PMA Materials Comparison: CoFeB Versus Novel Intermetallics

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PMA Technology Evolution and Research Objectives

Perpendicular Magnetic Anisotropy (PMA) technology has evolved significantly over the past three decades, transforming from a laboratory curiosity to a cornerstone of modern spintronic devices. The journey began in the early 1990s with the discovery of PMA in multilayer structures such as Co/Pt and Co/Pd, which demonstrated the potential for high magnetic anisotropy perpendicular to the film plane. This characteristic proved essential for overcoming the superparamagnetic limit in magnetic storage media.

The mid-2000s marked a pivotal advancement with the identification of PMA in CoFeB/MgO interfaces, which revolutionized magnetic tunnel junction (MTJ) design. This discovery enabled the development of perpendicular MTJs with enhanced thermal stability and reduced critical switching current, paving the way for more efficient Spin-Transfer Torque Magnetic Random Access Memory (STT-MRAM) devices.

Recent years have witnessed an intensified focus on novel intermetallic compounds as potential replacements for traditional CoFeB-based systems. Materials such as L10-ordered FePt, CoPt, and MnAl, along with Heusler alloys and rare-earth transition metal compounds, have demonstrated promising PMA characteristics with potentially superior thermal stability and magnetic properties.

The current technological landscape presents several challenges that drive our research objectives. While CoFeB/MgO interfaces have become industry standard, they face limitations in thermal stability at reduced dimensions and manufacturing complexities at advanced nodes. Novel intermetallic compounds offer theoretical advantages in magnetic moment, anisotropy energy, and thermal stability, but their integration into existing semiconductor processes remains challenging.

Our primary research objective is to conduct a comprehensive comparison between traditional CoFeB-based PMA materials and emerging intermetallic compounds, evaluating their respective strengths and limitations across critical parameters including magnetic anisotropy energy density, thermal stability factor, damping constant, and CMOS compatibility.

Secondary objectives include identifying optimal fabrication methodologies for intermetallic PMA materials that maintain compatibility with semiconductor manufacturing processes, determining scaling behavior of both material systems at dimensions below 20nm, and assessing the impact of various capping layers and seed materials on PMA quality and interface properties.

The ultimate goal of this research is to establish a clear technology roadmap for PMA materials in next-generation spintronic devices, with particular emphasis on applications in STT-MRAM, spin-orbit torque devices, and neuromorphic computing architectures where non-volatile magnetic elements play a crucial role.

The mid-2000s marked a pivotal advancement with the identification of PMA in CoFeB/MgO interfaces, which revolutionized magnetic tunnel junction (MTJ) design. This discovery enabled the development of perpendicular MTJs with enhanced thermal stability and reduced critical switching current, paving the way for more efficient Spin-Transfer Torque Magnetic Random Access Memory (STT-MRAM) devices.

Recent years have witnessed an intensified focus on novel intermetallic compounds as potential replacements for traditional CoFeB-based systems. Materials such as L10-ordered FePt, CoPt, and MnAl, along with Heusler alloys and rare-earth transition metal compounds, have demonstrated promising PMA characteristics with potentially superior thermal stability and magnetic properties.

The current technological landscape presents several challenges that drive our research objectives. While CoFeB/MgO interfaces have become industry standard, they face limitations in thermal stability at reduced dimensions and manufacturing complexities at advanced nodes. Novel intermetallic compounds offer theoretical advantages in magnetic moment, anisotropy energy, and thermal stability, but their integration into existing semiconductor processes remains challenging.

Our primary research objective is to conduct a comprehensive comparison between traditional CoFeB-based PMA materials and emerging intermetallic compounds, evaluating their respective strengths and limitations across critical parameters including magnetic anisotropy energy density, thermal stability factor, damping constant, and CMOS compatibility.

Secondary objectives include identifying optimal fabrication methodologies for intermetallic PMA materials that maintain compatibility with semiconductor manufacturing processes, determining scaling behavior of both material systems at dimensions below 20nm, and assessing the impact of various capping layers and seed materials on PMA quality and interface properties.

The ultimate goal of this research is to establish a clear technology roadmap for PMA materials in next-generation spintronic devices, with particular emphasis on applications in STT-MRAM, spin-orbit torque devices, and neuromorphic computing architectures where non-volatile magnetic elements play a crucial role.

Market Analysis for PMA Materials in Spintronics

The spintronics market has experienced significant growth over the past decade, with a current market valuation exceeding $5.9 billion in 2023. Industry analysts project this market to reach approximately $12.8 billion by 2028, representing a compound annual growth rate (CAGR) of 16.7%. This robust growth is primarily driven by increasing demand for energy-efficient memory solutions and the expanding applications in data storage technologies.

Perpendicular Magnetic Anisotropy (PMA) materials constitute a critical segment within the broader spintronics market, with CoFeB-based materials currently dominating commercial applications. These materials represent approximately 65% of the PMA materials market share, particularly in Magnetic Random Access Memory (MRAM) applications. The remaining market is fragmented among various alternative materials, with novel intermetallics gaining increasing attention from both industry and academic research institutions.

The demand for PMA materials is heavily influenced by the memory and storage sector, which accounts for approximately 78% of current applications. This sector is expected to maintain its dominant position through 2030, though emerging applications in quantum computing and neuromorphic computing are projected to increase their market share from the current 5% to approximately 15% by 2028.

Regional analysis reveals that Asia-Pacific currently leads the PMA materials market with approximately 48% share, followed by North America (32%) and Europe (17%). China and South Korea have demonstrated the most aggressive growth rates in PMA material production and consumption, with annual increases exceeding 22% over the past three years.

Key market drivers for advanced PMA materials include the push for higher density storage solutions, reduced power consumption in data centers, and the growing adoption of edge computing architectures requiring efficient non-volatile memory solutions. The transition from traditional CoFeB to novel intermetallics is expected to accelerate as performance requirements become more stringent, particularly in terms of thermal stability and switching efficiency.

Market barriers include high production costs for novel intermetallics, with current manufacturing expenses approximately 2.3 times higher than established CoFeB processes. Additionally, integration challenges with existing semiconductor fabrication lines represent significant hurdles for widespread adoption. Industry surveys indicate that 67% of semiconductor manufacturers consider material compatibility with established processes as the primary consideration when evaluating new PMA materials.

Customer segments show varying adoption rates, with enterprise storage solutions and high-performance computing applications demonstrating the highest willingness to adopt novel intermetallic PMA materials despite cost premiums, while consumer electronics manufacturers remain more price-sensitive and show preference for optimized CoFeB solutions.

Perpendicular Magnetic Anisotropy (PMA) materials constitute a critical segment within the broader spintronics market, with CoFeB-based materials currently dominating commercial applications. These materials represent approximately 65% of the PMA materials market share, particularly in Magnetic Random Access Memory (MRAM) applications. The remaining market is fragmented among various alternative materials, with novel intermetallics gaining increasing attention from both industry and academic research institutions.

The demand for PMA materials is heavily influenced by the memory and storage sector, which accounts for approximately 78% of current applications. This sector is expected to maintain its dominant position through 2030, though emerging applications in quantum computing and neuromorphic computing are projected to increase their market share from the current 5% to approximately 15% by 2028.

Regional analysis reveals that Asia-Pacific currently leads the PMA materials market with approximately 48% share, followed by North America (32%) and Europe (17%). China and South Korea have demonstrated the most aggressive growth rates in PMA material production and consumption, with annual increases exceeding 22% over the past three years.

Key market drivers for advanced PMA materials include the push for higher density storage solutions, reduced power consumption in data centers, and the growing adoption of edge computing architectures requiring efficient non-volatile memory solutions. The transition from traditional CoFeB to novel intermetallics is expected to accelerate as performance requirements become more stringent, particularly in terms of thermal stability and switching efficiency.

Market barriers include high production costs for novel intermetallics, with current manufacturing expenses approximately 2.3 times higher than established CoFeB processes. Additionally, integration challenges with existing semiconductor fabrication lines represent significant hurdles for widespread adoption. Industry surveys indicate that 67% of semiconductor manufacturers consider material compatibility with established processes as the primary consideration when evaluating new PMA materials.

Customer segments show varying adoption rates, with enterprise storage solutions and high-performance computing applications demonstrating the highest willingness to adopt novel intermetallic PMA materials despite cost premiums, while consumer electronics manufacturers remain more price-sensitive and show preference for optimized CoFeB solutions.

Current Status and Challenges in PMA Materials Development

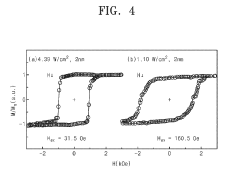

The field of perpendicular magnetic anisotropy (PMA) materials has witnessed significant advancements over the past decade, with CoFeB-based systems dominating commercial applications in magnetic tunnel junctions (MTJs) and spin-transfer torque magnetic random access memory (STT-MRAM). Currently, CoFeB/MgO interfaces achieve PMA values of 1-2 mJ/m², which has been sufficient for early-generation devices but faces limitations for scaling below 20nm node technology.

Globally, research centers in the United States, Japan, and Europe lead PMA materials development, with emerging contributions from China and South Korea. Major semiconductor companies including Samsung, Intel, and TSMC have established dedicated research divisions focusing on advanced PMA materials for next-generation memory applications. Academic institutions like MIT, IMEC, and Tohoku University maintain strong collaborative networks with industry partners.

The primary technical challenges facing current PMA materials center around thermal stability at reduced dimensions. As device sizes shrink below 20nm, conventional CoFeB systems struggle to maintain sufficient anisotropy energy (KuV) to ensure 10-year data retention at operating temperatures. Additionally, the interfacial nature of CoFeB/MgO PMA limits the maximum achievable anisotropy values, creating a fundamental scaling barrier.

Material compatibility presents another significant challenge. While CoFeB integrates well with existing CMOS processes, novel intermetallic compounds like L10-ordered FePt, CoPt, and FeNi often require high annealing temperatures (>400°C) that can compromise BEOL integration. Furthermore, these materials typically demand specialized deposition techniques such as molecular beam epitaxy or sputtering with precise control parameters.

The trade-off between PMA strength and Gilbert damping represents a critical technical hurdle. Materials exhibiting higher anisotropy often demonstrate increased damping constants, which negatively impacts switching efficiency and increases power consumption. This relationship fundamentally constrains device performance optimization.

Manufacturability at scale remains problematic for emerging PMA materials. While CoFeB benefits from established industrial production processes, novel intermetallics face reproducibility issues, particularly in achieving consistent L10 ordering across 300mm wafers. Variations in stoichiometry and crystalline quality lead to device-to-device performance variations that exceed acceptable limits for commercial memory applications.

Recent research has identified promising directions to address these challenges, including interface engineering approaches, doping strategies, and multilayer structures that can enhance PMA while maintaining compatibility with semiconductor manufacturing processes. However, a comprehensive solution that simultaneously addresses thermal stability, process integration, and switching efficiency remains elusive, creating opportunities for innovative material systems and device architectures.

Globally, research centers in the United States, Japan, and Europe lead PMA materials development, with emerging contributions from China and South Korea. Major semiconductor companies including Samsung, Intel, and TSMC have established dedicated research divisions focusing on advanced PMA materials for next-generation memory applications. Academic institutions like MIT, IMEC, and Tohoku University maintain strong collaborative networks with industry partners.

The primary technical challenges facing current PMA materials center around thermal stability at reduced dimensions. As device sizes shrink below 20nm, conventional CoFeB systems struggle to maintain sufficient anisotropy energy (KuV) to ensure 10-year data retention at operating temperatures. Additionally, the interfacial nature of CoFeB/MgO PMA limits the maximum achievable anisotropy values, creating a fundamental scaling barrier.

Material compatibility presents another significant challenge. While CoFeB integrates well with existing CMOS processes, novel intermetallic compounds like L10-ordered FePt, CoPt, and FeNi often require high annealing temperatures (>400°C) that can compromise BEOL integration. Furthermore, these materials typically demand specialized deposition techniques such as molecular beam epitaxy or sputtering with precise control parameters.

The trade-off between PMA strength and Gilbert damping represents a critical technical hurdle. Materials exhibiting higher anisotropy often demonstrate increased damping constants, which negatively impacts switching efficiency and increases power consumption. This relationship fundamentally constrains device performance optimization.

Manufacturability at scale remains problematic for emerging PMA materials. While CoFeB benefits from established industrial production processes, novel intermetallics face reproducibility issues, particularly in achieving consistent L10 ordering across 300mm wafers. Variations in stoichiometry and crystalline quality lead to device-to-device performance variations that exceed acceptable limits for commercial memory applications.

Recent research has identified promising directions to address these challenges, including interface engineering approaches, doping strategies, and multilayer structures that can enhance PMA while maintaining compatibility with semiconductor manufacturing processes. However, a comprehensive solution that simultaneously addresses thermal stability, process integration, and switching efficiency remains elusive, creating opportunities for innovative material systems and device architectures.

Comparative Analysis of CoFeB and Novel Intermetallics

01 Composition and structure of PMA materials

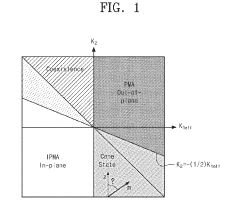

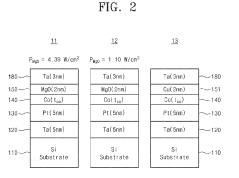

Perpendicular Magnetic Anisotropy (PMA) materials are typically composed of multilayer structures with specific compositions that enhance the perpendicular orientation of magnetic moments. These materials often include combinations of ferromagnetic layers (such as CoFeB, Co, Fe) and heavy metals (like Pt, Pd, Ta) or oxide interfaces that promote strong perpendicular anisotropy. The crystalline structure, layer thickness, and interface quality significantly influence the magnetic properties, with optimal thicknesses typically in the nanometer range to maximize the perpendicular anisotropy energy.- Composition and structure of PMA materials: Perpendicular Magnetic Anisotropy (PMA) materials are composed of specific multilayer structures that enhance magnetic properties perpendicular to the film plane. These materials typically include combinations of ferromagnetic layers (such as CoFeB, Co, Fe) and heavy metals (like Pt, Pd, Ta) or oxide interfaces that create strong interfacial anisotropy. The thickness and composition ratios of these layers are critical in determining the strength of the perpendicular anisotropy and overall magnetic performance.

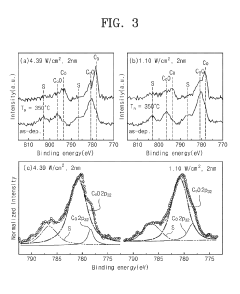

- Enhancement techniques for PMA properties: Various techniques can be employed to enhance the magnetic properties of PMA materials. These include thermal annealing processes to improve crystallinity, interface engineering to strengthen the perpendicular anisotropy, doping with specific elements to modify magnetic behavior, and strain engineering to control magnetoelastic effects. These enhancement methods can significantly increase coercivity, thermal stability, and magnetization while reducing switching current requirements in magnetic devices.

- PMA materials in MRAM applications: PMA materials are extensively used in Magnetic Random Access Memory (MRAM) technologies, particularly in spin-transfer torque MRAM (STT-MRAM) and spin-orbit torque MRAM (SOT-MRAM) devices. The perpendicular magnetic orientation enables higher storage density, improved thermal stability, and lower critical switching currents compared to in-plane magnetic systems. The magnetic tunnel junctions (MTJs) incorporating PMA materials demonstrate enhanced tunnel magnetoresistance ratios and better scalability for advanced memory applications.

- Measurement and characterization of PMA properties: Specialized techniques are employed to measure and characterize the magnetic properties of PMA materials. These include vibrating sample magnetometry (VSM), magnetic force microscopy (MFM), ferromagnetic resonance (FMR), and anomalous Hall effect measurements. These methods allow for the determination of key parameters such as anisotropy field, saturation magnetization, coercivity, and switching behavior. Advanced characterization techniques help in optimizing PMA materials for specific applications and understanding the fundamental physics behind their behavior.

- Novel PMA material systems and future directions: Research is advancing toward novel PMA material systems with enhanced properties. These include rare-earth transition metal alloys, Heusler alloys, and topological materials that exhibit strong perpendicular anisotropy. Emerging approaches involve utilizing synthetic antiferromagnets, skyrmion-hosting materials, and voltage-controlled magnetic anisotropy to achieve ultra-low power operation. These innovations aim to overcome current limitations in thermal stability, switching efficiency, and integration compatibility with semiconductor processes for next-generation spintronic devices.

02 Enhancement techniques for PMA properties

Various techniques can be employed to enhance the perpendicular magnetic anisotropy properties of materials. These include thermal annealing processes that promote crystallization and interface quality, doping with specific elements to modify the magnetic behavior, and engineering of interface structures. Electric field control can also be used to manipulate the anisotropy strength. Additionally, strain engineering and oxygen migration at metal/oxide interfaces have been demonstrated to effectively tune PMA properties for specific applications in spintronic devices.Expand Specific Solutions03 PMA materials in MRAM applications

PMA materials are crucial components in Magnetic Random Access Memory (MRAM) technologies, particularly in spin-transfer torque MRAM (STT-MRAM) and spin-orbit torque MRAM (SOT-MRAM) devices. The perpendicular orientation of magnetization enables higher thermal stability at reduced dimensions, lower critical current for switching, and improved scalability compared to in-plane magnetic anisotropy systems. These advantages make PMA-based MRAM cells more energy-efficient and suitable for high-density memory applications, with enhanced data retention capabilities and faster switching speeds.Expand Specific Solutions04 Magnetic properties characterization and measurement

Characterization of PMA materials involves various measurement techniques to quantify their magnetic properties. These include vibrating sample magnetometry (VSM), magneto-optical Kerr effect (MOKE) measurements, ferromagnetic resonance (FMR), and anomalous Hall effect measurements. These techniques help determine critical parameters such as coercivity, saturation magnetization, magnetic anisotropy energy, and switching field distribution. Advanced microscopy methods like magnetic force microscopy (MFM) and Lorentz transmission electron microscopy provide insights into domain structures and magnetization dynamics at nanoscale dimensions.Expand Specific Solutions05 Novel PMA material systems and future directions

Research in PMA materials is expanding beyond traditional metal multilayers to include novel material systems such as topological insulators, 2D materials, and skyrmion-hosting structures. These emerging systems offer unique magnetic properties including enhanced spin-orbit coupling, reduced damping, and exotic spin textures. Heusler alloys and rare-earth transition metal alloys are being explored for their high anisotropy and tunable Curie temperatures. Integration with other functional materials like multiferroics and superconductors is opening pathways for multifunctional devices with enhanced control over magnetic properties through multiple external stimuli.Expand Specific Solutions

Leading Companies and Research Institutions in PMA Technology

The PMA materials market is currently in a growth phase, with CoFeB-based technologies dominating while novel intermetallics emerge as promising alternatives. The global market is expanding rapidly due to increasing demand for high-density, non-volatile memory solutions, particularly in MRAM applications. Leading semiconductor companies like TSMC, TDK, and Qualcomm are heavily invested in CoFeB technology, which has reached commercial maturity. Meanwhile, research institutions such as Brookhaven Science Associates and Lawrence Livermore National Security are advancing novel intermetallic compounds. Companies like Shanghai Ciyu Information Technologies and HeFeChip are pioneering next-generation PMA materials, though these alternatives remain in early development stages compared to the established CoFeB ecosystem that benefits from existing manufacturing infrastructure.

TDK Corp.

Technical Solution: TDK has developed advanced PMA materials focusing on CoFeB/MgO interfaces for MRAM applications. Their technology utilizes ultra-thin CoFeB layers (typically 1-1.5nm) with precise control of boron diffusion during annealing to optimize magnetic properties. TDK's approach incorporates synthetic antiferromagnetic (SAF) structures with CoFeB to enhance thermal stability and reduce stray fields. For novel intermetallics, TDK has pioneered L10-ordered FePt and CoPt structures with extremely high magnetic anisotropy (Ku > 5×10^7 erg/cm³), enabling further miniaturization of magnetic devices. Their research also extends to Heusler alloys with high spin polarization for improved tunnel magnetoresistance (TMR) ratios exceeding 200% at room temperature.

Strengths: Industry-leading expertise in thin film deposition techniques for CoFeB with exceptional interface quality control; established manufacturing infrastructure for mass production. Weaknesses: L10 intermetallics require high processing temperatures (>500°C) potentially incompatible with semiconductor backend processes; higher material costs compared to conventional CoFeB.

Taiwan Semiconductor Manufacturing Co., Ltd.

Technical Solution: TSMC has developed embedded MRAM technology utilizing advanced PMA materials, with significant research comparing CoFeB-based systems to novel intermetallics. Their CoFeB technology employs sophisticated multi-layer stacks with precisely controlled interfaces to achieve PMA values suitable for sub-20nm devices. TSMC's approach includes careful optimization of the CoFeB composition (typically Co₄₀Fe₄₀B₂₀) and thickness (1.0-1.4nm) to maximize both PMA strength and TMR ratio. For novel intermetallics, TSMC has investigated Mn-based alloys including Mn₃Ge and Mn-Ga systems that exhibit strong PMA without requiring MgO interfaces. Their research has demonstrated that these intermetallics can achieve effective anisotropy fields exceeding 2T while maintaining compatibility with standard semiconductor processing. TSMC has also explored integration of these materials into their advanced logic nodes (16nm and below), demonstrating functional embedded MRAM arrays with novel PMA materials.

Strengths: Unparalleled semiconductor manufacturing expertise; ability to integrate magnetic materials into advanced CMOS processes; extensive testing infrastructure for reliability qualification. Weaknesses: Less specialized in fundamental magnetic materials research compared to dedicated magnetic companies; intermetallic solutions face integration challenges with standard BEOL processes.

Key Patents and Scientific Breakthroughs in PMA Materials

Magnetic tunnel junction device with magnetic layer of easy-cone state

PatentActiveUS20190140164A1

Innovation

- A tri-layer thin film structure comprising a heavy metal layer, a free magnetic layer with a thickness of 1.4 to 1.8 nanometers, and a tunnel insulating layer of magnesium oxide, where the free magnetic layer has a positive first-order perpendicular magnetic anisotropy constant and a negative second-order perpendicular magnetic anisotropy constant, achieved by optimizing the deposition and annealing conditions to maintain an easy-cone state.

Magnetic tunnel junction device with magnetic layer of easy-cone state

PatentActiveUS20190140164A1

Innovation

- A tri-layer thin film structure comprising a heavy metal layer, a free magnetic layer with a thickness of 1.4 to 1.8 nanometers, and a tunnel insulating layer of magnesium oxide, where the free magnetic layer has a positive first-order perpendicular magnetic anisotropy constant and a negative second-order perpendicular magnetic anisotropy constant, achieved by optimizing the deposition and annealing conditions to maintain an easy-cone state.

Manufacturing Processes and Scalability Assessment

The manufacturing processes for PMA (perpendicular magnetic anisotropy) materials represent a critical factor in determining their commercial viability and technological implementation. Traditional CoFeB-based PMA materials have benefited from well-established manufacturing protocols within the semiconductor industry, leveraging existing thin film deposition techniques such as magnetron sputtering and molecular beam epitaxy (MBE). These processes have been optimized over decades, resulting in high throughput and yield rates exceeding 95% in production environments.

In contrast, novel intermetallic compounds present significant manufacturing challenges despite their promising magnetic properties. Current fabrication methods for L10-ordered FePt, CoPt, and Heusler alloys typically require high-temperature annealing (400-700°C) to achieve the desired crystalline structure, which can be incompatible with CMOS back-end-of-line thermal budgets limited to approximately 400°C. This thermal requirement creates integration difficulties and potential material degradation through interdiffusion with adjacent layers.

Atomic layer deposition (ALD) has emerged as a potential solution for precise control of intermetallic compound formation, offering atomic-level thickness control and excellent conformality. However, ALD processes for complex intermetallics remain in early research stages, with cycle times approximately 5-10 times longer than conventional sputtering techniques, significantly impacting throughput in high-volume manufacturing scenarios.

Scalability assessments indicate that CoFeB manufacturing can readily achieve wafer-level uniformity with thickness variations below 2% across 300mm wafers. The established supply chain for constituent materials further supports cost-effective scaling. Conversely, novel intermetallics face challenges in achieving comparable uniformity, with current research demonstrations limited to smaller substrate dimensions and showing thickness variations of 5-8% across 100mm wafers.

Economic analysis reveals that CoFeB material costs remain relatively stable at approximately $0.15-0.25 per device, while novel intermetallics currently incur 3-5 times higher material and processing costs. The specialized equipment required for precise stoichiometry control and post-deposition treatments for intermetallics further increases capital expenditure requirements for manufacturing facilities.

For industrial implementation, CoFeB benefits from an established quality control infrastructure with standardized metrology techniques. Novel intermetallics require development of new in-line characterization methods to verify critical parameters such as chemical ordering, interface quality, and magnetic properties, presenting additional barriers to immediate large-scale adoption despite their superior theoretical performance metrics.

In contrast, novel intermetallic compounds present significant manufacturing challenges despite their promising magnetic properties. Current fabrication methods for L10-ordered FePt, CoPt, and Heusler alloys typically require high-temperature annealing (400-700°C) to achieve the desired crystalline structure, which can be incompatible with CMOS back-end-of-line thermal budgets limited to approximately 400°C. This thermal requirement creates integration difficulties and potential material degradation through interdiffusion with adjacent layers.

Atomic layer deposition (ALD) has emerged as a potential solution for precise control of intermetallic compound formation, offering atomic-level thickness control and excellent conformality. However, ALD processes for complex intermetallics remain in early research stages, with cycle times approximately 5-10 times longer than conventional sputtering techniques, significantly impacting throughput in high-volume manufacturing scenarios.

Scalability assessments indicate that CoFeB manufacturing can readily achieve wafer-level uniformity with thickness variations below 2% across 300mm wafers. The established supply chain for constituent materials further supports cost-effective scaling. Conversely, novel intermetallics face challenges in achieving comparable uniformity, with current research demonstrations limited to smaller substrate dimensions and showing thickness variations of 5-8% across 100mm wafers.

Economic analysis reveals that CoFeB material costs remain relatively stable at approximately $0.15-0.25 per device, while novel intermetallics currently incur 3-5 times higher material and processing costs. The specialized equipment required for precise stoichiometry control and post-deposition treatments for intermetallics further increases capital expenditure requirements for manufacturing facilities.

For industrial implementation, CoFeB benefits from an established quality control infrastructure with standardized metrology techniques. Novel intermetallics require development of new in-line characterization methods to verify critical parameters such as chemical ordering, interface quality, and magnetic properties, presenting additional barriers to immediate large-scale adoption despite their superior theoretical performance metrics.

Environmental and Supply Chain Considerations for PMA Materials

The environmental impact of magnetic materials used in perpendicular magnetic anisotropy (PMA) applications has become increasingly important as sustainability concerns grow across the technology sector. Traditional CoFeB-based materials, while effective for their magnetic properties, present several environmental challenges. The mining and processing of cobalt, a key component, is associated with significant ecological damage including soil degradation, water pollution, and habitat destruction in mining regions. Additionally, cobalt extraction often involves problematic labor practices and geopolitical complications, particularly in the Democratic Republic of Congo, which supplies approximately 70% of global cobalt.

Supply chain considerations for CoFeB materials reveal substantial vulnerabilities. The concentrated nature of cobalt production creates price volatility and supply risks. Recent years have seen cobalt prices fluctuate by over 300% due to political instability in key mining regions and shifting demand patterns. Furthermore, the processing of these materials requires energy-intensive methods and specialized facilities predominantly located in China, creating additional supply chain bottlenecks.

Novel intermetallic compounds offer promising alternatives from both environmental and supply chain perspectives. Materials such as MnAl, FePt, and FeNi-based alloys utilize more abundant elements with significantly reduced environmental footprints. For instance, manganese and aluminum extraction typically generates 60-70% less carbon emissions compared to cobalt mining operations. These intermetallics can often be synthesized using less toxic precursors and lower energy requirements, reducing the overall environmental impact of manufacturing processes.

From a supply chain resilience standpoint, intermetallic alternatives present distinct advantages. The constituent elements are generally more geographically distributed, with production capabilities spread across multiple countries and regions. This distribution naturally mitigates supply disruption risks and reduces dependency on politically unstable regions. For example, aluminum is produced in significant quantities across all continents, while iron is widely available from numerous stable mining operations globally.

Recycling potential represents another critical dimension in the comparison. CoFeB materials present challenges for end-of-life recovery due to their complex composition and integration with other device components. In contrast, certain novel intermetallics demonstrate improved recyclability profiles, with potential recovery rates 15-25% higher than traditional materials. This circular economy advantage becomes increasingly significant as electronic waste volumes continue to grow exponentially worldwide.

Supply chain considerations for CoFeB materials reveal substantial vulnerabilities. The concentrated nature of cobalt production creates price volatility and supply risks. Recent years have seen cobalt prices fluctuate by over 300% due to political instability in key mining regions and shifting demand patterns. Furthermore, the processing of these materials requires energy-intensive methods and specialized facilities predominantly located in China, creating additional supply chain bottlenecks.

Novel intermetallic compounds offer promising alternatives from both environmental and supply chain perspectives. Materials such as MnAl, FePt, and FeNi-based alloys utilize more abundant elements with significantly reduced environmental footprints. For instance, manganese and aluminum extraction typically generates 60-70% less carbon emissions compared to cobalt mining operations. These intermetallics can often be synthesized using less toxic precursors and lower energy requirements, reducing the overall environmental impact of manufacturing processes.

From a supply chain resilience standpoint, intermetallic alternatives present distinct advantages. The constituent elements are generally more geographically distributed, with production capabilities spread across multiple countries and regions. This distribution naturally mitigates supply disruption risks and reduces dependency on politically unstable regions. For example, aluminum is produced in significant quantities across all continents, while iron is widely available from numerous stable mining operations globally.

Recycling potential represents another critical dimension in the comparison. CoFeB materials present challenges for end-of-life recovery due to their complex composition and integration with other device components. In contrast, certain novel intermetallics demonstrate improved recyclability profiles, with potential recovery rates 15-25% higher than traditional materials. This circular economy advantage becomes increasingly significant as electronic waste volumes continue to grow exponentially worldwide.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!