PMSM application in underwater vehicles

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PMSM Underwater Evolution

The evolution of Permanent Magnet Synchronous Motors (PMSM) in underwater vehicles represents a significant advancement in marine propulsion technology. This progression can be traced through several key stages, each marked by notable technological improvements and expanding applications.

In the early stages of underwater vehicle development, traditional DC motors were the primary choice for propulsion. However, the limitations of these motors, such as maintenance requirements and efficiency issues, led to the exploration of alternative solutions. The introduction of PMSM technology in the 1980s marked a turning point in underwater propulsion systems.

The first generation of PMSM applications in underwater vehicles focused on small, unmanned underwater vehicles (UUVs) for research and exploration purposes. These early implementations demonstrated the potential of PMSM technology, showcasing improved efficiency and reduced maintenance needs compared to conventional motors.

As the technology matured, the second generation of PMSM applications saw increased adoption in larger autonomous underwater vehicles (AUVs) and remotely operated vehicles (ROVs). This phase was characterized by advancements in motor design, including enhanced power density and improved thermal management, allowing for extended operational capabilities in deep-sea environments.

The third generation of PMSM technology in underwater vehicles witnessed a shift towards more sophisticated control systems and integration with advanced power electronics. This period saw the development of sensorless control techniques and the implementation of vector control strategies, further improving the efficiency and reliability of PMSM-driven propulsion systems.

Recent developments in PMSM technology for underwater applications have focused on addressing the unique challenges posed by the marine environment. Innovations in sealing technologies and corrosion-resistant materials have significantly enhanced the durability and longevity of these motors in saltwater conditions. Additionally, advancements in rare-earth magnet materials have led to the creation of more compact and powerful PMSMs, enabling their use in a wider range of underwater vehicles.

The latest generation of PMSM applications in underwater vehicles is characterized by the integration of smart technologies and IoT capabilities. These developments allow for real-time monitoring of motor performance, predictive maintenance, and adaptive control strategies, further enhancing the reliability and efficiency of underwater propulsion systems.

Looking ahead, the evolution of PMSM technology in underwater vehicles is expected to continue, with a focus on further improving energy efficiency, reducing environmental impact, and expanding operational capabilities in extreme underwater environments. The integration of PMSM technology with emerging fields such as artificial intelligence and advanced materials science promises to unlock new possibilities for underwater exploration and marine operations.

In the early stages of underwater vehicle development, traditional DC motors were the primary choice for propulsion. However, the limitations of these motors, such as maintenance requirements and efficiency issues, led to the exploration of alternative solutions. The introduction of PMSM technology in the 1980s marked a turning point in underwater propulsion systems.

The first generation of PMSM applications in underwater vehicles focused on small, unmanned underwater vehicles (UUVs) for research and exploration purposes. These early implementations demonstrated the potential of PMSM technology, showcasing improved efficiency and reduced maintenance needs compared to conventional motors.

As the technology matured, the second generation of PMSM applications saw increased adoption in larger autonomous underwater vehicles (AUVs) and remotely operated vehicles (ROVs). This phase was characterized by advancements in motor design, including enhanced power density and improved thermal management, allowing for extended operational capabilities in deep-sea environments.

The third generation of PMSM technology in underwater vehicles witnessed a shift towards more sophisticated control systems and integration with advanced power electronics. This period saw the development of sensorless control techniques and the implementation of vector control strategies, further improving the efficiency and reliability of PMSM-driven propulsion systems.

Recent developments in PMSM technology for underwater applications have focused on addressing the unique challenges posed by the marine environment. Innovations in sealing technologies and corrosion-resistant materials have significantly enhanced the durability and longevity of these motors in saltwater conditions. Additionally, advancements in rare-earth magnet materials have led to the creation of more compact and powerful PMSMs, enabling their use in a wider range of underwater vehicles.

The latest generation of PMSM applications in underwater vehicles is characterized by the integration of smart technologies and IoT capabilities. These developments allow for real-time monitoring of motor performance, predictive maintenance, and adaptive control strategies, further enhancing the reliability and efficiency of underwater propulsion systems.

Looking ahead, the evolution of PMSM technology in underwater vehicles is expected to continue, with a focus on further improving energy efficiency, reducing environmental impact, and expanding operational capabilities in extreme underwater environments. The integration of PMSM technology with emerging fields such as artificial intelligence and advanced materials science promises to unlock new possibilities for underwater exploration and marine operations.

Market Demand Analysis

The market demand for Permanent Magnet Synchronous Motors (PMSM) in underwater vehicles has been steadily increasing due to their superior performance characteristics and energy efficiency. As the global focus on ocean exploration, underwater resource extraction, and marine research intensifies, the need for reliable and efficient propulsion systems in underwater vehicles has become paramount.

The underwater vehicle market encompasses a wide range of applications, including Autonomous Underwater Vehicles (AUVs), Remotely Operated Vehicles (ROVs), submarines, and other submersibles. These vehicles are utilized in various sectors such as defense, oil and gas exploration, scientific research, and environmental monitoring. The growing demand for these underwater vehicles directly translates to an increased market for PMSM technology.

In the defense sector, there is a rising need for advanced underwater vehicles for surveillance, reconnaissance, and anti-submarine warfare. PMSMs offer advantages such as reduced acoustic signatures and improved maneuverability, making them ideal for military applications. The oil and gas industry also contributes significantly to the market demand, as underwater vehicles equipped with PMSMs are essential for offshore exploration, pipeline inspection, and maintenance activities.

The scientific research community has been driving demand for underwater vehicles capable of operating at greater depths and for extended durations. PMSMs, with their high power density and efficiency, enable the development of vehicles that can meet these challenging requirements. Environmental monitoring and conservation efforts have also led to increased adoption of underwater vehicles for tasks such as marine ecosystem assessment, pollution monitoring, and climate change studies.

Market trends indicate a shift towards more autonomous and intelligent underwater vehicles, which require advanced propulsion systems. PMSMs, with their precise control capabilities and compatibility with sophisticated control algorithms, are well-positioned to meet this evolving demand. Additionally, the push for greener technologies in marine applications aligns with the energy-efficient nature of PMSMs, further driving their adoption in underwater vehicles.

The market for PMSMs in underwater vehicles is expected to grow significantly in the coming years. Factors such as increasing investments in ocean exploration, the expansion of offshore renewable energy projects, and the development of underwater communication networks are likely to fuel this growth. Moreover, as underwater vehicle technology advances, there is a growing demand for PMSMs with higher power outputs, improved reliability, and enhanced corrosion resistance to withstand harsh marine environments.

The underwater vehicle market encompasses a wide range of applications, including Autonomous Underwater Vehicles (AUVs), Remotely Operated Vehicles (ROVs), submarines, and other submersibles. These vehicles are utilized in various sectors such as defense, oil and gas exploration, scientific research, and environmental monitoring. The growing demand for these underwater vehicles directly translates to an increased market for PMSM technology.

In the defense sector, there is a rising need for advanced underwater vehicles for surveillance, reconnaissance, and anti-submarine warfare. PMSMs offer advantages such as reduced acoustic signatures and improved maneuverability, making them ideal for military applications. The oil and gas industry also contributes significantly to the market demand, as underwater vehicles equipped with PMSMs are essential for offshore exploration, pipeline inspection, and maintenance activities.

The scientific research community has been driving demand for underwater vehicles capable of operating at greater depths and for extended durations. PMSMs, with their high power density and efficiency, enable the development of vehicles that can meet these challenging requirements. Environmental monitoring and conservation efforts have also led to increased adoption of underwater vehicles for tasks such as marine ecosystem assessment, pollution monitoring, and climate change studies.

Market trends indicate a shift towards more autonomous and intelligent underwater vehicles, which require advanced propulsion systems. PMSMs, with their precise control capabilities and compatibility with sophisticated control algorithms, are well-positioned to meet this evolving demand. Additionally, the push for greener technologies in marine applications aligns with the energy-efficient nature of PMSMs, further driving their adoption in underwater vehicles.

The market for PMSMs in underwater vehicles is expected to grow significantly in the coming years. Factors such as increasing investments in ocean exploration, the expansion of offshore renewable energy projects, and the development of underwater communication networks are likely to fuel this growth. Moreover, as underwater vehicle technology advances, there is a growing demand for PMSMs with higher power outputs, improved reliability, and enhanced corrosion resistance to withstand harsh marine environments.

Technical Challenges

The application of Permanent Magnet Synchronous Motors (PMSM) in underwater vehicles faces several significant technical challenges. These challenges stem from the unique operating environment and the specific requirements of underwater propulsion systems.

One of the primary challenges is the need for high efficiency and reliability in a harsh underwater environment. PMSMs must operate under extreme pressure conditions and in corrosive saltwater, which can lead to accelerated wear and potential failure. Developing robust sealing and insulation techniques to protect the motor components from water ingress and corrosion is crucial.

Another major challenge is the requirement for compact design and high power density. Underwater vehicles have limited space, necessitating motors that can deliver high power output in a small form factor. This demands innovative approaches to motor design, including advanced magnetic materials and optimized winding configurations.

Thermal management presents a significant hurdle in PMSM applications for underwater vehicles. The absence of air cooling and the limited heat dissipation capabilities in water require sophisticated cooling systems. Engineers must develop effective liquid cooling solutions or explore novel heat transfer mechanisms to prevent overheating and maintain optimal motor performance.

Control systems for PMSMs in underwater applications face unique challenges due to the dynamic nature of the aquatic environment. Precise speed and torque control are essential for maneuvering and maintaining stability. Developing robust control algorithms that can adapt to changing water currents, vehicle dynamics, and varying loads is a complex task.

The need for low acoustic signatures in underwater vehicles adds another layer of complexity to PMSM design. Minimizing noise and vibration is crucial, especially for military applications. This requires advanced rotor balancing techniques, careful selection of bearing systems, and innovative approaches to reduce electromagnetic noise.

Energy efficiency and battery life are critical factors in underwater vehicle operation. PMSMs must be optimized to deliver maximum propulsion efficiency while minimizing energy consumption. This involves developing high-efficiency motor designs and implementing sophisticated energy management strategies.

Lastly, the integration of PMSMs with other vehicle systems poses significant challenges. Ensuring compatibility with power electronics, energy storage systems, and overall vehicle control architecture requires a holistic approach to system design and integration.

Addressing these technical challenges requires interdisciplinary research and development efforts, combining expertise in electrical engineering, materials science, fluid dynamics, and control systems. Overcoming these hurdles will be key to advancing the capabilities of underwater vehicles powered by PMSMs.

One of the primary challenges is the need for high efficiency and reliability in a harsh underwater environment. PMSMs must operate under extreme pressure conditions and in corrosive saltwater, which can lead to accelerated wear and potential failure. Developing robust sealing and insulation techniques to protect the motor components from water ingress and corrosion is crucial.

Another major challenge is the requirement for compact design and high power density. Underwater vehicles have limited space, necessitating motors that can deliver high power output in a small form factor. This demands innovative approaches to motor design, including advanced magnetic materials and optimized winding configurations.

Thermal management presents a significant hurdle in PMSM applications for underwater vehicles. The absence of air cooling and the limited heat dissipation capabilities in water require sophisticated cooling systems. Engineers must develop effective liquid cooling solutions or explore novel heat transfer mechanisms to prevent overheating and maintain optimal motor performance.

Control systems for PMSMs in underwater applications face unique challenges due to the dynamic nature of the aquatic environment. Precise speed and torque control are essential for maneuvering and maintaining stability. Developing robust control algorithms that can adapt to changing water currents, vehicle dynamics, and varying loads is a complex task.

The need for low acoustic signatures in underwater vehicles adds another layer of complexity to PMSM design. Minimizing noise and vibration is crucial, especially for military applications. This requires advanced rotor balancing techniques, careful selection of bearing systems, and innovative approaches to reduce electromagnetic noise.

Energy efficiency and battery life are critical factors in underwater vehicle operation. PMSMs must be optimized to deliver maximum propulsion efficiency while minimizing energy consumption. This involves developing high-efficiency motor designs and implementing sophisticated energy management strategies.

Lastly, the integration of PMSMs with other vehicle systems poses significant challenges. Ensuring compatibility with power electronics, energy storage systems, and overall vehicle control architecture requires a holistic approach to system design and integration.

Addressing these technical challenges requires interdisciplinary research and development efforts, combining expertise in electrical engineering, materials science, fluid dynamics, and control systems. Overcoming these hurdles will be key to advancing the capabilities of underwater vehicles powered by PMSMs.

Current PMSM Solutions

01 Control and optimization of PMSM

Various control strategies and optimization techniques are employed to enhance the performance of Permanent Magnet Synchronous Motors. These include advanced control algorithms, sensorless control methods, and efficiency optimization techniques to improve motor operation and energy efficiency.- Motor design and structure: PMSM designs focus on optimizing the arrangement of permanent magnets and stator windings to enhance efficiency and performance. Innovations include novel rotor configurations, improved magnet placement, and advanced stator designs to reduce cogging torque and increase power density.

- Control strategies and algorithms: Advanced control techniques are developed for PMSMs to improve their dynamic performance, efficiency, and reliability. These include sensorless control methods, adaptive control algorithms, and model predictive control strategies to enhance motor operation under various conditions.

- Efficiency improvement techniques: Various methods are employed to increase the efficiency of PMSMs, including optimizing magnetic circuit design, reducing losses in core materials, and implementing energy recovery systems. These techniques aim to maximize power output while minimizing energy consumption.

- Fault diagnosis and condition monitoring: Systems and methods for real-time fault detection, diagnosis, and condition monitoring of PMSMs are developed to enhance reliability and prevent unexpected failures. These include advanced sensor technologies, data analysis algorithms, and predictive maintenance strategies.

- Application-specific PMSM designs: Specialized PMSM designs are created for specific applications such as electric vehicles, industrial automation, and renewable energy systems. These designs focus on meeting unique requirements like high torque density, wide speed range, or operation in harsh environments.

02 PMSM design and construction

Innovations in PMSM design focus on improving motor structure, magnet arrangement, and material selection. These advancements aim to enhance power density, reduce cogging torque, and optimize overall motor performance for various applications.Expand Specific Solutions03 Thermal management in PMSM

Effective thermal management techniques are crucial for PMSM reliability and performance. This includes innovative cooling systems, temperature monitoring, and thermal modeling to prevent overheating and extend motor lifespan.Expand Specific Solutions04 PMSM for electric vehicle applications

Specialized PMSM designs and control strategies are developed for electric vehicle propulsion systems. These focus on high torque density, wide speed range operation, and energy efficiency to meet the demanding requirements of automotive applications.Expand Specific Solutions05 Fault diagnosis and reliability of PMSM

Advanced fault detection and diagnosis methods are implemented to improve PMSM reliability. These include real-time monitoring systems, predictive maintenance algorithms, and fault-tolerant control strategies to ensure continuous operation and minimize downtime.Expand Specific Solutions

Key Industry Players

The PMSM application in underwater vehicles market is in a growth phase, driven by increasing demand for efficient propulsion systems in marine robotics and autonomous underwater vehicles. The market size is expanding, with projections indicating significant growth potential in the coming years. Technologically, PMSM for underwater applications is maturing, with key players like Harbin Engineering University, Naval Research Laboratory, and iRobot Corp. leading research and development efforts. Companies such as Lockheed Martin, thyssenkrupp Marine Systems, and China National Offshore Oil Corp. are also investing in this technology, indicating its growing importance in the underwater vehicle industry.

Naval Research Laboratory

Technical Solution: The Naval Research Laboratory (NRL) has developed advanced PMSM (Permanent Magnet Synchronous Motor) technology for underwater vehicle propulsion. Their approach focuses on high-efficiency, compact designs optimized for deep-sea environments. NRL's PMSM systems incorporate innovative materials and control algorithms to enhance performance in high-pressure conditions. The motors utilize rare-earth permanent magnets and specialized stator windings to achieve high power density and torque-to-weight ratios[1]. NRL has also implemented advanced sensorless control techniques, enabling precise speed and position control without the need for additional sensors, which is crucial for reliability in harsh underwater environments[3].

Strengths: Expertise in deep-sea applications, high reliability, and advanced control systems. Weaknesses: Potentially higher costs due to specialized materials and limited scalability for commercial applications.

iRobot Corp.

Technical Solution: iRobot Corp. has adapted PMSM technology for use in autonomous underwater vehicles (AUVs) and remotely operated vehicles (ROVs). Their approach focuses on energy efficiency and compact design, crucial for extended underwater missions. iRobot's PMSM systems incorporate advanced thermal management techniques to optimize performance in varying water temperatures. The company has developed proprietary control algorithms that enable precise maneuvering and station-keeping in dynamic underwater environments[2]. iRobot's motors also feature corrosion-resistant materials and sealed designs to ensure longevity in saltwater conditions[4].

Strengths: Expertise in autonomous systems, energy-efficient designs, and robust environmental protection. Weaknesses: Primarily focused on smaller-scale vehicles, potentially limiting applicability to larger underwater systems.

Core PMSM Innovations

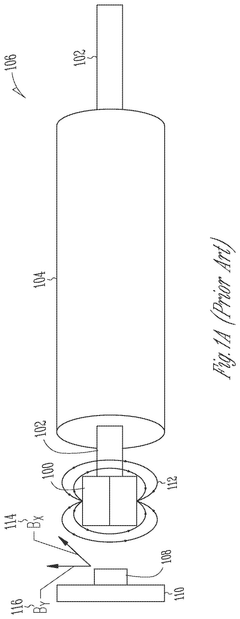

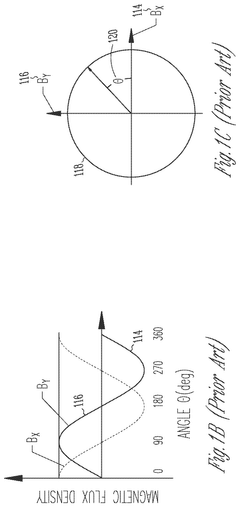

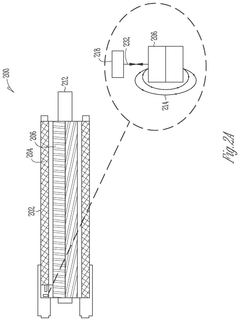

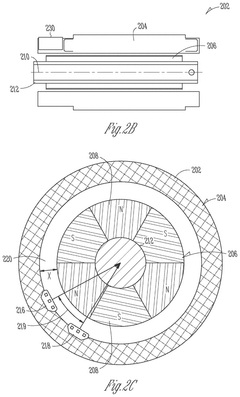

Permanent magnet synchronous motor (PMSM) integrated position sensing

PatentActiveUS12212257B2

Innovation

- The integration of analog magnetic flux sensors within the hollow cylindrical stator of the PMSM, arranged concentrically around the rotational axis at a constant mechanical angle relative to each other, allows for direct measurement of the magnetic flux from the rotor without external obstructions, enabling accurate rotor position sensing and reducing motor size and cost.

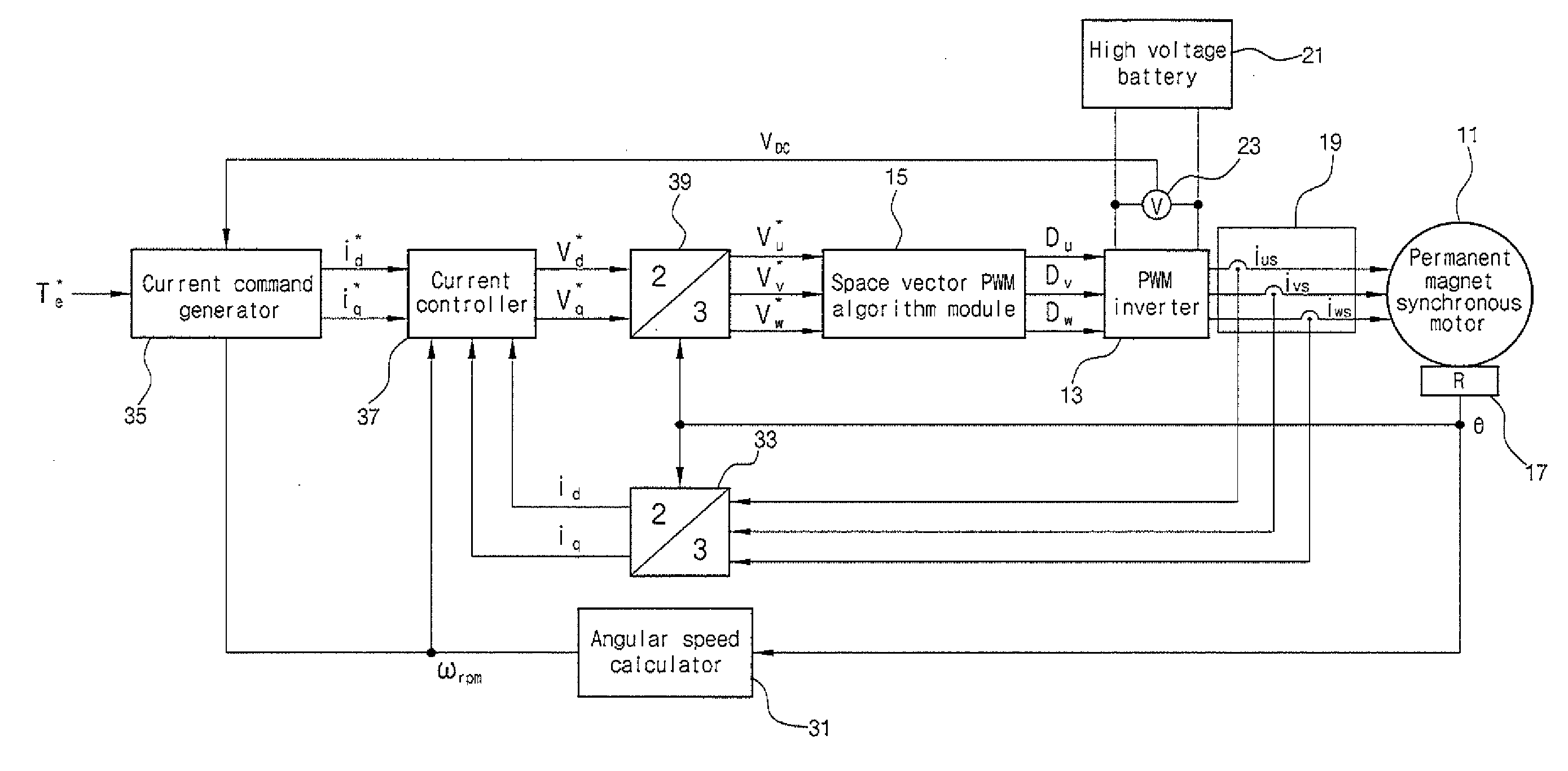

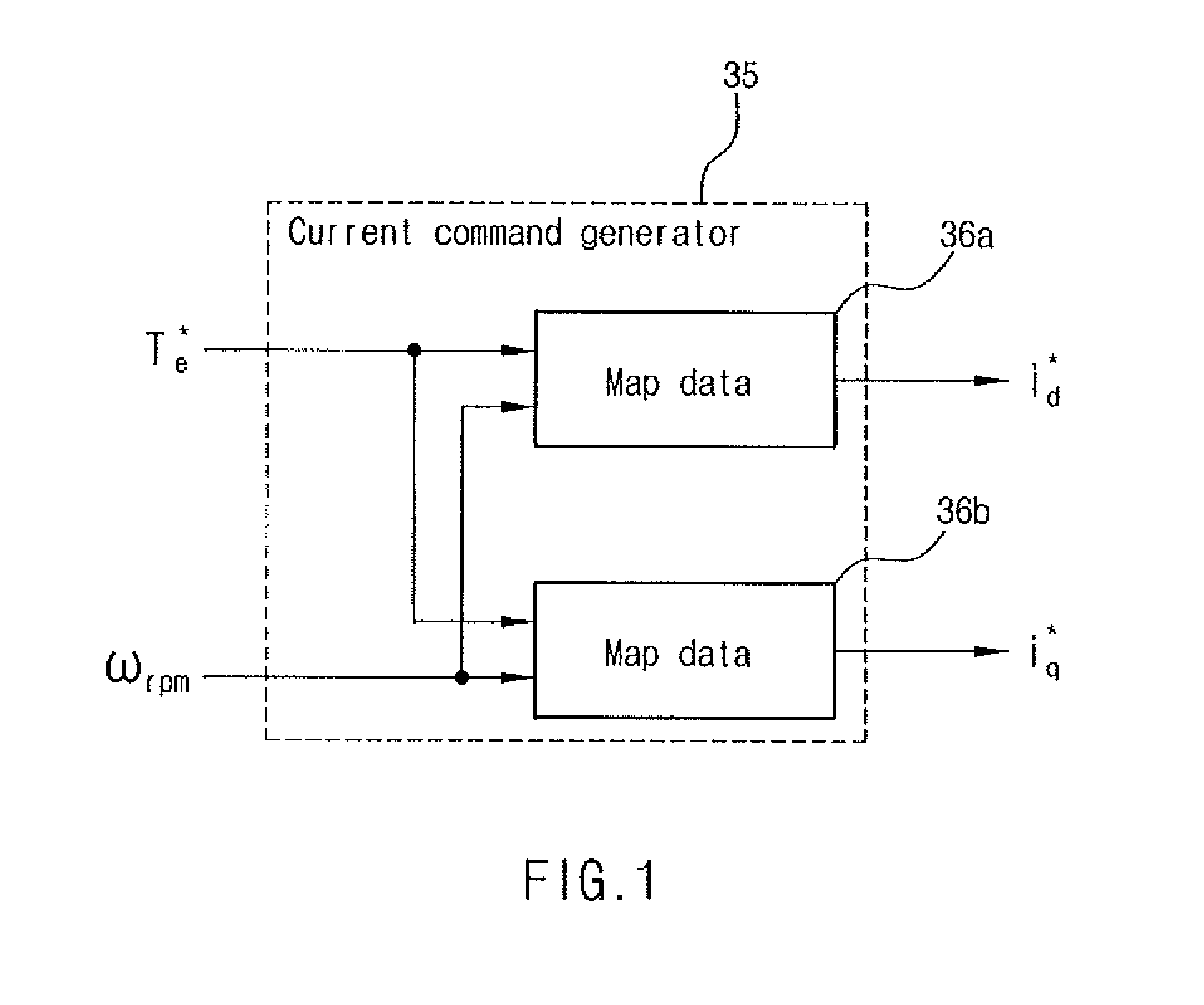

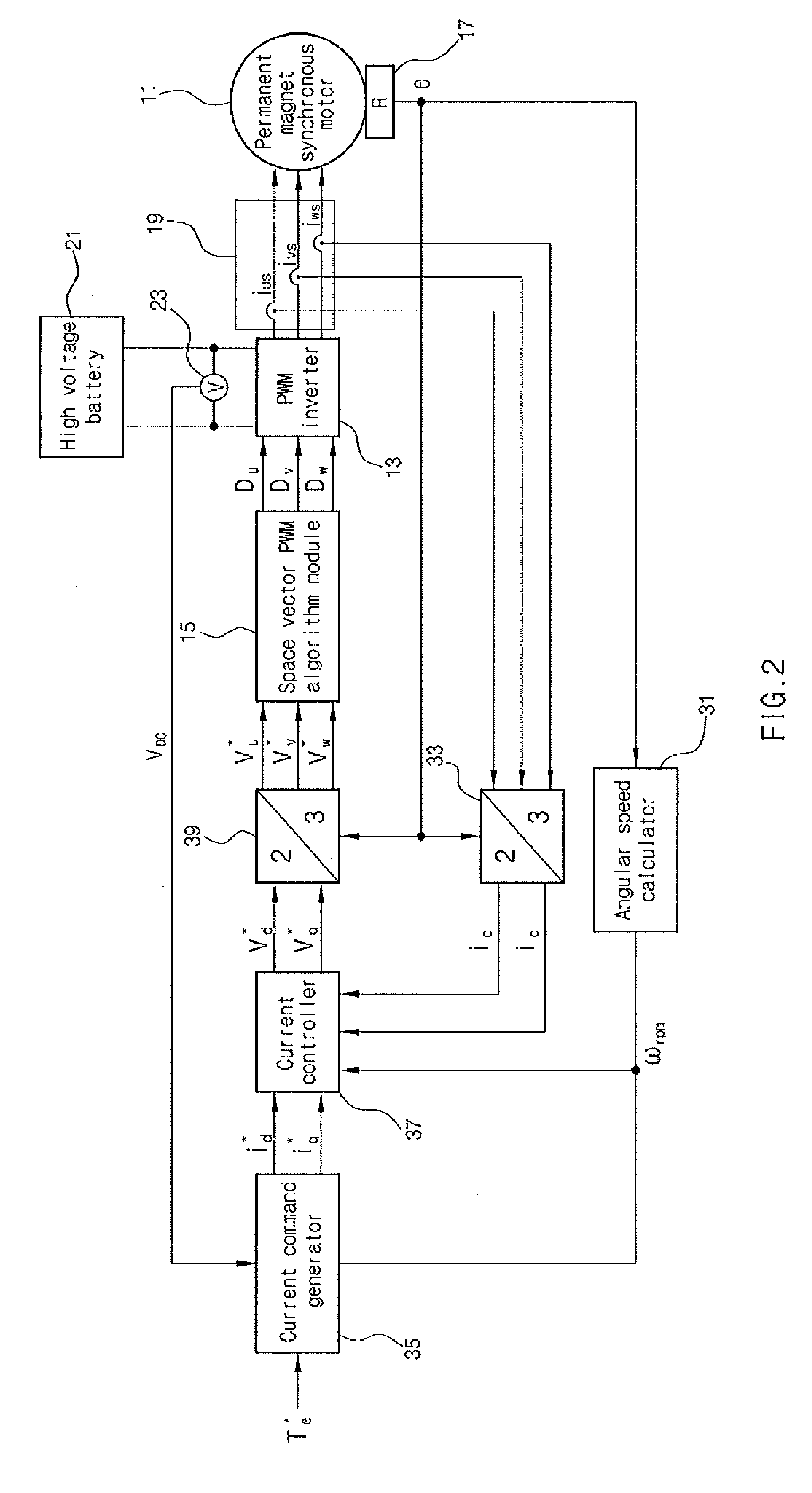

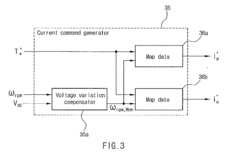

Method for controlling permanent magnet synchronous motor

PatentActiveUS20110241578A1

Innovation

- A method that detects battery voltage variations and compensates for them in real time by calculating a compensated speed, which is used to generate d-axis and q-axis current commands, thereby improving voltage utilization and motor control efficiency.

Environmental Impact

The application of Permanent Magnet Synchronous Motors (PMSM) in underwater vehicles has significant environmental implications. These motors offer improved efficiency and reduced emissions compared to traditional propulsion systems, contributing to a lower overall environmental impact of underwater operations.

PMSM technology in underwater vehicles leads to reduced fuel consumption and decreased greenhouse gas emissions. The high efficiency of these motors translates to less energy waste, which is particularly crucial in marine environments where energy conservation is paramount. This reduction in energy consumption directly correlates with a decrease in the carbon footprint of underwater operations, aligning with global efforts to combat climate change and preserve marine ecosystems.

The use of PMSM in underwater vehicles also minimizes noise pollution in marine environments. Conventional propulsion systems often generate significant underwater noise, which can disrupt marine life and ecosystems. PMSM technology operates more quietly, reducing acoustic disturbances to marine fauna. This is especially important in sensitive marine habitats and during scientific research missions where minimal environmental disturbance is crucial.

Furthermore, PMSM technology reduces the risk of oil leaks and spills associated with hydraulic systems commonly used in traditional underwater propulsion. This minimizes the potential for direct contamination of marine environments, protecting aquatic flora and fauna from harmful pollutants. The elimination of hydraulic fluids also simplifies maintenance procedures, reducing the overall environmental impact of vehicle upkeep.

The compact design of PMSM systems allows for more efficient use of space within underwater vehicles. This can lead to smaller vehicle designs, potentially reducing the physical impact on marine environments during operation and docking. Additionally, the improved maneuverability offered by PMSM technology enables more precise navigation, potentially minimizing unintended contact with sensitive marine structures such as coral reefs.

However, it is important to consider the environmental impact of PMSM production, particularly regarding the sourcing of rare earth materials used in permanent magnets. Responsible sourcing and recycling practices are essential to mitigate potential negative environmental effects associated with the manufacturing process. As technology advances, research into alternative materials and more sustainable production methods may further enhance the environmental benefits of PMSM technology in underwater applications.

In conclusion, while there are considerations regarding production, the overall environmental impact of PMSM application in underwater vehicles is largely positive. The technology contributes to reduced emissions, lower noise pollution, and decreased risk of marine contamination, aligning with global environmental protection goals and sustainable marine operations.

PMSM technology in underwater vehicles leads to reduced fuel consumption and decreased greenhouse gas emissions. The high efficiency of these motors translates to less energy waste, which is particularly crucial in marine environments where energy conservation is paramount. This reduction in energy consumption directly correlates with a decrease in the carbon footprint of underwater operations, aligning with global efforts to combat climate change and preserve marine ecosystems.

The use of PMSM in underwater vehicles also minimizes noise pollution in marine environments. Conventional propulsion systems often generate significant underwater noise, which can disrupt marine life and ecosystems. PMSM technology operates more quietly, reducing acoustic disturbances to marine fauna. This is especially important in sensitive marine habitats and during scientific research missions where minimal environmental disturbance is crucial.

Furthermore, PMSM technology reduces the risk of oil leaks and spills associated with hydraulic systems commonly used in traditional underwater propulsion. This minimizes the potential for direct contamination of marine environments, protecting aquatic flora and fauna from harmful pollutants. The elimination of hydraulic fluids also simplifies maintenance procedures, reducing the overall environmental impact of vehicle upkeep.

The compact design of PMSM systems allows for more efficient use of space within underwater vehicles. This can lead to smaller vehicle designs, potentially reducing the physical impact on marine environments during operation and docking. Additionally, the improved maneuverability offered by PMSM technology enables more precise navigation, potentially minimizing unintended contact with sensitive marine structures such as coral reefs.

However, it is important to consider the environmental impact of PMSM production, particularly regarding the sourcing of rare earth materials used in permanent magnets. Responsible sourcing and recycling practices are essential to mitigate potential negative environmental effects associated with the manufacturing process. As technology advances, research into alternative materials and more sustainable production methods may further enhance the environmental benefits of PMSM technology in underwater applications.

In conclusion, while there are considerations regarding production, the overall environmental impact of PMSM application in underwater vehicles is largely positive. The technology contributes to reduced emissions, lower noise pollution, and decreased risk of marine contamination, aligning with global environmental protection goals and sustainable marine operations.

Reliability Assessment

Reliability assessment is a critical aspect of PMSM (Permanent Magnet Synchronous Motor) applications in underwater vehicles. The harsh marine environment poses significant challenges to the motor's performance and longevity. Saltwater exposure, high pressure, and temperature fluctuations can all contribute to potential failure modes.

One key factor in reliability assessment is the evaluation of motor insulation systems. The insulation must withstand prolonged exposure to saltwater and maintain its integrity under high pressure conditions. Advanced polymer materials and coating technologies are being developed to enhance insulation reliability. These include nano-composite coatings and hydrophobic treatments that repel water and prevent corrosion.

Bearing systems are another crucial component for PMSM reliability in underwater applications. Traditional ball bearings are susceptible to corrosion and wear in marine environments. Magnetic bearings and ceramic bearings have shown promise in improving reliability by eliminating metal-to-metal contact and reducing friction. However, their implementation in underwater vehicles requires careful consideration of size, weight, and power constraints.

Thermal management is essential for maintaining PMSM reliability in underwater vehicles. Overheating can lead to premature failure of motor components and reduced efficiency. Advanced cooling systems, such as liquid cooling with dielectric fluids, are being explored to address this challenge. These systems must be designed to operate effectively under varying pressure conditions and maintain thermal stability across different operating depths.

Reliability assessment also involves analyzing the motor's control systems and power electronics. These components must be ruggedized to withstand the harsh underwater environment and potential electromagnetic interference. Redundancy in control systems and fault-tolerant designs are being implemented to enhance overall system reliability.

Accelerated life testing and environmental stress screening are vital tools in assessing PMSM reliability for underwater applications. These tests simulate extreme conditions and help identify potential failure modes before deployment. Advanced modeling and simulation techniques, including finite element analysis and computational fluid dynamics, are employed to predict motor performance and reliability under various underwater conditions.

Long-term reliability data collection and analysis are crucial for improving PMSM designs for underwater vehicles. Monitoring systems that track motor performance, temperature, vibration, and other key parameters provide valuable insights for predictive maintenance and design optimization. This data-driven approach enables continuous improvement of PMSM reliability in challenging underwater environments.

One key factor in reliability assessment is the evaluation of motor insulation systems. The insulation must withstand prolonged exposure to saltwater and maintain its integrity under high pressure conditions. Advanced polymer materials and coating technologies are being developed to enhance insulation reliability. These include nano-composite coatings and hydrophobic treatments that repel water and prevent corrosion.

Bearing systems are another crucial component for PMSM reliability in underwater applications. Traditional ball bearings are susceptible to corrosion and wear in marine environments. Magnetic bearings and ceramic bearings have shown promise in improving reliability by eliminating metal-to-metal contact and reducing friction. However, their implementation in underwater vehicles requires careful consideration of size, weight, and power constraints.

Thermal management is essential for maintaining PMSM reliability in underwater vehicles. Overheating can lead to premature failure of motor components and reduced efficiency. Advanced cooling systems, such as liquid cooling with dielectric fluids, are being explored to address this challenge. These systems must be designed to operate effectively under varying pressure conditions and maintain thermal stability across different operating depths.

Reliability assessment also involves analyzing the motor's control systems and power electronics. These components must be ruggedized to withstand the harsh underwater environment and potential electromagnetic interference. Redundancy in control systems and fault-tolerant designs are being implemented to enhance overall system reliability.

Accelerated life testing and environmental stress screening are vital tools in assessing PMSM reliability for underwater applications. These tests simulate extreme conditions and help identify potential failure modes before deployment. Advanced modeling and simulation techniques, including finite element analysis and computational fluid dynamics, are employed to predict motor performance and reliability under various underwater conditions.

Long-term reliability data collection and analysis are crucial for improving PMSM designs for underwater vehicles. Monitoring systems that track motor performance, temperature, vibration, and other key parameters provide valuable insights for predictive maintenance and design optimization. This data-driven approach enables continuous improvement of PMSM reliability in challenging underwater environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!