Hydroforming Techniques for Nitinol Sheet Metal Components

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nitinol Hydroforming Background and Objectives

Nitinol, a unique nickel-titanium alloy, has revolutionized various industries due to its exceptional shape memory and superelastic properties. The development of hydroforming techniques for Nitinol sheet metal components represents a significant advancement in manufacturing processes, offering new possibilities for creating complex, lightweight structures with enhanced functionality.

The evolution of Nitinol technology can be traced back to its discovery in 1959 at the Naval Ordnance Laboratory. Since then, researchers and engineers have been exploring innovative ways to harness its unique characteristics. The application of hydroforming techniques to Nitinol sheet metal components emerged as a promising avenue for expanding the material's potential in diverse fields, including aerospace, medical devices, and automotive industries.

Hydroforming, a process that uses high-pressure fluid to shape metal, has been successfully applied to various materials. However, its application to Nitinol presents unique challenges and opportunities due to the alloy's distinctive properties. The combination of Nitinol's shape memory effect and the precision of hydroforming techniques opens up new possibilities for creating intricate, customized components with unprecedented performance characteristics.

The primary objective of research in this field is to develop and optimize hydroforming techniques specifically tailored for Nitinol sheet metal components. This involves understanding the material's behavior under various pressure and temperature conditions, as well as developing precise control mechanisms to achieve desired shapes and properties in the final product.

Key technical goals include enhancing the formability of Nitinol sheets, improving the accuracy and repeatability of the hydroforming process, and expanding the range of achievable geometries. Additionally, researchers aim to develop methods for integrating the shape memory effect into the hydroforming process, potentially creating components that can change shape or configuration in response to environmental stimuli.

Another crucial aspect of this research is to address the challenges associated with Nitinol's unique phase transformation characteristics during the hydroforming process. This includes managing the material's temperature-dependent properties and ensuring consistent performance across different batches of the alloy.

As the field progresses, there is a growing focus on developing simulation models and predictive tools to optimize the hydroforming process for Nitinol components. These advancements aim to reduce the need for extensive trial-and-error experimentation, thereby accelerating the development of new applications and reducing production costs.

The intersection of Nitinol's exceptional properties with advanced hydroforming techniques represents a frontier in materials science and manufacturing technology. Success in this area has the potential to enable the creation of innovative products with unprecedented capabilities, driving progress in industries ranging from medical implants to aerospace components.

The evolution of Nitinol technology can be traced back to its discovery in 1959 at the Naval Ordnance Laboratory. Since then, researchers and engineers have been exploring innovative ways to harness its unique characteristics. The application of hydroforming techniques to Nitinol sheet metal components emerged as a promising avenue for expanding the material's potential in diverse fields, including aerospace, medical devices, and automotive industries.

Hydroforming, a process that uses high-pressure fluid to shape metal, has been successfully applied to various materials. However, its application to Nitinol presents unique challenges and opportunities due to the alloy's distinctive properties. The combination of Nitinol's shape memory effect and the precision of hydroforming techniques opens up new possibilities for creating intricate, customized components with unprecedented performance characteristics.

The primary objective of research in this field is to develop and optimize hydroforming techniques specifically tailored for Nitinol sheet metal components. This involves understanding the material's behavior under various pressure and temperature conditions, as well as developing precise control mechanisms to achieve desired shapes and properties in the final product.

Key technical goals include enhancing the formability of Nitinol sheets, improving the accuracy and repeatability of the hydroforming process, and expanding the range of achievable geometries. Additionally, researchers aim to develop methods for integrating the shape memory effect into the hydroforming process, potentially creating components that can change shape or configuration in response to environmental stimuli.

Another crucial aspect of this research is to address the challenges associated with Nitinol's unique phase transformation characteristics during the hydroforming process. This includes managing the material's temperature-dependent properties and ensuring consistent performance across different batches of the alloy.

As the field progresses, there is a growing focus on developing simulation models and predictive tools to optimize the hydroforming process for Nitinol components. These advancements aim to reduce the need for extensive trial-and-error experimentation, thereby accelerating the development of new applications and reducing production costs.

The intersection of Nitinol's exceptional properties with advanced hydroforming techniques represents a frontier in materials science and manufacturing technology. Success in this area has the potential to enable the creation of innovative products with unprecedented capabilities, driving progress in industries ranging from medical implants to aerospace components.

Market Analysis for Nitinol Components

The market for Nitinol components has been experiencing significant growth in recent years, driven by the unique properties of this shape memory alloy. Nitinol's superelasticity and shape memory characteristics make it particularly valuable in various industries, with the medical device sector leading the demand.

In the medical field, Nitinol is widely used in cardiovascular devices, orthopedic implants, and minimally invasive surgical instruments. The global market for Nitinol medical devices is projected to expand steadily, fueled by the increasing prevalence of cardiovascular diseases and the growing adoption of minimally invasive procedures. Stents, guidewires, and catheters are among the most common Nitinol-based medical devices.

Beyond healthcare, Nitinol finds applications in aerospace, automotive, and consumer electronics industries. In aerospace, Nitinol components are used in aircraft actuators and vibration damping systems. The automotive sector utilizes Nitinol in various applications, including engine valves and adaptive headlight systems. Consumer electronics benefit from Nitinol's properties in items such as mobile phone antennas and eyeglass frames.

The demand for Nitinol sheet metal components is particularly strong in industries requiring complex, lightweight structures with high fatigue resistance. Hydroforming techniques for Nitinol sheet metal offer advantages in producing intricate shapes while maintaining the material's unique properties, opening new possibilities for product design and performance enhancement.

Market trends indicate a growing interest in customized Nitinol components, especially in the medical device industry. This trend is driven by the need for patient-specific implants and devices, which can be more effectively produced using advanced manufacturing techniques like hydroforming.

Geographically, North America and Europe lead the Nitinol component market, primarily due to their advanced healthcare systems and robust medical device industries. However, the Asia-Pacific region is expected to show the fastest growth, attributed to increasing healthcare expenditure, rising awareness of minimally invasive procedures, and growing manufacturing capabilities in countries like China and India.

Challenges in the Nitinol component market include the high cost of raw materials and complex manufacturing processes. These factors can limit adoption in price-sensitive markets. Additionally, stringent regulatory requirements, particularly for medical applications, pose barriers to market entry and product development.

Despite these challenges, the overall market outlook for Nitinol components remains positive. Ongoing research and development in hydroforming techniques for Nitinol sheet metal are expected to further expand the material's applications and market potential, driving innovation across multiple industries.

In the medical field, Nitinol is widely used in cardiovascular devices, orthopedic implants, and minimally invasive surgical instruments. The global market for Nitinol medical devices is projected to expand steadily, fueled by the increasing prevalence of cardiovascular diseases and the growing adoption of minimally invasive procedures. Stents, guidewires, and catheters are among the most common Nitinol-based medical devices.

Beyond healthcare, Nitinol finds applications in aerospace, automotive, and consumer electronics industries. In aerospace, Nitinol components are used in aircraft actuators and vibration damping systems. The automotive sector utilizes Nitinol in various applications, including engine valves and adaptive headlight systems. Consumer electronics benefit from Nitinol's properties in items such as mobile phone antennas and eyeglass frames.

The demand for Nitinol sheet metal components is particularly strong in industries requiring complex, lightweight structures with high fatigue resistance. Hydroforming techniques for Nitinol sheet metal offer advantages in producing intricate shapes while maintaining the material's unique properties, opening new possibilities for product design and performance enhancement.

Market trends indicate a growing interest in customized Nitinol components, especially in the medical device industry. This trend is driven by the need for patient-specific implants and devices, which can be more effectively produced using advanced manufacturing techniques like hydroforming.

Geographically, North America and Europe lead the Nitinol component market, primarily due to their advanced healthcare systems and robust medical device industries. However, the Asia-Pacific region is expected to show the fastest growth, attributed to increasing healthcare expenditure, rising awareness of minimally invasive procedures, and growing manufacturing capabilities in countries like China and India.

Challenges in the Nitinol component market include the high cost of raw materials and complex manufacturing processes. These factors can limit adoption in price-sensitive markets. Additionally, stringent regulatory requirements, particularly for medical applications, pose barriers to market entry and product development.

Despite these challenges, the overall market outlook for Nitinol components remains positive. Ongoing research and development in hydroforming techniques for Nitinol sheet metal are expected to further expand the material's applications and market potential, driving innovation across multiple industries.

Hydroforming Challenges for Nitinol Sheets

Hydroforming of Nitinol sheet metal components presents several unique challenges due to the material's exceptional properties and behavior. One of the primary difficulties lies in the shape memory and superelastic characteristics of Nitinol, which can lead to unpredictable deformation during the forming process. This unpredictability makes it challenging to achieve precise and consistent shapes, especially for complex geometries.

The temperature sensitivity of Nitinol adds another layer of complexity to the hydroforming process. The material's phase transformation between austenite and martensite occurs within a narrow temperature range, which can significantly affect its mechanical properties during forming. Maintaining precise temperature control throughout the hydroforming operation is crucial but technically demanding.

Springback, a common issue in metal forming, is particularly pronounced in Nitinol due to its superelastic nature. After the hydroforming pressure is released, the material tends to partially return to its original shape, making it difficult to achieve the desired final dimensions. This necessitates sophisticated die design and process parameters to compensate for the springback effect.

The high strength of Nitinol, while beneficial for many applications, poses challenges during hydroforming. Higher pressures are often required to deform the material, which can lead to increased tool wear and the need for more robust hydroforming equipment. This can significantly impact the cost and complexity of the manufacturing process.

Surface finish is another critical concern in Nitinol hydroforming. The material is prone to surface defects and irregularities during forming, which can compromise both the aesthetic and functional properties of the final component. Achieving a smooth, defect-free surface often requires additional post-processing steps, adding to the overall manufacturing complexity and cost.

The limited formability of Nitinol sheets, especially when compared to more conventional metals, restricts the range of shapes and features that can be achieved through hydroforming. This limitation can constrain design possibilities and may require alternative manufacturing methods for certain component geometries.

Lastly, the high cost of Nitinol raw materials and the specialized equipment required for its processing contribute to the overall economic challenges of hydroforming Nitinol sheet metal components. These factors necessitate careful consideration of process efficiency and material utilization to ensure the economic viability of Nitinol hydroforming in industrial applications.

The temperature sensitivity of Nitinol adds another layer of complexity to the hydroforming process. The material's phase transformation between austenite and martensite occurs within a narrow temperature range, which can significantly affect its mechanical properties during forming. Maintaining precise temperature control throughout the hydroforming operation is crucial but technically demanding.

Springback, a common issue in metal forming, is particularly pronounced in Nitinol due to its superelastic nature. After the hydroforming pressure is released, the material tends to partially return to its original shape, making it difficult to achieve the desired final dimensions. This necessitates sophisticated die design and process parameters to compensate for the springback effect.

The high strength of Nitinol, while beneficial for many applications, poses challenges during hydroforming. Higher pressures are often required to deform the material, which can lead to increased tool wear and the need for more robust hydroforming equipment. This can significantly impact the cost and complexity of the manufacturing process.

Surface finish is another critical concern in Nitinol hydroforming. The material is prone to surface defects and irregularities during forming, which can compromise both the aesthetic and functional properties of the final component. Achieving a smooth, defect-free surface often requires additional post-processing steps, adding to the overall manufacturing complexity and cost.

The limited formability of Nitinol sheets, especially when compared to more conventional metals, restricts the range of shapes and features that can be achieved through hydroforming. This limitation can constrain design possibilities and may require alternative manufacturing methods for certain component geometries.

Lastly, the high cost of Nitinol raw materials and the specialized equipment required for its processing contribute to the overall economic challenges of hydroforming Nitinol sheet metal components. These factors necessitate careful consideration of process efficiency and material utilization to ensure the economic viability of Nitinol hydroforming in industrial applications.

Current Hydroforming Solutions for Nitinol

01 Hydroforming of Nitinol sheet metal components

Hydroforming techniques can be applied to Nitinol sheet metal components to create complex shapes. This process involves using high-pressure fluid to deform the Nitinol sheet into a desired form, taking advantage of its superelastic properties. The method allows for precise shaping of Nitinol components while maintaining their unique characteristics.- Hydroforming process for Nitinol sheet metal components: Hydroforming is a specialized forming process used for shaping Nitinol sheet metal components. This technique involves using high-pressure fluid to form the shape-memory alloy into complex geometries while maintaining its unique properties. The process allows for precise control over the final shape and can be used to create intricate designs that would be difficult to achieve with traditional forming methods.

- Temperature control in Nitinol hydroforming: Temperature management is crucial when hydroforming Nitinol components due to the material's temperature-dependent shape memory properties. Careful control of the forming temperature can help maintain the desired shape and mechanical characteristics of the final product. This may involve heating or cooling the material or the forming fluid to achieve optimal results.

- Tooling design for Nitinol sheet hydroforming: Specialized tooling is required for hydroforming Nitinol sheet metal components. The design of dies and molds must account for the unique properties of Nitinol, including its superelasticity and shape memory effect. Proper tooling design ensures uniform pressure distribution and helps prevent damage to the material during the forming process.

- Post-forming heat treatment of hydroformed Nitinol components: After hydroforming, Nitinol components often require post-forming heat treatment to set the final shape and optimize the material's properties. This process, known as shape setting, involves heating the formed component to a specific temperature and then cooling it in a controlled manner. The heat treatment helps to relieve internal stresses and ensure the desired shape memory behavior.

- Quality control and testing of hydroformed Nitinol sheet components: Rigorous quality control and testing procedures are essential for hydroformed Nitinol sheet metal components. This may include non-destructive testing methods to verify the integrity of the formed parts, as well as functional testing to ensure the components exhibit the required shape memory and superelastic properties. Dimensional accuracy and surface finish are also critical factors that need to be assessed.

02 Heat treatment of Nitinol during hydroforming

Heat treatment can be integrated into the hydroforming process for Nitinol sheet metal components. This combination allows for simultaneous shaping and property adjustment of the material. By controlling temperature during hydroforming, the shape memory and superelastic properties of Nitinol can be optimized for specific applications.Expand Specific Solutions03 Tooling design for Nitinol hydroforming

Specialized tooling is crucial for successful hydroforming of Nitinol sheet metal components. The design of dies and forming equipment must account for the unique properties of Nitinol, including its high strength and shape memory characteristics. Proper tooling ensures uniform pressure distribution and prevents damage to the Nitinol sheet during the forming process.Expand Specific Solutions04 Surface treatment of Nitinol before hydroforming

Surface preparation of Nitinol sheet metal is important before the hydroforming process. Treatments such as cleaning, etching, or coating can improve the formability of the material and enhance its performance in the final product. These pre-hydroforming treatments can also affect the biocompatibility and corrosion resistance of the Nitinol components.Expand Specific Solutions05 Quality control in Nitinol hydroforming

Implementing rigorous quality control measures is essential in the hydroforming of Nitinol sheet metal components. This includes monitoring of pressure, temperature, and material flow during the forming process. Advanced inspection techniques, such as non-destructive testing, can be used to ensure the integrity and performance of the hydroformed Nitinol components.Expand Specific Solutions

Key Players in Nitinol Manufacturing

The research on hydroforming techniques for Nitinol sheet metal components is in a developing stage, with growing market potential due to the unique properties of Nitinol. The technology is advancing, but still not fully mature, as evidenced by ongoing research at institutions like South China University of Technology and Harbin Engineering University. Companies such as Magna International and Ford Global Technologies are exploring applications in the automotive sector, while medical device manufacturers like Medtronic are investigating its use in biomedical implants. The market is expected to expand as the technology becomes more refined and cost-effective, driven by demand in aerospace, automotive, and healthcare industries.

Ford Global Technologies LLC

Technical Solution: Ford has developed advanced hydroforming techniques for Nitinol sheet metal components, focusing on automotive applications. Their approach involves precise temperature control during the forming process to exploit Nitinol's shape memory properties. They utilize a specialized die design that accommodates the material's superelastic behavior, allowing for complex geometries to be formed[1]. Ford's method incorporates a two-stage forming process: initial shaping at room temperature followed by a heat treatment phase to set the final shape[3]. This technique enables the production of lightweight, high-strength components with improved crash energy absorption characteristics[5].

Strengths: Ability to create complex, lightweight components with superior strength-to-weight ratios. Improved crash safety performance. Weaknesses: Higher production costs compared to traditional materials. Limited high-volume manufacturing capability due to specialized equipment requirements.

Mercedes-Benz Group AG

Technical Solution: Mercedes-Benz has pioneered a hydroforming technique for Nitinol sheet metal components specifically tailored for luxury vehicle applications. Their method employs a computer-controlled, variable pressure hydroforming system that adapts to the unique properties of Nitinol during the forming process[2]. The technique incorporates real-time monitoring of material phase transformation, allowing for precise control over the final component shape and properties[4]. Mercedes-Benz has also developed a proprietary surface treatment process that enhances the corrosion resistance and durability of the formed Nitinol components[6].

Strengths: High precision in forming complex shapes. Enhanced material properties through controlled processing. Excellent finish quality suitable for luxury vehicles. Weaknesses: High initial investment in specialized equipment. Limited to lower volume, high-end applications due to cost constraints.

Innovative Nitinol Hydroforming Patents

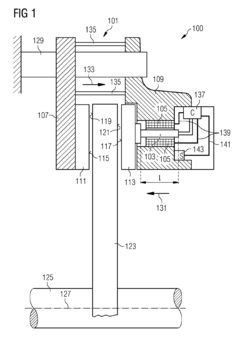

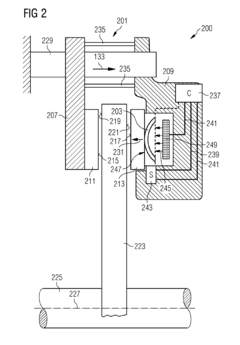

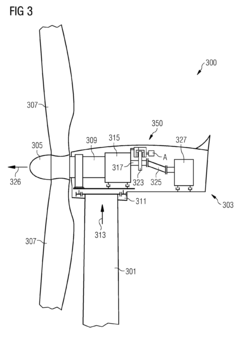

Braking system for a wind turbine

PatentInactiveEP2597329A1

Innovation

- A braking system utilizing shape memory material within a brake caliper, activated by heating, magnetic fields, or electromagnetic radiation, which changes shape to apply friction forces to a brake disk, eliminating the need for hydraulic or pneumatic fluids and associated components, thereby reducing weight, space, and energy consumption.

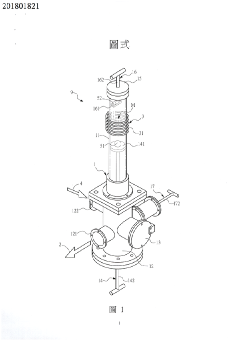

Nickel-titanium alloy fabrication method by using high vacuum crucible-free floating melting process in which a titanium material is heated in a floating condition with an induction coil and a nickel material is added into the titanium material when the titanium material is in a partly melted condition

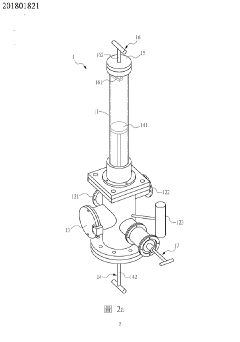

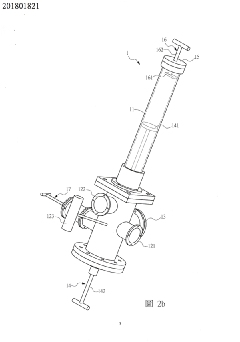

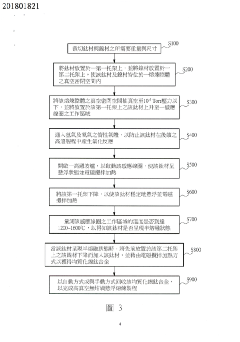

PatentInactiveTW201801821A

Innovation

- Utilization of high vacuum crucible-free floating melting process for nickel-titanium alloy fabrication, allowing for better control of composition and reduced contamination.

- Introduction of nickel material when titanium is in a partly melted condition, enabling better mixing and homogeneity of the final alloy.

- Use of electromagnetic stirring and heating in a floating condition, providing uniform heating and mixing of the materials.

Material Properties and Characterization

Nitinol, a nickel-titanium alloy, exhibits unique material properties that make it particularly suitable for hydroforming applications in sheet metal components. This shape memory alloy demonstrates exceptional elasticity, biocompatibility, and the ability to return to its original shape after deformation, making it invaluable in various industries, including medical devices and aerospace.

The characterization of Nitinol's material properties is crucial for successful hydroforming processes. One of the key attributes of Nitinol is its superelasticity, which allows it to undergo large deformations without permanent plastic deformation. This property is particularly advantageous in hydroforming, as it enables the material to conform to complex shapes under high pressure without losing its structural integrity.

Nitinol's phase transformation behavior is another critical aspect that influences its performance in hydroforming applications. The material undergoes a reversible solid-state phase transformation between austenite and martensite, which is responsible for its shape memory effect. This transformation can be induced by both temperature changes and applied stress, allowing for precise control of the material's behavior during the hydroforming process.

The mechanical properties of Nitinol sheet metal, including yield strength, ultimate tensile strength, and elongation, vary significantly depending on the alloy composition and heat treatment. These properties must be carefully characterized to optimize the hydroforming process parameters and ensure the desired final component characteristics.

Surface properties of Nitinol sheets also play a crucial role in hydroforming. The oxide layer that naturally forms on Nitinol surfaces can affect the material's corrosion resistance and biocompatibility. Understanding and controlling this surface layer is essential for applications in medical devices and other corrosive environments.

Fatigue behavior is another critical aspect of Nitinol characterization, particularly for components subjected to cyclic loading. The unique pseudoelastic behavior of Nitinol can lead to improved fatigue resistance compared to conventional alloys, but proper characterization is necessary to predict and optimize component life.

Thermal properties, including the transformation temperatures and thermal conductivity, are vital for understanding the material's behavior during and after the hydroforming process. These properties influence the shape memory effect and can be tailored through composition and heat treatment to meet specific application requirements.

In conclusion, a comprehensive understanding of Nitinol's material properties and their characterization is fundamental to developing effective hydroforming techniques for sheet metal components. This knowledge enables engineers to optimize process parameters, predict material behavior, and ultimately produce high-quality, complex-shaped components that leverage the unique attributes of this remarkable alloy.

The characterization of Nitinol's material properties is crucial for successful hydroforming processes. One of the key attributes of Nitinol is its superelasticity, which allows it to undergo large deformations without permanent plastic deformation. This property is particularly advantageous in hydroforming, as it enables the material to conform to complex shapes under high pressure without losing its structural integrity.

Nitinol's phase transformation behavior is another critical aspect that influences its performance in hydroforming applications. The material undergoes a reversible solid-state phase transformation between austenite and martensite, which is responsible for its shape memory effect. This transformation can be induced by both temperature changes and applied stress, allowing for precise control of the material's behavior during the hydroforming process.

The mechanical properties of Nitinol sheet metal, including yield strength, ultimate tensile strength, and elongation, vary significantly depending on the alloy composition and heat treatment. These properties must be carefully characterized to optimize the hydroforming process parameters and ensure the desired final component characteristics.

Surface properties of Nitinol sheets also play a crucial role in hydroforming. The oxide layer that naturally forms on Nitinol surfaces can affect the material's corrosion resistance and biocompatibility. Understanding and controlling this surface layer is essential for applications in medical devices and other corrosive environments.

Fatigue behavior is another critical aspect of Nitinol characterization, particularly for components subjected to cyclic loading. The unique pseudoelastic behavior of Nitinol can lead to improved fatigue resistance compared to conventional alloys, but proper characterization is necessary to predict and optimize component life.

Thermal properties, including the transformation temperatures and thermal conductivity, are vital for understanding the material's behavior during and after the hydroforming process. These properties influence the shape memory effect and can be tailored through composition and heat treatment to meet specific application requirements.

In conclusion, a comprehensive understanding of Nitinol's material properties and their characterization is fundamental to developing effective hydroforming techniques for sheet metal components. This knowledge enables engineers to optimize process parameters, predict material behavior, and ultimately produce high-quality, complex-shaped components that leverage the unique attributes of this remarkable alloy.

Environmental Impact Assessment

The environmental impact assessment of hydroforming techniques for Nitinol sheet metal components reveals several important considerations. Nitinol, an alloy of nickel and titanium, is known for its shape memory and superelastic properties, making it valuable in various industries, including medical devices and aerospace. However, the production and processing of Nitinol have potential environmental implications that must be carefully evaluated.

The extraction and refining of nickel and titanium, the primary components of Nitinol, involve energy-intensive processes that contribute to greenhouse gas emissions. Mining operations for these metals can lead to habitat disruption, soil erosion, and water pollution if not properly managed. Additionally, the production of Nitinol alloy requires high temperatures, further increasing energy consumption and associated carbon footprint.

Hydroforming, as a manufacturing technique for Nitinol sheet metal components, offers some environmental advantages over traditional forming methods. It typically requires less material waste and can produce more complex shapes in a single operation, potentially reducing the need for additional manufacturing steps. This efficiency can lead to lower overall energy consumption and reduced material usage, contributing to a more sustainable production process.

However, hydroforming also presents environmental challenges. The process uses high-pressure fluids, often water-based emulsions or oils, which need proper handling and disposal to prevent contamination of water sources. The equipment used in hydroforming consumes significant amounts of electricity, particularly for high-pressure pumps, which indirectly contributes to carbon emissions depending on the energy source.

Waste management is another critical aspect of the environmental assessment. While hydroforming generally produces less solid waste compared to traditional machining processes, the disposal of used forming fluids and any chemical additives requires careful consideration to comply with environmental regulations and minimize ecological impact.

The lifecycle analysis of Nitinol components produced through hydroforming should also consider the potential for recycling and reuse. Nitinol's unique properties make it challenging to recycle through conventional methods, potentially leading to increased landfill waste if proper recycling technologies are not developed or implemented.

To mitigate environmental impacts, several strategies can be employed. These include optimizing the hydroforming process to reduce energy consumption, implementing closed-loop systems for forming fluids to minimize waste, and exploring more sustainable sources of nickel and titanium. Additionally, investing in research for improved Nitinol recycling methods could significantly enhance the overall environmental profile of these components.

In conclusion, while hydroforming of Nitinol sheet metal components offers some environmental benefits in terms of material efficiency and reduced waste, the overall environmental impact remains significant. Continued research and development in cleaner production methods, sustainable material sourcing, and improved recycling techniques are essential to enhance the environmental sustainability of this manufacturing process.

The extraction and refining of nickel and titanium, the primary components of Nitinol, involve energy-intensive processes that contribute to greenhouse gas emissions. Mining operations for these metals can lead to habitat disruption, soil erosion, and water pollution if not properly managed. Additionally, the production of Nitinol alloy requires high temperatures, further increasing energy consumption and associated carbon footprint.

Hydroforming, as a manufacturing technique for Nitinol sheet metal components, offers some environmental advantages over traditional forming methods. It typically requires less material waste and can produce more complex shapes in a single operation, potentially reducing the need for additional manufacturing steps. This efficiency can lead to lower overall energy consumption and reduced material usage, contributing to a more sustainable production process.

However, hydroforming also presents environmental challenges. The process uses high-pressure fluids, often water-based emulsions or oils, which need proper handling and disposal to prevent contamination of water sources. The equipment used in hydroforming consumes significant amounts of electricity, particularly for high-pressure pumps, which indirectly contributes to carbon emissions depending on the energy source.

Waste management is another critical aspect of the environmental assessment. While hydroforming generally produces less solid waste compared to traditional machining processes, the disposal of used forming fluids and any chemical additives requires careful consideration to comply with environmental regulations and minimize ecological impact.

The lifecycle analysis of Nitinol components produced through hydroforming should also consider the potential for recycling and reuse. Nitinol's unique properties make it challenging to recycle through conventional methods, potentially leading to increased landfill waste if proper recycling technologies are not developed or implemented.

To mitigate environmental impacts, several strategies can be employed. These include optimizing the hydroforming process to reduce energy consumption, implementing closed-loop systems for forming fluids to minimize waste, and exploring more sustainable sources of nickel and titanium. Additionally, investing in research for improved Nitinol recycling methods could significantly enhance the overall environmental profile of these components.

In conclusion, while hydroforming of Nitinol sheet metal components offers some environmental benefits in terms of material efficiency and reduced waste, the overall environmental impact remains significant. Continued research and development in cleaner production methods, sustainable material sourcing, and improved recycling techniques are essential to enhance the environmental sustainability of this manufacturing process.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!