Enhancements in PMSM designs for wearable gadgets

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PMSM Evolution in Wearables

The evolution of Permanent Magnet Synchronous Motors (PMSMs) in wearable technology has been a journey of miniaturization, efficiency enhancement, and integration. Initially, PMSMs were primarily used in larger industrial applications due to their high power density and efficiency. However, as wearable gadgets gained popularity, the demand for compact, lightweight, and energy-efficient motors grew exponentially.

In the early stages of wearable technology, around the mid-2000s, PMSMs were adapted from larger applications but were still relatively bulky for wearable devices. The focus was on reducing size while maintaining performance. This led to the development of smaller magnetic components and more efficient winding techniques.

By the early 2010s, significant advancements in materials science played a crucial role in PMSM evolution for wearables. The introduction of high-performance neodymium magnets allowed for further size reduction without compromising on magnetic flux density. This breakthrough enabled the integration of PMSMs into a wider range of wearable devices, including smartwatches and fitness trackers.

The mid-2010s saw a shift towards optimizing energy efficiency in PMSMs for wearables. Engineers focused on reducing core losses and improving motor control algorithms. This period also marked the beginning of integrating PMSMs with advanced sensor technologies, enabling more precise motion tracking and haptic feedback in wearable devices.

Recent years have witnessed a convergence of PMSM technology with flexible electronics. This has led to the development of ultra-thin, flexible PMSMs that can conform to the contours of the human body. These motors are now being incorporated into smart textiles and skin-adhered wearables, opening up new possibilities in health monitoring and augmented reality applications.

The latest trend in PMSM evolution for wearables is the integration of smart materials and adaptive control systems. These innovations allow PMSMs to adjust their performance based on user activity and environmental conditions, further enhancing energy efficiency and user experience. Additionally, there's a growing focus on sustainable manufacturing processes and materials for PMSMs, aligning with the global push for eco-friendly technologies in consumer electronics.

Looking ahead, the evolution of PMSMs in wearables is expected to continue towards even smaller form factors, higher energy densities, and seamless integration with other wearable components. The future may see the development of self-powered PMSMs that can harvest energy from body movements, potentially revolutionizing the power management in wearable devices.

In the early stages of wearable technology, around the mid-2000s, PMSMs were adapted from larger applications but were still relatively bulky for wearable devices. The focus was on reducing size while maintaining performance. This led to the development of smaller magnetic components and more efficient winding techniques.

By the early 2010s, significant advancements in materials science played a crucial role in PMSM evolution for wearables. The introduction of high-performance neodymium magnets allowed for further size reduction without compromising on magnetic flux density. This breakthrough enabled the integration of PMSMs into a wider range of wearable devices, including smartwatches and fitness trackers.

The mid-2010s saw a shift towards optimizing energy efficiency in PMSMs for wearables. Engineers focused on reducing core losses and improving motor control algorithms. This period also marked the beginning of integrating PMSMs with advanced sensor technologies, enabling more precise motion tracking and haptic feedback in wearable devices.

Recent years have witnessed a convergence of PMSM technology with flexible electronics. This has led to the development of ultra-thin, flexible PMSMs that can conform to the contours of the human body. These motors are now being incorporated into smart textiles and skin-adhered wearables, opening up new possibilities in health monitoring and augmented reality applications.

The latest trend in PMSM evolution for wearables is the integration of smart materials and adaptive control systems. These innovations allow PMSMs to adjust their performance based on user activity and environmental conditions, further enhancing energy efficiency and user experience. Additionally, there's a growing focus on sustainable manufacturing processes and materials for PMSMs, aligning with the global push for eco-friendly technologies in consumer electronics.

Looking ahead, the evolution of PMSMs in wearables is expected to continue towards even smaller form factors, higher energy densities, and seamless integration with other wearable components. The future may see the development of self-powered PMSMs that can harvest energy from body movements, potentially revolutionizing the power management in wearable devices.

Market Demand Analysis

The market demand for enhanced Permanent Magnet Synchronous Motors (PMSMs) in wearable gadgets has been experiencing significant growth in recent years. This surge is primarily driven by the increasing consumer appetite for compact, efficient, and high-performance wearable devices across various sectors, including healthcare, fitness, and consumer electronics.

In the healthcare sector, wearable devices equipped with PMSMs are gaining traction for applications such as portable medical equipment and rehabilitation devices. These motors enable precise control and smooth operation, crucial for medical-grade wearables. The aging population and the trend towards remote patient monitoring have further accelerated the demand for such devices.

The fitness and sports industry has also become a major driver for PMSM-equipped wearables. Smart watches, fitness trackers, and other performance-monitoring devices rely on efficient motor designs to provide accurate measurements and extended battery life. As health consciousness grows globally, the market for these devices is expected to expand substantially.

Consumer electronics represent another significant market segment for PMSM-enhanced wearables. From smart glasses to augmented reality headsets, these devices require compact, powerful motors for features like haptic feedback and optical adjustments. The increasing integration of wearable technology into daily life is fueling demand for more sophisticated and energy-efficient motor designs.

The automotive industry is emerging as a potential growth area for PMSM-equipped wearables. Advanced driver assistance systems (ADAS) and autonomous driving technologies are incorporating wearable devices for enhanced safety and user experience, creating new opportunities for PMSM applications.

Market analysis indicates that the miniaturization trend in wearable technology is a key factor driving innovations in PMSM designs. Consumers are demanding smaller, lighter devices with improved functionality, pushing manufacturers to develop more compact and efficient motor solutions.

Energy efficiency remains a critical consideration in the wearable gadget market. Enhanced PMSM designs that offer higher power density and lower energy consumption are highly sought after, as they directly impact device battery life and overall user experience.

The global market for wearable devices is projected to grow substantially in the coming years, with a corresponding increase in demand for advanced PMSM solutions. This growth is expected to be particularly strong in regions with high technology adoption rates, such as North America, Europe, and parts of Asia.

As the wearable technology ecosystem continues to evolve, there is an increasing need for customized PMSM designs that can meet the specific requirements of different wearable applications. This trend is likely to drive further innovation and specialization in the PMSM market for wearable gadgets.

In the healthcare sector, wearable devices equipped with PMSMs are gaining traction for applications such as portable medical equipment and rehabilitation devices. These motors enable precise control and smooth operation, crucial for medical-grade wearables. The aging population and the trend towards remote patient monitoring have further accelerated the demand for such devices.

The fitness and sports industry has also become a major driver for PMSM-equipped wearables. Smart watches, fitness trackers, and other performance-monitoring devices rely on efficient motor designs to provide accurate measurements and extended battery life. As health consciousness grows globally, the market for these devices is expected to expand substantially.

Consumer electronics represent another significant market segment for PMSM-enhanced wearables. From smart glasses to augmented reality headsets, these devices require compact, powerful motors for features like haptic feedback and optical adjustments. The increasing integration of wearable technology into daily life is fueling demand for more sophisticated and energy-efficient motor designs.

The automotive industry is emerging as a potential growth area for PMSM-equipped wearables. Advanced driver assistance systems (ADAS) and autonomous driving technologies are incorporating wearable devices for enhanced safety and user experience, creating new opportunities for PMSM applications.

Market analysis indicates that the miniaturization trend in wearable technology is a key factor driving innovations in PMSM designs. Consumers are demanding smaller, lighter devices with improved functionality, pushing manufacturers to develop more compact and efficient motor solutions.

Energy efficiency remains a critical consideration in the wearable gadget market. Enhanced PMSM designs that offer higher power density and lower energy consumption are highly sought after, as they directly impact device battery life and overall user experience.

The global market for wearable devices is projected to grow substantially in the coming years, with a corresponding increase in demand for advanced PMSM solutions. This growth is expected to be particularly strong in regions with high technology adoption rates, such as North America, Europe, and parts of Asia.

As the wearable technology ecosystem continues to evolve, there is an increasing need for customized PMSM designs that can meet the specific requirements of different wearable applications. This trend is likely to drive further innovation and specialization in the PMSM market for wearable gadgets.

PMSM Challenges in Wearables

The integration of Permanent Magnet Synchronous Motors (PMSMs) into wearable gadgets presents a unique set of challenges that demand innovative solutions. The miniaturization requirements of wearable devices place significant constraints on motor size and weight, necessitating a delicate balance between performance and compactness. Engineers must grapple with the task of maintaining high efficiency and torque output while dramatically reducing the motor's footprint.

Thermal management emerges as a critical concern in PMSM designs for wearables. The close proximity to the human body limits the permissible operating temperatures, requiring advanced cooling strategies and materials with superior heat dissipation properties. This challenge is compounded by the need for sealed, water-resistant designs in many wearable applications, further restricting heat dissipation options.

Power consumption optimization stands as another formidable hurdle. Wearable devices typically rely on small batteries, making energy efficiency paramount. PMSM designs must incorporate sophisticated control algorithms and low-loss materials to maximize runtime without compromising performance. This often involves a trade-off between motor efficiency and the complexity of the control system.

Noise and vibration reduction pose significant challenges in wearable PMSM applications. The close contact with the user's body amplifies the perception of mechanical disturbances, necessitating advanced rotor balancing techniques and innovative damping solutions. Engineers must explore novel bearing designs and motor structures to minimize acoustic emissions and vibrational feedback.

Durability and reliability under varied environmental conditions present ongoing challenges. Wearable devices are subjected to frequent movement, impacts, and exposure to moisture and temperature fluctuations. PMSM designs must incorporate robust construction techniques and materials that can withstand these stresses while maintaining consistent performance over an extended lifespan.

The integration of sensors and feedback mechanisms within the confined space of wearable PMSMs adds another layer of complexity. Accurate position sensing and temperature monitoring are crucial for optimal motor control and safety, yet traditional sensing solutions may be too bulky or power-hungry for wearable applications. This drives the need for innovative, miniaturized sensing technologies that can be seamlessly integrated into the motor assembly.

Manufacturability and cost-effectiveness remain persistent challenges in PMSM designs for wearables. The intricate nature of miniaturized motors, combined with the need for high-precision components, can lead to increased production costs. Designers must explore novel manufacturing techniques and materials to streamline production processes without compromising quality or performance.

Thermal management emerges as a critical concern in PMSM designs for wearables. The close proximity to the human body limits the permissible operating temperatures, requiring advanced cooling strategies and materials with superior heat dissipation properties. This challenge is compounded by the need for sealed, water-resistant designs in many wearable applications, further restricting heat dissipation options.

Power consumption optimization stands as another formidable hurdle. Wearable devices typically rely on small batteries, making energy efficiency paramount. PMSM designs must incorporate sophisticated control algorithms and low-loss materials to maximize runtime without compromising performance. This often involves a trade-off between motor efficiency and the complexity of the control system.

Noise and vibration reduction pose significant challenges in wearable PMSM applications. The close contact with the user's body amplifies the perception of mechanical disturbances, necessitating advanced rotor balancing techniques and innovative damping solutions. Engineers must explore novel bearing designs and motor structures to minimize acoustic emissions and vibrational feedback.

Durability and reliability under varied environmental conditions present ongoing challenges. Wearable devices are subjected to frequent movement, impacts, and exposure to moisture and temperature fluctuations. PMSM designs must incorporate robust construction techniques and materials that can withstand these stresses while maintaining consistent performance over an extended lifespan.

The integration of sensors and feedback mechanisms within the confined space of wearable PMSMs adds another layer of complexity. Accurate position sensing and temperature monitoring are crucial for optimal motor control and safety, yet traditional sensing solutions may be too bulky or power-hungry for wearable applications. This drives the need for innovative, miniaturized sensing technologies that can be seamlessly integrated into the motor assembly.

Manufacturability and cost-effectiveness remain persistent challenges in PMSM designs for wearables. The intricate nature of miniaturized motors, combined with the need for high-precision components, can lead to increased production costs. Designers must explore novel manufacturing techniques and materials to streamline production processes without compromising quality or performance.

Current PMSM Solutions

01 Rotor design optimization

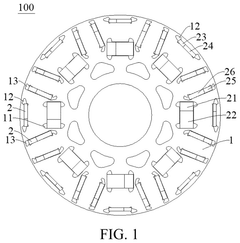

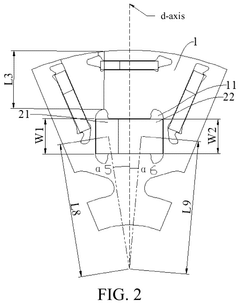

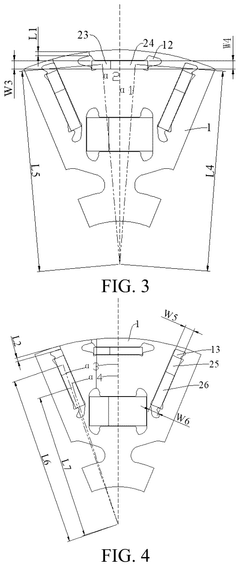

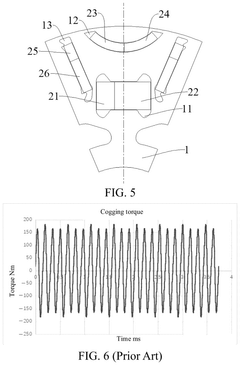

Enhancing PMSM performance through improved rotor designs, including optimized magnet arrangements, flux barrier configurations, and rotor core structures. These advancements aim to increase torque density, reduce cogging torque, and improve overall efficiency of the motor.- Rotor design optimization: Enhancing PMSM performance through improved rotor design, including optimized magnet arrangements, flux barrier configurations, and rotor core structures. These improvements aim to increase torque density, reduce cogging torque, and enhance overall motor efficiency.

- Stator winding configurations: Advanced stator winding techniques for PMSMs, focusing on innovative coil arrangements, distributed and concentrated winding designs, and optimized slot-pole combinations. These enhancements aim to improve power density, reduce copper losses, and enhance motor performance across various operating conditions.

- Thermal management and cooling systems: Implementing effective thermal management solutions for PMSMs, including advanced cooling techniques, heat dissipation structures, and temperature monitoring systems. These enhancements aim to improve motor reliability, extend operational life, and maintain high performance under demanding conditions.

- Control strategies and power electronics: Developing sophisticated control algorithms and power electronic systems for PMSMs, including advanced sensorless control techniques, adaptive control strategies, and high-efficiency inverter designs. These enhancements aim to improve motor dynamics, efficiency, and overall system performance.

- Materials and manufacturing techniques: Exploring novel materials and manufacturing processes for PMSM components, including advanced magnetic materials, high-performance electrical steels, and innovative fabrication methods. These enhancements aim to improve motor performance, reduce costs, and enhance manufacturability.

02 Stator winding configurations

Innovative stator winding designs and arrangements to enhance PMSM performance. This includes concentrated windings, distributed windings, and hybrid configurations to optimize copper utilization, reduce losses, and improve power density.Expand Specific Solutions03 Thermal management solutions

Advanced cooling techniques and thermal management systems for PMSMs to improve heat dissipation, increase power density, and enhance overall motor reliability. This includes innovative cooling channel designs, advanced materials, and integrated cooling solutions.Expand Specific Solutions04 Control strategies and algorithms

Development of sophisticated control algorithms and strategies to optimize PMSM performance. This includes sensorless control techniques, advanced vector control methods, and adaptive control algorithms to improve efficiency, dynamic response, and reliability across various operating conditions.Expand Specific Solutions05 Integration of advanced materials

Incorporation of novel materials in PMSM design, such as high-performance magnetic materials, advanced insulation materials, and innovative core materials. These materials aim to improve magnetic properties, reduce losses, and enhance overall motor performance and efficiency.Expand Specific Solutions

Key PMSM Manufacturers

The market for PMSM designs in wearable gadgets is in a growth phase, driven by increasing demand for compact, efficient motors in smartwatches, fitness trackers, and other wearable devices. The global market size is expanding rapidly, with key players like Samsung Electronics, Sony Group Corp., and Goertek Inc. leading innovation. Technological maturity varies, with established companies like Gree Electric Appliances and Koninklijke Philips NV leveraging their expertise in motor design, while newer entrants like VueReal and Acurable are pushing boundaries with novel approaches. Research institutions such as Harbin Institute of Technology Shenzhen and Fudan University are contributing to advancements, indicating a dynamic ecosystem of industry and academia collaboration.

Koninklijke Philips NV

Technical Solution: Philips has focused on enhancing PMSM designs for medical wearables, prioritizing precision and reliability. Their approach includes the development of ultra-low-noise PMSMs suitable for sensitive medical applications. They have implemented advanced sensorless control techniques to improve the accuracy of motor positioning while reducing the overall size of the motor system[2]. Philips has also developed a unique rotor design that minimizes cogging torque, crucial for smooth operation in medical wearables[4].

Strengths: Expertise in medical-grade precision and reliability, advanced sensorless control techniques. Weaknesses: Potentially limited application outside of medical wearables, higher costs due to stringent quality requirements.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed advanced PMSM designs for wearable gadgets, focusing on miniaturization and energy efficiency. Their approach involves using high-performance magnets and optimized stator designs to reduce size while maintaining power output. They have implemented a novel cooling system that allows for higher power density in compact wearable devices[1]. Samsung's PMSMs utilize advanced control algorithms to maximize efficiency across various operating conditions, crucial for the variable loads experienced in wearables[3].

Strengths: Industry-leading miniaturization techniques, advanced cooling systems, and sophisticated control algorithms. Weaknesses: Potentially higher production costs due to use of premium materials and complex manufacturing processes.

PMSM Innovation Analysis

Rotor and motor

PatentPendingUS20250112510A1

Innovation

- The rotor design includes a rotor core with multiple mounting grooves, where permanent magnets with different materials are arranged in a segmented manner. This configuration reduces cogging torque, torque fluctuation, and jitter, while minimizing the use of rare earth materials to lower costs.

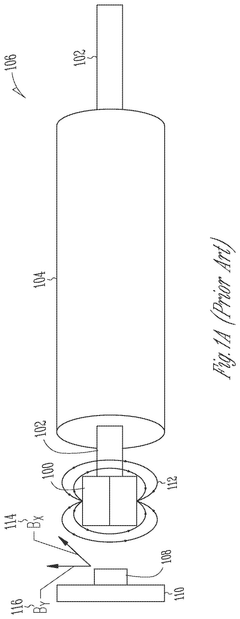

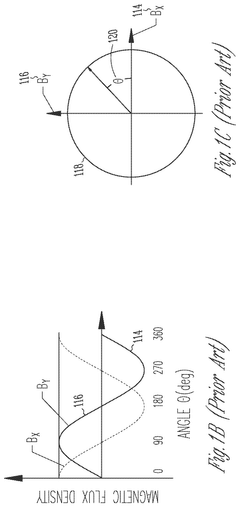

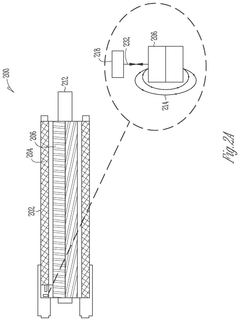

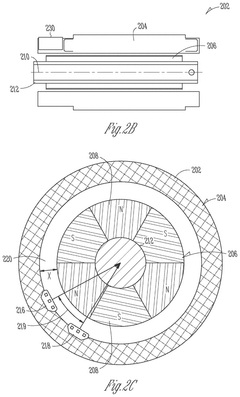

Permanent magnet synchronous motor (PMSM) integrated position sensing

PatentActiveUS12212257B2

Innovation

- The integration of analog magnetic flux sensors within the hollow cylindrical stator of the PMSM, arranged concentrically around the rotational axis at a constant mechanical angle relative to each other, allows for direct measurement of the magnetic flux from the rotor without external obstructions, enabling accurate rotor position sensing and reducing motor size and cost.

Energy Efficiency Standards

Energy efficiency standards play a crucial role in the development and implementation of Permanent Magnet Synchronous Motors (PMSMs) for wearable gadgets. These standards serve as benchmarks for manufacturers and designers to ensure that their products meet specific energy performance criteria, ultimately contributing to reduced power consumption and extended battery life in wearable devices.

The International Electrotechnical Commission (IEC) has established several standards relevant to PMSMs in wearable applications. IEC 60034-30-1 defines efficiency classes for electric motors, including those used in small-scale applications. While not specifically tailored for wearable gadgets, these standards provide a foundation for energy efficiency considerations in PMSM designs.

In the context of wearable technology, energy efficiency standards often focus on power density and overall system efficiency. The IEEE 1528 standard, which addresses electromagnetic compatibility in wireless devices, indirectly influences PMSM designs by setting limits on electromagnetic emissions. This standard ensures that motors in wearable gadgets do not interfere with other electronic components or nearby devices.

The European Union's Ecodesign Directive (2009/125/EC) sets energy efficiency requirements for various products, including small electric motors. Although not explicitly targeting wearable gadgets, these regulations have driven innovations in motor design that benefit the wearable technology sector. Manufacturers must consider these standards when developing PMSMs for the European market.

In the United States, the Department of Energy (DOE) has established energy conservation standards for small electric motors under 10 CFR Part 431. While these standards primarily address larger motors, they have influenced the development of more efficient motor technologies that can be scaled down for use in wearable devices.

The growing emphasis on energy efficiency in wearable technology has led to the development of industry-specific guidelines. The Wearable Technologies Working Group (WTWG) of the Consumer Technology Association (CTA) has been working on creating standards and best practices for wearable devices, including considerations for energy-efficient motor designs.

As the wearable technology market continues to expand, there is an increasing need for specialized energy efficiency standards tailored to the unique requirements of PMSMs in wearable gadgets. Future standards are likely to address factors such as miniaturization, thermal management, and integration with energy harvesting technologies to further optimize the performance of these motors in wearable applications.

The International Electrotechnical Commission (IEC) has established several standards relevant to PMSMs in wearable applications. IEC 60034-30-1 defines efficiency classes for electric motors, including those used in small-scale applications. While not specifically tailored for wearable gadgets, these standards provide a foundation for energy efficiency considerations in PMSM designs.

In the context of wearable technology, energy efficiency standards often focus on power density and overall system efficiency. The IEEE 1528 standard, which addresses electromagnetic compatibility in wireless devices, indirectly influences PMSM designs by setting limits on electromagnetic emissions. This standard ensures that motors in wearable gadgets do not interfere with other electronic components or nearby devices.

The European Union's Ecodesign Directive (2009/125/EC) sets energy efficiency requirements for various products, including small electric motors. Although not explicitly targeting wearable gadgets, these regulations have driven innovations in motor design that benefit the wearable technology sector. Manufacturers must consider these standards when developing PMSMs for the European market.

In the United States, the Department of Energy (DOE) has established energy conservation standards for small electric motors under 10 CFR Part 431. While these standards primarily address larger motors, they have influenced the development of more efficient motor technologies that can be scaled down for use in wearable devices.

The growing emphasis on energy efficiency in wearable technology has led to the development of industry-specific guidelines. The Wearable Technologies Working Group (WTWG) of the Consumer Technology Association (CTA) has been working on creating standards and best practices for wearable devices, including considerations for energy-efficient motor designs.

As the wearable technology market continues to expand, there is an increasing need for specialized energy efficiency standards tailored to the unique requirements of PMSMs in wearable gadgets. Future standards are likely to address factors such as miniaturization, thermal management, and integration with energy harvesting technologies to further optimize the performance of these motors in wearable applications.

Miniaturization Techniques

Miniaturization techniques play a crucial role in enhancing Permanent Magnet Synchronous Motor (PMSM) designs for wearable gadgets. As the demand for smaller, lighter, and more efficient wearable devices continues to grow, the need for compact and powerful motors becomes increasingly important.

One of the primary miniaturization techniques employed in PMSM designs is the use of advanced materials. High-performance magnetic materials, such as neodymium-iron-boron (NdFeB) alloys, allow for stronger magnetic fields in smaller volumes. This enables the reduction of motor size while maintaining or even improving performance characteristics.

Optimized winding techniques also contribute significantly to motor miniaturization. Multi-layer winding and concentrated winding methods help maximize the copper fill factor, reducing the overall size of the stator while maintaining high torque output. These techniques also minimize end-turn losses, further improving efficiency in compact designs.

Advanced manufacturing processes, such as 3D printing and micro-machining, enable the production of complex geometries and intricate components. These technologies allow for the creation of optimized motor structures that were previously impossible or impractical to manufacture, leading to more compact and efficient designs.

Thermal management is a critical aspect of miniaturization in PMSM designs for wearable gadgets. Innovative cooling solutions, such as integrated heat pipes or phase-change materials, help dissipate heat more effectively in smaller form factors. This allows for higher power densities without compromising reliability or performance.

Integration of motor components with other device elements is another key miniaturization strategy. By combining the motor with gearboxes, sensors, or control electronics in a single package, overall device size can be reduced. This approach also often leads to improved system efficiency and reduced assembly complexity.

Novel rotor designs, such as halbach arrays or spoke-type configurations, enable higher torque density in compact packages. These designs optimize the magnetic field distribution, allowing for smaller motors that can deliver the required performance for wearable applications.

Advancements in control algorithms and power electronics also contribute to miniaturization efforts. More sophisticated control strategies can extract maximum performance from smaller motors, while compact, efficient power electronics reduce the overall footprint of the motor drive system.

As miniaturization techniques continue to evolve, the boundaries of PMSM design for wearable gadgets are constantly being pushed. These advancements not only enable smaller and more powerful devices but also open up new possibilities for wearable technology applications across various industries.

One of the primary miniaturization techniques employed in PMSM designs is the use of advanced materials. High-performance magnetic materials, such as neodymium-iron-boron (NdFeB) alloys, allow for stronger magnetic fields in smaller volumes. This enables the reduction of motor size while maintaining or even improving performance characteristics.

Optimized winding techniques also contribute significantly to motor miniaturization. Multi-layer winding and concentrated winding methods help maximize the copper fill factor, reducing the overall size of the stator while maintaining high torque output. These techniques also minimize end-turn losses, further improving efficiency in compact designs.

Advanced manufacturing processes, such as 3D printing and micro-machining, enable the production of complex geometries and intricate components. These technologies allow for the creation of optimized motor structures that were previously impossible or impractical to manufacture, leading to more compact and efficient designs.

Thermal management is a critical aspect of miniaturization in PMSM designs for wearable gadgets. Innovative cooling solutions, such as integrated heat pipes or phase-change materials, help dissipate heat more effectively in smaller form factors. This allows for higher power densities without compromising reliability or performance.

Integration of motor components with other device elements is another key miniaturization strategy. By combining the motor with gearboxes, sensors, or control electronics in a single package, overall device size can be reduced. This approach also often leads to improved system efficiency and reduced assembly complexity.

Novel rotor designs, such as halbach arrays or spoke-type configurations, enable higher torque density in compact packages. These designs optimize the magnetic field distribution, allowing for smaller motors that can deliver the required performance for wearable applications.

Advancements in control algorithms and power electronics also contribute to miniaturization efforts. More sophisticated control strategies can extract maximum performance from smaller motors, while compact, efficient power electronics reduce the overall footprint of the motor drive system.

As miniaturization techniques continue to evolve, the boundaries of PMSM design for wearable gadgets are constantly being pushed. These advancements not only enable smaller and more powerful devices but also open up new possibilities for wearable technology applications across various industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!