Nitinol in Developing New Generation of Field-Operated Valves

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nitinol Valve Tech Evolution

The evolution of Nitinol valve technology represents a significant advancement in the field of field-operated valves. Nitinol, a nickel-titanium alloy, has unique properties that make it particularly suitable for valve applications. Its shape memory and superelastic characteristics have revolutionized the design and functionality of valves across various industries.

In the early stages of Nitinol valve development, researchers focused on harnessing the material's shape memory effect. This property allows Nitinol to return to a predetermined shape when heated, enabling the creation of valves that could open and close in response to temperature changes. These initial designs were primarily used in simple flow control applications and laid the foundation for more sophisticated valve systems.

As understanding of Nitinol's properties deepened, engineers began to exploit its superelasticity. This characteristic allows Nitinol to undergo large deformations and return to its original shape without permanent damage. This led to the development of valves with improved durability and reliability, capable of withstanding repeated cycles of opening and closing without fatigue.

The next significant milestone in Nitinol valve technology was the integration of actuator systems. By combining Nitinol components with electrical or thermal actuators, researchers created valves that could be precisely controlled in response to external signals. This advancement opened up new possibilities for remote operation and automation in valve systems, particularly beneficial in hard-to-reach or hazardous environments.

Recent years have seen a focus on miniaturization and efficiency in Nitinol valve design. Microvalves utilizing Nitinol have found applications in microfluidics and medical devices, offering unprecedented control over small-scale fluid flow. Additionally, improvements in Nitinol processing and manufacturing techniques have led to valves with faster response times and lower energy consumption.

The latest frontier in Nitinol valve technology involves the development of smart valves. These incorporate sensors and advanced control systems, allowing for real-time monitoring and adjustment of valve performance. Such intelligent systems can optimize flow rates, predict maintenance needs, and even self-diagnose issues, representing a significant leap forward in valve technology.

Looking ahead, research is focusing on enhancing the biocompatibility of Nitinol valves for medical applications, improving their resistance to extreme environments for industrial use, and exploring new alloy compositions to further expand the material's capabilities. The ongoing evolution of Nitinol valve technology continues to push the boundaries of what is possible in fluid control systems, promising even more innovative solutions in the future.

In the early stages of Nitinol valve development, researchers focused on harnessing the material's shape memory effect. This property allows Nitinol to return to a predetermined shape when heated, enabling the creation of valves that could open and close in response to temperature changes. These initial designs were primarily used in simple flow control applications and laid the foundation for more sophisticated valve systems.

As understanding of Nitinol's properties deepened, engineers began to exploit its superelasticity. This characteristic allows Nitinol to undergo large deformations and return to its original shape without permanent damage. This led to the development of valves with improved durability and reliability, capable of withstanding repeated cycles of opening and closing without fatigue.

The next significant milestone in Nitinol valve technology was the integration of actuator systems. By combining Nitinol components with electrical or thermal actuators, researchers created valves that could be precisely controlled in response to external signals. This advancement opened up new possibilities for remote operation and automation in valve systems, particularly beneficial in hard-to-reach or hazardous environments.

Recent years have seen a focus on miniaturization and efficiency in Nitinol valve design. Microvalves utilizing Nitinol have found applications in microfluidics and medical devices, offering unprecedented control over small-scale fluid flow. Additionally, improvements in Nitinol processing and manufacturing techniques have led to valves with faster response times and lower energy consumption.

The latest frontier in Nitinol valve technology involves the development of smart valves. These incorporate sensors and advanced control systems, allowing for real-time monitoring and adjustment of valve performance. Such intelligent systems can optimize flow rates, predict maintenance needs, and even self-diagnose issues, representing a significant leap forward in valve technology.

Looking ahead, research is focusing on enhancing the biocompatibility of Nitinol valves for medical applications, improving their resistance to extreme environments for industrial use, and exploring new alloy compositions to further expand the material's capabilities. The ongoing evolution of Nitinol valve technology continues to push the boundaries of what is possible in fluid control systems, promising even more innovative solutions in the future.

Market Demand Analysis

The market demand for Nitinol-based field-operated valves is experiencing significant growth, driven by several key factors in various industries. The oil and gas sector, in particular, shows a strong appetite for these advanced valves due to their unique properties and potential to enhance operational efficiency.

Nitinol's shape memory and superelastic characteristics make it an ideal material for developing valves that can withstand extreme conditions and operate reliably in challenging environments. This has led to increased interest from companies involved in deep-sea exploration and extraction, where traditional valve materials often struggle to perform consistently under high pressure and corrosive conditions.

The aerospace industry is another major driver of demand for Nitinol-based field-operated valves. As aircraft manufacturers strive for lighter and more fuel-efficient designs, the lightweight nature of Nitinol valves offers a compelling solution. These valves can help reduce overall aircraft weight while maintaining or even improving performance, contributing to fuel savings and reduced emissions.

In the medical device sector, there is growing interest in Nitinol-based valves for applications such as artificial heart valves and other implantable devices. The biocompatibility of Nitinol, combined with its ability to change shape in response to temperature variations, makes it an attractive option for developing minimally invasive medical devices.

The automotive industry is also exploring the potential of Nitinol-based valves, particularly in the context of electric and hybrid vehicles. As these vehicles become more prevalent, there is a need for advanced thermal management systems, where Nitinol valves could play a crucial role in regulating coolant flow and optimizing battery performance.

Market analysts predict a compound annual growth rate (CAGR) for the Nitinol-based valve market that outpaces traditional valve technologies. This growth is expected to be sustained over the next decade as more industries recognize the benefits of these advanced valves and as manufacturing processes become more refined and cost-effective.

However, the market demand is not without challenges. The relatively high cost of Nitinol compared to conventional materials remains a barrier to widespread adoption in some sectors. Additionally, there is a need for increased education and awareness among potential end-users about the long-term benefits and return on investment that Nitinol-based valves can offer.

Despite these challenges, the overall market trajectory for Nitinol-based field-operated valves remains positive. As research and development efforts continue to improve the material's properties and manufacturing techniques, it is anticipated that new applications will emerge, further expanding the market potential across various industries.

Nitinol's shape memory and superelastic characteristics make it an ideal material for developing valves that can withstand extreme conditions and operate reliably in challenging environments. This has led to increased interest from companies involved in deep-sea exploration and extraction, where traditional valve materials often struggle to perform consistently under high pressure and corrosive conditions.

The aerospace industry is another major driver of demand for Nitinol-based field-operated valves. As aircraft manufacturers strive for lighter and more fuel-efficient designs, the lightweight nature of Nitinol valves offers a compelling solution. These valves can help reduce overall aircraft weight while maintaining or even improving performance, contributing to fuel savings and reduced emissions.

In the medical device sector, there is growing interest in Nitinol-based valves for applications such as artificial heart valves and other implantable devices. The biocompatibility of Nitinol, combined with its ability to change shape in response to temperature variations, makes it an attractive option for developing minimally invasive medical devices.

The automotive industry is also exploring the potential of Nitinol-based valves, particularly in the context of electric and hybrid vehicles. As these vehicles become more prevalent, there is a need for advanced thermal management systems, where Nitinol valves could play a crucial role in regulating coolant flow and optimizing battery performance.

Market analysts predict a compound annual growth rate (CAGR) for the Nitinol-based valve market that outpaces traditional valve technologies. This growth is expected to be sustained over the next decade as more industries recognize the benefits of these advanced valves and as manufacturing processes become more refined and cost-effective.

However, the market demand is not without challenges. The relatively high cost of Nitinol compared to conventional materials remains a barrier to widespread adoption in some sectors. Additionally, there is a need for increased education and awareness among potential end-users about the long-term benefits and return on investment that Nitinol-based valves can offer.

Despite these challenges, the overall market trajectory for Nitinol-based field-operated valves remains positive. As research and development efforts continue to improve the material's properties and manufacturing techniques, it is anticipated that new applications will emerge, further expanding the market potential across various industries.

Current Challenges

The development of new generation field-operated valves using Nitinol faces several significant challenges. One of the primary obstacles is the complex behavior of Nitinol under varying temperature and stress conditions. The material's unique shape memory and superelastic properties, while advantageous, also introduce difficulties in predicting and controlling its performance in valve applications.

Achieving precise and repeatable actuation is another major hurdle. Field-operated valves require consistent and accurate movement, which can be challenging to maintain with Nitinol due to its sensitivity to temperature fluctuations and mechanical stress. Engineers must develop sophisticated control systems to ensure reliable valve operation across a wide range of environmental conditions.

The durability and fatigue resistance of Nitinol in valve applications present ongoing concerns. While the material exhibits excellent corrosion resistance and biocompatibility, repeated cycling in valve operations can lead to material fatigue and potential failure over time. Researchers are working to improve the long-term reliability of Nitinol-based valves through advanced material processing techniques and optimized design strategies.

Manufacturing challenges also persist in the production of Nitinol components for field-operated valves. The material's high melting point and reactivity make traditional manufacturing processes difficult and costly. Precision machining and forming of Nitinol parts require specialized equipment and expertise, which can limit scalability and increase production costs.

Integration of Nitinol components with other valve materials and systems poses additional challenges. Compatibility issues may arise when combining Nitinol with other metals or polymers, particularly in terms of thermal expansion mismatches and potential galvanic corrosion. Engineers must carefully consider these factors in valve design to ensure long-term performance and reliability.

The cost-effectiveness of Nitinol-based valves remains a significant hurdle for widespread adoption. While the material offers unique advantages, its higher cost compared to traditional valve materials can be prohibitive for some applications. Researchers are exploring ways to optimize material usage and improve manufacturing processes to reduce overall costs.

Regulatory approval and standardization present challenges in the development and commercialization of Nitinol-based field-operated valves. The unique properties of the material may require new testing protocols and safety standards, particularly for applications in critical industries such as aerospace or medical devices.

Achieving precise and repeatable actuation is another major hurdle. Field-operated valves require consistent and accurate movement, which can be challenging to maintain with Nitinol due to its sensitivity to temperature fluctuations and mechanical stress. Engineers must develop sophisticated control systems to ensure reliable valve operation across a wide range of environmental conditions.

The durability and fatigue resistance of Nitinol in valve applications present ongoing concerns. While the material exhibits excellent corrosion resistance and biocompatibility, repeated cycling in valve operations can lead to material fatigue and potential failure over time. Researchers are working to improve the long-term reliability of Nitinol-based valves through advanced material processing techniques and optimized design strategies.

Manufacturing challenges also persist in the production of Nitinol components for field-operated valves. The material's high melting point and reactivity make traditional manufacturing processes difficult and costly. Precision machining and forming of Nitinol parts require specialized equipment and expertise, which can limit scalability and increase production costs.

Integration of Nitinol components with other valve materials and systems poses additional challenges. Compatibility issues may arise when combining Nitinol with other metals or polymers, particularly in terms of thermal expansion mismatches and potential galvanic corrosion. Engineers must carefully consider these factors in valve design to ensure long-term performance and reliability.

The cost-effectiveness of Nitinol-based valves remains a significant hurdle for widespread adoption. While the material offers unique advantages, its higher cost compared to traditional valve materials can be prohibitive for some applications. Researchers are exploring ways to optimize material usage and improve manufacturing processes to reduce overall costs.

Regulatory approval and standardization present challenges in the development and commercialization of Nitinol-based field-operated valves. The unique properties of the material may require new testing protocols and safety standards, particularly for applications in critical industries such as aerospace or medical devices.

Existing Nitinol Solutions

01 Nitinol applications in medical devices

Nitinol, a shape memory alloy, is widely used in medical devices due to its unique properties. It is particularly useful in minimally invasive surgical instruments, dental tools, and orthopedic implants. The material's superelasticity and shape memory effect allow for the creation of devices that can change shape or deploy within the body, improving surgical outcomes and patient comfort.- Nitinol applications in medical devices: Nitinol, a shape memory alloy, is widely used in medical devices due to its unique properties. It can be used in various medical applications such as stents, guidewires, and surgical instruments. The material's superelasticity and shape memory effect allow for minimally invasive procedures and improved patient outcomes.

- Nitinol in automotive and aerospace industries: Nitinol finds applications in automotive and aerospace industries due to its exceptional mechanical properties. It can be used in actuators, vibration damping systems, and structural components. The material's ability to withstand high stress and recover its original shape makes it suitable for various field operations in these sectors.

- Nitinol processing and manufacturing techniques: Various processing and manufacturing techniques are employed to optimize Nitinol's properties for specific field operations. These include heat treatment, cold working, and surface modification. Advanced manufacturing methods such as additive manufacturing and precision machining are also used to create complex Nitinol components for different applications.

- Nitinol-based actuators and sensors: Nitinol is utilized in the development of actuators and sensors for various field operations. Its shape memory effect allows for the creation of compact and efficient actuators, while its sensitivity to temperature changes makes it suitable for sensor applications. These Nitinol-based devices find use in robotics, automation, and environmental monitoring.

- Nitinol in oil and gas industry: The oil and gas industry employs Nitinol in various field operations due to its corrosion resistance and ability to withstand harsh environments. It is used in downhole tools, seals, and connectors. Nitinol's superelasticity and shape memory properties enable the development of innovative solutions for challenging drilling and extraction operations.

02 Nitinol in automotive and aerospace industries

Nitinol finds applications in automotive and aerospace industries due to its high strength-to-weight ratio and temperature-responsive properties. It is used in actuators, vibration damping systems, and adaptive structures. The material's ability to recover its original shape after deformation makes it valuable for creating self-repairing or morphing components in vehicles and aircraft.Expand Specific Solutions03 Nitinol processing and manufacturing techniques

Various processing and manufacturing techniques are employed to optimize Nitinol's properties for specific applications. These include heat treatment, cold working, and surface modification. Advanced manufacturing methods such as additive manufacturing and precision machining are used to create complex Nitinol structures. Proper processing is crucial to achieve desired shape memory and superelastic behaviors.Expand Specific Solutions04 Nitinol in energy and environmental applications

Nitinol is utilized in energy harvesting and environmental applications due to its thermomechanical properties. It is used in thermal energy conversion devices, actuators for solar tracking systems, and smart materials for energy-efficient buildings. The material's ability to convert thermal energy into mechanical work makes it valuable for developing sustainable energy solutions.Expand Specific Solutions05 Nitinol in consumer products and robotics

Nitinol is incorporated into various consumer products and robotic applications. It is used in eyeglass frames, cellular phone antennas, and smart textiles. In robotics, Nitinol actuators enable the development of soft robots and adaptive gripping mechanisms. The material's flexibility and shape memory properties allow for the creation of innovative and responsive consumer goods and robotic systems.Expand Specific Solutions

Key Industry Players

The research on Nitinol for field-operated valves is in a growth phase, with increasing market potential due to its unique shape memory and superelastic properties. The global smart materials market, which includes Nitinol, is projected to reach significant size in the coming years. Technologically, while Nitinol has been used in various applications, its implementation in field-operated valves is still evolving. Companies like Hitachi, Bayer, and Aerojet Rocketdyne are likely at the forefront of this research, leveraging their expertise in materials science and engineering. Smaller specialized firms such as AUSCO and Fisher Controls may also be contributing to advancements in this niche area.

SAMSON AG

Technical Solution: SAMSON AG has developed advanced field-operated valves using Nitinol, a shape memory alloy. Their technology leverages Nitinol's unique properties to create valves that can operate in extreme temperatures and pressures. The company's valves incorporate Nitinol actuators that can change shape in response to temperature variations, allowing for precise control and self-adjustment[1]. SAMSON's valves also feature Nitinol-based sealing elements that provide excellent wear resistance and maintain tight shut-off even after prolonged use[2]. The company has implemented a proprietary heat treatment process to optimize Nitinol's performance characteristics specifically for valve applications[3].

Strengths: Excellent temperature and pressure tolerance, self-adjusting capabilities, and long-term reliability. Weaknesses: Higher initial cost compared to traditional valve materials, and potential for complex manufacturing processes.

Fisher Controls International LLC

Technical Solution: Fisher Controls has pioneered the use of Nitinol in their next-generation control valves. Their research focuses on utilizing Nitinol's superelasticity to create valves with enhanced durability and responsiveness. Fisher's valves incorporate Nitinol-based trim components that can withstand high-cycle operations without fatigue[4]. The company has also developed a unique Nitinol-enhanced diaphragm design that provides improved pressure sensitivity and control accuracy[5]. Fisher's valves feature Nitinol-infused coatings on critical components, significantly reducing wear and extending service life[6].

Strengths: High durability, improved control accuracy, and extended service life. Weaknesses: Potentially higher manufacturing costs and limited supplier base for specialized Nitinol components.

Core Nitinol Innovations

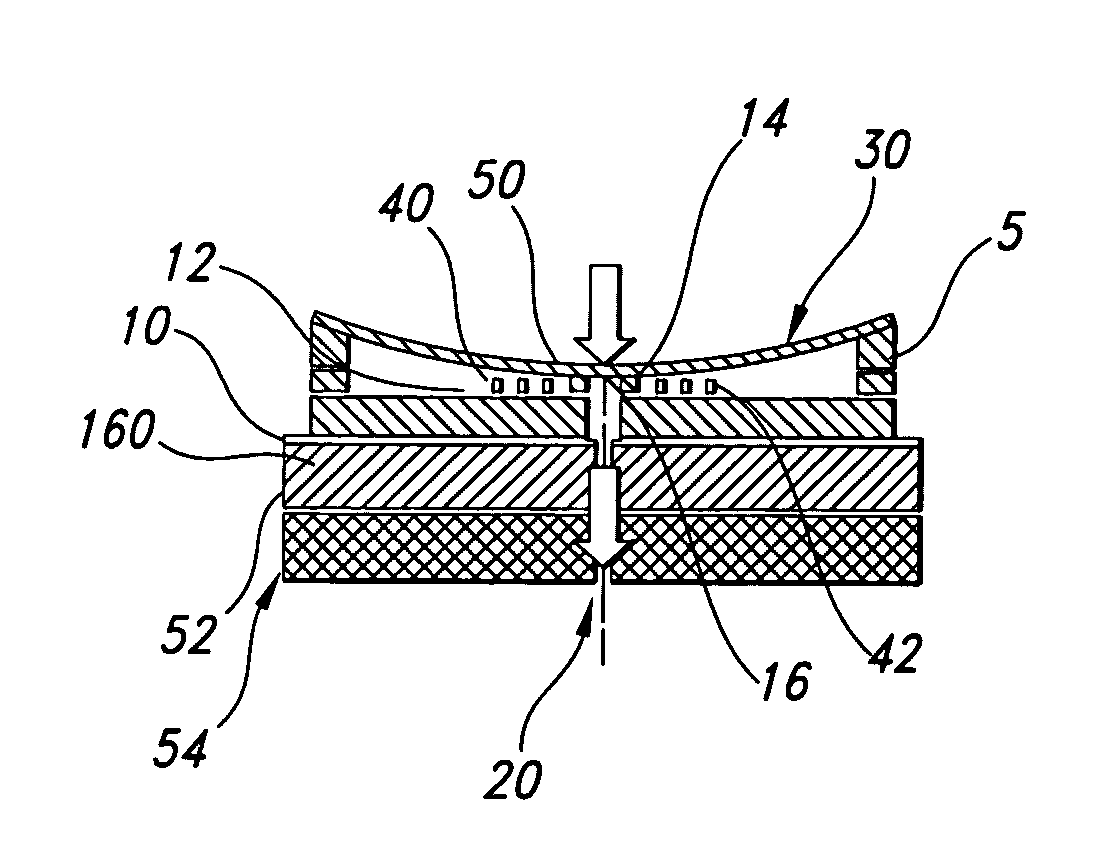

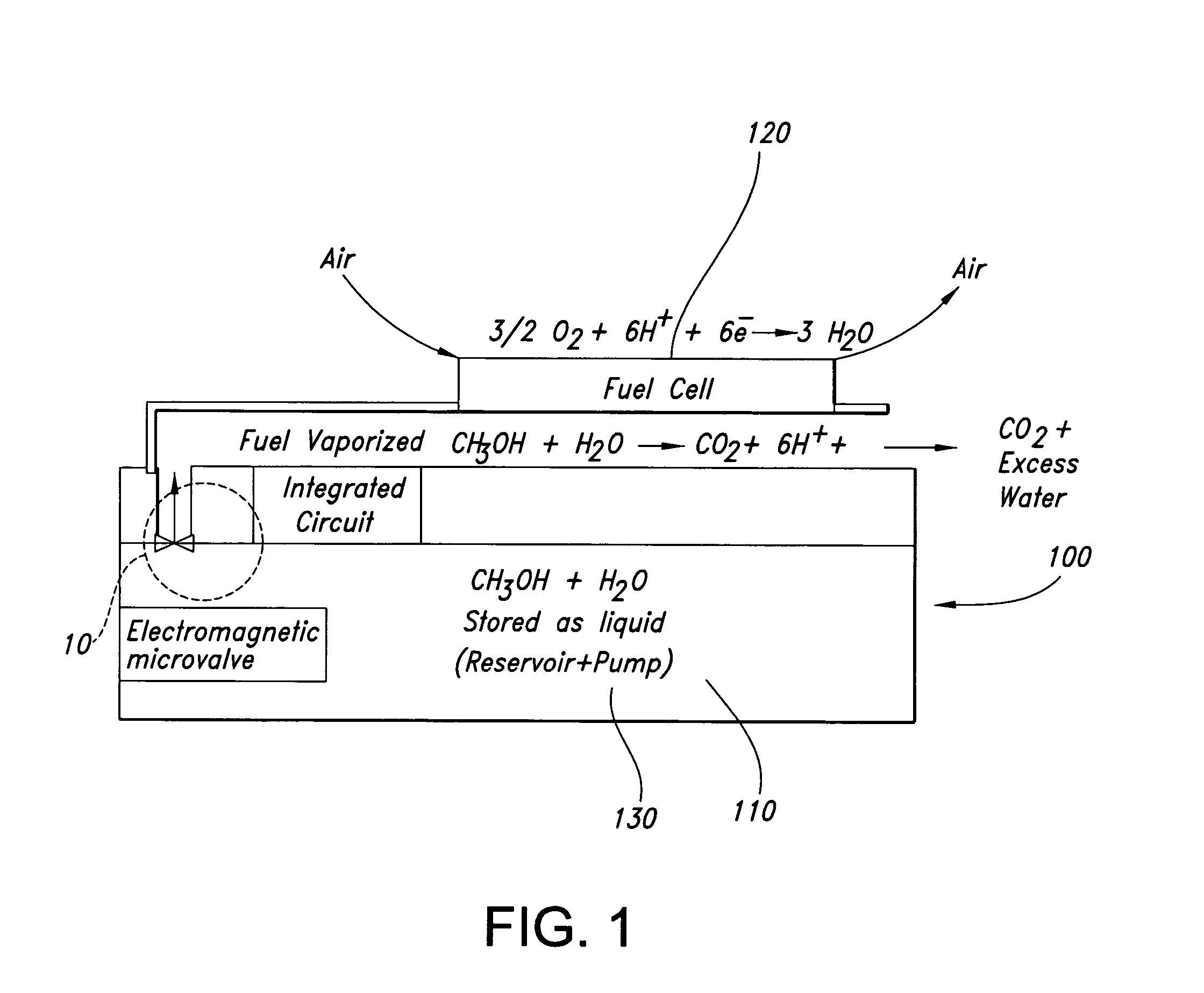

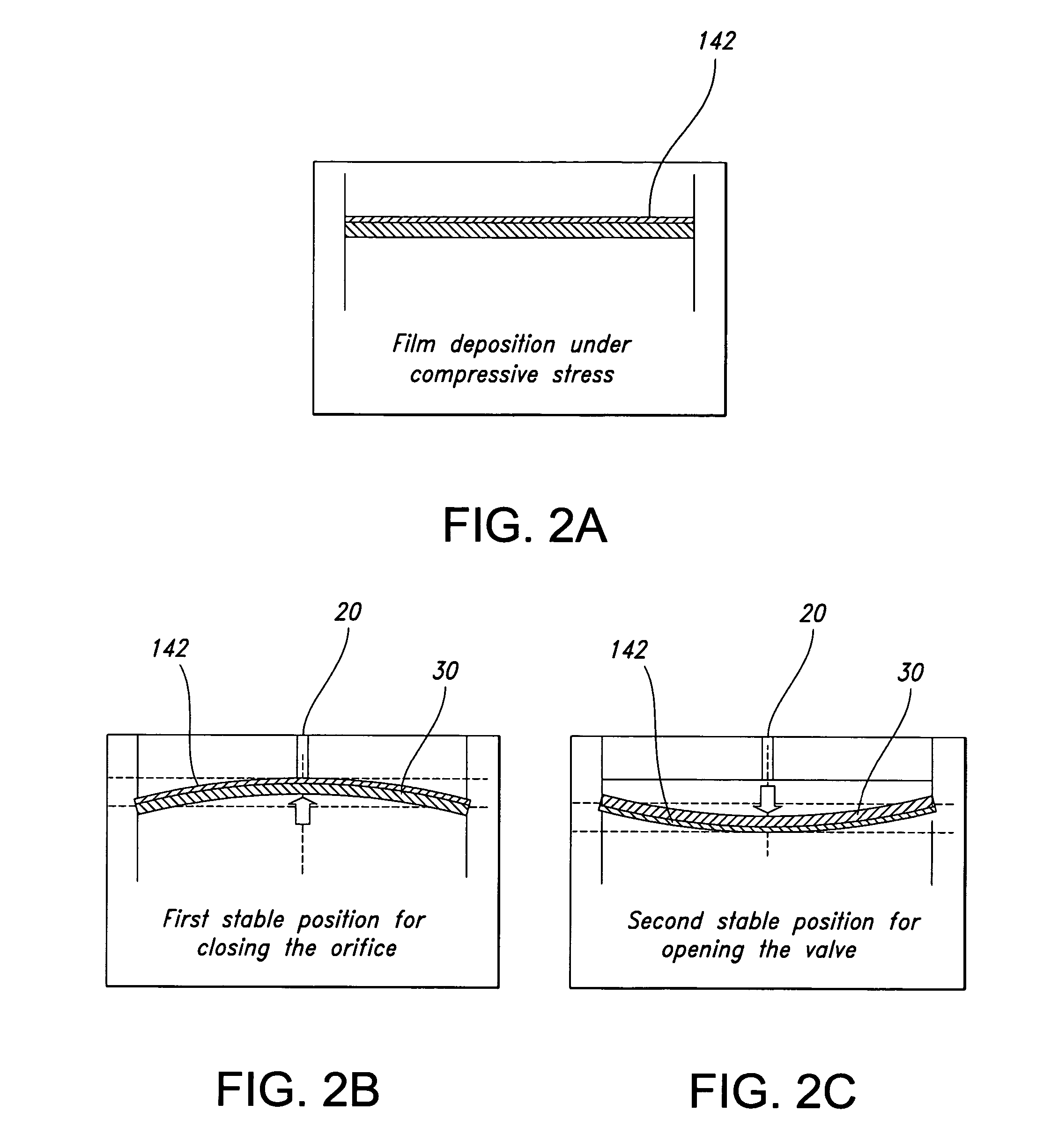

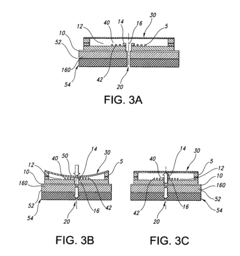

Single substrate electromagnetic actuator

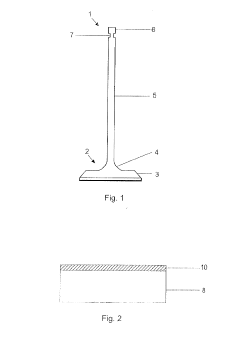

PatentInactiveUS20050116798A1

Innovation

- A magnetic microvalve is developed on a single substrate using a latching miniature electromechanical actuator with a pre-stressed membrane and electromagnetic force generator, allowing for bidirectional movement and low power consumption, and is fabricated using surface micro-machining techniques compatible with CMOS processes.

Valve for internal-combustion engines

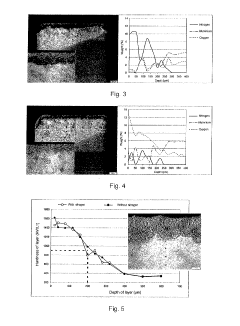

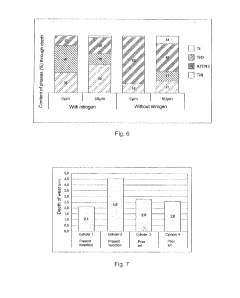

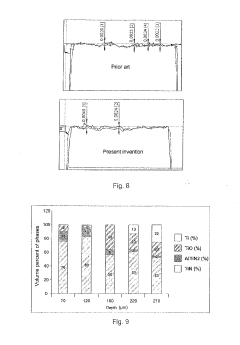

PatentInactiveUS20190128150A1

Innovation

- A titanium valve with a nitrided layer formed by laser remelting in a nitrogen-rich atmosphere, achieving a thickness of up to 500 microns with 50% volume of titanium nitrides or aluminium-titanium nitrides, providing surface hardness between 1100 HV and 2000 HV and hardness of at least 700 HV to a depth of 200 microns, applied to the valve tip for enhanced wear resistance.

Material Properties

Nitinol, an equiatomic alloy of nickel and titanium, exhibits remarkable properties that make it highly suitable for use in field-operated valves. Its unique characteristics stem from its shape memory effect and superelasticity, which are intrinsically linked to its crystalline structure and phase transformations.

The shape memory effect of Nitinol allows it to return to a predetermined shape when heated above its transformation temperature. This property is particularly valuable in valve applications, as it enables the material to actuate and change shape in response to temperature changes, facilitating precise control of fluid flow. The transformation temperature can be tailored through careful composition control and heat treatment, allowing for customization to specific operational requirements.

Superelasticity, another key property of Nitinol, allows the material to undergo large deformations and return to its original shape upon unloading. This characteristic is crucial for valve components that need to withstand repeated cycles of stress and strain without permanent deformation. The superelastic behavior of Nitinol is typically observed at temperatures above its austenite finish temperature, where the material can recover strains of up to 8% without plastic deformation.

The mechanical properties of Nitinol are highly dependent on its microstructure and processing history. In its austenitic phase, Nitinol exhibits a Young's modulus of approximately 83 GPa, which is significantly lower than that of conventional valve materials like stainless steel. This lower stiffness can be advantageous in certain valve designs, allowing for greater flexibility and responsiveness to actuation forces.

Corrosion resistance is another critical property of Nitinol for valve applications. The material forms a stable titanium oxide layer on its surface, providing excellent protection against corrosion in various environments. This characteristic is particularly important for valves operating in harsh or corrosive fluids, ensuring long-term reliability and performance.

The fatigue resistance of Nitinol is superior to many conventional materials, with a fatigue limit that can exceed 400 MPa under certain conditions. This high fatigue strength is essential for valve components subjected to cyclic loading, contributing to extended service life and reduced maintenance requirements.

Thermal properties of Nitinol also play a significant role in its performance in field-operated valves. The material exhibits a relatively low thermal conductivity compared to other metallic alloys, which can be beneficial in applications where thermal isolation is desired. Additionally, the latent heat associated with the phase transformation can be utilized in certain valve designs to enhance actuation efficiency.

The shape memory effect of Nitinol allows it to return to a predetermined shape when heated above its transformation temperature. This property is particularly valuable in valve applications, as it enables the material to actuate and change shape in response to temperature changes, facilitating precise control of fluid flow. The transformation temperature can be tailored through careful composition control and heat treatment, allowing for customization to specific operational requirements.

Superelasticity, another key property of Nitinol, allows the material to undergo large deformations and return to its original shape upon unloading. This characteristic is crucial for valve components that need to withstand repeated cycles of stress and strain without permanent deformation. The superelastic behavior of Nitinol is typically observed at temperatures above its austenite finish temperature, where the material can recover strains of up to 8% without plastic deformation.

The mechanical properties of Nitinol are highly dependent on its microstructure and processing history. In its austenitic phase, Nitinol exhibits a Young's modulus of approximately 83 GPa, which is significantly lower than that of conventional valve materials like stainless steel. This lower stiffness can be advantageous in certain valve designs, allowing for greater flexibility and responsiveness to actuation forces.

Corrosion resistance is another critical property of Nitinol for valve applications. The material forms a stable titanium oxide layer on its surface, providing excellent protection against corrosion in various environments. This characteristic is particularly important for valves operating in harsh or corrosive fluids, ensuring long-term reliability and performance.

The fatigue resistance of Nitinol is superior to many conventional materials, with a fatigue limit that can exceed 400 MPa under certain conditions. This high fatigue strength is essential for valve components subjected to cyclic loading, contributing to extended service life and reduced maintenance requirements.

Thermal properties of Nitinol also play a significant role in its performance in field-operated valves. The material exhibits a relatively low thermal conductivity compared to other metallic alloys, which can be beneficial in applications where thermal isolation is desired. Additionally, the latent heat associated with the phase transformation can be utilized in certain valve designs to enhance actuation efficiency.

Environmental Impact

The environmental impact of using Nitinol in field-operated valves is a crucial consideration in the development and implementation of this technology. Nitinol, an alloy of nickel and titanium, offers unique properties that make it attractive for valve applications, but its production and use also have environmental implications.

The manufacturing process of Nitinol involves energy-intensive methods, including vacuum arc remelting and vacuum induction melting. These processes contribute to increased energy consumption and associated greenhouse gas emissions. However, the long-term durability and reliability of Nitinol-based valves may offset some of these initial environmental costs by reducing the need for frequent replacements and maintenance.

One significant environmental advantage of Nitinol-based field-operated valves is their potential to improve energy efficiency in various systems. The shape memory and superelastic properties of Nitinol allow for more precise control and actuation, potentially leading to reduced energy consumption in industrial processes, HVAC systems, and other applications where valves play a critical role.

The use of Nitinol in valves may also contribute to reduced material waste. The alloy's resistance to corrosion and fatigue can lead to longer-lasting components, reducing the frequency of valve replacements and the associated waste generation. Additionally, the ability of Nitinol to return to its original shape after deformation can potentially reduce the need for replacement parts in certain applications.

However, the environmental impact of Nitinol production and disposal must be carefully managed. The extraction and processing of nickel and titanium, the primary components of Nitinol, can have significant environmental consequences, including habitat disruption and potential water and soil contamination. Proper recycling and disposal methods for Nitinol-based valves at the end of their lifecycle are essential to minimize environmental harm.

The potential for Nitinol to replace more environmentally harmful materials in valve applications should also be considered. For instance, if Nitinol-based valves can replace those made with materials that require more frequent replacement or have higher environmental impacts during production, the overall environmental benefit could be substantial.

In conclusion, while the production of Nitinol has some environmental drawbacks, its use in field-operated valves presents opportunities for improved energy efficiency and reduced material waste. Balancing these factors and implementing responsible manufacturing and disposal practices will be crucial in maximizing the environmental benefits of this technology.

The manufacturing process of Nitinol involves energy-intensive methods, including vacuum arc remelting and vacuum induction melting. These processes contribute to increased energy consumption and associated greenhouse gas emissions. However, the long-term durability and reliability of Nitinol-based valves may offset some of these initial environmental costs by reducing the need for frequent replacements and maintenance.

One significant environmental advantage of Nitinol-based field-operated valves is their potential to improve energy efficiency in various systems. The shape memory and superelastic properties of Nitinol allow for more precise control and actuation, potentially leading to reduced energy consumption in industrial processes, HVAC systems, and other applications where valves play a critical role.

The use of Nitinol in valves may also contribute to reduced material waste. The alloy's resistance to corrosion and fatigue can lead to longer-lasting components, reducing the frequency of valve replacements and the associated waste generation. Additionally, the ability of Nitinol to return to its original shape after deformation can potentially reduce the need for replacement parts in certain applications.

However, the environmental impact of Nitinol production and disposal must be carefully managed. The extraction and processing of nickel and titanium, the primary components of Nitinol, can have significant environmental consequences, including habitat disruption and potential water and soil contamination. Proper recycling and disposal methods for Nitinol-based valves at the end of their lifecycle are essential to minimize environmental harm.

The potential for Nitinol to replace more environmentally harmful materials in valve applications should also be considered. For instance, if Nitinol-based valves can replace those made with materials that require more frequent replacement or have higher environmental impacts during production, the overall environmental benefit could be substantial.

In conclusion, while the production of Nitinol has some environmental drawbacks, its use in field-operated valves presents opportunities for improved energy efficiency and reduced material waste. Balancing these factors and implementing responsible manufacturing and disposal practices will be crucial in maximizing the environmental benefits of this technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!