Nitinol's Role in Stress Shielding for Orthopedic Implants

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nitinol in Orthopedics: Background and Objectives

Nitinol, a unique alloy of nickel and titanium, has revolutionized the field of orthopedic implants since its discovery in the 1960s. This shape memory alloy possesses remarkable properties that make it particularly suitable for addressing the long-standing issue of stress shielding in orthopedic applications. Stress shielding occurs when the stiffness of an implant causes a reduction in bone density, leading to potential complications and implant failure.

The primary objective of utilizing Nitinol in orthopedic implants is to mitigate the effects of stress shielding by more closely matching the mechanical properties of bone. Nitinol's superelastic behavior allows it to deform under stress and return to its original shape when the stress is removed, much like natural bone tissue. This characteristic enables a more even distribution of stress between the implant and surrounding bone, potentially reducing bone resorption and improving long-term implant stability.

The evolution of Nitinol in orthopedics has been marked by significant milestones. Initially used in orthodontic wires and vascular stents, its application in load-bearing orthopedic implants has gained traction over the past two decades. Researchers and engineers have focused on optimizing Nitinol's composition and processing techniques to enhance its biocompatibility and mechanical properties specifically for orthopedic use.

Current technological trends in Nitinol-based orthopedic implants include the development of porous structures to promote osseointegration, surface modifications to enhance biocompatibility, and the integration of Nitinol with other materials to create hybrid implants with tailored properties. These advancements aim to address not only stress shielding but also other challenges in orthopedic implantology, such as implant loosening and infection.

The potential impact of Nitinol on the orthopedic implant market is substantial. As the global population ages and the demand for joint replacements and spinal implants increases, the need for materials that can provide long-term stability and reduce complications becomes more critical. Nitinol's unique properties position it as a promising solution to these challenges, potentially improving patient outcomes and reducing healthcare costs associated with implant revisions.

Looking ahead, the objectives for Nitinol in orthopedic applications include further refinement of its mechanical properties to more closely mimic those of natural bone across different anatomical locations. Additionally, researchers aim to develop manufacturing techniques that allow for patient-specific implant designs, leveraging Nitinol's shape memory properties to create implants that can adapt to individual patient anatomy and loading conditions.

The primary objective of utilizing Nitinol in orthopedic implants is to mitigate the effects of stress shielding by more closely matching the mechanical properties of bone. Nitinol's superelastic behavior allows it to deform under stress and return to its original shape when the stress is removed, much like natural bone tissue. This characteristic enables a more even distribution of stress between the implant and surrounding bone, potentially reducing bone resorption and improving long-term implant stability.

The evolution of Nitinol in orthopedics has been marked by significant milestones. Initially used in orthodontic wires and vascular stents, its application in load-bearing orthopedic implants has gained traction over the past two decades. Researchers and engineers have focused on optimizing Nitinol's composition and processing techniques to enhance its biocompatibility and mechanical properties specifically for orthopedic use.

Current technological trends in Nitinol-based orthopedic implants include the development of porous structures to promote osseointegration, surface modifications to enhance biocompatibility, and the integration of Nitinol with other materials to create hybrid implants with tailored properties. These advancements aim to address not only stress shielding but also other challenges in orthopedic implantology, such as implant loosening and infection.

The potential impact of Nitinol on the orthopedic implant market is substantial. As the global population ages and the demand for joint replacements and spinal implants increases, the need for materials that can provide long-term stability and reduce complications becomes more critical. Nitinol's unique properties position it as a promising solution to these challenges, potentially improving patient outcomes and reducing healthcare costs associated with implant revisions.

Looking ahead, the objectives for Nitinol in orthopedic applications include further refinement of its mechanical properties to more closely mimic those of natural bone across different anatomical locations. Additionally, researchers aim to develop manufacturing techniques that allow for patient-specific implant designs, leveraging Nitinol's shape memory properties to create implants that can adapt to individual patient anatomy and loading conditions.

Market Analysis for Nitinol-based Implants

The market for Nitinol-based orthopedic implants has been experiencing significant growth in recent years, driven by the increasing prevalence of orthopedic disorders and the growing demand for minimally invasive surgical procedures. Nitinol, a nickel-titanium alloy known for its unique shape memory and superelastic properties, has emerged as a game-changing material in the field of orthopedic implants.

The global orthopedic implants market is projected to reach substantial value in the coming years, with Nitinol-based implants playing a crucial role in this growth. The adoption of Nitinol in orthopedic applications is primarily fueled by its ability to address stress shielding, a common issue with traditional metallic implants. Stress shielding occurs when the implant bears a disproportionate amount of load, leading to bone resorption and potential implant failure.

Nitinol's superelastic properties allow for the design of implants that more closely match the mechanical properties of bone, significantly reducing stress shielding effects. This has led to increased interest from both medical professionals and patients, driving market demand for Nitinol-based orthopedic solutions.

The market for Nitinol-based implants spans various orthopedic applications, including spinal devices, joint replacement implants, and fracture fixation systems. Among these, spinal devices represent the largest segment, with Nitinol being extensively used in interbody fusion cages and dynamic stabilization systems. The joint replacement segment is also showing promising growth, particularly in applications such as hip and knee implants.

Geographically, North America currently dominates the Nitinol-based orthopedic implants market, followed by Europe and Asia-Pacific. The United States, in particular, holds a significant market share due to its advanced healthcare infrastructure and high adoption rate of innovative medical technologies. However, emerging economies in Asia-Pacific and Latin America are expected to witness rapid growth in the coming years, driven by improving healthcare access and rising disposable incomes.

Key market players in the Nitinol-based orthopedic implants sector include established medical device companies as well as specialized Nitinol manufacturers. These companies are investing heavily in research and development to expand their product portfolios and improve the performance of Nitinol implants. Collaborations between material scientists, orthopedic surgeons, and implant manufacturers are becoming increasingly common, fostering innovation in this field.

Despite the promising outlook, the market faces certain challenges. The high cost of Nitinol and the complex manufacturing processes required for Nitinol-based implants can impact their widespread adoption, particularly in price-sensitive markets. Additionally, regulatory hurdles and the need for long-term clinical data on the performance of Nitinol implants pose challenges to market growth.

The global orthopedic implants market is projected to reach substantial value in the coming years, with Nitinol-based implants playing a crucial role in this growth. The adoption of Nitinol in orthopedic applications is primarily fueled by its ability to address stress shielding, a common issue with traditional metallic implants. Stress shielding occurs when the implant bears a disproportionate amount of load, leading to bone resorption and potential implant failure.

Nitinol's superelastic properties allow for the design of implants that more closely match the mechanical properties of bone, significantly reducing stress shielding effects. This has led to increased interest from both medical professionals and patients, driving market demand for Nitinol-based orthopedic solutions.

The market for Nitinol-based implants spans various orthopedic applications, including spinal devices, joint replacement implants, and fracture fixation systems. Among these, spinal devices represent the largest segment, with Nitinol being extensively used in interbody fusion cages and dynamic stabilization systems. The joint replacement segment is also showing promising growth, particularly in applications such as hip and knee implants.

Geographically, North America currently dominates the Nitinol-based orthopedic implants market, followed by Europe and Asia-Pacific. The United States, in particular, holds a significant market share due to its advanced healthcare infrastructure and high adoption rate of innovative medical technologies. However, emerging economies in Asia-Pacific and Latin America are expected to witness rapid growth in the coming years, driven by improving healthcare access and rising disposable incomes.

Key market players in the Nitinol-based orthopedic implants sector include established medical device companies as well as specialized Nitinol manufacturers. These companies are investing heavily in research and development to expand their product portfolios and improve the performance of Nitinol implants. Collaborations between material scientists, orthopedic surgeons, and implant manufacturers are becoming increasingly common, fostering innovation in this field.

Despite the promising outlook, the market faces certain challenges. The high cost of Nitinol and the complex manufacturing processes required for Nitinol-based implants can impact their widespread adoption, particularly in price-sensitive markets. Additionally, regulatory hurdles and the need for long-term clinical data on the performance of Nitinol implants pose challenges to market growth.

Current Challenges in Stress Shielding Mitigation

Stress shielding remains a significant challenge in orthopedic implants, particularly in load-bearing applications such as hip and knee replacements. This phenomenon occurs when the implant, typically made of materials much stiffer than bone, bears a disproportionate amount of the load, leading to bone resorption and potential implant loosening over time. The current challenges in mitigating stress shielding are multifaceted and require innovative solutions.

One of the primary obstacles is achieving an optimal balance between implant strength and stiffness. Traditional materials like titanium and cobalt-chromium alloys, while biocompatible and durable, have elastic moduli significantly higher than that of bone. This mismatch in mechanical properties is at the root of stress shielding. Researchers are exploring composite materials and novel alloy compositions to more closely match bone's mechanical properties, but progress has been limited by manufacturing constraints and long-term stability concerns.

Surface modification techniques, such as porous coatings and trabecular metal structures, have shown promise in promoting osseointegration and reducing stress shielding. However, these approaches often face challenges in terms of manufacturing scalability, consistency in pore size and distribution, and long-term wear characteristics. Additionally, the optimal porosity for bone ingrowth may compromise the implant's overall mechanical strength, creating a delicate trade-off that designers must navigate.

Another significant challenge lies in the dynamic nature of bone remodeling. Implants that may initially provide an appropriate mechanical environment can become problematic as the surrounding bone adapts over time. Developing implants that can adjust their mechanical properties in response to changing physiological conditions remains a formidable technical hurdle. Smart materials and adaptive designs are being investigated, but issues of biocompatibility, long-term stability, and regulatory approval present substantial barriers.

The variability in patient anatomy, bone quality, and activity levels further complicates the development of universally effective solutions to stress shielding. Personalized implants, tailored to individual patient characteristics, offer a potential avenue for improvement. However, the cost and time associated with custom manufacturing, as well as the need for advanced imaging and modeling techniques, currently limit widespread adoption of this approach.

Lastly, the long-term evaluation of new materials and designs poses a significant challenge. The true impact of stress shielding often manifests over years or decades, making it difficult to rapidly iterate and improve implant designs. This extended timeline for clinical validation can slow the adoption of innovative solutions, as surgeons and patients understandably prioritize proven long-term outcomes over newer, potentially superior technologies with limited clinical history.

One of the primary obstacles is achieving an optimal balance between implant strength and stiffness. Traditional materials like titanium and cobalt-chromium alloys, while biocompatible and durable, have elastic moduli significantly higher than that of bone. This mismatch in mechanical properties is at the root of stress shielding. Researchers are exploring composite materials and novel alloy compositions to more closely match bone's mechanical properties, but progress has been limited by manufacturing constraints and long-term stability concerns.

Surface modification techniques, such as porous coatings and trabecular metal structures, have shown promise in promoting osseointegration and reducing stress shielding. However, these approaches often face challenges in terms of manufacturing scalability, consistency in pore size and distribution, and long-term wear characteristics. Additionally, the optimal porosity for bone ingrowth may compromise the implant's overall mechanical strength, creating a delicate trade-off that designers must navigate.

Another significant challenge lies in the dynamic nature of bone remodeling. Implants that may initially provide an appropriate mechanical environment can become problematic as the surrounding bone adapts over time. Developing implants that can adjust their mechanical properties in response to changing physiological conditions remains a formidable technical hurdle. Smart materials and adaptive designs are being investigated, but issues of biocompatibility, long-term stability, and regulatory approval present substantial barriers.

The variability in patient anatomy, bone quality, and activity levels further complicates the development of universally effective solutions to stress shielding. Personalized implants, tailored to individual patient characteristics, offer a potential avenue for improvement. However, the cost and time associated with custom manufacturing, as well as the need for advanced imaging and modeling techniques, currently limit widespread adoption of this approach.

Lastly, the long-term evaluation of new materials and designs poses a significant challenge. The true impact of stress shielding often manifests over years or decades, making it difficult to rapidly iterate and improve implant designs. This extended timeline for clinical validation can slow the adoption of innovative solutions, as surgeons and patients understandably prioritize proven long-term outcomes over newer, potentially superior technologies with limited clinical history.

Existing Nitinol Solutions for Stress Shielding

01 Nitinol stress shielding in medical implants

Nitinol's superelastic properties are utilized in medical implants to reduce stress shielding effects. This shape memory alloy can be designed to match the elastic modulus of bone, minimizing the risk of bone resorption and implant loosening. The material's ability to deform and recover allows for better load distribution between the implant and surrounding tissue.- Nitinol stress shielding in medical implants: Nitinol's superelastic properties are utilized in medical implants to reduce stress shielding effects. This shape memory alloy can be designed to match the elastic modulus of surrounding tissues, promoting better integration and reducing the risk of implant loosening or failure. The material's ability to distribute stress more evenly helps maintain bone density and prevents bone resorption around the implant.

- Nitinol in orthopedic and spinal applications: Nitinol is used in orthopedic and spinal devices to address stress shielding concerns. Its unique properties allow for the creation of dynamic stabilization systems that can flex and bend with the body's natural movements while providing necessary support. This approach helps to distribute loads more physiologically, reducing the risk of adjacent segment degeneration in spinal applications and promoting better bone healing in fracture fixation devices.

- Surface modification of Nitinol for improved biocompatibility: Various surface modification techniques are applied to Nitinol implants to enhance their biocompatibility and reduce stress shielding effects. These methods include creating porous surfaces, applying bioactive coatings, or modifying the oxide layer. Such modifications can improve osseointegration, reduce inflammation, and create a more favorable interface between the implant and surrounding tissues, thereby minimizing stress concentration and shielding effects.

- Nitinol in cardiovascular applications: In cardiovascular devices, Nitinol's stress shielding properties are exploited to create stents and heart valve frames that adapt to the natural movement of blood vessels and heart tissue. The material's superelasticity allows for the design of devices that provide necessary support while minimizing the risk of vessel wall damage or restenosis. This approach helps maintain the natural compliance of blood vessels and reduces the likelihood of complications associated with rigid implants.

- Manufacturing and processing techniques for Nitinol: Advanced manufacturing and processing techniques are employed to optimize Nitinol's properties for specific stress shielding applications. These methods include precise heat treatments, laser cutting, and innovative forming processes that allow for the creation of complex geometries and tailored mechanical properties. By controlling the material's microstructure and phase transformation characteristics, engineers can fine-tune its behavior to achieve the desired balance between support and flexibility in various medical devices.

02 Nitinol in orthopedic and spinal devices

Nitinol is used in orthopedic and spinal devices to address stress shielding concerns. Its unique properties allow for the creation of dynamic stabilization systems and flexible implants that can better mimic natural bone mechanics. This approach helps maintain bone density and promotes healing while providing necessary support.Expand Specific Solutions03 Surface modification of Nitinol for improved biocompatibility

Various surface modification techniques are applied to Nitinol implants to enhance biocompatibility and reduce stress shielding. These methods include coatings, surface treatments, and texturing to improve osseointegration and reduce the risk of adverse tissue reactions while maintaining the material's beneficial mechanical properties.Expand Specific Solutions04 Nitinol in cardiovascular applications

Nitinol's stress shielding properties are leveraged in cardiovascular devices such as stents and heart valve frames. The material's superelasticity allows for the creation of self-expanding devices that can adapt to vessel or tissue movement, reducing the risk of restenosis and improving long-term outcomes.Expand Specific Solutions05 Manufacturing processes for Nitinol stress shielding devices

Specialized manufacturing processes are developed to optimize Nitinol's stress shielding properties in medical devices. These include precision shape setting, heat treatments, and innovative design approaches that allow for the creation of complex geometries and tailored mechanical responses to physiological loads.Expand Specific Solutions

Key Players in Nitinol Implant Industry

The competitive landscape for Nitinol's role in stress shielding for orthopedic implants is evolving rapidly. The industry is in a growth phase, with increasing market size driven by an aging population and rising demand for minimally invasive procedures. Technological maturity is advancing, with companies like Arthrex GmbH, Wright Medical Technology, and Boston Scientific Ltd. leading innovation. Academic institutions such as Jilin University, Mayo Foundation, and Texas A&M University are contributing significant research. The market is characterized by a mix of established medical device manufacturers and specialized Nitinol producers like ADMEDES GmbH and Fort Wayne Metals, indicating a competitive but collaborative environment for technological advancement.

Wright Medical Technology, Inc.

Technical Solution: Wright Medical Technology has developed a novel approach to address stress shielding in orthopedic implants using Nitinol. Their technology involves creating a porous Nitinol structure that mimics the mechanical properties of bone, reducing the mismatch between implant and bone stiffness[1]. This porous Nitinol scaffold allows for bone ingrowth, promoting osseointegration while maintaining the superelastic properties of Nitinol. The company has also implemented a surface treatment process to enhance biocompatibility and reduce the risk of nickel ion release[2]. Additionally, Wright Medical has explored the use of Nitinol in dynamic compression plates, where the material's shape memory effect is utilized to provide controlled, gradual compression at the fracture site, potentially improving healing outcomes[3].

Strengths: Excellent bone-mimicking mechanical properties, promotes osseointegration, reduces stress shielding. Weaknesses: Potential for nickel sensitivity in some patients, higher manufacturing costs compared to traditional materials.

ADMEDES GmbH

Technical Solution: ADMEDES GmbH has pioneered the use of Nitinol in minimally invasive orthopedic implants to address stress shielding. Their approach focuses on creating thin-walled, expandable Nitinol structures that can be inserted through small incisions and then deployed to their full size in situ[4]. This technique allows for a more even distribution of stress across the bone-implant interface, reducing the risk of stress shielding. ADMEDES has also developed a proprietary heat treatment process for Nitinol that optimizes its mechanical properties for specific orthopedic applications, such as spinal fusion devices and intramedullary nails[5]. Furthermore, the company has implemented advanced surface modification techniques to improve the biocompatibility and osseointegration of their Nitinol implants, including the application of hydroxyapatite coatings[6].

Strengths: Minimally invasive implantation, customizable mechanical properties, improved stress distribution. Weaknesses: Limited long-term clinical data, potential for mechanical fatigue in high-stress applications.

Innovative Nitinol Alloy Designs for Implants

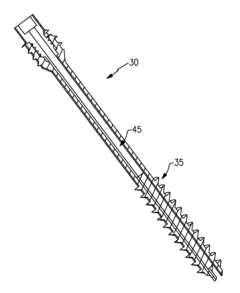

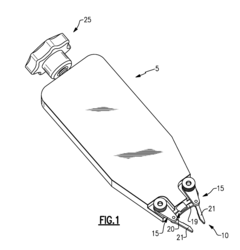

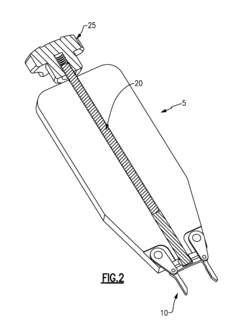

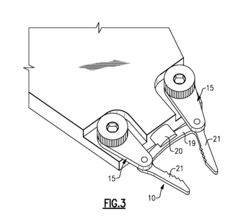

Devices for controlling the unloading of superelastic and shape memory orthopedic implants

PatentActiveUS20170100163A1

Innovation

- The development of devices with adjustable retaining mechanisms, such as internal pins and delivery devices, allows surgeons to control the deformation and recoverable strain of Nitinol staples, screws, plates, and intramedullary implants, enabling precise application and maintenance of compressive loads on bone fragments during healing.

Corrosion resistant titanium-based alloy having high strength and low elastic modulus

PatentWO2013100562A1

Innovation

- A titanium-based alloy composition with a weight ratio of niobium (34-44%), zirconium (2-10%), and silver (2-10%) is developed, which balances low elastic modulus, high strength, and excellent corrosion resistance, preventing stress shielding and enhancing biocompatibility.

Biomechanical Testing of Nitinol Implants

Biomechanical testing of Nitinol implants is a critical step in evaluating their performance and suitability for orthopedic applications, particularly in addressing stress shielding concerns. These tests aim to simulate the physiological loads and conditions that the implants will experience in vivo, providing valuable insights into their mechanical behavior and long-term durability.

One of the primary focuses of biomechanical testing for Nitinol implants is assessing their stress-strain characteristics under various loading conditions. This includes cyclic loading tests to evaluate fatigue resistance, as well as static loading tests to determine yield strength and ultimate tensile strength. The superelastic properties of Nitinol are of particular interest, as they allow the material to undergo large deformations and return to its original shape upon unloading.

Stress distribution analysis is another crucial aspect of biomechanical testing for Nitinol implants. Finite element analysis (FEA) is often employed to model the stress distribution within the implant and surrounding bone tissue. This helps researchers and engineers optimize the implant design to minimize stress shielding effects and promote more natural load transfer to the bone.

Corrosion resistance testing is also an essential component of the biomechanical evaluation process. Nitinol implants are exposed to simulated physiological fluids to assess their susceptibility to corrosion and ion release. This is particularly important given the potential for nickel ions to cause adverse reactions in some patients.

In vivo testing in animal models provides valuable data on the long-term performance of Nitinol implants. These studies typically involve implantation in large animals, such as sheep or pigs, followed by periodic assessments of bone-implant integration, stress shielding effects, and overall implant stability.

Mechanical compatibility testing between Nitinol implants and surrounding bone tissue is crucial for understanding the potential for stress shielding. This involves comparing the elastic modulus of Nitinol with that of bone and evaluating how the implant affects load distribution in the bone-implant system.

Surface characterization techniques, such as scanning electron microscopy (SEM) and atomic force microscopy (AFM), are used to analyze the surface properties of Nitinol implants before and after biomechanical testing. This helps in understanding how surface characteristics may influence stress shielding and osseointegration.

Finally, biomechanical testing of Nitinol implants often includes comparative studies with traditional implant materials, such as titanium alloys or stainless steel. These comparisons provide valuable insights into the potential advantages of Nitinol in mitigating stress shielding and improving overall implant performance in orthopedic applications.

One of the primary focuses of biomechanical testing for Nitinol implants is assessing their stress-strain characteristics under various loading conditions. This includes cyclic loading tests to evaluate fatigue resistance, as well as static loading tests to determine yield strength and ultimate tensile strength. The superelastic properties of Nitinol are of particular interest, as they allow the material to undergo large deformations and return to its original shape upon unloading.

Stress distribution analysis is another crucial aspect of biomechanical testing for Nitinol implants. Finite element analysis (FEA) is often employed to model the stress distribution within the implant and surrounding bone tissue. This helps researchers and engineers optimize the implant design to minimize stress shielding effects and promote more natural load transfer to the bone.

Corrosion resistance testing is also an essential component of the biomechanical evaluation process. Nitinol implants are exposed to simulated physiological fluids to assess their susceptibility to corrosion and ion release. This is particularly important given the potential for nickel ions to cause adverse reactions in some patients.

In vivo testing in animal models provides valuable data on the long-term performance of Nitinol implants. These studies typically involve implantation in large animals, such as sheep or pigs, followed by periodic assessments of bone-implant integration, stress shielding effects, and overall implant stability.

Mechanical compatibility testing between Nitinol implants and surrounding bone tissue is crucial for understanding the potential for stress shielding. This involves comparing the elastic modulus of Nitinol with that of bone and evaluating how the implant affects load distribution in the bone-implant system.

Surface characterization techniques, such as scanning electron microscopy (SEM) and atomic force microscopy (AFM), are used to analyze the surface properties of Nitinol implants before and after biomechanical testing. This helps in understanding how surface characteristics may influence stress shielding and osseointegration.

Finally, biomechanical testing of Nitinol implants often includes comparative studies with traditional implant materials, such as titanium alloys or stainless steel. These comparisons provide valuable insights into the potential advantages of Nitinol in mitigating stress shielding and improving overall implant performance in orthopedic applications.

Regulatory Pathway for Nitinol Orthopedic Devices

The regulatory pathway for Nitinol orthopedic devices is a complex process that requires careful navigation through various regulatory bodies, primarily the U.S. Food and Drug Administration (FDA). This pathway is crucial for ensuring the safety and efficacy of Nitinol-based implants, particularly in addressing stress shielding concerns in orthopedic applications.

The FDA classifies most Nitinol orthopedic devices as Class II medical devices, which typically require a 510(k) premarket notification submission. This process involves demonstrating that the new device is substantially equivalent to a legally marketed predicate device. For Nitinol implants, this often includes comparing the mechanical properties, biocompatibility, and stress shielding characteristics to existing approved devices.

Key considerations in the regulatory pathway include material characterization, mechanical testing, and biocompatibility assessment. Manufacturers must provide comprehensive data on the Nitinol alloy composition, its phase transformation temperatures, and its superelastic properties. This information is critical for evaluating the device's performance under physiological conditions and its potential to mitigate stress shielding effects.

Fatigue testing is another crucial aspect of the regulatory process for Nitinol orthopedic implants. Given the cyclic loading these devices experience in vivo, manufacturers must demonstrate the long-term durability and resistance to fatigue failure. This often involves simulated use testing that replicates the expected in vivo loading conditions over millions of cycles.

Biocompatibility testing, following ISO 10993 guidelines, is essential to assess the potential biological risks associated with Nitinol implants. This includes evaluating cytotoxicity, sensitization, irritation, and systemic toxicity. Additionally, given the unique properties of Nitinol, special attention is paid to nickel ion release and its potential long-term effects on surrounding tissues.

Clinical data requirements for Nitinol orthopedic devices can vary depending on the specific application and the degree of novelty. In some cases, well-established predicate devices may allow for limited clinical data. However, for novel applications or designs aimed at significantly reducing stress shielding, more extensive clinical studies may be necessary to demonstrate safety and efficacy.

Post-market surveillance is a critical component of the regulatory pathway for Nitinol orthopedic implants. Manufacturers are required to implement robust systems for monitoring device performance and reporting adverse events. This ongoing process helps identify any long-term issues related to stress shielding or other complications that may not have been apparent during premarket evaluation.

International regulatory considerations are also important for global market access. While the FDA pathway is often considered a gold standard, manufacturers must also navigate regulatory requirements in other major markets, such as the European Union's Medical Device Regulation (MDR) and Japan's Pharmaceuticals and Medical Devices Agency (PMDA) guidelines.

The FDA classifies most Nitinol orthopedic devices as Class II medical devices, which typically require a 510(k) premarket notification submission. This process involves demonstrating that the new device is substantially equivalent to a legally marketed predicate device. For Nitinol implants, this often includes comparing the mechanical properties, biocompatibility, and stress shielding characteristics to existing approved devices.

Key considerations in the regulatory pathway include material characterization, mechanical testing, and biocompatibility assessment. Manufacturers must provide comprehensive data on the Nitinol alloy composition, its phase transformation temperatures, and its superelastic properties. This information is critical for evaluating the device's performance under physiological conditions and its potential to mitigate stress shielding effects.

Fatigue testing is another crucial aspect of the regulatory process for Nitinol orthopedic implants. Given the cyclic loading these devices experience in vivo, manufacturers must demonstrate the long-term durability and resistance to fatigue failure. This often involves simulated use testing that replicates the expected in vivo loading conditions over millions of cycles.

Biocompatibility testing, following ISO 10993 guidelines, is essential to assess the potential biological risks associated with Nitinol implants. This includes evaluating cytotoxicity, sensitization, irritation, and systemic toxicity. Additionally, given the unique properties of Nitinol, special attention is paid to nickel ion release and its potential long-term effects on surrounding tissues.

Clinical data requirements for Nitinol orthopedic devices can vary depending on the specific application and the degree of novelty. In some cases, well-established predicate devices may allow for limited clinical data. However, for novel applications or designs aimed at significantly reducing stress shielding, more extensive clinical studies may be necessary to demonstrate safety and efficacy.

Post-market surveillance is a critical component of the regulatory pathway for Nitinol orthopedic implants. Manufacturers are required to implement robust systems for monitoring device performance and reporting adverse events. This ongoing process helps identify any long-term issues related to stress shielding or other complications that may not have been apparent during premarket evaluation.

International regulatory considerations are also important for global market access. While the FDA pathway is often considered a gold standard, manufacturers must also navigate regulatory requirements in other major markets, such as the European Union's Medical Device Regulation (MDR) and Japan's Pharmaceuticals and Medical Devices Agency (PMDA) guidelines.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!