Exploring Nitinol’s Use in Digital Microfluidic Platforms

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nitinol in Microfluidics: Background and Objectives

Nitinol, a unique nickel-titanium alloy, has emerged as a promising material in the field of digital microfluidic platforms. This shape memory alloy, discovered in the 1960s, has garnered significant attention due to its exceptional properties, including shape memory effect and superelasticity. These characteristics make Nitinol particularly suitable for applications in microfluidic devices, where precise control and manipulation of small volumes of fluids are essential.

The evolution of microfluidic technology has been driven by the need for miniaturized, efficient, and cost-effective systems for various applications in chemistry, biology, and medicine. Digital microfluidic platforms, in particular, have gained traction due to their ability to manipulate discrete droplets of fluids on a planar surface. The integration of Nitinol into these platforms represents a significant technological advancement, offering new possibilities for fluid control and actuation.

The primary objective of exploring Nitinol's use in digital microfluidic platforms is to leverage its unique properties to enhance the performance and functionality of these systems. By harnessing Nitinol's shape memory effect, researchers aim to develop more efficient and responsive actuators for droplet manipulation. This could lead to improved precision in fluid handling, faster reaction times, and increased overall system reliability.

Another key goal is to exploit Nitinol's superelasticity to create flexible and adaptable microfluidic components. This property allows for the design of structures that can undergo large deformations without permanent damage, potentially leading to more robust and versatile microfluidic devices. Such advancements could expand the application range of digital microfluidic platforms, enabling their use in more challenging environments or complex experimental setups.

Furthermore, the exploration of Nitinol in this context seeks to address some of the limitations of current microfluidic technologies. Traditional materials used in microfluidics, such as polymers and silicon, often lack the responsiveness and adaptability required for advanced fluid manipulation techniques. Nitinol's unique properties offer the potential to overcome these limitations, paving the way for more sophisticated and efficient microfluidic systems.

The integration of Nitinol into digital microfluidic platforms also aligns with broader trends in miniaturization and smart materials in technology. As the demand for more compact and intelligent systems grows across various industries, the development of Nitinol-based microfluidic devices could have far-reaching implications. This research direction not only aims to advance the field of microfluidics but also contributes to the broader landscape of smart material applications in micro- and nanotechnology.

The evolution of microfluidic technology has been driven by the need for miniaturized, efficient, and cost-effective systems for various applications in chemistry, biology, and medicine. Digital microfluidic platforms, in particular, have gained traction due to their ability to manipulate discrete droplets of fluids on a planar surface. The integration of Nitinol into these platforms represents a significant technological advancement, offering new possibilities for fluid control and actuation.

The primary objective of exploring Nitinol's use in digital microfluidic platforms is to leverage its unique properties to enhance the performance and functionality of these systems. By harnessing Nitinol's shape memory effect, researchers aim to develop more efficient and responsive actuators for droplet manipulation. This could lead to improved precision in fluid handling, faster reaction times, and increased overall system reliability.

Another key goal is to exploit Nitinol's superelasticity to create flexible and adaptable microfluidic components. This property allows for the design of structures that can undergo large deformations without permanent damage, potentially leading to more robust and versatile microfluidic devices. Such advancements could expand the application range of digital microfluidic platforms, enabling their use in more challenging environments or complex experimental setups.

Furthermore, the exploration of Nitinol in this context seeks to address some of the limitations of current microfluidic technologies. Traditional materials used in microfluidics, such as polymers and silicon, often lack the responsiveness and adaptability required for advanced fluid manipulation techniques. Nitinol's unique properties offer the potential to overcome these limitations, paving the way for more sophisticated and efficient microfluidic systems.

The integration of Nitinol into digital microfluidic platforms also aligns with broader trends in miniaturization and smart materials in technology. As the demand for more compact and intelligent systems grows across various industries, the development of Nitinol-based microfluidic devices could have far-reaching implications. This research direction not only aims to advance the field of microfluidics but also contributes to the broader landscape of smart material applications in micro- and nanotechnology.

Market Analysis for Nitinol-based Microfluidic Devices

The market for Nitinol-based microfluidic devices is experiencing significant growth, driven by the increasing demand for miniaturized and efficient analytical systems across various industries. The global microfluidics market, which encompasses Nitinol-based devices, is projected to reach substantial value in the coming years, with a compound annual growth rate (CAGR) outpacing many other sectors in the life sciences and healthcare industries.

The healthcare and pharmaceutical sectors are the primary drivers of this market growth. The ability of Nitinol-based microfluidic devices to handle small sample volumes, reduce reagent consumption, and provide rapid analysis makes them particularly attractive for point-of-care diagnostics, drug discovery, and personalized medicine applications. These devices offer advantages in terms of cost-effectiveness, portability, and improved sensitivity compared to traditional analytical methods.

In the biotechnology sector, Nitinol-based microfluidic platforms are gaining traction for applications such as single-cell analysis, protein crystallization, and high-throughput screening. The unique properties of Nitinol, including its shape memory and superelasticity, enable the creation of innovative microfluidic designs that can enhance mixing, separation, and manipulation of fluids at the microscale.

The environmental monitoring and food safety industries are also emerging as significant markets for Nitinol-based microfluidic devices. These sectors benefit from the ability to perform rapid on-site testing for contaminants, pathogens, and other analytes of interest. The portability and robustness of Nitinol-based devices make them well-suited for field applications in diverse environmental conditions.

Academic and research institutions represent another important market segment, as they continue to explore novel applications and push the boundaries of microfluidic technology. The versatility of Nitinol in microfluidic platforms allows for the development of custom-designed devices tailored to specific research needs, fostering innovation and driving market expansion.

Geographically, North America and Europe currently dominate the market for Nitinol-based microfluidic devices, owing to their well-established healthcare infrastructure and strong research and development capabilities. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, fueled by increasing investments in healthcare technology and rising demand for advanced diagnostic tools.

Despite the promising market outlook, challenges such as high initial costs, lack of standardization, and the need for specialized expertise in device fabrication and operation may hinder widespread adoption. Overcoming these barriers through technological advancements and strategic collaborations will be crucial for realizing the full market potential of Nitinol-based microfluidic devices.

The healthcare and pharmaceutical sectors are the primary drivers of this market growth. The ability of Nitinol-based microfluidic devices to handle small sample volumes, reduce reagent consumption, and provide rapid analysis makes them particularly attractive for point-of-care diagnostics, drug discovery, and personalized medicine applications. These devices offer advantages in terms of cost-effectiveness, portability, and improved sensitivity compared to traditional analytical methods.

In the biotechnology sector, Nitinol-based microfluidic platforms are gaining traction for applications such as single-cell analysis, protein crystallization, and high-throughput screening. The unique properties of Nitinol, including its shape memory and superelasticity, enable the creation of innovative microfluidic designs that can enhance mixing, separation, and manipulation of fluids at the microscale.

The environmental monitoring and food safety industries are also emerging as significant markets for Nitinol-based microfluidic devices. These sectors benefit from the ability to perform rapid on-site testing for contaminants, pathogens, and other analytes of interest. The portability and robustness of Nitinol-based devices make them well-suited for field applications in diverse environmental conditions.

Academic and research institutions represent another important market segment, as they continue to explore novel applications and push the boundaries of microfluidic technology. The versatility of Nitinol in microfluidic platforms allows for the development of custom-designed devices tailored to specific research needs, fostering innovation and driving market expansion.

Geographically, North America and Europe currently dominate the market for Nitinol-based microfluidic devices, owing to their well-established healthcare infrastructure and strong research and development capabilities. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, fueled by increasing investments in healthcare technology and rising demand for advanced diagnostic tools.

Despite the promising market outlook, challenges such as high initial costs, lack of standardization, and the need for specialized expertise in device fabrication and operation may hinder widespread adoption. Overcoming these barriers through technological advancements and strategic collaborations will be crucial for realizing the full market potential of Nitinol-based microfluidic devices.

Current Challenges in Nitinol Integration

The integration of Nitinol into digital microfluidic platforms presents several significant challenges that researchers and engineers must overcome. One of the primary obstacles is the precise control of Nitinol's shape-memory and superelastic properties within the microscale environment of microfluidic devices. The material's behavior at this scale can be unpredictable, making it difficult to achieve consistent and reliable actuation for fluid manipulation.

Another major challenge lies in the fabrication and integration process. Incorporating Nitinol elements into microfluidic platforms requires advanced manufacturing techniques that can maintain the material's unique properties while ensuring compatibility with other components of the system. This often involves complex microfabrication processes, including precise patterning and deposition of Nitinol thin films or wires, which can be technically demanding and costly.

The biocompatibility of Nitinol in microfluidic applications, particularly those intended for biomedical use, remains a concern. While Nitinol is generally considered biocompatible, its long-term effects in continuous contact with biological fluids and tissues within a microfluidic environment are not fully understood. This necessitates extensive testing and validation to ensure safety and reliability for potential in vitro or in vivo applications.

Temperature control and energy efficiency pose additional challenges. Nitinol's shape-memory effect is temperature-dependent, requiring precise thermal management within the microfluidic platform. Achieving rapid and localized heating for actuation while maintaining overall temperature stability in the system is technically challenging and energy-intensive, potentially limiting the applicability of Nitinol-based microfluidic devices in portable or low-power applications.

The scalability of Nitinol-integrated microfluidic systems is another hurdle. While Nitinol offers unique advantages at small scales, translating these benefits to larger, more complex microfluidic networks without compromising performance or increasing costs significantly is a major engineering challenge. This scalability issue affects both the manufacturing process and the operational efficiency of the devices.

Lastly, the long-term reliability and fatigue resistance of Nitinol components in microfluidic platforms remain areas of concern. The repeated actuation cycles and exposure to various fluids and environmental conditions can potentially degrade Nitinol's performance over time. Developing strategies to mitigate fatigue and ensure consistent operation throughout the device's lifespan is crucial for the widespread adoption of this technology in practical applications.

Another major challenge lies in the fabrication and integration process. Incorporating Nitinol elements into microfluidic platforms requires advanced manufacturing techniques that can maintain the material's unique properties while ensuring compatibility with other components of the system. This often involves complex microfabrication processes, including precise patterning and deposition of Nitinol thin films or wires, which can be technically demanding and costly.

The biocompatibility of Nitinol in microfluidic applications, particularly those intended for biomedical use, remains a concern. While Nitinol is generally considered biocompatible, its long-term effects in continuous contact with biological fluids and tissues within a microfluidic environment are not fully understood. This necessitates extensive testing and validation to ensure safety and reliability for potential in vitro or in vivo applications.

Temperature control and energy efficiency pose additional challenges. Nitinol's shape-memory effect is temperature-dependent, requiring precise thermal management within the microfluidic platform. Achieving rapid and localized heating for actuation while maintaining overall temperature stability in the system is technically challenging and energy-intensive, potentially limiting the applicability of Nitinol-based microfluidic devices in portable or low-power applications.

The scalability of Nitinol-integrated microfluidic systems is another hurdle. While Nitinol offers unique advantages at small scales, translating these benefits to larger, more complex microfluidic networks without compromising performance or increasing costs significantly is a major engineering challenge. This scalability issue affects both the manufacturing process and the operational efficiency of the devices.

Lastly, the long-term reliability and fatigue resistance of Nitinol components in microfluidic platforms remain areas of concern. The repeated actuation cycles and exposure to various fluids and environmental conditions can potentially degrade Nitinol's performance over time. Developing strategies to mitigate fatigue and ensure consistent operation throughout the device's lifespan is crucial for the widespread adoption of this technology in practical applications.

Existing Nitinol-based Microfluidic Solutions

01 Shape memory properties of Nitinol

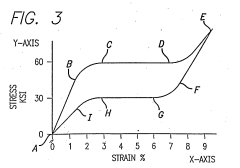

Nitinol is a shape memory alloy that can return to its original shape when heated. This unique property makes it useful in various applications, including medical devices, aerospace, and automotive industries. The shape memory effect allows for the creation of compact, deployable structures and self-expanding devices.- Shape memory properties of Nitinol: Nitinol is a shape memory alloy that can return to its original shape when heated. This unique property makes it useful in various applications, including medical devices, aerospace, and automotive industries. The shape memory effect allows for the creation of compact, deployable structures and self-expanding devices.

- Superelasticity of Nitinol: Nitinol exhibits superelastic behavior, allowing it to undergo large deformations and return to its original shape without permanent damage. This property is particularly valuable in medical applications, such as stents and orthodontic wires, where flexibility and resilience are crucial.

- Nitinol in medical devices: Nitinol is widely used in the medical field for various devices and implants. Its biocompatibility, corrosion resistance, and unique mechanical properties make it suitable for applications such as cardiovascular stents, orthopedic implants, and surgical instruments. The material's ability to change shape at body temperature allows for minimally invasive procedures.

- Nitinol in industrial applications: Nitinol finds applications in various industrial sectors due to its unique properties. It is used in actuators, couplings, and seals in aerospace and automotive industries. The material's ability to withstand high stress and strain makes it suitable for vibration damping and energy absorption applications.

- Processing and manufacturing of Nitinol: The production and processing of Nitinol require specialized techniques due to its unique properties. This includes precise control of composition, heat treatment, and forming methods. Advanced manufacturing processes, such as additive manufacturing and laser processing, are being explored to create complex Nitinol structures and improve its performance for specific applications.

02 Superelasticity of Nitinol

Nitinol exhibits superelastic behavior, allowing it to undergo large deformations and return to its original shape without permanent damage. This property is particularly valuable in medical applications, such as stents and orthodontic wires, where flexibility and resilience are crucial.Expand Specific Solutions03 Nitinol in medical devices

Nitinol is widely used in medical devices due to its biocompatibility and unique properties. It is commonly used in stents, guidewires, and surgical instruments. The material's ability to change shape at body temperature makes it ideal for minimally invasive procedures and implantable devices.Expand Specific Solutions04 Manufacturing and processing of Nitinol

The production and processing of Nitinol require specialized techniques due to its unique properties. This includes methods for shaping, heat treatment, and surface modification. Advanced manufacturing processes, such as laser cutting and additive manufacturing, are being developed to create complex Nitinol structures.Expand Specific Solutions05 Nitinol in industrial applications

Nitinol finds applications in various industrial sectors beyond medicine. It is used in aerospace for vibration damping and actuators, in automotive for safety devices, and in consumer products for eyeglass frames and cell phone antennas. The material's unique properties allow for innovative designs and improved performance in these applications.Expand Specific Solutions

Key Players in Nitinol Microfluidic Research

The exploration of Nitinol's use in digital microfluidic platforms is in an emerging stage, with the market showing significant growth potential. The technology's maturity is still developing, as evidenced by ongoing research at institutions like The University of Chicago, Nanyang Technological University, and Cornell University. Companies such as BOE Technology Group and Intel Corp. are likely investing in this field, leveraging their expertise in sensor technology and microfluidics. The integration of Nitinol in digital microfluidic platforms represents a convergence of materials science and microfluidics, potentially revolutionizing applications in biomedical engineering and lab-on-a-chip technologies.

Nanyang Technological University

Technical Solution: Nanyang Technological University has made notable contributions to the integration of Nitinol in digital microfluidic platforms. Their research team has developed a novel approach using Nitinol-based micro-pillars to create tunable wetting surfaces for digital microfluidics[7]. This innovation allows for dynamic control of surface properties, enabling advanced droplet manipulation techniques. The university has also explored the use of Nitinol thin films as flexible and responsive substrates for digital microfluidic devices, enhancing the adaptability of these platforms to various experimental conditions[9]. Additionally, they have investigated the application of Nitinol in creating smart microfluidic mixers that can be activated on-demand, improving the efficiency of mixing processes in digital microfluidic systems[11].

Strengths: Advanced surface control capabilities, flexible and adaptive microfluidic platforms, and improved mixing efficiency. Weaknesses: Potential challenges in achieving uniform Nitinol properties across large surface areas and ensuring long-term stability of the smart surfaces.

Wuhan University

Technical Solution: Wuhan University has made significant strides in exploring Nitinol's use in digital microfluidic platforms. Their research team has developed a novel approach using Nitinol-based micro-actuators for precise droplet manipulation in digital microfluidic devices[8]. This innovation allows for enhanced control over droplet movement, merging, and splitting operations. The university has also investigated the integration of Nitinol shape memory alloys in creating adaptive microfluidic channels that can change their geometry in response to external stimuli, enabling dynamic flow control and mixing[10]. Furthermore, they have explored the use of Nitinol in developing self-cleaning surfaces for digital microfluidic platforms, addressing issues related to sample carryover and cross-contamination[12].

Strengths: Precise droplet manipulation, adaptive channel geometries, and improved platform cleanliness. Weaknesses: Potential challenges in achieving rapid actuation speeds and ensuring uniform performance across different environmental conditions.

Innovative Nitinol Applications in Digital Microfluidics

Nitinol alloy for with good mechanical stability and a good superelastic operating window

PatentWO2006081011A2

Innovation

- A nickel-titanium alloy with a ternary element such as platinum or palladium is used to enhance radiopacity while maintaining superelastic properties, allowing for a thinner strut design that maintains flexibility and mechanical stability.

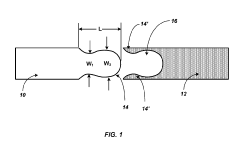

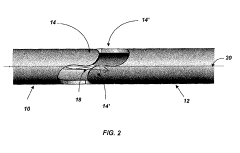

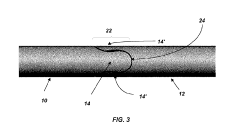

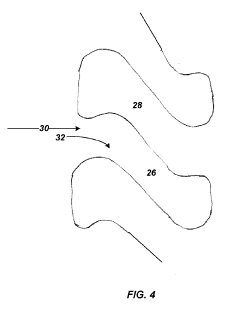

Mechanical Joining Of Nitinol Tubes

PatentActiveUS20190186659A1

Innovation

- A mechanical joint is formed by using Nitinol tubes with protruding lobes that interlock with corresponding lobes on another metallic tubular component, allowing for translation, rotational, or hinging motion to create a snap-fit joint, eliminating the need for welding and intermediate materials.

Biocompatibility and Safety Considerations

The integration of Nitinol in digital microfluidic platforms necessitates a thorough examination of biocompatibility and safety considerations. Nitinol, an alloy of nickel and titanium, has gained significant attention in biomedical applications due to its unique properties, including shape memory and superelasticity. However, its use in microfluidic devices that may come into contact with biological samples or be used in medical diagnostics requires careful evaluation.

One of the primary concerns regarding Nitinol's biocompatibility is the potential release of nickel ions. Nickel is known to cause allergic reactions in some individuals and can be cytotoxic at high concentrations. Studies have shown that the formation of a stable titanium oxide layer on the surface of Nitinol can significantly reduce nickel release. However, the stability of this protective layer in the context of microfluidic applications, where the material may be exposed to various reagents and biological fluids, needs to be thoroughly investigated.

The surface properties of Nitinol play a crucial role in its biocompatibility. Factors such as surface roughness, wettability, and chemical composition can influence protein adsorption, cell adhesion, and the potential for bacterial colonization. In digital microfluidic platforms, these surface characteristics may also affect droplet manipulation and the overall performance of the device. Therefore, optimizing surface treatments and coatings for Nitinol components in microfluidic applications is essential to ensure both biocompatibility and functionality.

Another important aspect to consider is the potential for corrosion of Nitinol in the microfluidic environment. The presence of various chemicals, pH changes, and electrochemical reactions that may occur during device operation could potentially lead to material degradation. This not only poses a risk to the structural integrity of the device but may also result in the release of potentially harmful corrosion products into the biological samples being analyzed.

The manufacturing process of Nitinol components for microfluidic devices also warrants attention from a safety perspective. Techniques such as laser cutting, etching, or additive manufacturing may introduce surface defects or alter the material's properties, potentially affecting its biocompatibility. Stringent quality control measures and post-processing treatments may be necessary to ensure the consistency and safety of Nitinol-based microfluidic components.

Regulatory considerations must also be addressed when incorporating Nitinol into digital microfluidic platforms intended for medical or diagnostic use. Compliance with standards such as ISO 10993 for biological evaluation of medical devices will be crucial. This may involve extensive in vitro and in vivo testing to assess cytotoxicity, sensitization, irritation, and long-term biocompatibility of the Nitinol components within the specific context of the microfluidic device.

One of the primary concerns regarding Nitinol's biocompatibility is the potential release of nickel ions. Nickel is known to cause allergic reactions in some individuals and can be cytotoxic at high concentrations. Studies have shown that the formation of a stable titanium oxide layer on the surface of Nitinol can significantly reduce nickel release. However, the stability of this protective layer in the context of microfluidic applications, where the material may be exposed to various reagents and biological fluids, needs to be thoroughly investigated.

The surface properties of Nitinol play a crucial role in its biocompatibility. Factors such as surface roughness, wettability, and chemical composition can influence protein adsorption, cell adhesion, and the potential for bacterial colonization. In digital microfluidic platforms, these surface characteristics may also affect droplet manipulation and the overall performance of the device. Therefore, optimizing surface treatments and coatings for Nitinol components in microfluidic applications is essential to ensure both biocompatibility and functionality.

Another important aspect to consider is the potential for corrosion of Nitinol in the microfluidic environment. The presence of various chemicals, pH changes, and electrochemical reactions that may occur during device operation could potentially lead to material degradation. This not only poses a risk to the structural integrity of the device but may also result in the release of potentially harmful corrosion products into the biological samples being analyzed.

The manufacturing process of Nitinol components for microfluidic devices also warrants attention from a safety perspective. Techniques such as laser cutting, etching, or additive manufacturing may introduce surface defects or alter the material's properties, potentially affecting its biocompatibility. Stringent quality control measures and post-processing treatments may be necessary to ensure the consistency and safety of Nitinol-based microfluidic components.

Regulatory considerations must also be addressed when incorporating Nitinol into digital microfluidic platforms intended for medical or diagnostic use. Compliance with standards such as ISO 10993 for biological evaluation of medical devices will be crucial. This may involve extensive in vitro and in vivo testing to assess cytotoxicity, sensitization, irritation, and long-term biocompatibility of the Nitinol components within the specific context of the microfluidic device.

Manufacturing Processes for Nitinol Microfluidic Components

The manufacturing processes for Nitinol microfluidic components are critical to the successful implementation of this shape memory alloy in digital microfluidic platforms. Nitinol's unique properties, including superelasticity and shape memory effect, require specialized fabrication techniques to ensure optimal performance in microfluidic devices.

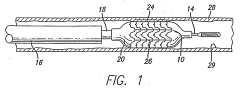

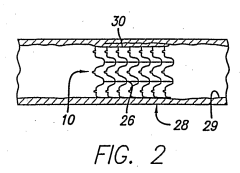

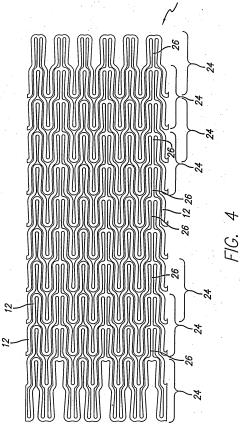

One of the primary manufacturing methods for Nitinol microfluidic components is laser cutting. This precision technique allows for the creation of intricate patterns and structures on thin Nitinol sheets or tubes. The process involves using a high-powered laser to selectively remove material, resulting in precise geometries essential for microfluidic applications. Laser cutting offers advantages such as minimal heat-affected zones and the ability to produce complex shapes with high accuracy.

Another important manufacturing process is photochemical etching. This technique involves selectively removing material from a Nitinol sheet using chemical etchants and photoresist masks. Photochemical etching is particularly useful for creating large quantities of identical components with fine features, making it suitable for mass production of Nitinol microfluidic devices.

Micro-electrical discharge machining (micro-EDM) is also employed in the fabrication of Nitinol microfluidic components. This process uses electrical discharges to erode material from the workpiece, allowing for the creation of small, high-precision features. Micro-EDM is especially valuable for producing three-dimensional structures and complex geometries that may be challenging to achieve with other manufacturing methods.

Heat treatment plays a crucial role in the manufacturing of Nitinol microfluidic components. Proper heat treatment is essential for setting the desired shape memory properties and ensuring the material's functionality in the final device. The process typically involves heating the Nitinol component to a specific temperature, holding it for a predetermined time, and then rapidly cooling it to lock in the desired crystal structure.

Surface modification techniques are often employed to enhance the performance of Nitinol microfluidic components. These may include electropolishing to improve surface smoothness and corrosion resistance, or the application of specialized coatings to modify surface properties such as hydrophobicity or biocompatibility.

Assembly and integration of Nitinol components into microfluidic devices require precision bonding techniques. Methods such as laser welding, adhesive bonding, or mechanical fastening may be used, depending on the specific design requirements and compatibility with other materials in the microfluidic platform.

Quality control and testing are integral parts of the manufacturing process for Nitinol microfluidic components. This includes dimensional inspection, material characterization, and functional testing to ensure that the manufactured components meet the required specifications and perform as intended in the microfluidic environment.

One of the primary manufacturing methods for Nitinol microfluidic components is laser cutting. This precision technique allows for the creation of intricate patterns and structures on thin Nitinol sheets or tubes. The process involves using a high-powered laser to selectively remove material, resulting in precise geometries essential for microfluidic applications. Laser cutting offers advantages such as minimal heat-affected zones and the ability to produce complex shapes with high accuracy.

Another important manufacturing process is photochemical etching. This technique involves selectively removing material from a Nitinol sheet using chemical etchants and photoresist masks. Photochemical etching is particularly useful for creating large quantities of identical components with fine features, making it suitable for mass production of Nitinol microfluidic devices.

Micro-electrical discharge machining (micro-EDM) is also employed in the fabrication of Nitinol microfluidic components. This process uses electrical discharges to erode material from the workpiece, allowing for the creation of small, high-precision features. Micro-EDM is especially valuable for producing three-dimensional structures and complex geometries that may be challenging to achieve with other manufacturing methods.

Heat treatment plays a crucial role in the manufacturing of Nitinol microfluidic components. Proper heat treatment is essential for setting the desired shape memory properties and ensuring the material's functionality in the final device. The process typically involves heating the Nitinol component to a specific temperature, holding it for a predetermined time, and then rapidly cooling it to lock in the desired crystal structure.

Surface modification techniques are often employed to enhance the performance of Nitinol microfluidic components. These may include electropolishing to improve surface smoothness and corrosion resistance, or the application of specialized coatings to modify surface properties such as hydrophobicity or biocompatibility.

Assembly and integration of Nitinol components into microfluidic devices require precision bonding techniques. Methods such as laser welding, adhesive bonding, or mechanical fastening may be used, depending on the specific design requirements and compatibility with other materials in the microfluidic platform.

Quality control and testing are integral parts of the manufacturing process for Nitinol microfluidic components. This includes dimensional inspection, material characterization, and functional testing to ensure that the manufactured components meet the required specifications and perform as intended in the microfluidic environment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!