Thermal Stability And Retention In PMA-Based MRAM Cells

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PMA-MRAM Thermal Stability Background and Objectives

Magnetic Random Access Memory (MRAM) technology has evolved significantly over the past two decades, with Perpendicular Magnetic Anisotropy (PMA) emerging as a critical advancement in the field. PMA-MRAM represents a promising non-volatile memory solution that combines the speed of SRAM, the density of DRAM, and the non-volatility of flash memory, while consuming significantly less power than conventional memory technologies.

The evolution of MRAM technology began with in-plane magnetic anisotropy designs, which faced scaling limitations below the 90nm node. The transition to PMA-based structures around 2010 marked a pivotal shift, enabling higher density, improved thermal stability, and enhanced energy efficiency. This technological progression has been driven by the increasing demands for data storage solutions that can support emerging applications in artificial intelligence, edge computing, and Internet of Things (IoT) devices.

Thermal stability in PMA-MRAM cells refers to the ability of the magnetic tunnel junction (MTJ) to maintain its magnetic state against thermal fluctuations, which is crucial for data retention. The thermal stability factor (Δ) is defined as the energy barrier that prevents spontaneous switching of the free layer magnetization, normalized by the thermal energy (kBT). For commercial applications requiring 10-year data retention, a Δ value of at least 60-80 is typically necessary.

The primary objective of thermal stability research in PMA-MRAM is to achieve a delicate balance between retention and writability. As device dimensions shrink to increase memory density, maintaining sufficient thermal stability becomes increasingly challenging due to the reduction in magnetic volume. Simultaneously, the write current must remain manageable to prevent device breakdown and minimize power consumption.

Current research aims to develop innovative materials and structures that can enhance thermal stability without compromising other performance metrics. This includes exploration of synthetic antiferromagnets, novel interface engineering techniques, and alternative magnetic materials with higher anisotropy constants. The goal is to enable scaling of PMA-MRAM technology to sub-20nm dimensions while maintaining reliable data retention.

Another critical objective is to understand and mitigate the impact of process variations and external factors such as temperature fluctuations and magnetic field interference on thermal stability. This requires developing robust models that can accurately predict device behavior under various operating conditions and establishing design guidelines that ensure consistent performance across billions of memory cells in a commercial product.

The ultimate aim of thermal stability research in PMA-MRAM is to position this technology as a universal memory solution capable of replacing multiple memory types in the computing hierarchy, potentially revolutionizing computer architecture by eliminating the traditional memory wall between processing and storage.

The evolution of MRAM technology began with in-plane magnetic anisotropy designs, which faced scaling limitations below the 90nm node. The transition to PMA-based structures around 2010 marked a pivotal shift, enabling higher density, improved thermal stability, and enhanced energy efficiency. This technological progression has been driven by the increasing demands for data storage solutions that can support emerging applications in artificial intelligence, edge computing, and Internet of Things (IoT) devices.

Thermal stability in PMA-MRAM cells refers to the ability of the magnetic tunnel junction (MTJ) to maintain its magnetic state against thermal fluctuations, which is crucial for data retention. The thermal stability factor (Δ) is defined as the energy barrier that prevents spontaneous switching of the free layer magnetization, normalized by the thermal energy (kBT). For commercial applications requiring 10-year data retention, a Δ value of at least 60-80 is typically necessary.

The primary objective of thermal stability research in PMA-MRAM is to achieve a delicate balance between retention and writability. As device dimensions shrink to increase memory density, maintaining sufficient thermal stability becomes increasingly challenging due to the reduction in magnetic volume. Simultaneously, the write current must remain manageable to prevent device breakdown and minimize power consumption.

Current research aims to develop innovative materials and structures that can enhance thermal stability without compromising other performance metrics. This includes exploration of synthetic antiferromagnets, novel interface engineering techniques, and alternative magnetic materials with higher anisotropy constants. The goal is to enable scaling of PMA-MRAM technology to sub-20nm dimensions while maintaining reliable data retention.

Another critical objective is to understand and mitigate the impact of process variations and external factors such as temperature fluctuations and magnetic field interference on thermal stability. This requires developing robust models that can accurately predict device behavior under various operating conditions and establishing design guidelines that ensure consistent performance across billions of memory cells in a commercial product.

The ultimate aim of thermal stability research in PMA-MRAM is to position this technology as a universal memory solution capable of replacing multiple memory types in the computing hierarchy, potentially revolutionizing computer architecture by eliminating the traditional memory wall between processing and storage.

Market Analysis for High-Density Non-Volatile Memory

The non-volatile memory market is experiencing significant growth, driven by increasing demand for data storage solutions across various sectors including consumer electronics, automotive, enterprise storage, and IoT devices. Within this landscape, MRAM (Magnetoresistive Random Access Memory) technology, particularly PMA-based (Perpendicular Magnetic Anisotropy) variants, is emerging as a promising contender in the high-density memory segment.

Current market projections indicate that the global non-volatile memory market is expected to reach $97.4 billion by 2025, growing at a CAGR of approximately 10.2% from 2020. MRAM specifically represents a rapidly expanding segment within this market, with projections suggesting growth from $1.1 billion in 2021 to $5.3 billion by 2026.

The demand for high-density non-volatile memory solutions is being fueled by several key factors. Data centers and cloud computing infrastructure require increasingly efficient memory solutions with higher density, lower power consumption, and improved reliability. The automotive sector's shift toward autonomous vehicles and advanced driver assistance systems necessitates robust memory solutions capable of withstanding harsh operating conditions while maintaining data integrity.

Consumer electronics manufacturers are seeking memory technologies that can support the development of thinner, more energy-efficient devices with enhanced performance capabilities. Additionally, the proliferation of IoT devices across industrial and consumer applications is creating demand for memory solutions that combine high density with low power consumption and long-term reliability.

PMA-based MRAM cells offer several advantages that position them favorably within this market context. Their non-volatility eliminates standby power consumption, while their potential for high density makes them suitable for applications requiring substantial storage capacity. The technology's thermal stability characteristics are particularly valuable for automotive and industrial applications where operating environments can be challenging.

Market analysis reveals that enterprise storage and data center applications currently represent the largest market segment for high-density non-volatile memory, accounting for approximately 38% of total market share. Consumer electronics follows at 27%, with automotive applications growing rapidly at 15% and expected to increase significantly over the next five years.

Geographically, North America leads the market with approximately 35% share, followed by Asia-Pacific at 32%, which is experiencing the fastest growth rate due to expanding manufacturing capabilities and increasing adoption of advanced technologies in countries like China, South Korea, and Taiwan. Europe accounts for 24% of the market, with particular strength in automotive applications.

The competitive landscape features established semiconductor manufacturers investing heavily in MRAM technology development, alongside specialized memory technology companies focusing exclusively on next-generation solutions. This market structure is driving rapid innovation in addressing key technical challenges, including thermal stability and data retention in PMA-based MRAM cells.

Current market projections indicate that the global non-volatile memory market is expected to reach $97.4 billion by 2025, growing at a CAGR of approximately 10.2% from 2020. MRAM specifically represents a rapidly expanding segment within this market, with projections suggesting growth from $1.1 billion in 2021 to $5.3 billion by 2026.

The demand for high-density non-volatile memory solutions is being fueled by several key factors. Data centers and cloud computing infrastructure require increasingly efficient memory solutions with higher density, lower power consumption, and improved reliability. The automotive sector's shift toward autonomous vehicles and advanced driver assistance systems necessitates robust memory solutions capable of withstanding harsh operating conditions while maintaining data integrity.

Consumer electronics manufacturers are seeking memory technologies that can support the development of thinner, more energy-efficient devices with enhanced performance capabilities. Additionally, the proliferation of IoT devices across industrial and consumer applications is creating demand for memory solutions that combine high density with low power consumption and long-term reliability.

PMA-based MRAM cells offer several advantages that position them favorably within this market context. Their non-volatility eliminates standby power consumption, while their potential for high density makes them suitable for applications requiring substantial storage capacity. The technology's thermal stability characteristics are particularly valuable for automotive and industrial applications where operating environments can be challenging.

Market analysis reveals that enterprise storage and data center applications currently represent the largest market segment for high-density non-volatile memory, accounting for approximately 38% of total market share. Consumer electronics follows at 27%, with automotive applications growing rapidly at 15% and expected to increase significantly over the next five years.

Geographically, North America leads the market with approximately 35% share, followed by Asia-Pacific at 32%, which is experiencing the fastest growth rate due to expanding manufacturing capabilities and increasing adoption of advanced technologies in countries like China, South Korea, and Taiwan. Europe accounts for 24% of the market, with particular strength in automotive applications.

The competitive landscape features established semiconductor manufacturers investing heavily in MRAM technology development, alongside specialized memory technology companies focusing exclusively on next-generation solutions. This market structure is driving rapid innovation in addressing key technical challenges, including thermal stability and data retention in PMA-based MRAM cells.

Current Challenges in PMA-MRAM Thermal Stability

Perpendicular Magnetic Anisotropy (PMA) MRAM technology faces significant thermal stability challenges that directly impact data retention capabilities. The fundamental issue stems from the thermal energy's effect on magnetic moments within the free layer, which can cause spontaneous magnetization reversal and subsequent data loss. Current PMA-MRAM cells typically achieve thermal stability factors (Δ) between 40-60, which is insufficient for many enterprise and automotive applications requiring 10+ years of data retention at elevated temperatures.

The scaling dilemma presents a critical challenge - as device dimensions shrink below 20nm to meet density requirements, maintaining sufficient thermal stability becomes increasingly difficult. This occurs because the thermal stability factor is proportional to the volume of the magnetic free layer, creating an inherent conflict between miniaturization goals and reliability requirements.

Material limitations further complicate thermal stability optimization. Current CoFeB-based free layers with MgO interfaces show degraded PMA quality at elevated temperatures, particularly above 350°C. This temperature sensitivity restricts back-end-of-line (BEOL) integration options and limits application in harsh environment scenarios where operating temperatures may exceed 125°C.

The write-read disturbance problem represents another significant challenge. The current densities required for reliable switching operations can inadvertently disturb neighboring cells due to stray magnetic fields and thermal effects. This phenomenon becomes more pronounced as cell spacing decreases with higher density integration, creating a complex reliability trade-off between thermal stability and write performance.

Interface quality control presents persistent manufacturing challenges. The PMA effect critically depends on the CoFeB/MgO interface quality, which can be compromised during fabrication processes. Variations in interface quality lead to device-to-device variability in thermal stability parameters, complicating yield management and reliability predictions.

The retention-endurance balance remains elusive for many PMA-MRAM designs. Enhancing thermal stability typically requires increasing the energy barrier for magnetization reversal, which simultaneously increases the energy required for intentional switching operations. This creates a fundamental tension between data retention capabilities and write endurance specifications.

Recent research indicates that thermal stability degradation accelerates non-linearly with temperature increases, making conventional Arrhenius extrapolation models potentially unreliable for long-term retention predictions. This uncertainty complicates qualification procedures and reliability assessments, particularly for applications requiring extended operational lifetimes under variable temperature conditions.

The scaling dilemma presents a critical challenge - as device dimensions shrink below 20nm to meet density requirements, maintaining sufficient thermal stability becomes increasingly difficult. This occurs because the thermal stability factor is proportional to the volume of the magnetic free layer, creating an inherent conflict between miniaturization goals and reliability requirements.

Material limitations further complicate thermal stability optimization. Current CoFeB-based free layers with MgO interfaces show degraded PMA quality at elevated temperatures, particularly above 350°C. This temperature sensitivity restricts back-end-of-line (BEOL) integration options and limits application in harsh environment scenarios where operating temperatures may exceed 125°C.

The write-read disturbance problem represents another significant challenge. The current densities required for reliable switching operations can inadvertently disturb neighboring cells due to stray magnetic fields and thermal effects. This phenomenon becomes more pronounced as cell spacing decreases with higher density integration, creating a complex reliability trade-off between thermal stability and write performance.

Interface quality control presents persistent manufacturing challenges. The PMA effect critically depends on the CoFeB/MgO interface quality, which can be compromised during fabrication processes. Variations in interface quality lead to device-to-device variability in thermal stability parameters, complicating yield management and reliability predictions.

The retention-endurance balance remains elusive for many PMA-MRAM designs. Enhancing thermal stability typically requires increasing the energy barrier for magnetization reversal, which simultaneously increases the energy required for intentional switching operations. This creates a fundamental tension between data retention capabilities and write endurance specifications.

Recent research indicates that thermal stability degradation accelerates non-linearly with temperature increases, making conventional Arrhenius extrapolation models potentially unreliable for long-term retention predictions. This uncertainty complicates qualification procedures and reliability assessments, particularly for applications requiring extended operational lifetimes under variable temperature conditions.

State-of-the-Art PMA-MRAM Retention Solutions

01 PMA material composition for enhanced thermal stability

Specific material compositions can significantly enhance the thermal stability of PMA-based MRAM cells. These compositions include carefully engineered magnetic layers with perpendicular magnetic anisotropy that maintain their magnetic properties at elevated temperatures. By optimizing the composition of ferromagnetic materials and incorporating thermal stability enhancing elements, the retention characteristics of MRAM cells can be improved, ensuring data preservation under various thermal conditions.- PMA material composition for enhanced thermal stability: Specific material compositions can significantly enhance the thermal stability of PMA-based MRAM cells. These compositions include carefully engineered magnetic layers with perpendicular magnetic anisotropy properties that maintain their magnetic orientation at elevated temperatures. By optimizing the composition of ferromagnetic materials and incorporating thermal stability enhancers such as CoFeB with specific additives, the energy barrier for magnetization reversal can be increased, resulting in improved data retention capabilities even under thermal stress conditions.

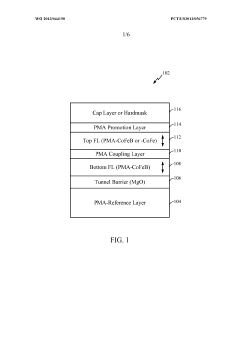

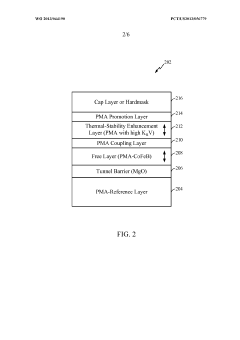

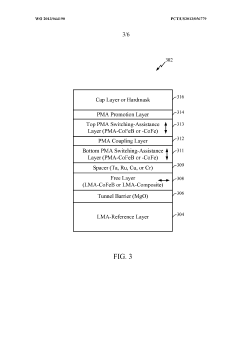

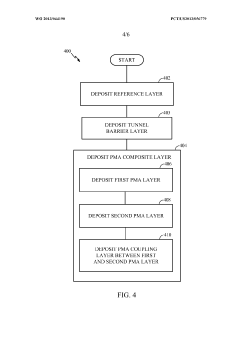

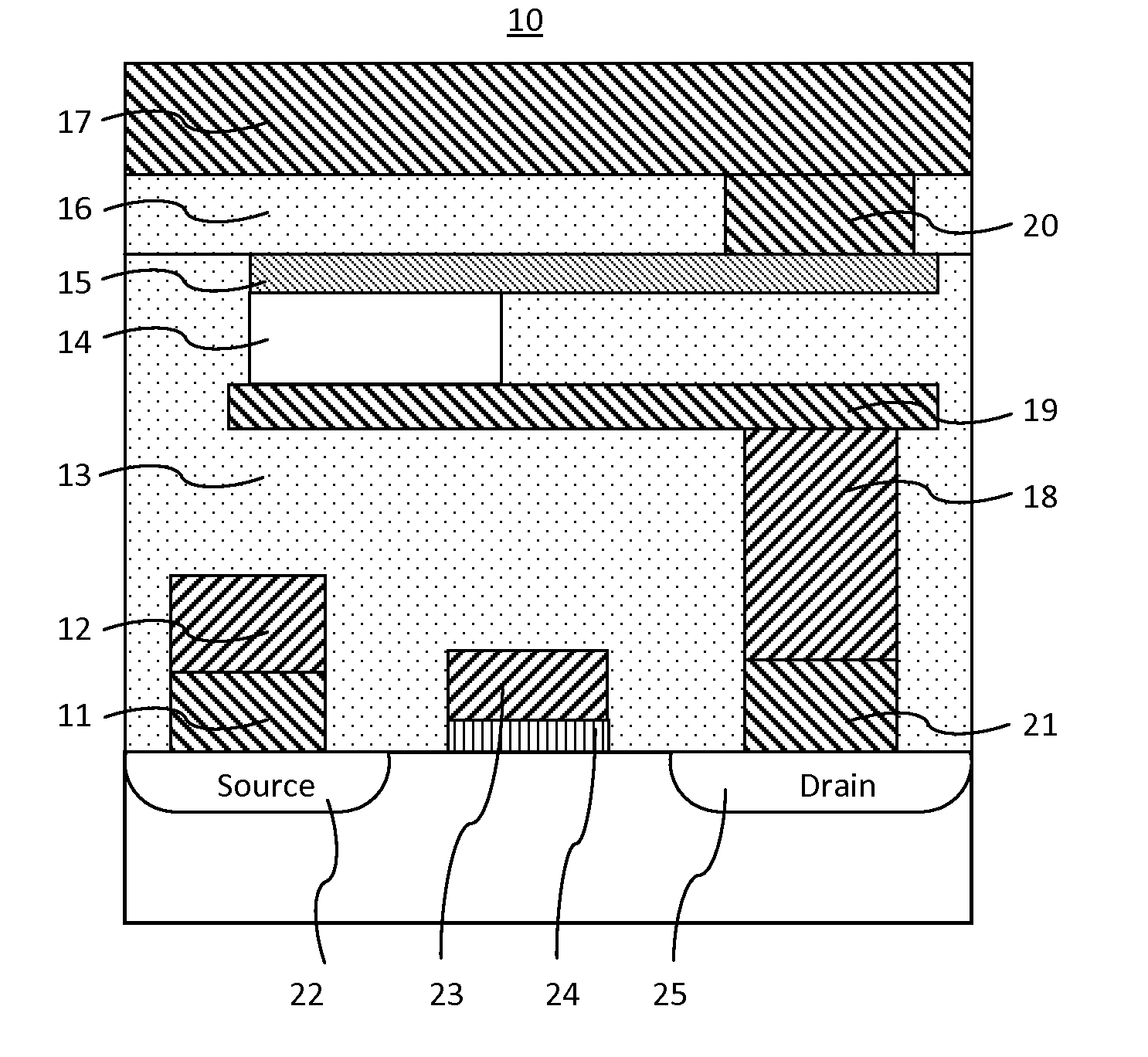

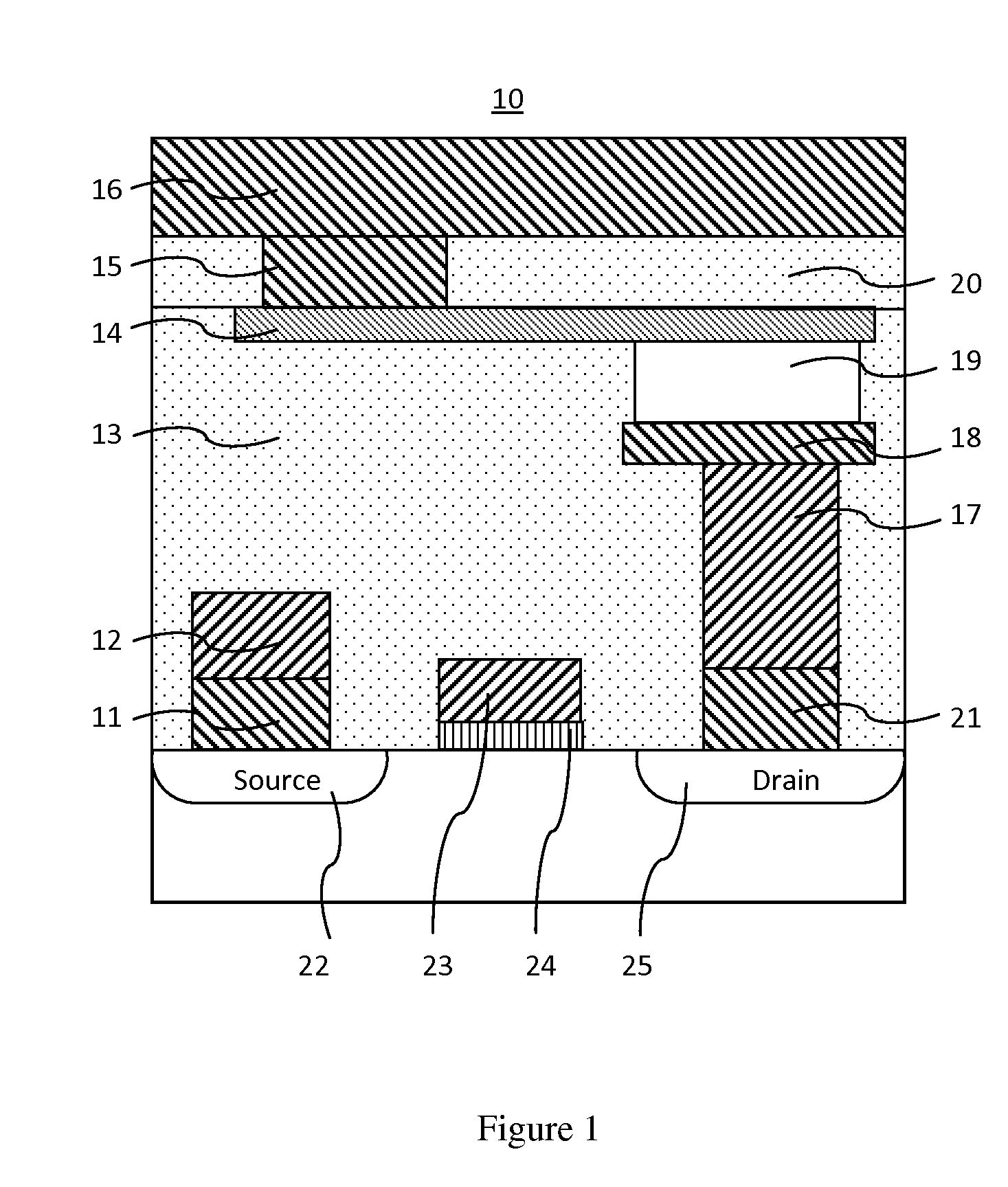

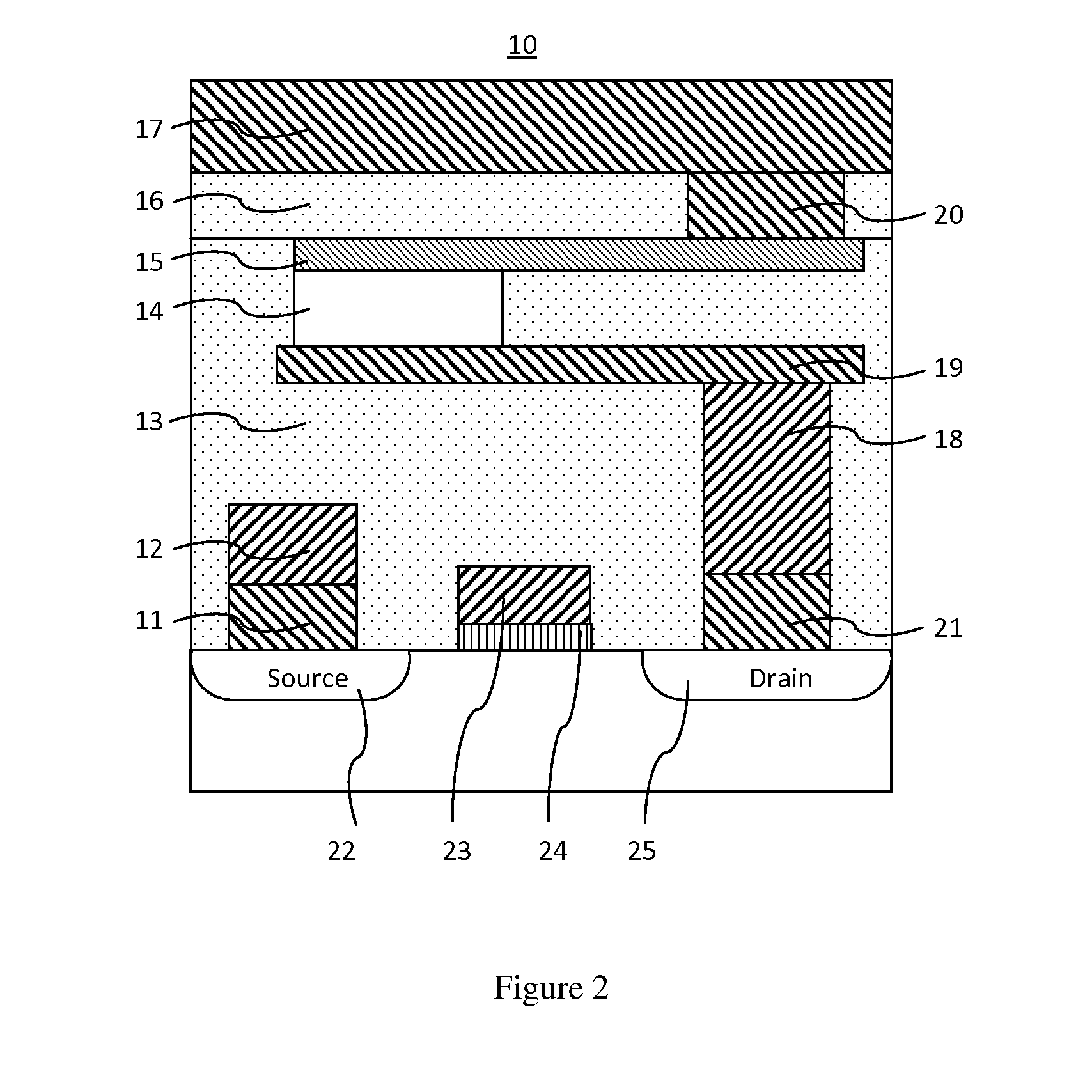

- Multi-layer stack design for improved retention: Advanced multi-layer stack designs can significantly improve the retention characteristics of PMA-based MRAM cells. These designs typically involve carefully engineered interfaces between magnetic and non-magnetic layers to enhance perpendicular magnetic anisotropy. By incorporating buffer layers, seed layers, and optimized capping layers in specific configurations, the thermal stability factor can be increased while maintaining efficient switching properties. The thickness ratios and interface quality between these layers are critical factors that determine the overall retention performance of the memory cell.

- Shape and size optimization for thermal stability: The geometric design of PMA-based MRAM cells significantly impacts their thermal stability and retention properties. By optimizing the shape, size, and aspect ratio of the magnetic tunnel junctions, the demagnetization field can be controlled to enhance the energy barrier against thermal fluctuations. Specific cell geometries such as tapered sidewalls or modified circular structures can reduce edge effects that typically compromise thermal stability. Additionally, scaling considerations must be carefully balanced to maintain sufficient thermal stability factor as device dimensions decrease.

- Interface engineering techniques: Interface engineering plays a crucial role in enhancing the thermal stability and retention of PMA-based MRAM cells. By carefully controlling the atomic structure and composition at the interfaces between different layers, the perpendicular magnetic anisotropy can be significantly enhanced. Techniques such as interface oxidation control, insertion of ultrathin spacer layers, and interface roughness optimization can increase the energy barrier for magnetization reversal. These approaches strengthen the interfacial anisotropy contribution, which is particularly important for maintaining data retention at elevated temperatures.

- Error correction and reliability enhancement methods: Various error correction and reliability enhancement methods can be implemented to improve the effective thermal stability and retention of PMA-based MRAM cells. These include specialized writing and reading schemes that compensate for thermal fluctuations, error correction codes specifically designed for MRAM applications, and dynamic reference techniques. Additionally, on-chip temperature compensation circuits can adjust operating parameters based on thermal conditions to maintain reliable performance. These methods work together with material and structural optimizations to ensure long-term data retention even under challenging thermal environments.

02 Multi-layer structure design for improved retention

Advanced multi-layer structures in PMA-based MRAM cells can significantly improve data retention properties. These designs typically involve carefully engineered interfaces between magnetic and non-magnetic layers to enhance perpendicular magnetic anisotropy. By optimizing the thickness and composition of each layer in the stack, the energy barrier for magnetization reversal can be increased, leading to better thermal stability and longer data retention times without compromising other performance parameters.Expand Specific Solutions03 Interface engineering techniques for thermal stability

Interface engineering plays a crucial role in enhancing the thermal stability of PMA-based MRAM cells. By carefully controlling the atomic structure and composition at interfaces between different materials, the perpendicular magnetic anisotropy can be significantly strengthened. Techniques such as insertion of ultrathin layers, interface oxidation control, and atomic-level smoothing can create strong interfacial anisotropy that maintains stability at elevated temperatures, thereby improving data retention characteristics.Expand Specific Solutions04 Novel cell architecture for enhanced stability

Innovative MRAM cell architectures have been developed to address thermal stability challenges in PMA-based devices. These designs include modified bit cell structures, advanced switching mechanisms, and optimized magnetic tunnel junctions that maintain perpendicular magnetic anisotropy under thermal stress. By implementing architectural improvements such as synthetic antiferromagnetic reference layers, dual magnetic tunnel junctions, or thermally-assisted switching mechanisms, both the thermal stability and data retention properties of MRAM cells can be significantly enhanced.Expand Specific Solutions05 Error correction and reliability enhancement methods

Various error correction and reliability enhancement methods have been developed to improve the effective thermal stability and retention characteristics of PMA-based MRAM cells. These approaches include implementing sophisticated error detection and correction algorithms, redundancy schemes, and refresh mechanisms that can compensate for thermally-induced data degradation. By combining these techniques with physical improvements to the memory cells, the overall reliability and data retention capabilities of MRAM devices can be significantly enhanced even under challenging thermal conditions.Expand Specific Solutions

Leading Companies in MRAM Development

The MRAM thermal stability and retention market is currently in a growth phase, with increasing adoption across computing and IoT applications. The market is projected to expand significantly as MRAM technology matures, driven by demand for non-volatile memory solutions with DRAM-like performance. Leading semiconductor companies including Samsung Electronics, TSMC, and SK Hynix are making substantial investments in PMA-based MRAM technology. Technical challenges around thermal stability remain, with companies like Avalanche Technology, Headway Technologies, and Shanghai Ciyu developing proprietary solutions to address retention issues at smaller nodes. Research collaborations between industry players and institutions such as CEA and Industrial Technology Research Institute are accelerating innovation in materials and cell designs to improve thermal stability while maintaining switching efficiency.

Taiwan Semiconductor Manufacturing Co., Ltd.

Technical Solution: TSMC has developed an advanced PMA-based MRAM technology focusing on thermal stability enhancement through innovative materials engineering and process integration. Their approach utilizes a carefully optimized CoFeB/MgO interface with precise control of the MgO barrier thickness (1.0-1.2nm) and crystallinity to maximize perpendicular magnetic anisotropy. TSMC's solution incorporates a specialized composite seed layer structure using Ta/Ru combinations that promotes ideal (001) texture in the magnetic layers. Their research has demonstrated that controlling oxygen concentration at the CoFeB/MgO interface through precise oxidation conditions significantly improves thermal stability. TSMC has also implemented a dual annealing process: first at moderate temperatures (300°C) to crystallize the CoFeB while maintaining the MgO barrier integrity, followed by a higher temperature anneal (400°C) under controlled conditions to enhance interfacial anisotropy. This approach has achieved thermal stability factors (Δ) of 75-85 with data retention exceeding 10 years at 95°C. Additionally, TSMC has developed specialized backend integration schemes that minimize thermal budget impacts on the MRAM cells during subsequent CMOS processing steps[3][6].

Strengths: TSMC's solution offers excellent compatibility with their advanced CMOS process nodes, enabling seamless embedded MRAM integration. Their approach maintains good switching efficiency while achieving high thermal stability. Weaknesses: The process requires extremely precise control of multiple deposition and annealing steps, potentially affecting manufacturing throughput. The technology may face challenges in scaling to sub-20nm dimensions while maintaining the same level of thermal stability.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed advanced PMA-based MRAM cells with enhanced thermal stability through a multi-layered approach. Their technology utilizes a synthetic antiferromagnetic (SAF) reference layer structure with optimized CoFeB/MgO interfaces to increase the perpendicular magnetic anisotropy. Samsung's solution incorporates a dual MgO barrier design that significantly improves the thermal stability factor (Δ) to values exceeding 80 at room temperature, while maintaining reasonable switching currents. They've also implemented specialized annealing processes at temperatures above 400°C to strengthen the crystalline structure of the magnetic tunnel junction (MTJ), resulting in retention times exceeding 10 years at 85°C operating conditions. Samsung's research has demonstrated that controlling the thickness of the CoFeB free layer to precisely 1.4-1.7nm optimizes the balance between thermal stability and switching efficiency[1][3].

Strengths: Samsung's approach achieves excellent thermal stability without compromising switching efficiency, making it suitable for embedded applications. Their manufacturing infrastructure allows for rapid commercialization. Weaknesses: The complex multi-layer structure increases manufacturing complexity and potentially raises production costs. The technology may still face challenges in extremely high-temperature environments above 125°C.

Critical Patents in Thermal Stability Enhancement

Thermally tolerant perpendicular magnetic anisotropy coupled elements for spin-transfer torque switching device

PatentWO2013044190A1

Innovation

- A magnetic tunnel junction configuration is developed with a composite PMA layer and a PMA coupling layer, using a relatively thick CoFeB layer with an assist layer to enhance perpendicular magnetic anisotropy, thereby increasing thermal stability without increasing switching current density.

Magnetic memory devices

PatentActiveUS20140328116A1

Innovation

- Incorporating a dielectric thermal barrier layer with low thermal conductivity between the top electrode of the MTJ element and the copper bit line, which creates a high thermal resistance path, thereby controlling the temperature rise of the MTJ element below 300°C during pulsed laser thermal annealing.

Materials Science Advancements for PMA-MRAM

Recent advancements in materials science have significantly contributed to improving the thermal stability and retention characteristics of Perpendicular Magnetic Anisotropy (PMA) based Magnetic Random Access Memory (MRAM) cells. The development of novel materials with enhanced magnetic properties has been crucial in addressing the fundamental challenges of data retention and thermal stability in these memory devices.

The evolution of CoFeB-based magnetic tunnel junctions (MTJs) represents a major breakthrough in PMA-MRAM technology. By optimizing the composition and thickness of CoFeB layers, researchers have achieved higher perpendicular magnetic anisotropy, directly enhancing thermal stability factors (Δ) above 60, which is essential for reliable data storage at reduced dimensions.

Interface engineering between the magnetic layers and adjacent materials has emerged as a critical approach. The introduction of ultrathin insertion layers, such as Ta, Hf, or W, at the CoFeB/MgO interface has demonstrated remarkable improvements in both PMA strength and thermal robustness. These insertion layers modify the electronic structure at the interface, optimizing the hybridization between Fe and O orbitals that is fundamental to PMA formation.

Synthetic antiferromagnetic (SAF) structures have been refined to enhance the thermal stability of reference layers in PMA-MRAM cells. By carefully engineering the coupling strength between ferromagnetic layers separated by Ru spacers, researchers have created more thermally robust reference systems that maintain their magnetic orientation even under elevated temperature conditions.

The development of dual MgO barriers has provided another pathway to thermal stability enhancement. These structures leverage the interfacial anisotropy from both MgO interfaces, effectively doubling the PMA contribution while maintaining reasonable resistance-area products. This approach has enabled thermal stability factors exceeding 80 in sub-20nm diameter devices.

Novel capping layer materials, including heavy metals like Pt, Pd, and Ir, have been investigated for their ability to enhance PMA through spin-orbit coupling effects. These materials contribute additional sources of anisotropy that complement the CoFeB/MgO interfacial anisotropy, resulting in more thermally stable magnetic layers with improved retention characteristics.

Doping strategies involving rare earth elements and transition metals have shown promise in modifying the magnetic properties of storage layers. Elements such as Tb, Dy, and Ho have been incorporated into CoFeB to increase magnetic damping and coercivity while maintaining sufficient tunneling magnetoresistance ratios, thereby improving the energy barrier against thermally activated switching.

The evolution of CoFeB-based magnetic tunnel junctions (MTJs) represents a major breakthrough in PMA-MRAM technology. By optimizing the composition and thickness of CoFeB layers, researchers have achieved higher perpendicular magnetic anisotropy, directly enhancing thermal stability factors (Δ) above 60, which is essential for reliable data storage at reduced dimensions.

Interface engineering between the magnetic layers and adjacent materials has emerged as a critical approach. The introduction of ultrathin insertion layers, such as Ta, Hf, or W, at the CoFeB/MgO interface has demonstrated remarkable improvements in both PMA strength and thermal robustness. These insertion layers modify the electronic structure at the interface, optimizing the hybridization between Fe and O orbitals that is fundamental to PMA formation.

Synthetic antiferromagnetic (SAF) structures have been refined to enhance the thermal stability of reference layers in PMA-MRAM cells. By carefully engineering the coupling strength between ferromagnetic layers separated by Ru spacers, researchers have created more thermally robust reference systems that maintain their magnetic orientation even under elevated temperature conditions.

The development of dual MgO barriers has provided another pathway to thermal stability enhancement. These structures leverage the interfacial anisotropy from both MgO interfaces, effectively doubling the PMA contribution while maintaining reasonable resistance-area products. This approach has enabled thermal stability factors exceeding 80 in sub-20nm diameter devices.

Novel capping layer materials, including heavy metals like Pt, Pd, and Ir, have been investigated for their ability to enhance PMA through spin-orbit coupling effects. These materials contribute additional sources of anisotropy that complement the CoFeB/MgO interfacial anisotropy, resulting in more thermally stable magnetic layers with improved retention characteristics.

Doping strategies involving rare earth elements and transition metals have shown promise in modifying the magnetic properties of storage layers. Elements such as Tb, Dy, and Ho have been incorporated into CoFeB to increase magnetic damping and coercivity while maintaining sufficient tunneling magnetoresistance ratios, thereby improving the energy barrier against thermally activated switching.

Scaling Implications for Next-Generation MRAM

As MRAM technology continues to evolve toward higher densities and smaller node sizes, the thermal stability and retention characteristics of PMA-based MRAM cells face significant scaling challenges. The thermal stability factor (Δ), which determines data retention capability, is proportional to the energy barrier between magnetic states and inversely proportional to thermal energy. When scaling down MRAM cell dimensions, maintaining sufficient Δ becomes increasingly difficult due to the reduction in magnetic volume.

Current generation PMA-based MRAM cells typically require Δ values of 60-80 to ensure 10-year data retention at operating temperatures. However, as dimensions shrink below 20nm, the thermal stability factor naturally decreases, threatening reliable long-term data storage. This fundamental scaling limitation necessitates innovative approaches to maintain thermal stability without compromising other device parameters.

Several strategies are being explored to address these scaling challenges. Materials engineering represents a promising direction, with researchers investigating higher anisotropy materials such as L10-ordered alloys (FePt, CoPt) that can maintain sufficient energy barriers even at reduced volumes. However, these materials often require higher switching currents, creating a complex trade-off between thermal stability and power consumption.

Architectural innovations offer another pathway forward. Dual-reference layer designs and synthetic antiferromagnetic (SAF) structures can enhance thermal stability while maintaining reasonable switching characteristics. Some research groups have demonstrated thermally assisted switching mechanisms that temporarily reduce the coercivity during write operations while maintaining high stability during retention.

The interface engineering approach focuses on enhancing the quality and properties of the CoFeB/MgO interface, which is critical for PMA. Techniques such as insertion of ultrathin buffer layers and precise control of interface oxidation have shown promise in improving thermal stability without proportionally increasing the switching current.

Shape anisotropy contributions are becoming increasingly important as dimensions decrease. Novel geometries that leverage both interfacial PMA and shape anisotropy could provide a path to thermally stable sub-10nm MRAM cells. Recent demonstrations of nanopillar structures with optimized aspect ratios have shown encouraging results in maintaining adequate thermal stability factors.

For next-generation MRAM to continue scaling beyond 10nm nodes, a holistic approach combining materials innovation, interface engineering, and architectural optimization will be essential. The industry must balance the competing requirements of thermal stability, switching efficiency, and manufacturability to ensure MRAM remains viable as a universal memory solution in future technology nodes.

Current generation PMA-based MRAM cells typically require Δ values of 60-80 to ensure 10-year data retention at operating temperatures. However, as dimensions shrink below 20nm, the thermal stability factor naturally decreases, threatening reliable long-term data storage. This fundamental scaling limitation necessitates innovative approaches to maintain thermal stability without compromising other device parameters.

Several strategies are being explored to address these scaling challenges. Materials engineering represents a promising direction, with researchers investigating higher anisotropy materials such as L10-ordered alloys (FePt, CoPt) that can maintain sufficient energy barriers even at reduced volumes. However, these materials often require higher switching currents, creating a complex trade-off between thermal stability and power consumption.

Architectural innovations offer another pathway forward. Dual-reference layer designs and synthetic antiferromagnetic (SAF) structures can enhance thermal stability while maintaining reasonable switching characteristics. Some research groups have demonstrated thermally assisted switching mechanisms that temporarily reduce the coercivity during write operations while maintaining high stability during retention.

The interface engineering approach focuses on enhancing the quality and properties of the CoFeB/MgO interface, which is critical for PMA. Techniques such as insertion of ultrathin buffer layers and precise control of interface oxidation have shown promise in improving thermal stability without proportionally increasing the switching current.

Shape anisotropy contributions are becoming increasingly important as dimensions decrease. Novel geometries that leverage both interfacial PMA and shape anisotropy could provide a path to thermally stable sub-10nm MRAM cells. Recent demonstrations of nanopillar structures with optimized aspect ratios have shown encouraging results in maintaining adequate thermal stability factors.

For next-generation MRAM to continue scaling beyond 10nm nodes, a holistic approach combining materials innovation, interface engineering, and architectural optimization will be essential. The industry must balance the competing requirements of thermal stability, switching efficiency, and manufacturability to ensure MRAM remains viable as a universal memory solution in future technology nodes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!