PETG Composite Films: Innovations in Barrier Properties

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PETG Film Evolution

PETG (Polyethylene Terephthalate Glycol-modified) films have undergone significant evolution since their introduction in the 1970s. Initially developed as an improvement over PET, PETG offered enhanced clarity, toughness, and processability. The early stages of PETG film development focused primarily on its use in packaging applications, where its superior impact resistance and ease of thermoforming provided distinct advantages.

Throughout the 1980s and 1990s, researchers and manufacturers concentrated on refining the production processes for PETG films, leading to improvements in film uniformity and surface quality. This period also saw the expansion of PETG film applications beyond packaging, into areas such as medical devices and consumer electronics.

The turn of the millennium marked a significant shift in PETG film evolution, with increased emphasis on enhancing barrier properties. This focus was driven by growing demand for packaging materials with improved shelf life and protection against moisture, oxygen, and other environmental factors. Researchers began exploring various techniques to improve the inherent barrier properties of PETG, including the incorporation of nanoparticles and the development of multi-layer structures.

In the past decade, the evolution of PETG films has been characterized by a strong push towards sustainability and enhanced functionality. Manufacturers have invested in developing bio-based alternatives and improving the recyclability of PETG films. Simultaneously, advancements in nanotechnology have opened new avenues for creating PETG composite films with superior barrier properties.

Recent innovations have focused on the integration of active and intelligent features into PETG films. These include the incorporation of antimicrobial agents, oxygen scavengers, and even smart sensors for monitoring product freshness. Such developments have significantly expanded the potential applications of PETG films in high-value sectors like pharmaceuticals and electronics.

The latest frontier in PETG film evolution involves the development of ultra-thin, high-performance barrier films. These films aim to combine exceptional barrier properties with reduced material usage, addressing both performance and sustainability concerns. Researchers are exploring advanced coating technologies and novel composite structures to achieve this goal.

As we look to the future, the evolution of PETG films is likely to continue along the paths of enhanced sustainability, improved barrier properties, and increased functionality. The integration of nanotechnology, smart materials, and eco-friendly additives will play a crucial role in shaping the next generation of PETG composite films, promising exciting innovations in barrier properties and beyond.

Throughout the 1980s and 1990s, researchers and manufacturers concentrated on refining the production processes for PETG films, leading to improvements in film uniformity and surface quality. This period also saw the expansion of PETG film applications beyond packaging, into areas such as medical devices and consumer electronics.

The turn of the millennium marked a significant shift in PETG film evolution, with increased emphasis on enhancing barrier properties. This focus was driven by growing demand for packaging materials with improved shelf life and protection against moisture, oxygen, and other environmental factors. Researchers began exploring various techniques to improve the inherent barrier properties of PETG, including the incorporation of nanoparticles and the development of multi-layer structures.

In the past decade, the evolution of PETG films has been characterized by a strong push towards sustainability and enhanced functionality. Manufacturers have invested in developing bio-based alternatives and improving the recyclability of PETG films. Simultaneously, advancements in nanotechnology have opened new avenues for creating PETG composite films with superior barrier properties.

Recent innovations have focused on the integration of active and intelligent features into PETG films. These include the incorporation of antimicrobial agents, oxygen scavengers, and even smart sensors for monitoring product freshness. Such developments have significantly expanded the potential applications of PETG films in high-value sectors like pharmaceuticals and electronics.

The latest frontier in PETG film evolution involves the development of ultra-thin, high-performance barrier films. These films aim to combine exceptional barrier properties with reduced material usage, addressing both performance and sustainability concerns. Researchers are exploring advanced coating technologies and novel composite structures to achieve this goal.

As we look to the future, the evolution of PETG films is likely to continue along the paths of enhanced sustainability, improved barrier properties, and increased functionality. The integration of nanotechnology, smart materials, and eco-friendly additives will play a crucial role in shaping the next generation of PETG composite films, promising exciting innovations in barrier properties and beyond.

Barrier Film Demand

The demand for barrier films has been steadily increasing across various industries, driven by the growing need for advanced packaging solutions and the rising awareness of food safety and product preservation. The global barrier film market has witnessed significant growth in recent years, with a particular focus on innovations in materials like PETG composite films.

In the food and beverage industry, barrier films play a crucial role in extending shelf life and maintaining product quality. As consumers become more health-conscious and demand fresher, preservative-free products, the need for high-performance barrier packaging has intensified. This trend has led to increased adoption of barrier films in applications such as fresh produce packaging, ready-to-eat meals, and snack foods.

The pharmaceutical and healthcare sectors have also contributed substantially to the demand for barrier films. With stringent regulations on drug packaging and the need to protect sensitive medical devices from moisture and oxygen, there is a growing requirement for advanced barrier materials. PETG composite films, with their enhanced barrier properties, are well-positioned to address these challenges in the healthcare industry.

In the electronics sector, the miniaturization of devices and the increasing complexity of components have created a demand for barrier films that can protect sensitive electronics from environmental factors. This has opened up new opportunities for PETG composite films in applications such as flexible displays, wearable technology, and smart packaging.

The sustainability trend has also influenced the barrier film market. As consumers and regulators push for more environmentally friendly packaging solutions, there is a growing demand for barrier films that are recyclable, biodegradable, or made from renewable resources. This has led to increased research and development efforts in creating sustainable PETG composite films with improved barrier properties.

Geographically, the Asia-Pacific region has emerged as a significant market for barrier films, driven by rapid industrialization, urbanization, and changing consumer lifestyles. The region's booming e-commerce sector has further fueled the demand for protective packaging materials, including barrier films.

The automotive industry has also shown increasing interest in barrier films, particularly for electric vehicle battery protection and lightweight component packaging. As the automotive sector continues to evolve towards electrification and lightweight design, the demand for high-performance barrier materials like PETG composite films is expected to grow.

Overall, the barrier film market is poised for continued growth, with PETG composite films playing a significant role in meeting the diverse and evolving needs of various industries. The ongoing innovations in barrier properties of these films are likely to open up new applications and market opportunities in the coming years.

In the food and beverage industry, barrier films play a crucial role in extending shelf life and maintaining product quality. As consumers become more health-conscious and demand fresher, preservative-free products, the need for high-performance barrier packaging has intensified. This trend has led to increased adoption of barrier films in applications such as fresh produce packaging, ready-to-eat meals, and snack foods.

The pharmaceutical and healthcare sectors have also contributed substantially to the demand for barrier films. With stringent regulations on drug packaging and the need to protect sensitive medical devices from moisture and oxygen, there is a growing requirement for advanced barrier materials. PETG composite films, with their enhanced barrier properties, are well-positioned to address these challenges in the healthcare industry.

In the electronics sector, the miniaturization of devices and the increasing complexity of components have created a demand for barrier films that can protect sensitive electronics from environmental factors. This has opened up new opportunities for PETG composite films in applications such as flexible displays, wearable technology, and smart packaging.

The sustainability trend has also influenced the barrier film market. As consumers and regulators push for more environmentally friendly packaging solutions, there is a growing demand for barrier films that are recyclable, biodegradable, or made from renewable resources. This has led to increased research and development efforts in creating sustainable PETG composite films with improved barrier properties.

Geographically, the Asia-Pacific region has emerged as a significant market for barrier films, driven by rapid industrialization, urbanization, and changing consumer lifestyles. The region's booming e-commerce sector has further fueled the demand for protective packaging materials, including barrier films.

The automotive industry has also shown increasing interest in barrier films, particularly for electric vehicle battery protection and lightweight component packaging. As the automotive sector continues to evolve towards electrification and lightweight design, the demand for high-performance barrier materials like PETG composite films is expected to grow.

Overall, the barrier film market is poised for continued growth, with PETG composite films playing a significant role in meeting the diverse and evolving needs of various industries. The ongoing innovations in barrier properties of these films are likely to open up new applications and market opportunities in the coming years.

PETG Composite Challenges

Despite the numerous advantages of PETG composite films, several challenges persist in their development and application. One of the primary obstacles is achieving consistent and uniform dispersion of nanoparticles or additives within the PETG matrix. Inadequate dispersion can lead to agglomeration, compromising the film's barrier properties and mechanical strength. This issue is particularly pronounced when dealing with high loadings of nanofillers, which are often necessary to achieve significant improvements in barrier performance.

Another significant challenge lies in maintaining the transparency of PETG films after the incorporation of additives. Many barrier-enhancing particles can cause light scattering or absorption, resulting in reduced optical clarity. This is a critical concern for packaging applications where product visibility is essential. Balancing the trade-off between improved barrier properties and maintained transparency remains a complex task for researchers and manufacturers.

The compatibility between PETG and various additives poses another hurdle. Poor interfacial adhesion between the polymer matrix and fillers can lead to weak points in the composite structure, potentially creating pathways for gas or moisture permeation. Enhancing the compatibility often requires surface modification of additives or the use of compatibilizers, which adds complexity and cost to the manufacturing process.

Scalability and cost-effectiveness present additional challenges in the commercialization of PETG composite films. While laboratory-scale production may demonstrate promising results, translating these innovations to industrial-scale manufacturing while maintaining consistent quality and performance can be problematic. The increased complexity of composite systems often leads to higher production costs, which must be justified by significant performance improvements to be commercially viable.

Environmental concerns and regulatory compliance also pose challenges for PETG composite development. As sustainability becomes increasingly important, there is a growing need for biodegradable or easily recyclable composite films. However, the addition of nanoparticles or other additives can complicate recycling processes and may raise concerns about potential environmental impacts, particularly for nanoparticle-based composites.

Lastly, the long-term stability and performance of PETG composite films under various environmental conditions remain areas of ongoing research. Factors such as temperature fluctuations, humidity, and exposure to UV radiation can affect the composite structure over time, potentially leading to degradation of barrier properties or mechanical integrity. Developing composites that maintain their enhanced properties throughout the product lifecycle is crucial for their successful application in demanding packaging scenarios.

Another significant challenge lies in maintaining the transparency of PETG films after the incorporation of additives. Many barrier-enhancing particles can cause light scattering or absorption, resulting in reduced optical clarity. This is a critical concern for packaging applications where product visibility is essential. Balancing the trade-off between improved barrier properties and maintained transparency remains a complex task for researchers and manufacturers.

The compatibility between PETG and various additives poses another hurdle. Poor interfacial adhesion between the polymer matrix and fillers can lead to weak points in the composite structure, potentially creating pathways for gas or moisture permeation. Enhancing the compatibility often requires surface modification of additives or the use of compatibilizers, which adds complexity and cost to the manufacturing process.

Scalability and cost-effectiveness present additional challenges in the commercialization of PETG composite films. While laboratory-scale production may demonstrate promising results, translating these innovations to industrial-scale manufacturing while maintaining consistent quality and performance can be problematic. The increased complexity of composite systems often leads to higher production costs, which must be justified by significant performance improvements to be commercially viable.

Environmental concerns and regulatory compliance also pose challenges for PETG composite development. As sustainability becomes increasingly important, there is a growing need for biodegradable or easily recyclable composite films. However, the addition of nanoparticles or other additives can complicate recycling processes and may raise concerns about potential environmental impacts, particularly for nanoparticle-based composites.

Lastly, the long-term stability and performance of PETG composite films under various environmental conditions remain areas of ongoing research. Factors such as temperature fluctuations, humidity, and exposure to UV radiation can affect the composite structure over time, potentially leading to degradation of barrier properties or mechanical integrity. Developing composites that maintain their enhanced properties throughout the product lifecycle is crucial for their successful application in demanding packaging scenarios.

Current PETG Solutions

01 Composition of PETG composite films

PETG composite films can be formulated with various additives to enhance their barrier properties. These additives may include nanoparticles, clay minerals, or other fillers that improve the film's resistance to gas and moisture permeation. The composition and ratio of these components significantly influence the overall barrier performance of the composite film.- Composition of PETG composite films: PETG composite films can be formulated with various additives and fillers to enhance their barrier properties. These may include nanoparticles, clay minerals, or other polymers to create a more effective barrier against gases and moisture. The specific composition can be tailored to meet the desired barrier requirements for different applications.

- Surface treatment and coating techniques: Surface treatments and coatings can be applied to PETG composite films to improve their barrier properties. These may include plasma treatments, chemical modifications, or the application of thin barrier layers. Such treatments can enhance the film's resistance to gas and moisture permeation, improving overall barrier performance.

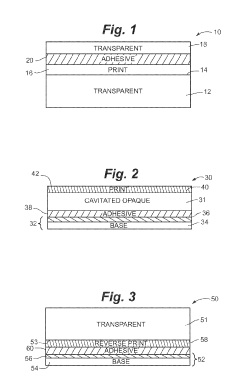

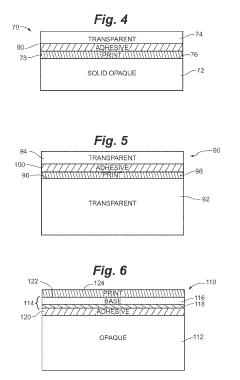

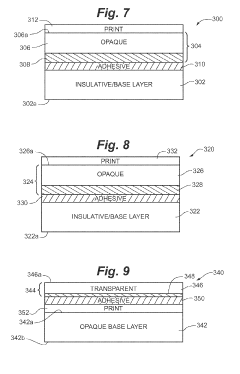

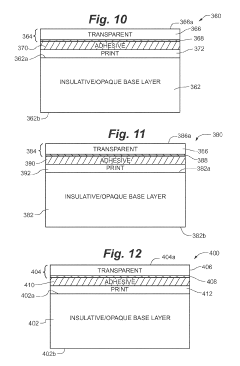

- Multi-layer film structures: PETG composite films can be designed as multi-layer structures to optimize barrier properties. By combining PETG with other materials in a layered configuration, it is possible to create films with enhanced barrier characteristics. The selection and arrangement of layers can be customized to achieve specific barrier requirements for various applications.

- Orientation and crystallinity control: The barrier properties of PETG composite films can be improved by controlling the orientation and crystallinity of the polymer chains. Techniques such as biaxial orientation or controlled cooling during processing can be employed to optimize the film's molecular structure, resulting in enhanced barrier performance against gases and moisture.

- Incorporation of active barrier components: PETG composite films can be formulated with active barrier components to enhance their protective properties. These may include oxygen scavengers, moisture absorbers, or antimicrobial agents. The incorporation of such active components can provide additional functionality to the film, improving its overall barrier performance and extending the shelf life of packaged products.

02 Surface treatment and coating techniques

Surface treatments and coating techniques can be applied to PETG films to improve their barrier properties. These may include plasma treatment, chemical vapor deposition, or the application of specialized barrier coatings. Such treatments can modify the surface characteristics of the film, reducing its permeability to gases and moisture.Expand Specific Solutions03 Multilayer film structures

PETG composite films can be designed as multilayer structures to enhance barrier properties. By combining PETG with other materials that have complementary barrier characteristics, such as ethylene vinyl alcohol (EVOH) or polyamide, the overall barrier performance of the film can be significantly improved. The arrangement and thickness of these layers play a crucial role in determining the film's barrier efficiency.Expand Specific Solutions04 Processing and manufacturing techniques

The processing and manufacturing techniques used in producing PETG composite films can greatly affect their barrier properties. Factors such as extrusion temperature, cooling rate, and orientation processes can influence the crystallinity and molecular orientation of the film, which in turn impacts its barrier performance. Optimizing these parameters can lead to improved barrier properties without the need for additional additives.Expand Specific Solutions05 Testing and characterization methods

Various testing and characterization methods are employed to evaluate the barrier properties of PETG composite films. These may include oxygen transmission rate (OTR) tests, water vapor transmission rate (WVTR) tests, and permeability measurements. Advanced analytical techniques such as scanning electron microscopy (SEM) and X-ray diffraction (XRD) can also be used to study the film's structure and its relationship to barrier performance.Expand Specific Solutions

PETG Film Manufacturers

The PETG composite films market is in a growth phase, driven by increasing demand for enhanced barrier properties in packaging. The market size is expanding due to applications in food, beverage, and pharmaceutical industries. Technologically, the field is advancing rapidly, with companies like The Coca-Cola Co., Kureha Corp., and DuPont de Nemours, Inc. leading innovations. These firms are developing proprietary formulations and manufacturing processes to improve film performance. Smaller players like Plantic Technologies Ltd. and ColorMatrix Holdings, Inc. are also contributing to technological advancements, focusing on specialized applications and eco-friendly solutions. The competitive landscape is characterized by a mix of established chemical giants and innovative startups, each striving to differentiate through unique product offerings and sustainable practices.

Mitsubishi Gas Chemical Co., Inc.

Technical Solution: Mitsubishi Gas Chemical has developed a novel approach to improving PETG barrier properties through the incorporation of their proprietary MX-Nylon. This high-barrier polyamide is blended with PETG to create a composite film with exceptional gas barrier properties[4]. The company has also implemented a co-extrusion process to produce multi-layer PETG films with alternating layers of PETG and MX-Nylon, resulting in films with oxygen transmission rates reduced by up to 70% compared to standard PETG[6]. Furthermore, Mitsubishi has explored the use of oxygen scavengers in PETG composites, which actively absorb oxygen molecules, providing an additional barrier mechanism[8]. Their latest innovation involves the development of a nano-coating technology that can be applied to PETG films, further enhancing their barrier properties without significantly affecting transparency or flexibility[7].

Strengths: Proprietary high-barrier materials, expertise in multi-layer film production, and innovative coating technologies. Weaknesses: Potential limitations in film flexibility and higher material costs due to the use of specialty polymers.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed advanced PETG composite films with enhanced barrier properties. Their technology involves incorporating nanoparticles, such as clay or graphene, into the PETG matrix to create a tortuous path for gas molecules, significantly improving oxygen and moisture barrier properties[1]. The company has also implemented a multi-layer film structure, combining PETG with other high-barrier materials like EVOH or nylon, to achieve synergistic barrier effects[3]. Additionally, DuPont has explored surface modification techniques, such as plasma treatment or coating with metal oxides, to further enhance the barrier performance of PETG films[5]. These innovations have resulted in PETG composite films with up to 50% improvement in oxygen transmission rate compared to standard PETG[2].

Strengths: Extensive R&D capabilities, diverse product portfolio, and strong market presence. Weaknesses: Higher production costs associated with advanced technologies and potential challenges in scaling up nanocomposite production.

Key PETG Innovations

Barrier film

PatentInactiveUS7854994B2

Innovation

- A film-forming barrier polymer composition comprising 45-90% starch or modified starch, 4-12% water-soluble polymers like polyvinyl alcohol, 5-45% non-crystallizing plasticizers, 0.3-2.5% fatty acids, and 0.25-3% emulsifiers, which is biodegradable and water-soluble, enhancing oxygen and carbon dioxide barrier properties and compatibility with recyclable plastics.

Composite film having barrier properties for use as in-mold labels, article with in-mold labels, and methods of making same

PatentActiveUS10286628B2

Innovation

- Development of multi-layer or composite films with barrier materials that can seal on themselves, providing water vapor, oxygen, light, aroma, and flavor retention barriers, compatible with standard in-mold labeling processes, and capable of withstanding extreme processing conditions.

Sustainability Aspects

Sustainability has become a crucial aspect in the development of PETG composite films, particularly in relation to their barrier properties. As industries strive to reduce their environmental impact, the focus on creating more sustainable packaging solutions has intensified. PETG composite films offer promising opportunities in this regard, with ongoing research and development aimed at enhancing their eco-friendly characteristics while maintaining or improving their barrier properties.

One of the primary sustainability concerns addressed in PETG composite film innovations is the reduction of material usage. By incorporating nanocomposites and other advanced materials, researchers have successfully developed thinner films that maintain excellent barrier properties. This approach not only conserves raw materials but also reduces the overall weight of packaging, leading to decreased transportation costs and associated carbon emissions.

Recyclability is another key focus area in the sustainability of PETG composite films. Recent innovations have explored the integration of biodegradable or easily separable components within the film structure. These advancements aim to facilitate easier recycling processes, addressing the end-of-life challenges often associated with multi-layer barrier films. Some promising approaches include the use of compatibilizers that allow for better separation of different polymer layers during recycling.

The incorporation of bio-based materials in PETG composite films has gained significant attention in recent years. Researchers are exploring the use of renewable resources, such as cellulose nanofibers or starch-based compounds, to partially replace petroleum-based components. These bio-based additives not only contribute to reducing the carbon footprint but also often enhance the barrier properties of the films, creating a synergy between sustainability and performance.

Energy efficiency in the production of PETG composite films is another area where sustainability improvements are being made. Innovations in processing technologies, such as more efficient extrusion methods and lower temperature curing processes, are helping to reduce the energy consumption associated with film manufacturing. These advancements not only contribute to environmental sustainability but also offer potential cost savings for manufacturers.

Lastly, the development of PETG composite films with enhanced durability and reusability is contributing to sustainability efforts. By creating films that can withstand multiple use cycles or offer extended shelf life for packaged products, the overall environmental impact of packaging can be significantly reduced. This approach aligns with the growing trend towards circular economy principles in the packaging industry.

One of the primary sustainability concerns addressed in PETG composite film innovations is the reduction of material usage. By incorporating nanocomposites and other advanced materials, researchers have successfully developed thinner films that maintain excellent barrier properties. This approach not only conserves raw materials but also reduces the overall weight of packaging, leading to decreased transportation costs and associated carbon emissions.

Recyclability is another key focus area in the sustainability of PETG composite films. Recent innovations have explored the integration of biodegradable or easily separable components within the film structure. These advancements aim to facilitate easier recycling processes, addressing the end-of-life challenges often associated with multi-layer barrier films. Some promising approaches include the use of compatibilizers that allow for better separation of different polymer layers during recycling.

The incorporation of bio-based materials in PETG composite films has gained significant attention in recent years. Researchers are exploring the use of renewable resources, such as cellulose nanofibers or starch-based compounds, to partially replace petroleum-based components. These bio-based additives not only contribute to reducing the carbon footprint but also often enhance the barrier properties of the films, creating a synergy between sustainability and performance.

Energy efficiency in the production of PETG composite films is another area where sustainability improvements are being made. Innovations in processing technologies, such as more efficient extrusion methods and lower temperature curing processes, are helping to reduce the energy consumption associated with film manufacturing. These advancements not only contribute to environmental sustainability but also offer potential cost savings for manufacturers.

Lastly, the development of PETG composite films with enhanced durability and reusability is contributing to sustainability efforts. By creating films that can withstand multiple use cycles or offer extended shelf life for packaged products, the overall environmental impact of packaging can be significantly reduced. This approach aligns with the growing trend towards circular economy principles in the packaging industry.

Regulatory Compliance

Regulatory compliance plays a crucial role in the development and commercialization of PETG composite films with enhanced barrier properties. As these innovative materials find applications in various industries, particularly in food packaging and medical devices, adherence to stringent regulations is paramount to ensure consumer safety and product integrity.

In the food packaging sector, PETG composite films must comply with regulations set forth by the U.S. Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA). These agencies establish guidelines for food contact materials, including specific migration limits for chemical substances and overall migration limits. Manufacturers must demonstrate that their PETG composite films do not transfer harmful substances to food products under normal use conditions.

For medical device applications, PETG composite films are subject to regulations such as the FDA's 21 CFR Part 820 Quality System Regulation and the European Union's Medical Device Regulation (MDR). These frameworks outline requirements for design controls, risk management, and biocompatibility testing. Manufacturers must provide evidence of material safety and performance through extensive documentation and testing protocols.

Environmental regulations also impact the development of PETG composite films. With increasing focus on sustainability, manufacturers must consider end-of-life scenarios and comply with regulations related to recyclability and biodegradability. The European Union's Packaging and Packaging Waste Directive and similar regulations in other regions set targets for recycling and recovery of packaging materials.

Compliance with chemical regulations, such as the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) in the European Union and the Toxic Substances Control Act (TSCA) in the United States, is essential for PETG composite films. These regulations require manufacturers to assess and manage the risks associated with chemical substances used in their products.

To ensure regulatory compliance, manufacturers of PETG composite films must implement robust quality management systems and maintain comprehensive documentation. This includes detailed records of material composition, manufacturing processes, and test results. Regular audits and inspections by regulatory bodies may be conducted to verify compliance.

As regulations evolve to address emerging concerns and technological advancements, manufacturers must stay informed and adapt their products accordingly. This may involve reformulating materials, modifying production processes, or conducting additional testing to meet new requirements. Proactive engagement with regulatory agencies and industry associations can help manufacturers anticipate and prepare for upcoming regulatory changes.

In the food packaging sector, PETG composite films must comply with regulations set forth by the U.S. Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA). These agencies establish guidelines for food contact materials, including specific migration limits for chemical substances and overall migration limits. Manufacturers must demonstrate that their PETG composite films do not transfer harmful substances to food products under normal use conditions.

For medical device applications, PETG composite films are subject to regulations such as the FDA's 21 CFR Part 820 Quality System Regulation and the European Union's Medical Device Regulation (MDR). These frameworks outline requirements for design controls, risk management, and biocompatibility testing. Manufacturers must provide evidence of material safety and performance through extensive documentation and testing protocols.

Environmental regulations also impact the development of PETG composite films. With increasing focus on sustainability, manufacturers must consider end-of-life scenarios and comply with regulations related to recyclability and biodegradability. The European Union's Packaging and Packaging Waste Directive and similar regulations in other regions set targets for recycling and recovery of packaging materials.

Compliance with chemical regulations, such as the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) in the European Union and the Toxic Substances Control Act (TSCA) in the United States, is essential for PETG composite films. These regulations require manufacturers to assess and manage the risks associated with chemical substances used in their products.

To ensure regulatory compliance, manufacturers of PETG composite films must implement robust quality management systems and maintain comprehensive documentation. This includes detailed records of material composition, manufacturing processes, and test results. Regular audits and inspections by regulatory bodies may be conducted to verify compliance.

As regulations evolve to address emerging concerns and technological advancements, manufacturers must stay informed and adapt their products accordingly. This may involve reformulating materials, modifying production processes, or conducting additional testing to meet new requirements. Proactive engagement with regulatory agencies and industry associations can help manufacturers anticipate and prepare for upcoming regulatory changes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!