Designing Nitinol-Based Micropumps for Biomedical Applications

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nitinol Micropump Evolution and Objectives

Nitinol, a unique nickel-titanium alloy, has revolutionized the field of biomedical engineering since its discovery in the 1960s. This shape memory alloy's exceptional properties, including superelasticity and shape memory effect, have made it an ideal material for various medical applications, particularly in the development of micropumps for biomedical use.

The evolution of Nitinol-based micropumps can be traced back to the early 1990s when researchers first recognized the potential of this material for creating miniature actuators. Initially, these devices were rudimentary, utilizing simple shape memory effects to generate pumping action. However, as understanding of Nitinol's properties deepened, more sophisticated designs emerged.

By the early 2000s, researchers had developed Nitinol micropumps capable of precise fluid control on a microscale. These early designs often relied on the material's thermal shape memory properties, where temperature changes induced by electrical current could trigger pumping action. This marked a significant advancement in the field of microfluidics and laid the groundwork for more complex biomedical applications.

The past decade has seen rapid progress in Nitinol micropump technology. Innovations in fabrication techniques, such as laser micromachining and thin-film deposition, have enabled the creation of increasingly miniaturized and efficient devices. Furthermore, the integration of smart materials and advanced control systems has led to the development of adaptive micropumps capable of responding to environmental stimuli.

Current objectives in Nitinol micropump design focus on several key areas. Firstly, there is a push towards further miniaturization to enable integration into increasingly compact medical devices. This includes the development of nanostructured Nitinol materials with enhanced properties at the microscale.

Secondly, researchers are working to improve the energy efficiency of these micropumps. This involves optimizing the shape memory effect and exploring novel actuation mechanisms that require less power input. The goal is to create long-lasting, self-powered devices suitable for implantable medical applications.

Another critical objective is enhancing the biocompatibility of Nitinol micropumps. While Nitinol is generally well-tolerated by the body, long-term implantation can still pose challenges. Researchers are investigating surface modification techniques and exploring new Nitinol alloy compositions to improve long-term stability and reduce the risk of adverse reactions.

Finally, there is a growing emphasis on developing multifunctional Nitinol micropumps. These advanced devices aim to combine pumping capabilities with other functionalities such as drug delivery, sensing, or even energy harvesting. Such integration could lead to revolutionary medical devices capable of autonomous operation within the human body.

The evolution of Nitinol-based micropumps can be traced back to the early 1990s when researchers first recognized the potential of this material for creating miniature actuators. Initially, these devices were rudimentary, utilizing simple shape memory effects to generate pumping action. However, as understanding of Nitinol's properties deepened, more sophisticated designs emerged.

By the early 2000s, researchers had developed Nitinol micropumps capable of precise fluid control on a microscale. These early designs often relied on the material's thermal shape memory properties, where temperature changes induced by electrical current could trigger pumping action. This marked a significant advancement in the field of microfluidics and laid the groundwork for more complex biomedical applications.

The past decade has seen rapid progress in Nitinol micropump technology. Innovations in fabrication techniques, such as laser micromachining and thin-film deposition, have enabled the creation of increasingly miniaturized and efficient devices. Furthermore, the integration of smart materials and advanced control systems has led to the development of adaptive micropumps capable of responding to environmental stimuli.

Current objectives in Nitinol micropump design focus on several key areas. Firstly, there is a push towards further miniaturization to enable integration into increasingly compact medical devices. This includes the development of nanostructured Nitinol materials with enhanced properties at the microscale.

Secondly, researchers are working to improve the energy efficiency of these micropumps. This involves optimizing the shape memory effect and exploring novel actuation mechanisms that require less power input. The goal is to create long-lasting, self-powered devices suitable for implantable medical applications.

Another critical objective is enhancing the biocompatibility of Nitinol micropumps. While Nitinol is generally well-tolerated by the body, long-term implantation can still pose challenges. Researchers are investigating surface modification techniques and exploring new Nitinol alloy compositions to improve long-term stability and reduce the risk of adverse reactions.

Finally, there is a growing emphasis on developing multifunctional Nitinol micropumps. These advanced devices aim to combine pumping capabilities with other functionalities such as drug delivery, sensing, or even energy harvesting. Such integration could lead to revolutionary medical devices capable of autonomous operation within the human body.

Biomedical Micropump Market Analysis

The biomedical micropump market is experiencing significant growth driven by increasing demand for minimally invasive drug delivery systems and the rising prevalence of chronic diseases. The global market for biomedical micropumps is expected to expand at a compound annual growth rate (CAGR) of over 8% from 2021 to 2026. This growth is primarily attributed to the aging population, advancements in healthcare technology, and the need for precise drug administration in various medical treatments.

The market for Nitinol-based micropumps, a subset of the broader biomedical micropump market, is particularly promising due to the unique properties of Nitinol. This shape memory alloy offers excellent biocompatibility, corrosion resistance, and the ability to return to a predetermined shape when heated, making it ideal for implantable medical devices. The Nitinol micropump segment is expected to grow faster than the overall market, with a projected CAGR of around 10% over the next five years.

Key application areas driving the demand for Nitinol-based micropumps include diabetes management, pain management, and cardiovascular treatments. In diabetes care, these micropumps are being developed for continuous insulin delivery systems, offering patients more precise and convenient glucose control. For pain management, Nitinol micropumps are being integrated into implantable drug delivery devices, providing targeted and controlled release of pain medications.

Geographically, North America currently dominates the biomedical micropump market, accounting for approximately 40% of the global market share. This is due to the region's advanced healthcare infrastructure, high healthcare expenditure, and strong presence of key market players. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by improving healthcare access, rising disposable incomes, and increasing adoption of advanced medical technologies in countries like China and India.

The competitive landscape of the Nitinol-based micropump market is characterized by a mix of established medical device manufacturers and innovative startups. Major players are investing heavily in research and development to improve pump efficiency, reduce size, and enhance biocompatibility. Collaborations between medical device companies and research institutions are also becoming more common, accelerating the development of novel micropump designs.

Despite the positive market outlook, challenges remain in the widespread adoption of Nitinol-based micropumps. These include regulatory hurdles, the need for long-term clinical data on safety and efficacy, and the high initial costs associated with developing and manufacturing these advanced devices. However, as technology continues to improve and production scales up, these barriers are expected to diminish, further driving market growth and innovation in biomedical micropump applications.

The market for Nitinol-based micropumps, a subset of the broader biomedical micropump market, is particularly promising due to the unique properties of Nitinol. This shape memory alloy offers excellent biocompatibility, corrosion resistance, and the ability to return to a predetermined shape when heated, making it ideal for implantable medical devices. The Nitinol micropump segment is expected to grow faster than the overall market, with a projected CAGR of around 10% over the next five years.

Key application areas driving the demand for Nitinol-based micropumps include diabetes management, pain management, and cardiovascular treatments. In diabetes care, these micropumps are being developed for continuous insulin delivery systems, offering patients more precise and convenient glucose control. For pain management, Nitinol micropumps are being integrated into implantable drug delivery devices, providing targeted and controlled release of pain medications.

Geographically, North America currently dominates the biomedical micropump market, accounting for approximately 40% of the global market share. This is due to the region's advanced healthcare infrastructure, high healthcare expenditure, and strong presence of key market players. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by improving healthcare access, rising disposable incomes, and increasing adoption of advanced medical technologies in countries like China and India.

The competitive landscape of the Nitinol-based micropump market is characterized by a mix of established medical device manufacturers and innovative startups. Major players are investing heavily in research and development to improve pump efficiency, reduce size, and enhance biocompatibility. Collaborations between medical device companies and research institutions are also becoming more common, accelerating the development of novel micropump designs.

Despite the positive market outlook, challenges remain in the widespread adoption of Nitinol-based micropumps. These include regulatory hurdles, the need for long-term clinical data on safety and efficacy, and the high initial costs associated with developing and manufacturing these advanced devices. However, as technology continues to improve and production scales up, these barriers are expected to diminish, further driving market growth and innovation in biomedical micropump applications.

Nitinol Micropump Challenges

The development of Nitinol-based micropumps for biomedical applications faces several significant challenges that require innovative solutions. One of the primary obstacles is the precise control of the shape memory effect and superelasticity of Nitinol in microscale devices. The unique properties of Nitinol, while advantageous, also present difficulties in achieving consistent and reliable actuation at the micro-level.

Material compatibility is another crucial challenge. Nitinol must interact safely with biological tissues and fluids without causing adverse reactions or degradation. This necessitates careful surface treatment and potentially the development of biocompatible coatings that do not interfere with the material's shape memory properties.

The miniaturization of Nitinol-based components poses significant fabrication challenges. Traditional manufacturing methods may not be suitable for creating intricate micropump structures, requiring the development of new microfabrication techniques. These methods must ensure high precision and repeatability while maintaining the material's functional properties.

Power management and efficiency are critical concerns in micropump design. Nitinol actuation typically requires thermal stimulation, which can be challenging to implement efficiently at the microscale. Developing low-power actuation mechanisms that can operate within the constraints of implantable or portable biomedical devices is a significant hurdle.

The dynamic response of Nitinol micropumps is another area of concern. Achieving rapid and precise control over pump operation, including flow rate and pressure, requires overcoming the inherent thermal inertia of the material. This challenge is compounded by the need for consistent performance across varying physiological conditions.

Durability and long-term reliability present ongoing challenges. Nitinol micropumps must withstand repeated actuation cycles and exposure to biological environments without fatigue or degradation. Ensuring consistent performance over extended periods is crucial for many biomedical applications, particularly in implantable devices.

Integration with other biomedical systems and sensors adds another layer of complexity. Nitinol micropumps must be designed to function seamlessly within larger medical devices or diagnostic systems, requiring careful consideration of interfaces, control systems, and overall system architecture.

Regulatory compliance and safety validation pose significant challenges in the development process. Stringent biocompatibility testing, performance verification, and risk assessment are necessary to meet regulatory standards for medical devices, adding time and cost to the development cycle.

Addressing these challenges requires a multidisciplinary approach, combining expertise in materials science, biomedical engineering, microfabrication, and systems integration. Overcoming these obstacles will be crucial for realizing the full potential of Nitinol-based micropumps in advancing biomedical technologies and improving patient care.

Material compatibility is another crucial challenge. Nitinol must interact safely with biological tissues and fluids without causing adverse reactions or degradation. This necessitates careful surface treatment and potentially the development of biocompatible coatings that do not interfere with the material's shape memory properties.

The miniaturization of Nitinol-based components poses significant fabrication challenges. Traditional manufacturing methods may not be suitable for creating intricate micropump structures, requiring the development of new microfabrication techniques. These methods must ensure high precision and repeatability while maintaining the material's functional properties.

Power management and efficiency are critical concerns in micropump design. Nitinol actuation typically requires thermal stimulation, which can be challenging to implement efficiently at the microscale. Developing low-power actuation mechanisms that can operate within the constraints of implantable or portable biomedical devices is a significant hurdle.

The dynamic response of Nitinol micropumps is another area of concern. Achieving rapid and precise control over pump operation, including flow rate and pressure, requires overcoming the inherent thermal inertia of the material. This challenge is compounded by the need for consistent performance across varying physiological conditions.

Durability and long-term reliability present ongoing challenges. Nitinol micropumps must withstand repeated actuation cycles and exposure to biological environments without fatigue or degradation. Ensuring consistent performance over extended periods is crucial for many biomedical applications, particularly in implantable devices.

Integration with other biomedical systems and sensors adds another layer of complexity. Nitinol micropumps must be designed to function seamlessly within larger medical devices or diagnostic systems, requiring careful consideration of interfaces, control systems, and overall system architecture.

Regulatory compliance and safety validation pose significant challenges in the development process. Stringent biocompatibility testing, performance verification, and risk assessment are necessary to meet regulatory standards for medical devices, adding time and cost to the development cycle.

Addressing these challenges requires a multidisciplinary approach, combining expertise in materials science, biomedical engineering, microfabrication, and systems integration. Overcoming these obstacles will be crucial for realizing the full potential of Nitinol-based micropumps in advancing biomedical technologies and improving patient care.

Current Nitinol Micropump Designs

01 Nitinol-based actuators for micropumps

Nitinol, a shape memory alloy, is used as an actuator in micropumps due to its unique properties. When heated, Nitinol undergoes a phase transformation, allowing it to change shape and generate force. This property is utilized in micropump designs to create efficient and compact pumping mechanisms for various applications in microfluidics and medical devices.- Nitinol-based actuators for micropumps: Nitinol, a shape memory alloy, is used as an actuator in micropumps due to its unique properties. When heated, Nitinol undergoes a phase transformation, allowing it to change shape and generate force. This property is utilized in micropump designs to create efficient and compact pumping mechanisms for various applications.

- Microfluidic devices incorporating Nitinol-based micropumps: Nitinol-based micropumps are integrated into microfluidic devices for precise fluid control and manipulation. These devices are used in various fields such as medical diagnostics, drug delivery systems, and lab-on-a-chip applications. The incorporation of Nitinol actuators allows for miniaturization and improved performance of these microfluidic systems.

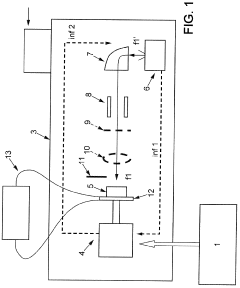

- Control systems for Nitinol-based micropumps: Advanced control systems are developed to regulate the operation of Nitinol-based micropumps. These systems manage the heating and cooling cycles of the Nitinol actuators, ensuring precise and repeatable pumping actions. The control mechanisms may include temperature sensors, feedback loops, and microcontrollers to optimize pump performance and efficiency.

- Fabrication techniques for Nitinol-based micropumps: Various fabrication methods are employed to manufacture Nitinol-based micropumps. These techniques may include micromachining, laser cutting, and additive manufacturing processes. The fabrication methods aim to achieve high precision in the production of Nitinol components and their integration with other micropump elements, ensuring optimal performance and reliability.

- Applications of Nitinol-based micropumps: Nitinol-based micropumps find applications in diverse fields. They are used in medical devices for drug delivery, implantable systems, and diagnostic tools. In industrial settings, these micropumps are employed for precise fluid handling in analytical instruments and cooling systems. The compact size and efficient operation of Nitinol-based micropumps make them suitable for portable and space-constrained applications.

02 Fabrication techniques for Nitinol-based micropumps

Various fabrication techniques are employed to create Nitinol-based micropumps. These may include micromachining, laser cutting, and additive manufacturing processes. The fabrication methods are crucial for achieving precise dimensions and integrating Nitinol components with other materials to create functional micropump systems.Expand Specific Solutions03 Control systems for Nitinol-based micropumps

Control systems are essential for the operation of Nitinol-based micropumps. These systems typically involve temperature regulation to activate the shape memory effect of Nitinol. Advanced control mechanisms may incorporate feedback loops, sensors, and microprocessors to achieve precise and programmable pumping actions.Expand Specific Solutions04 Applications of Nitinol-based micropumps

Nitinol-based micropumps find applications in various fields, including medical devices, lab-on-a-chip systems, and microfluidic devices. They are particularly useful in drug delivery systems, cooling systems for electronics, and miniaturized analytical instruments where precise fluid control is required.Expand Specific Solutions05 Integration of Nitinol micropumps with other components

The integration of Nitinol-based micropumps with other components is crucial for creating complete microfluidic systems. This involves combining the pump with valves, channels, reservoirs, and sensors. The integration process often requires innovative design solutions to ensure compatibility between different materials and components while maintaining the overall system's efficiency and reliability.Expand Specific Solutions

Key Nitinol Micropump Manufacturers

The development of Nitinol-based micropumps for biomedical applications is in an emerging phase, with significant potential for growth. The market size is expanding as these devices find applications in drug delivery, lab-on-a-chip systems, and microfluidics. Technologically, the field is progressing rapidly, with companies like Abbott Laboratories, Becton, Dickinson & Co., and Novo Nordisk A/S leading research and development efforts. Academic institutions such as Massachusetts Institute of Technology and Zhejiang University are contributing to advancements in materials science and bioengineering. The technology's maturity is advancing, with prototypes and early-stage products emerging, but widespread commercial adoption is still in progress. Collaboration between industry leaders and research institutions is driving innovation in this specialized field.

Abbott Laboratories

Technical Solution: Abbott Laboratories has developed a novel approach to Nitinol-based micropumps for drug delivery systems. Their design utilizes a Nitinol wire mesh structure that expands and contracts in response to electrical stimulation, creating a peristaltic pumping action[4]. The micropump incorporates a series of chambers lined with the Nitinol mesh, allowing for precise control of drug release rates. Abbott's technology also includes a microprocessor-controlled power management system that optimizes energy consumption, extending the operational life of implantable devices[5]. To address biocompatibility concerns, the company has developed a proprietary coating for the Nitinol components that reduces protein adsorption and minimizes the risk of thrombus formation[6]. The micropump design also incorporates fail-safe mechanisms to prevent unintended drug release in case of device malfunction.

Strengths: Advanced drug delivery control, energy-efficient design, and enhanced biocompatibility. Weaknesses: Complexity of the system may lead to higher production costs and potential reliability issues.

Novo Nordisk A/S

Technical Solution: Novo Nordisk has developed a Nitinol-based micropump system specifically tailored for insulin delivery in diabetes management. Their approach utilizes a Nitinol actuator in the form of a thin, coiled wire that changes shape when heated, creating a precise pumping action[7]. The design incorporates a reservoir system with multiple chambers, allowing for the delivery of different types of insulin or other medications as needed. Novo Nordisk's micropump features a closed-loop control system that integrates continuous glucose monitoring data to adjust insulin delivery rates automatically[8]. The company has also developed a proprietary surface modification technique for the Nitinol components to enhance long-term stability and reduce the risk of insulin aggregation within the device[9]. To improve user experience, the micropump is designed to be compact and easily integrated with wearable insulin delivery systems.

Strengths: Specialized for diabetes management, integrated closed-loop control, and user-friendly design. Weaknesses: Limited application outside of insulin delivery and potential high costs for diabetic patients.

Nitinol Micropump Patent Analysis

Biomedical product with a substrate comprising a nickel-titanium alloy and a coating layer comprising calcium phosphate

PatentInactiveEP1293219A1

Innovation

- A substrate with a nickel-titanium alloy is coated with a layer of calcium phosphate, applied through immersion in a supersaturated calcium phosphate solution, which acts as a sink for nickel ions, preventing release and enhancing biocompatibility, while maintaining the material's shape memory effect.

Layer of nickel-titanium alloy containing inserted nitrogen atoms, and associated treatment process

PatentWO2008050071A2

Innovation

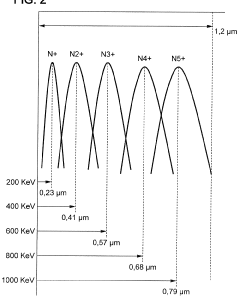

- A layer of nickel-titanium alloy with inserted nitrogen atoms, achieved through ion implantation, which increases surface hardness and reduces nickel release kinetics by creating a nitrogen concentration profile with specific Gaussian curves and multi-energy ion implantation, resulting in enhanced corrosion resistance and biocompatibility.

Biocompatibility and Safety Regulations

The biocompatibility and safety regulations for Nitinol-based micropumps in biomedical applications are critical considerations that must be thoroughly addressed during the design and development process. Nitinol, an alloy of nickel and titanium, has gained significant attention in the medical device industry due to its unique properties, including shape memory and superelasticity. However, its use in implantable devices, such as micropumps, requires careful evaluation to ensure patient safety and regulatory compliance.

One of the primary concerns regarding Nitinol's biocompatibility is the potential release of nickel ions, which can cause allergic reactions or toxicity in some patients. To mitigate this risk, surface treatments and coatings have been developed to create a protective barrier between the Nitinol and the surrounding tissue. These treatments often involve the formation of a stable titanium oxide layer, which reduces nickel ion leaching and improves overall biocompatibility.

Regulatory bodies, such as the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA), have established stringent guidelines for the use of Nitinol in medical devices. These regulations typically require extensive in vitro and in vivo testing to demonstrate the long-term safety and performance of Nitinol-based implants. Manufacturers must provide comprehensive data on material characterization, corrosion resistance, and biocompatibility testing in accordance with ISO 10993 standards.

The design of Nitinol-based micropumps must also consider the potential for mechanical failure and its consequences. Fatigue testing and durability assessments are essential to ensure that the device can withstand the cyclic loading conditions experienced during long-term implantation. Additionally, the risk of particle generation due to wear or corrosion must be evaluated and minimized to prevent adverse tissue reactions or device malfunction.

Sterilization processes for Nitinol-based micropumps require careful consideration, as some methods may alter the material's properties or compromise its surface integrity. Validated sterilization protocols that maintain the device's functionality and biocompatibility are crucial for regulatory approval and clinical use. Furthermore, packaging and storage conditions must be optimized to preserve the device's sterility and prevent any degradation of the Nitinol components.

As the field of biomedical micropumps continues to evolve, regulatory agencies are likely to update their guidelines to address emerging technologies and materials. Manufacturers and researchers must stay informed about these changes and adapt their development processes accordingly. Collaboration between material scientists, biomedical engineers, and regulatory experts is essential to navigate the complex landscape of biocompatibility and safety regulations for Nitinol-based micropumps.

One of the primary concerns regarding Nitinol's biocompatibility is the potential release of nickel ions, which can cause allergic reactions or toxicity in some patients. To mitigate this risk, surface treatments and coatings have been developed to create a protective barrier between the Nitinol and the surrounding tissue. These treatments often involve the formation of a stable titanium oxide layer, which reduces nickel ion leaching and improves overall biocompatibility.

Regulatory bodies, such as the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA), have established stringent guidelines for the use of Nitinol in medical devices. These regulations typically require extensive in vitro and in vivo testing to demonstrate the long-term safety and performance of Nitinol-based implants. Manufacturers must provide comprehensive data on material characterization, corrosion resistance, and biocompatibility testing in accordance with ISO 10993 standards.

The design of Nitinol-based micropumps must also consider the potential for mechanical failure and its consequences. Fatigue testing and durability assessments are essential to ensure that the device can withstand the cyclic loading conditions experienced during long-term implantation. Additionally, the risk of particle generation due to wear or corrosion must be evaluated and minimized to prevent adverse tissue reactions or device malfunction.

Sterilization processes for Nitinol-based micropumps require careful consideration, as some methods may alter the material's properties or compromise its surface integrity. Validated sterilization protocols that maintain the device's functionality and biocompatibility are crucial for regulatory approval and clinical use. Furthermore, packaging and storage conditions must be optimized to preserve the device's sterility and prevent any degradation of the Nitinol components.

As the field of biomedical micropumps continues to evolve, regulatory agencies are likely to update their guidelines to address emerging technologies and materials. Manufacturers and researchers must stay informed about these changes and adapt their development processes accordingly. Collaboration between material scientists, biomedical engineers, and regulatory experts is essential to navigate the complex landscape of biocompatibility and safety regulations for Nitinol-based micropumps.

Energy Efficiency in Micropump Design

Energy efficiency is a critical factor in the design of Nitinol-based micropumps for biomedical applications. The power consumption of these devices directly impacts their operational lifespan and overall effectiveness in medical treatments. To optimize energy efficiency, several key aspects must be considered in the design process.

Firstly, the shape memory effect of Nitinol alloys can be harnessed to create efficient actuation mechanisms. By carefully engineering the transformation temperatures and stress-strain characteristics of the Nitinol components, designers can minimize the energy required for each pump cycle. This involves selecting appropriate Nitinol compositions and heat treatments to tailor the material properties for specific biomedical applications.

The geometric design of the micropump plays a crucial role in energy efficiency. Streamlined flow channels and optimized valve configurations can reduce fluid resistance and minimize energy losses due to turbulence. Computational fluid dynamics (CFD) simulations are often employed to analyze and refine the pump geometry, ensuring smooth flow patterns and efficient energy transfer from the Nitinol actuator to the fluid.

Thermal management is another vital aspect of energy-efficient micropump design. Nitinol's phase transformation is temperature-dependent, and excess heat generation can lead to reduced efficiency and potential tissue damage in biomedical applications. Advanced thermal design techniques, such as incorporating heat sinks or utilizing surrounding body fluids for cooling, can help maintain optimal operating temperatures and improve overall energy efficiency.

Control systems and actuation strategies also contribute significantly to energy efficiency. Implementing precise control algorithms that optimize the timing and magnitude of Nitinol actuation can minimize unnecessary power consumption. Pulse-width modulation (PWM) techniques and adaptive control systems can be employed to fine-tune the pump's operation based on varying physiological demands, further enhancing energy efficiency.

Miniaturization and integration of components are essential considerations in micropump design. By reducing the overall size and mass of the device, the energy required for actuation can be minimized. Additionally, integrating energy harvesting technologies, such as piezoelectric elements or thermoelectric generators, can supplement the pump's power supply and extend its operational lifespan.

Material selection beyond Nitinol also impacts energy efficiency. Using low-friction coatings on moving parts and selecting biocompatible materials with favorable mechanical properties can reduce energy losses due to friction and wear. Furthermore, incorporating smart materials that respond to environmental stimuli can enable passive control mechanisms, reducing the need for active energy input.

Firstly, the shape memory effect of Nitinol alloys can be harnessed to create efficient actuation mechanisms. By carefully engineering the transformation temperatures and stress-strain characteristics of the Nitinol components, designers can minimize the energy required for each pump cycle. This involves selecting appropriate Nitinol compositions and heat treatments to tailor the material properties for specific biomedical applications.

The geometric design of the micropump plays a crucial role in energy efficiency. Streamlined flow channels and optimized valve configurations can reduce fluid resistance and minimize energy losses due to turbulence. Computational fluid dynamics (CFD) simulations are often employed to analyze and refine the pump geometry, ensuring smooth flow patterns and efficient energy transfer from the Nitinol actuator to the fluid.

Thermal management is another vital aspect of energy-efficient micropump design. Nitinol's phase transformation is temperature-dependent, and excess heat generation can lead to reduced efficiency and potential tissue damage in biomedical applications. Advanced thermal design techniques, such as incorporating heat sinks or utilizing surrounding body fluids for cooling, can help maintain optimal operating temperatures and improve overall energy efficiency.

Control systems and actuation strategies also contribute significantly to energy efficiency. Implementing precise control algorithms that optimize the timing and magnitude of Nitinol actuation can minimize unnecessary power consumption. Pulse-width modulation (PWM) techniques and adaptive control systems can be employed to fine-tune the pump's operation based on varying physiological demands, further enhancing energy efficiency.

Miniaturization and integration of components are essential considerations in micropump design. By reducing the overall size and mass of the device, the energy required for actuation can be minimized. Additionally, integrating energy harvesting technologies, such as piezoelectric elements or thermoelectric generators, can supplement the pump's power supply and extend its operational lifespan.

Material selection beyond Nitinol also impacts energy efficiency. Using low-friction coatings on moving parts and selecting biocompatible materials with favorable mechanical properties can reduce energy losses due to friction and wear. Furthermore, incorporating smart materials that respond to environmental stimuli can enable passive control mechanisms, reducing the need for active energy input.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!