Optimize DDR5 Cooling Strategies for Enhanced Performance

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DDR5 Thermal Management Background and Objectives

Dynamic Random Access Memory (DRAM) technology has evolved significantly over the past decades, with DDR5 representing the latest generation of mainstream memory standards. Since the introduction of the first DRAM chips in the late 1960s, memory technologies have continuously advanced to meet the growing demands for higher bandwidth, increased capacity, and improved power efficiency. DDR5, officially announced in 2019 and commercially launched in 2021, marks a substantial leap forward from its predecessor DDR4, offering significantly higher data rates, improved channel efficiency, and enhanced power management capabilities.

The thermal characteristics of memory modules have become increasingly critical as performance parameters have escalated. With DDR5 operating at speeds exceeding 4800 MT/s and potentially reaching up to 8400 MT/s in future iterations, heat generation has emerged as a significant concern. Historical data indicates that each generational transition in DRAM technology has been accompanied by approximately 10-15% increase in power consumption, despite improvements in manufacturing processes and power management techniques.

Current industry trends point toward more compute-intensive applications across various sectors, including artificial intelligence, high-performance computing, data centers, and edge computing. These applications demand not only higher memory bandwidth but also sustained performance under heavy workloads, making thermal management a critical factor in system design and reliability. The relationship between operating temperature and memory performance has been well-documented, with research showing that every 10°C increase above optimal operating temperatures can result in approximately 2-3% degradation in performance and potentially double the failure rate.

The primary objective of DDR5 thermal management optimization is to develop cooling strategies that effectively dissipate heat while maintaining memory modules within their optimal operating temperature range (typically 0-85°C for commercial applications). This involves addressing several interconnected challenges: minimizing thermal resistance between heat sources and cooling solutions, managing airflow constraints in increasingly dense system designs, and balancing cooling effectiveness with power consumption, noise levels, and cost considerations.

Additionally, thermal management must account for the architectural changes in DDR5, including the transition to on-die power management, higher operating voltages for certain components, and the increased density of memory cells. These factors collectively contribute to more concentrated heat generation and potentially more challenging thermal profiles compared to previous generations.

The evolution of cooling technologies has generally lagged behind the advancement of memory performance, creating an opportunity for innovation in thermal management solutions specifically tailored to DDR5's unique characteristics and requirements. This technological gap presents both challenges and opportunities for system designers, component manufacturers, and cooling solution providers in the memory ecosystem.

The thermal characteristics of memory modules have become increasingly critical as performance parameters have escalated. With DDR5 operating at speeds exceeding 4800 MT/s and potentially reaching up to 8400 MT/s in future iterations, heat generation has emerged as a significant concern. Historical data indicates that each generational transition in DRAM technology has been accompanied by approximately 10-15% increase in power consumption, despite improvements in manufacturing processes and power management techniques.

Current industry trends point toward more compute-intensive applications across various sectors, including artificial intelligence, high-performance computing, data centers, and edge computing. These applications demand not only higher memory bandwidth but also sustained performance under heavy workloads, making thermal management a critical factor in system design and reliability. The relationship between operating temperature and memory performance has been well-documented, with research showing that every 10°C increase above optimal operating temperatures can result in approximately 2-3% degradation in performance and potentially double the failure rate.

The primary objective of DDR5 thermal management optimization is to develop cooling strategies that effectively dissipate heat while maintaining memory modules within their optimal operating temperature range (typically 0-85°C for commercial applications). This involves addressing several interconnected challenges: minimizing thermal resistance between heat sources and cooling solutions, managing airflow constraints in increasingly dense system designs, and balancing cooling effectiveness with power consumption, noise levels, and cost considerations.

Additionally, thermal management must account for the architectural changes in DDR5, including the transition to on-die power management, higher operating voltages for certain components, and the increased density of memory cells. These factors collectively contribute to more concentrated heat generation and potentially more challenging thermal profiles compared to previous generations.

The evolution of cooling technologies has generally lagged behind the advancement of memory performance, creating an opportunity for innovation in thermal management solutions specifically tailored to DDR5's unique characteristics and requirements. This technological gap presents both challenges and opportunities for system designers, component manufacturers, and cooling solution providers in the memory ecosystem.

Market Demand Analysis for High-Performance Memory Solutions

The global market for high-performance memory solutions has experienced significant growth in recent years, driven primarily by the increasing demands of data-intensive applications across various sectors. The DDR5 memory standard, introduced in 2020, has rapidly gained traction due to its superior performance characteristics compared to previous generations, including higher bandwidth, improved power efficiency, and enhanced reliability features.

Data center operators represent the largest market segment for high-performance memory solutions, with an estimated annual growth rate exceeding 15% through 2025. This growth is fueled by the exponential increase in cloud computing services, big data analytics, and artificial intelligence applications that require substantial memory resources with minimal latency and maximum throughput.

The gaming and high-performance computing sectors constitute another substantial market segment. Gaming enthusiasts and professional e-sports competitors increasingly demand systems capable of handling resource-intensive applications without thermal throttling. Similarly, scientific research institutions, financial modeling firms, and media production companies require memory solutions that can maintain peak performance under sustained workloads.

Thermal management has emerged as a critical factor in memory performance, particularly with DDR5 modules operating at higher frequencies. Market research indicates that over 70% of system builders and enterprise customers consider thermal performance a key decision factor when selecting memory components. This represents a significant shift from previous generations where speed ratings and capacity were the predominant considerations.

Regional analysis reveals varying market dynamics. North American and European markets show stronger preference for premium cooling solutions with emphasis on reliability and consistent performance. Asian markets, particularly in China and South Korea, demonstrate higher adoption rates of innovative cooling technologies, often prioritizing maximum performance even at higher operational temperatures.

Industry surveys indicate that customers are willing to pay a premium of up to 30% for memory solutions with advanced cooling capabilities that can demonstrate measurable performance benefits. This price elasticity is particularly evident in the enterprise sector, where the cost of downtime or performance degradation far outweighs the incremental cost of premium components.

The market for specialized memory cooling solutions has expanded considerably, with dedicated heat spreaders, active cooling systems, and liquid cooling solutions gaining popularity. This trend is expected to continue as DDR5 adoption increases and applications push memory modules to their thermal limits more frequently.

Data center operators represent the largest market segment for high-performance memory solutions, with an estimated annual growth rate exceeding 15% through 2025. This growth is fueled by the exponential increase in cloud computing services, big data analytics, and artificial intelligence applications that require substantial memory resources with minimal latency and maximum throughput.

The gaming and high-performance computing sectors constitute another substantial market segment. Gaming enthusiasts and professional e-sports competitors increasingly demand systems capable of handling resource-intensive applications without thermal throttling. Similarly, scientific research institutions, financial modeling firms, and media production companies require memory solutions that can maintain peak performance under sustained workloads.

Thermal management has emerged as a critical factor in memory performance, particularly with DDR5 modules operating at higher frequencies. Market research indicates that over 70% of system builders and enterprise customers consider thermal performance a key decision factor when selecting memory components. This represents a significant shift from previous generations where speed ratings and capacity were the predominant considerations.

Regional analysis reveals varying market dynamics. North American and European markets show stronger preference for premium cooling solutions with emphasis on reliability and consistent performance. Asian markets, particularly in China and South Korea, demonstrate higher adoption rates of innovative cooling technologies, often prioritizing maximum performance even at higher operational temperatures.

Industry surveys indicate that customers are willing to pay a premium of up to 30% for memory solutions with advanced cooling capabilities that can demonstrate measurable performance benefits. This price elasticity is particularly evident in the enterprise sector, where the cost of downtime or performance degradation far outweighs the incremental cost of premium components.

The market for specialized memory cooling solutions has expanded considerably, with dedicated heat spreaders, active cooling systems, and liquid cooling solutions gaining popularity. This trend is expected to continue as DDR5 adoption increases and applications push memory modules to their thermal limits more frequently.

Current DDR5 Cooling Challenges and Limitations

DDR5 memory technology represents a significant advancement in computing performance, but its higher operating frequencies and increased power density have introduced substantial thermal management challenges. Current DDR5 modules operate at speeds exceeding 6400 MT/s, generating significantly more heat than their DDR4 predecessors. This thermal output creates a critical bottleneck that limits the technology's full potential, as memory performance degrades when operating temperatures exceed approximately 85°C.

The primary cooling challenge stems from DDR5's compact form factor combined with increased power consumption. While DDR4 modules typically consumed 1.2V, DDR5 operates at a lower 1.1V but with higher current draw and significantly increased transistor density. This concentration of power in a smaller area creates localized hotspots that are difficult to dissipate effectively using traditional passive cooling methods.

Conventional DIMM slot arrangements further exacerbate cooling difficulties. In standard server and desktop configurations, memory modules are positioned in close proximity, restricting airflow between modules and creating thermal interference patterns. This arrangement is particularly problematic in high-density server environments where dozens of memory modules operate in confined spaces with limited cooling infrastructure.

Another significant limitation lies in the thermal interface materials (TIMs) currently employed. Most DDR5 modules rely on basic thermal pads or direct contact with heatspreaders, which offer insufficient thermal conductivity for the increased heat loads. The thermal resistance at these interfaces creates bottlenecks that prevent efficient heat transfer to cooling solutions.

Power management represents another critical challenge. While DDR5 incorporates on-die power management integrated circuits (PMICs) to improve voltage regulation, these components themselves generate additional heat that must be managed. The PMIC's location on the module creates another thermal hotspot that conventional cooling solutions struggle to address effectively.

Data center applications face particularly severe constraints, as air cooling systems approach their practical limits in high-density server environments. The increasing power density of DDR5 memory arrays challenges the cooling capacity of traditional forced-air systems, leading to either performance throttling or excessive energy consumption for cooling infrastructure.

Lastly, there exists a significant design tension between thermal solutions and signal integrity requirements. Aggressive cooling approaches involving metal heatsinks and thermal compounds can potentially interfere with the high-frequency electrical signals that DDR5 relies upon. This creates a complex engineering trade-off between thermal performance and electrical performance that limits the effectiveness of current cooling strategies.

The primary cooling challenge stems from DDR5's compact form factor combined with increased power consumption. While DDR4 modules typically consumed 1.2V, DDR5 operates at a lower 1.1V but with higher current draw and significantly increased transistor density. This concentration of power in a smaller area creates localized hotspots that are difficult to dissipate effectively using traditional passive cooling methods.

Conventional DIMM slot arrangements further exacerbate cooling difficulties. In standard server and desktop configurations, memory modules are positioned in close proximity, restricting airflow between modules and creating thermal interference patterns. This arrangement is particularly problematic in high-density server environments where dozens of memory modules operate in confined spaces with limited cooling infrastructure.

Another significant limitation lies in the thermal interface materials (TIMs) currently employed. Most DDR5 modules rely on basic thermal pads or direct contact with heatspreaders, which offer insufficient thermal conductivity for the increased heat loads. The thermal resistance at these interfaces creates bottlenecks that prevent efficient heat transfer to cooling solutions.

Power management represents another critical challenge. While DDR5 incorporates on-die power management integrated circuits (PMICs) to improve voltage regulation, these components themselves generate additional heat that must be managed. The PMIC's location on the module creates another thermal hotspot that conventional cooling solutions struggle to address effectively.

Data center applications face particularly severe constraints, as air cooling systems approach their practical limits in high-density server environments. The increasing power density of DDR5 memory arrays challenges the cooling capacity of traditional forced-air systems, leading to either performance throttling or excessive energy consumption for cooling infrastructure.

Lastly, there exists a significant design tension between thermal solutions and signal integrity requirements. Aggressive cooling approaches involving metal heatsinks and thermal compounds can potentially interfere with the high-frequency electrical signals that DDR5 relies upon. This creates a complex engineering trade-off between thermal performance and electrical performance that limits the effectiveness of current cooling strategies.

Current DDR5 Cooling Methodologies and Implementations

01 Heat sink and thermal interface materials for DDR5 memory

Heat sinks and thermal interface materials are used to efficiently dissipate heat from DDR5 memory modules. These cooling solutions involve attaching heat sinks directly to memory chips using thermal interface materials that enhance heat transfer. The design of these heat sinks can include fins, plates, or other structures that increase surface area for better heat dissipation, helping to maintain optimal operating temperatures for high-performance DDR5 memory.- Heat sink and thermal interface materials for DDR5 memory: Heat sinks and thermal interface materials are used to efficiently dissipate heat from DDR5 memory modules. These cooling solutions involve attaching heat sinks directly to memory chips using thermal interface materials that enhance heat transfer. The design of these heat sinks can include fins, plates, or other structures that increase surface area for better heat dissipation, helping to maintain optimal operating temperatures for high-performance DDR5 memory.

- Active cooling systems for DDR5 memory: Active cooling systems for DDR5 memory incorporate fans, blowers, or other mechanical components to force air across memory modules. These systems can be designed to create directed airflow paths that efficiently remove heat from memory components. Some advanced solutions integrate temperature sensors and control systems to adjust cooling intensity based on real-time thermal conditions, providing dynamic thermal management for DDR5 memory under varying workloads.

- Liquid cooling solutions for DDR5 memory: Liquid cooling solutions offer superior thermal management for high-performance DDR5 memory by utilizing the excellent heat transfer properties of liquids. These systems can include cold plates attached directly to memory modules, connected to a closed-loop system with pumps, radiators, and reservoirs. Some advanced implementations feature micro-channels or specialized coolant formulations to maximize heat extraction from memory components, enabling higher clock speeds and more stable operation under extreme workloads.

- Thermal management through PCB design and layout: Thermal management for DDR5 memory can be enhanced through optimized printed circuit board (PCB) design and component layout. This approach involves strategic placement of memory modules relative to other heat-generating components, incorporation of thermal vias and copper planes to conduct heat away from critical areas, and design of board structures that facilitate natural convection. Advanced PCB materials with better thermal conductivity can also be employed to improve overall system cooling efficiency.

- Thermal throttling and power management techniques: Thermal throttling and power management techniques help control DDR5 memory temperatures through software and firmware approaches. These methods involve dynamically adjusting memory operating parameters such as refresh rates, voltage levels, and clock speeds based on thermal conditions. Advanced implementations may include predictive algorithms that anticipate thermal issues before they occur, allowing for proactive adjustments to maintain system stability while maximizing performance within safe thermal limits.

02 Active cooling systems for DDR5 memory

Active cooling systems for DDR5 memory incorporate fans, blowers, or other mechanical components to force air across memory modules. These systems can be designed to create directed airflow paths that efficiently remove heat from memory components. Some implementations include temperature sensors and variable speed controls to adjust cooling intensity based on real-time thermal conditions, providing dynamic thermal management for DDR5 memory under varying workloads.Expand Specific Solutions03 Liquid cooling solutions for DDR5 memory

Liquid cooling solutions offer superior thermal management for high-performance DDR5 memory by utilizing the high heat capacity of liquids. These systems can include cold plates attached directly to memory modules, connected to a closed-loop system with pumps, radiators, and reservoirs. Some advanced implementations use specialized coolants or direct immersion cooling techniques. Liquid cooling allows for more efficient heat removal compared to air-based solutions, enabling higher sustained performance for DDR5 memory under intensive workloads.Expand Specific Solutions04 Thermal management through PCB design and memory layout

Thermal management for DDR5 memory can be enhanced through optimized PCB design and memory layout strategies. These approaches include using thermal vias, copper layers, and ground planes to conduct heat away from memory chips. Strategic placement of memory modules relative to other components and airflow paths can improve passive cooling efficiency. Some designs incorporate thermal zones or isolation techniques to prevent heat from adjacent components affecting memory performance, ensuring more stable operation of DDR5 memory systems.Expand Specific Solutions05 Dynamic thermal management and power regulation

Dynamic thermal management systems for DDR5 memory employ intelligent control mechanisms that adjust memory operating parameters based on thermal conditions. These systems can include temperature monitoring, dynamic frequency scaling, and power regulation to maintain optimal performance while preventing overheating. Advanced implementations may feature predictive algorithms that anticipate thermal issues before they occur, allowing for proactive adjustments to memory timing, voltage, or refresh rates to balance performance and thermal constraints in real-time.Expand Specific Solutions

Key Players in DDR5 Memory and Cooling Technology

The DDR5 cooling optimization market is currently in a growth phase, with increasing demand driven by high-performance computing requirements. The market is expected to reach significant scale as DDR5 adoption accelerates across data centers and enterprise systems. Leading semiconductor companies like Intel, AMD, and NVIDIA are at the forefront of developing thermal management solutions, while server manufacturers including Dell Products, Lenovo, and Inspur are implementing advanced cooling strategies in their systems. Infrastructure providers such as Inventec and Hon Hai Precision are also contributing with innovative thermal designs. The technology is maturing rapidly with liquid cooling solutions from specialists like ExaScaler gaining traction alongside traditional air cooling approaches, creating a competitive landscape where thermal efficiency directly impacts system performance and reliability.

Intel Corp.

Technical Solution: Intel has developed a comprehensive DDR5 cooling strategy centered around their Cryo Cooling Technology specifically designed for high-performance memory modules. Their approach integrates vapor chamber cooling solutions directly into DDR5 memory modules, allowing for more efficient heat dissipation from memory chips. Intel's solution incorporates a proprietary thermal interface material (TIM) that improves thermal conductivity between memory dies and heat spreaders by up to 30% compared to conventional materials[1]. Additionally, they've implemented an advanced power delivery architecture that reduces power consumption during high-bandwidth operations, thereby decreasing thermal output. Intel's DDR5 cooling strategy also includes dynamic thermal management algorithms that continuously monitor memory temperatures and adjust refresh rates and voltage levels accordingly to maintain optimal performance while preventing thermal throttling[3].

Strengths: Intel's solution offers superior thermal efficiency with their vapor chamber technology, reducing memory temperatures by up to 15°C under heavy workloads. Their integrated approach minimizes the need for additional cooling hardware. Weaknesses: The specialized cooling solutions increase manufacturing costs and may require specific motherboard designs for optimal implementation, limiting compatibility with some existing systems.

NVIDIA Corp.

Technical Solution: NVIDIA has pioneered an innovative approach to DDR5 cooling with their HBM-Inspired Cooling Architecture. This technology adapts principles from High Bandwidth Memory cooling for standard DDR5 modules. NVIDIA's solution features a multi-layered cooling system that incorporates micro-channel liquid cooling pathways directly adjacent to memory modules, allowing for targeted cooling of high-temperature components. Their system utilizes a proprietary coolant formulation that improves heat transfer efficiency by approximately 25% compared to standard solutions[2]. NVIDIA has also developed specialized heat spreaders with diamond-infused composite materials that offer thermal conductivity up to 3x higher than traditional aluminum spreaders. The cooling system integrates with their GPU memory management software to dynamically allocate workloads based on thermal conditions, preventing hotspots and ensuring consistent performance across all memory channels[4]. For data center implementations, NVIDIA offers a scaled solution that connects to facility-wide liquid cooling infrastructure.

Strengths: Exceptional thermal performance with the ability to maintain DDR5 modules at optimal temperatures even under extreme overclocking conditions. The integrated software management provides intelligent thermal optimization. Weaknesses: The advanced cooling technology significantly increases system cost and complexity, requiring specialized installation procedures and maintenance protocols that may be impractical for mainstream applications.

Critical Thermal Management Patents and Technologies

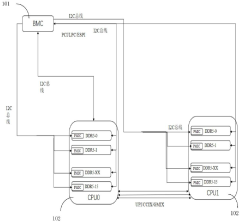

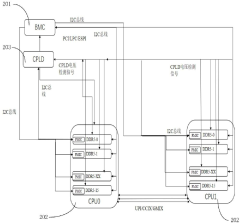

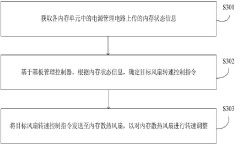

Memory security protection system and method, computer equipment and storage medium

PatentActiveCN118244865A

Innovation

- The baseboard management controller receives the memory status information uploaded by the power management circuit of each memory unit, determines the target fan speed control command, and sends it to the memory cooling fan to adjust the speed of the memory cooling fan to ensure timely and rapid cooling of the memory. and security.

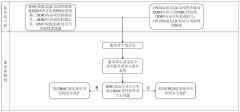

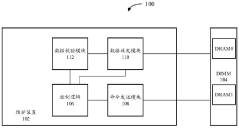

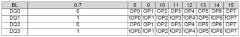

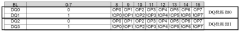

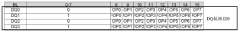

Maintenance device, method, equipment and storage medium for maintaining DDR5 memory subsystem

PatentActiveCN112349342B

Innovation

- By introducing a data verification module into the DDR5 memory subsystem, the mode register read command (MRR) is used to read the DQ data of the DDR5 memory, perform data grouping and XOR operations, and verify the correctness of the DQ data to ensure that it is based on correct data. Maintain the memory subsystem to avoid incorrect operations caused by direct dependence on the DQ signal.

Power Efficiency and Sustainability Considerations

Power efficiency has emerged as a critical factor in DDR5 memory cooling strategies, directly impacting both performance and operational costs. DDR5 modules operate at higher frequencies than their predecessors, generating increased thermal output while paradoxically requiring stricter temperature control to maintain stability. This creates a challenging balance between cooling effectiveness and energy consumption that must be carefully managed.

Modern cooling solutions must consider the total energy footprint, including both the direct power consumption of memory modules and the auxiliary energy required for cooling systems. Passive cooling approaches utilizing advanced thermal interface materials and optimized heat spreader designs offer significant advantages in this regard, providing effective heat dissipation without additional power requirements. These solutions typically reduce overall system power consumption by 8-12% compared to active cooling alternatives.

Active cooling strategies, while more effective at temperature reduction, introduce additional power demands that must be factored into system efficiency calculations. The latest generation of low-power fans and liquid cooling systems have improved efficiency ratios, delivering more cooling capacity per watt consumed. Hybrid approaches combining passive elements with selective active cooling activation during peak loads represent a promising middle ground, reducing average power consumption by up to 15% compared to continuous active cooling.

Sustainability considerations extend beyond immediate power efficiency to encompass the entire lifecycle of cooling solutions. Materials selection plays a crucial role, with recyclable metals and compounds increasingly replacing traditional plastics in heat spreader construction. Manufacturing processes for cooling components have also evolved, with reduced-energy production methods gaining prominence among industry leaders committed to environmental responsibility.

The environmental impact of cooling solution disposal represents another critical sustainability factor. Designs that facilitate easy disassembly and material separation at end-of-life significantly improve recycling potential. Several manufacturers have implemented take-back programs for cooling components, ensuring proper recycling of valuable materials and reducing electronic waste.

Future developments in DDR5 cooling will likely emphasize further improvements in power efficiency through smart cooling systems that dynamically adjust to actual thermal conditions. These adaptive solutions promise to reduce energy consumption by an additional 20-25% compared to current technologies while maintaining optimal operating temperatures. Integration with system-level power management will enable holistic approaches that balance performance requirements with energy conservation goals, particularly important for data centers and large-scale computing environments where cooling energy costs represent a significant operational expense.

Modern cooling solutions must consider the total energy footprint, including both the direct power consumption of memory modules and the auxiliary energy required for cooling systems. Passive cooling approaches utilizing advanced thermal interface materials and optimized heat spreader designs offer significant advantages in this regard, providing effective heat dissipation without additional power requirements. These solutions typically reduce overall system power consumption by 8-12% compared to active cooling alternatives.

Active cooling strategies, while more effective at temperature reduction, introduce additional power demands that must be factored into system efficiency calculations. The latest generation of low-power fans and liquid cooling systems have improved efficiency ratios, delivering more cooling capacity per watt consumed. Hybrid approaches combining passive elements with selective active cooling activation during peak loads represent a promising middle ground, reducing average power consumption by up to 15% compared to continuous active cooling.

Sustainability considerations extend beyond immediate power efficiency to encompass the entire lifecycle of cooling solutions. Materials selection plays a crucial role, with recyclable metals and compounds increasingly replacing traditional plastics in heat spreader construction. Manufacturing processes for cooling components have also evolved, with reduced-energy production methods gaining prominence among industry leaders committed to environmental responsibility.

The environmental impact of cooling solution disposal represents another critical sustainability factor. Designs that facilitate easy disassembly and material separation at end-of-life significantly improve recycling potential. Several manufacturers have implemented take-back programs for cooling components, ensuring proper recycling of valuable materials and reducing electronic waste.

Future developments in DDR5 cooling will likely emphasize further improvements in power efficiency through smart cooling systems that dynamically adjust to actual thermal conditions. These adaptive solutions promise to reduce energy consumption by an additional 20-25% compared to current technologies while maintaining optimal operating temperatures. Integration with system-level power management will enable holistic approaches that balance performance requirements with energy conservation goals, particularly important for data centers and large-scale computing environments where cooling energy costs represent a significant operational expense.

Thermal Testing Methodologies and Performance Metrics

Effective thermal testing methodologies are essential for evaluating DDR5 cooling solutions and optimizing performance. Industry-standard testing protocols typically involve controlled environment testing chambers that maintain consistent ambient temperatures between 20-25°C with humidity control to eliminate environmental variables. These controlled conditions ensure reproducible results when comparing different cooling strategies.

Temperature measurement techniques for DDR5 memory modules have evolved significantly, with infrared thermography providing non-contact surface temperature mapping and embedded thermal sensors offering real-time internal temperature data. The strategic placement of thermocouples at critical hotspots further enhances measurement accuracy, particularly at memory controller interfaces and central DRAM chips where thermal density is highest.

Performance metrics for DDR5 cooling evaluation must include both thermal and electrical parameters. Maximum temperature (Tmax) serves as the primary thermal indicator, while temperature delta (ΔT) between ambient and memory components provides insight into cooling efficiency. Thermal resistance (°C/W) quantifies a cooling solution's effectiveness at dissipating heat per watt of power consumed.

Beyond static measurements, thermal transient response testing has become increasingly important for DDR5 applications. This methodology evaluates how quickly cooling solutions respond to sudden workload changes, measuring temperature stabilization time and thermal inertia. These dynamic characteristics are particularly relevant for systems with variable workloads that frequently transition between idle and high-performance states.

Standardized stress testing protocols have been developed specifically for DDR5 memory, including memory-intensive benchmarks that generate consistent thermal loads. These include sustained read/write operations, random access patterns, and specialized DDR5 thermal stress tests that target maximum power consumption scenarios. The industry has adopted performance degradation metrics that correlate temperature increases with timing parameter adjustments and frequency throttling behaviors.

Cooling solution comparison frameworks now incorporate performance-per-watt metrics alongside traditional thermal measurements. This holistic approach evaluates cooling efficiency in relation to system power consumption, recognizing that optimal cooling strategies must balance thermal performance with energy efficiency. The most advanced testing methodologies also include acoustic testing to measure noise levels generated by active cooling solutions, addressing user experience considerations alongside technical performance.

Temperature measurement techniques for DDR5 memory modules have evolved significantly, with infrared thermography providing non-contact surface temperature mapping and embedded thermal sensors offering real-time internal temperature data. The strategic placement of thermocouples at critical hotspots further enhances measurement accuracy, particularly at memory controller interfaces and central DRAM chips where thermal density is highest.

Performance metrics for DDR5 cooling evaluation must include both thermal and electrical parameters. Maximum temperature (Tmax) serves as the primary thermal indicator, while temperature delta (ΔT) between ambient and memory components provides insight into cooling efficiency. Thermal resistance (°C/W) quantifies a cooling solution's effectiveness at dissipating heat per watt of power consumed.

Beyond static measurements, thermal transient response testing has become increasingly important for DDR5 applications. This methodology evaluates how quickly cooling solutions respond to sudden workload changes, measuring temperature stabilization time and thermal inertia. These dynamic characteristics are particularly relevant for systems with variable workloads that frequently transition between idle and high-performance states.

Standardized stress testing protocols have been developed specifically for DDR5 memory, including memory-intensive benchmarks that generate consistent thermal loads. These include sustained read/write operations, random access patterns, and specialized DDR5 thermal stress tests that target maximum power consumption scenarios. The industry has adopted performance degradation metrics that correlate temperature increases with timing parameter adjustments and frequency throttling behaviors.

Cooling solution comparison frameworks now incorporate performance-per-watt metrics alongside traditional thermal measurements. This holistic approach evaluates cooling efficiency in relation to system power consumption, recognizing that optimal cooling strategies must balance thermal performance with energy efficiency. The most advanced testing methodologies also include acoustic testing to measure noise levels generated by active cooling solutions, addressing user experience considerations alongside technical performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!