybrid energy harvesting systems incorporating Nitinol: Hybrid energy harvesting systems that combine Nitinol with other materials or technologies to enhance energy conversion efficiency. These systems may integrate Nitinol with piezoelectric materials, electromagnetic generators, or other energy harvesting mechanisms to capture and convert multiple forms of ambient energy simultaneously.

- Nitinol-based energy harvesting for specific applications: Specialized energy harvesting solutions using Nitinol for particular applications or environments. These may include energy harvesting devices for automotive, aerospace, or marine applications, as well as biomedical implants or wearable devices that can generate power from body heat or motion.

02 Thermal energy harvesting with Nitinol

Systems and methods for harvesting thermal energy using Nitinol alloys. These designs exploit Nitinol's temperature-dependent phase transformation to generate electricity from temperature gradients or fluctuations in the environment, potentially powering small electronic devices or sensors.Expand Specific Solutions03 Mechanical energy harvesting using Nitinol

Devices and techniques for converting mechanical energy into electrical energy using Nitinol's superelastic properties. These systems can harvest energy from various sources of mechanical motion, such as vibrations, compressions, or bending, to power low-energy electronic devices or charge batteries.Expand Specific Solutions04 Nitinol-based actuators for energy generation

Actuator systems incorporating Nitinol elements to generate electrical energy. These actuators can convert thermal or mechanical inputs into controlled movements, which are then used to drive generators or other energy conversion mechanisms, providing a novel approach to energy harvesting.Expand Specific Solutions05 Integration of Nitinol in energy harvesting circuits

Circuit designs and configurations that incorporate Nitinol elements for energy harvesting applications. These circuits optimize the energy conversion process, manage power output, and integrate with storage or utilization systems, enhancing the efficiency and practicality of Nitinol-based energy harvesting technologies.Expand Specific Solutions

Key Players in Nitinol Energy Harvesting Industry

The market for Nitinol-based small-scale energy harvesting devices is in an early growth stage, with increasing research interest but limited commercial applications. The global market size for energy harvesting systems is projected to reach $1.5 billion by 2027, with small-scale devices being a significant segment. Technologically, Nitinol-based energy harvesters are still emerging, with varying levels of maturity across different applications. Key players like Texas Instruments, Honeywell, and 3M are investing in R&D, while academic institutions such as MIT, Drexel University, and the University of Florida are advancing fundamental research. Collaborations between industry and academia, exemplified by partnerships involving Robert Bosch GmbH and Massachusetts Institute of Technology, are driving innovation in this field.

Massachusetts Institute of Technology

Technical Solution: MIT has developed a novel approach to small-scale energy harvesting using Nitinol, focusing on its unique shape memory and superelastic properties. Their research involves creating micro-actuators that can convert small temperature fluctuations into mechanical energy, which is then transformed into electrical power. The system utilizes thin Nitinol wires arranged in a specific geometric configuration to maximize energy output. This design allows for efficient energy harvesting from ambient temperature changes, potentially powering small electronic devices or sensors in various environments[1][3]. The MIT team has also explored combining Nitinol with piezoelectric materials to further enhance energy conversion efficiency, creating a hybrid system that can harvest energy from both thermal and mechanical sources simultaneously[5].

Strengths: High energy density, ability to harvest from multiple sources, and potential for miniaturization. Weaknesses: Complexity in manufacturing and potential high costs for large-scale production.

Drexel University

Technical Solution: Drexel University researchers have focused on leveraging Nitinol's phase transformation properties for energy harvesting in small-scale devices. Their approach involves creating a composite material that combines Nitinol with a polymer matrix, allowing for enhanced control over the material's response to thermal stimuli. This composite is designed to generate electrical energy through the coupling of thermal and mechanical effects during Nitinol's phase transitions. The team has developed a unique layered structure that amplifies the energy output by optimizing the stress distribution within the material[2]. Additionally, they have explored the use of nanostructured Nitinol to increase the surface area and improve energy conversion efficiency at the microscale[4].

Strengths: Enhanced control over material properties, potential for integration into flexible devices. Weaknesses: Challenges in scaling up production and ensuring long-term stability of the composite material.

Core Innovations in Nitinol for Energy Harvesting

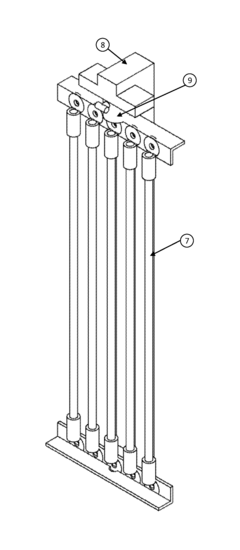

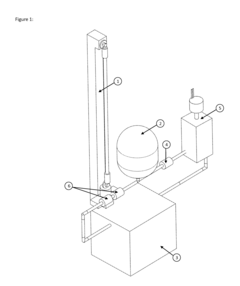

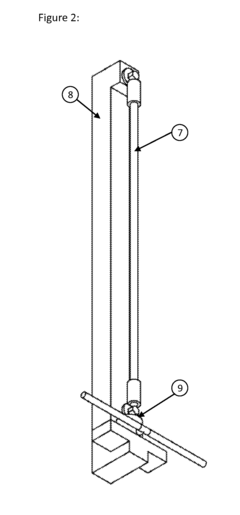

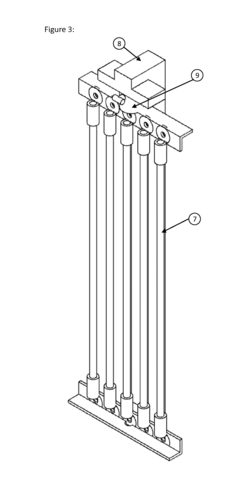

Nitinol Heat Engine with Mechanical Storage Mechanism

PatentInactiveUS20160069331A1

Innovation

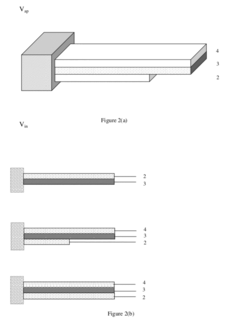

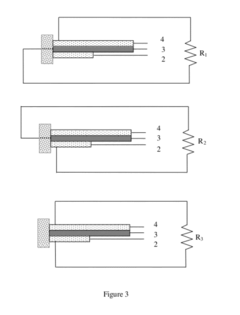

- A modularized nitinol heat engine system with reduced moving parts, hydraulic or mechanical energy transfer mechanisms, and a control system to decouple energy harvesting from power generation, utilizing hydraulic cylinders, ratchets, or rack and pinion gears to store energy efficiently and provide continuous power output.

Energy harvesting device

PatentInactiveUS20120119625A1

Innovation

- A piezoelectric energy harvesting device utilizing a piezoelectric layer made from lead magnesium niobate-lead titanate (PMN-PT) or lead zirconate titanate (PZT) with a thickness of 1-150 μm, combined with a non-piezoelectric layer, capable of converting ambient vibrational energy into electricity, and a driving element to operate at resonance frequency, enhancing energy conversion efficiency and power output.

Environmental Impact of Nitinol Energy Harvesters

The environmental impact of Nitinol-based energy harvesters is a crucial consideration in the development and deployment of small-scale energy harvesting devices. Nitinol, a nickel-titanium alloy known for its shape memory and superelastic properties, offers unique advantages in energy harvesting applications. However, its environmental implications must be carefully evaluated.

One of the primary environmental benefits of Nitinol energy harvesters is their potential to reduce reliance on traditional energy sources, thereby decreasing greenhouse gas emissions. These devices can capture ambient energy from various sources, such as vibrations, temperature fluctuations, and mechanical stress, converting it into usable electrical energy. This capability makes them particularly valuable in remote or hard-to-reach locations, where conventional power sources may be impractical or environmentally detrimental.

The longevity and durability of Nitinol-based devices contribute to their positive environmental profile. Due to Nitinol's exceptional fatigue resistance and ability to withstand repeated stress cycles without degradation, these energy harvesters can operate for extended periods with minimal maintenance. This longevity reduces the need for frequent replacements, ultimately minimizing waste generation and resource consumption associated with manufacturing and disposal.

However, the production of Nitinol itself raises some environmental concerns. The extraction and processing of nickel and titanium, the primary components of Nitinol, can have significant environmental impacts, including habitat disruption, water pollution, and energy-intensive refining processes. Additionally, the precise composition and heat treatment required for Nitinol production may involve energy-intensive manufacturing processes, potentially offsetting some of the environmental benefits gained during the device's operational life.

End-of-life considerations for Nitinol energy harvesters also warrant attention. While Nitinol is recyclable, the separation and recovery of nickel and titanium from used devices may present challenges. Proper recycling infrastructure and processes must be developed to ensure that these materials are effectively reclaimed and reused, minimizing the environmental impact of disposal.

The scalability of Nitinol-based energy harvesting solutions offers promising environmental prospects. As these technologies become more widespread, economies of scale may lead to more efficient production methods and improved recycling processes, further enhancing their overall environmental profile. Moreover, the integration of Nitinol energy harvesters into existing structures and systems can promote energy efficiency without requiring significant additional resources or infrastructure.

In conclusion, while Nitinol energy harvesters show considerable promise in reducing reliance on conventional energy sources and promoting sustainable energy solutions, a comprehensive life cycle assessment is essential to fully understand and mitigate their environmental impact. Continued research and development efforts should focus on optimizing production processes, enhancing energy conversion efficiency, and improving end-of-life management to maximize the environmental benefits of these innovative devices.

One of the primary environmental benefits of Nitinol energy harvesters is their potential to reduce reliance on traditional energy sources, thereby decreasing greenhouse gas emissions. These devices can capture ambient energy from various sources, such as vibrations, temperature fluctuations, and mechanical stress, converting it into usable electrical energy. This capability makes them particularly valuable in remote or hard-to-reach locations, where conventional power sources may be impractical or environmentally detrimental.

The longevity and durability of Nitinol-based devices contribute to their positive environmental profile. Due to Nitinol's exceptional fatigue resistance and ability to withstand repeated stress cycles without degradation, these energy harvesters can operate for extended periods with minimal maintenance. This longevity reduces the need for frequent replacements, ultimately minimizing waste generation and resource consumption associated with manufacturing and disposal.

However, the production of Nitinol itself raises some environmental concerns. The extraction and processing of nickel and titanium, the primary components of Nitinol, can have significant environmental impacts, including habitat disruption, water pollution, and energy-intensive refining processes. Additionally, the precise composition and heat treatment required for Nitinol production may involve energy-intensive manufacturing processes, potentially offsetting some of the environmental benefits gained during the device's operational life.

End-of-life considerations for Nitinol energy harvesters also warrant attention. While Nitinol is recyclable, the separation and recovery of nickel and titanium from used devices may present challenges. Proper recycling infrastructure and processes must be developed to ensure that these materials are effectively reclaimed and reused, minimizing the environmental impact of disposal.

The scalability of Nitinol-based energy harvesting solutions offers promising environmental prospects. As these technologies become more widespread, economies of scale may lead to more efficient production methods and improved recycling processes, further enhancing their overall environmental profile. Moreover, the integration of Nitinol energy harvesters into existing structures and systems can promote energy efficiency without requiring significant additional resources or infrastructure.

In conclusion, while Nitinol energy harvesters show considerable promise in reducing reliance on conventional energy sources and promoting sustainable energy solutions, a comprehensive life cycle assessment is essential to fully understand and mitigate their environmental impact. Continued research and development efforts should focus on optimizing production processes, enhancing energy conversion efficiency, and improving end-of-life management to maximize the environmental benefits of these innovative devices.

Scalability and Integration Challenges

The integration of Nitinol into small-scale energy harvesting devices presents significant scalability and integration challenges. One of the primary obstacles is the miniaturization of Nitinol-based components while maintaining their shape memory and superelastic properties. As devices become smaller, the surface area-to-volume ratio increases, potentially affecting the heat transfer characteristics and response time of Nitinol elements.

Manufacturing processes for small-scale Nitinol components require precise control over material composition and heat treatment. Achieving consistent performance across large batches of miniaturized devices can be challenging, as slight variations in processing parameters can lead to significant differences in the shape memory effect and superelastic behavior.

Integration of Nitinol with other materials and components in energy harvesting devices poses additional challenges. The thermal expansion mismatch between Nitinol and surrounding materials can lead to stress concentrations and potential failure points. Furthermore, the biocompatibility of Nitinol must be carefully considered when integrating it into wearable or implantable energy harvesting devices.

Electrical connectivity and interfacing Nitinol components with electronic circuits present another set of integration challenges. The unique properties of Nitinol can make it difficult to establish reliable and durable electrical connections, particularly in dynamic applications where the material undergoes repeated shape changes.

Scalability issues also arise in the context of power output and efficiency. As the size of Nitinol-based energy harvesters decreases, the amount of energy that can be harvested typically reduces. Optimizing the design to maximize energy conversion efficiency at small scales becomes crucial for practical applications.

The cost-effectiveness of integrating Nitinol into small-scale energy harvesting devices is another scalability concern. While Nitinol offers unique advantages, its relatively high cost compared to conventional materials may limit widespread adoption in certain applications. Developing cost-effective manufacturing processes and optimizing material usage are essential for commercial viability.

Lastly, the long-term reliability and fatigue resistance of Nitinol in small-scale energy harvesting devices require careful consideration. The repeated cycling of Nitinol elements in these applications can lead to material degradation over time, potentially affecting device performance and lifespan. Addressing these durability concerns is crucial for ensuring the long-term viability of Nitinol-based energy harvesting solutions.

Manufacturing processes for small-scale Nitinol components require precise control over material composition and heat treatment. Achieving consistent performance across large batches of miniaturized devices can be challenging, as slight variations in processing parameters can lead to significant differences in the shape memory effect and superelastic behavior.

Integration of Nitinol with other materials and components in energy harvesting devices poses additional challenges. The thermal expansion mismatch between Nitinol and surrounding materials can lead to stress concentrations and potential failure points. Furthermore, the biocompatibility of Nitinol must be carefully considered when integrating it into wearable or implantable energy harvesting devices.

Electrical connectivity and interfacing Nitinol components with electronic circuits present another set of integration challenges. The unique properties of Nitinol can make it difficult to establish reliable and durable electrical connections, particularly in dynamic applications where the material undergoes repeated shape changes.

Scalability issues also arise in the context of power output and efficiency. As the size of Nitinol-based energy harvesters decreases, the amount of energy that can be harvested typically reduces. Optimizing the design to maximize energy conversion efficiency at small scales becomes crucial for practical applications.

The cost-effectiveness of integrating Nitinol into small-scale energy harvesting devices is another scalability concern. While Nitinol offers unique advantages, its relatively high cost compared to conventional materials may limit widespread adoption in certain applications. Developing cost-effective manufacturing processes and optimizing material usage are essential for commercial viability.

Lastly, the long-term reliability and fatigue resistance of Nitinol in small-scale energy harvesting devices require careful consideration. The repeated cycling of Nitinol elements in these applications can lead to material degradation over time, potentially affecting device performance and lifespan. Addressing these durability concerns is crucial for ensuring the long-term viability of Nitinol-based energy harvesting solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!