Hybrid PMSM systems for multi-mission satellites

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PMSM Satellite Evolution

The evolution of Permanent Magnet Synchronous Motors (PMSM) in satellite applications has been a significant technological advancement in the aerospace industry. Initially, satellites relied on conventional electric propulsion systems, which were less efficient and had limited capabilities. The introduction of PMSM technology marked a turning point in satellite propulsion and power generation.

In the early stages of PMSM adoption, these motors were primarily used for attitude control and momentum management in satellites. Their compact size, high efficiency, and precise control capabilities made them ideal for these applications. As the technology matured, PMSMs began to play a more crucial role in satellite systems, expanding their use to power generation and propulsion.

The development of hybrid PMSM systems for multi-mission satellites represents a significant leap forward in satellite technology. These systems combine the advantages of PMSMs with other propulsion technologies, creating versatile and adaptable satellite platforms. The hybrid approach allows satellites to perform a wide range of missions with improved efficiency and reliability.

One of the key milestones in PMSM satellite evolution was the integration of advanced control algorithms and power electronics. These advancements enabled better motor performance, increased power density, and improved overall system efficiency. The incorporation of rare-earth permanent magnets further enhanced the power-to-weight ratio of PMSMs, making them even more suitable for space applications.

As satellite missions became more complex and demanding, the role of PMSMs expanded to include electric propulsion for orbit raising and station-keeping. This application significantly reduced the amount of propellant required for these maneuvers, extending satellite lifespans and reducing launch costs. The ability to use PMSMs for both attitude control and propulsion led to more compact and efficient satellite designs.

Recent developments in PMSM technology for satellites have focused on improving reliability, thermal management, and radiation resistance. These enhancements have made PMSMs more robust and suitable for long-duration missions in harsh space environments. Additionally, the integration of smart sensors and advanced diagnostic systems has improved the monitoring and maintenance of PMSM-based satellite systems.

The evolution of PMSM technology in satellites has also been driven by the growing demand for small satellites and constellations. These applications require highly efficient, compact, and reliable propulsion systems, which PMSMs are well-suited to provide. The scalability of PMSM technology has enabled its use in a wide range of satellite sizes, from CubeSats to large geostationary platforms.

In the early stages of PMSM adoption, these motors were primarily used for attitude control and momentum management in satellites. Their compact size, high efficiency, and precise control capabilities made them ideal for these applications. As the technology matured, PMSMs began to play a more crucial role in satellite systems, expanding their use to power generation and propulsion.

The development of hybrid PMSM systems for multi-mission satellites represents a significant leap forward in satellite technology. These systems combine the advantages of PMSMs with other propulsion technologies, creating versatile and adaptable satellite platforms. The hybrid approach allows satellites to perform a wide range of missions with improved efficiency and reliability.

One of the key milestones in PMSM satellite evolution was the integration of advanced control algorithms and power electronics. These advancements enabled better motor performance, increased power density, and improved overall system efficiency. The incorporation of rare-earth permanent magnets further enhanced the power-to-weight ratio of PMSMs, making them even more suitable for space applications.

As satellite missions became more complex and demanding, the role of PMSMs expanded to include electric propulsion for orbit raising and station-keeping. This application significantly reduced the amount of propellant required for these maneuvers, extending satellite lifespans and reducing launch costs. The ability to use PMSMs for both attitude control and propulsion led to more compact and efficient satellite designs.

Recent developments in PMSM technology for satellites have focused on improving reliability, thermal management, and radiation resistance. These enhancements have made PMSMs more robust and suitable for long-duration missions in harsh space environments. Additionally, the integration of smart sensors and advanced diagnostic systems has improved the monitoring and maintenance of PMSM-based satellite systems.

The evolution of PMSM technology in satellites has also been driven by the growing demand for small satellites and constellations. These applications require highly efficient, compact, and reliable propulsion systems, which PMSMs are well-suited to provide. The scalability of PMSM technology has enabled its use in a wide range of satellite sizes, from CubeSats to large geostationary platforms.

Multi-Mission Demand

The demand for multi-mission satellites has been steadily increasing in recent years, driven by the growing need for versatile and cost-effective space-based solutions. These satellites are designed to perform multiple functions and serve various purposes, making them highly attractive for both commercial and government applications. The market for multi-mission satellites is expected to expand significantly in the coming years, with a projected compound annual growth rate of over 5% through 2025.

One of the key factors fueling this demand is the rising interest in Earth observation and remote sensing capabilities. Governments, environmental agencies, and private companies are seeking more comprehensive and frequent data collection for applications such as climate monitoring, disaster management, and urban planning. Multi-mission satellites equipped with advanced sensors and imaging systems can provide valuable insights across these diverse domains, making them a preferred choice for many stakeholders.

The telecommunications sector is another major driver of multi-mission satellite demand. As global connectivity requirements continue to grow, especially in remote and underserved areas, multi-mission satellites offer a flexible solution for providing broadband internet, mobile communications, and broadcasting services. The ability to reconfigure and repurpose these satellites in orbit adds to their appeal, allowing operators to adapt to changing market needs and technological advancements.

In the defense and security sector, multi-mission satellites are becoming increasingly important for intelligence gathering, surveillance, and reconnaissance activities. The ability to integrate multiple payloads on a single platform provides military and government agencies with enhanced situational awareness and operational flexibility. This trend is expected to continue as geopolitical tensions and security concerns drive investments in space-based assets.

The scientific community also benefits from multi-mission satellites, as they enable researchers to conduct diverse experiments and observations simultaneously. This approach not only reduces costs but also facilitates interdisciplinary studies and collaborations. Universities and research institutions are showing growing interest in participating in multi-mission satellite projects, further expanding the market potential.

As the space industry moves towards more sustainable and efficient practices, multi-mission satellites align well with these objectives. By consolidating multiple functions into a single platform, these satellites help reduce launch costs, minimize space debris, and optimize resource utilization. This sustainability aspect is becoming increasingly important for both commercial operators and government agencies, driving further demand for multi-mission satellite solutions.

One of the key factors fueling this demand is the rising interest in Earth observation and remote sensing capabilities. Governments, environmental agencies, and private companies are seeking more comprehensive and frequent data collection for applications such as climate monitoring, disaster management, and urban planning. Multi-mission satellites equipped with advanced sensors and imaging systems can provide valuable insights across these diverse domains, making them a preferred choice for many stakeholders.

The telecommunications sector is another major driver of multi-mission satellite demand. As global connectivity requirements continue to grow, especially in remote and underserved areas, multi-mission satellites offer a flexible solution for providing broadband internet, mobile communications, and broadcasting services. The ability to reconfigure and repurpose these satellites in orbit adds to their appeal, allowing operators to adapt to changing market needs and technological advancements.

In the defense and security sector, multi-mission satellites are becoming increasingly important for intelligence gathering, surveillance, and reconnaissance activities. The ability to integrate multiple payloads on a single platform provides military and government agencies with enhanced situational awareness and operational flexibility. This trend is expected to continue as geopolitical tensions and security concerns drive investments in space-based assets.

The scientific community also benefits from multi-mission satellites, as they enable researchers to conduct diverse experiments and observations simultaneously. This approach not only reduces costs but also facilitates interdisciplinary studies and collaborations. Universities and research institutions are showing growing interest in participating in multi-mission satellite projects, further expanding the market potential.

As the space industry moves towards more sustainable and efficient practices, multi-mission satellites align well with these objectives. By consolidating multiple functions into a single platform, these satellites help reduce launch costs, minimize space debris, and optimize resource utilization. This sustainability aspect is becoming increasingly important for both commercial operators and government agencies, driving further demand for multi-mission satellite solutions.

Hybrid PMSM Challenges

The development of Hybrid Permanent Magnet Synchronous Motor (PMSM) systems for multi-mission satellites faces several significant challenges. These challenges stem from the unique requirements of space applications and the complex nature of hybrid motor systems.

One of the primary challenges is the need for high reliability and longevity in the harsh space environment. Hybrid PMSM systems must withstand extreme temperature fluctuations, radiation exposure, and vacuum conditions while maintaining consistent performance over extended periods. This necessitates the use of specialized materials and robust design techniques that can withstand these harsh conditions without degradation.

Power efficiency is another critical challenge for Hybrid PMSM systems in multi-mission satellites. Given the limited power resources available in space, these motors must operate with maximum efficiency to conserve energy. Balancing the power consumption between the permanent magnet and electromagnetic components of the hybrid system while maintaining optimal performance is a complex task that requires advanced control algorithms and precise system modeling.

The requirement for compact and lightweight designs presents another significant hurdle. Satellite systems have strict mass and volume constraints, necessitating the development of highly integrated and miniaturized Hybrid PMSM solutions. This challenge extends to the motor itself, as well as its associated power electronics and control systems.

Thermal management is a crucial concern in the vacuum of space, where heat dissipation relies solely on radiation. Hybrid PMSM systems generate heat during operation, which must be effectively managed to prevent overheating and ensure long-term reliability. Developing efficient cooling strategies without adding significant mass or complexity to the system is a major engineering challenge.

The multi-mission aspect of these satellites introduces additional complexities. Hybrid PMSM systems must be versatile enough to adapt to various operational modes and mission requirements. This demands advanced control strategies capable of optimizing motor performance across a wide range of operating conditions and mission profiles.

Electromagnetic compatibility (EMC) is another critical challenge. Hybrid PMSM systems must operate without interfering with sensitive satellite instruments or communication systems. Achieving this requires careful design considerations and extensive EMC testing to ensure the motor's electromagnetic emissions are within acceptable limits.

Lastly, the development of fault-tolerant designs is essential for space applications. Hybrid PMSM systems must be capable of operating reliably even in the event of partial failures. This requires redundancy in critical components and the implementation of sophisticated fault detection and mitigation strategies.

One of the primary challenges is the need for high reliability and longevity in the harsh space environment. Hybrid PMSM systems must withstand extreme temperature fluctuations, radiation exposure, and vacuum conditions while maintaining consistent performance over extended periods. This necessitates the use of specialized materials and robust design techniques that can withstand these harsh conditions without degradation.

Power efficiency is another critical challenge for Hybrid PMSM systems in multi-mission satellites. Given the limited power resources available in space, these motors must operate with maximum efficiency to conserve energy. Balancing the power consumption between the permanent magnet and electromagnetic components of the hybrid system while maintaining optimal performance is a complex task that requires advanced control algorithms and precise system modeling.

The requirement for compact and lightweight designs presents another significant hurdle. Satellite systems have strict mass and volume constraints, necessitating the development of highly integrated and miniaturized Hybrid PMSM solutions. This challenge extends to the motor itself, as well as its associated power electronics and control systems.

Thermal management is a crucial concern in the vacuum of space, where heat dissipation relies solely on radiation. Hybrid PMSM systems generate heat during operation, which must be effectively managed to prevent overheating and ensure long-term reliability. Developing efficient cooling strategies without adding significant mass or complexity to the system is a major engineering challenge.

The multi-mission aspect of these satellites introduces additional complexities. Hybrid PMSM systems must be versatile enough to adapt to various operational modes and mission requirements. This demands advanced control strategies capable of optimizing motor performance across a wide range of operating conditions and mission profiles.

Electromagnetic compatibility (EMC) is another critical challenge. Hybrid PMSM systems must operate without interfering with sensitive satellite instruments or communication systems. Achieving this requires careful design considerations and extensive EMC testing to ensure the motor's electromagnetic emissions are within acceptable limits.

Lastly, the development of fault-tolerant designs is essential for space applications. Hybrid PMSM systems must be capable of operating reliably even in the event of partial failures. This requires redundancy in critical components and the implementation of sophisticated fault detection and mitigation strategies.

Hybrid PMSM Solutions

01 Hybrid PMSM control systems

Advanced control systems for hybrid Permanent Magnet Synchronous Motors (PMSMs) that integrate multiple control strategies to optimize performance, efficiency, and reliability. These systems may combine vector control, direct torque control, and adaptive control techniques to enhance motor operation across various operating conditions.- Hybrid PMSM control systems: Advanced control systems for hybrid Permanent Magnet Synchronous Motors (PMSMs) that integrate multiple control strategies to optimize performance, efficiency, and reliability. These systems may combine vector control, direct torque control, and adaptive control techniques to enhance motor operation across various operating conditions.

- Energy management in hybrid PMSM systems: Innovative energy management strategies for hybrid PMSM systems, focusing on optimizing power distribution between different energy sources such as batteries, fuel cells, or supercapacitors. These approaches aim to improve overall system efficiency, extend driving range, and reduce emissions in hybrid electric vehicles.

- Fault diagnosis and tolerance in hybrid PMSM systems: Advanced fault diagnosis and tolerance mechanisms for hybrid PMSM systems, incorporating real-time monitoring, predictive maintenance, and fault-tolerant control strategies. These technologies aim to enhance system reliability, minimize downtime, and ensure safe operation under various fault conditions.

- Thermal management in hybrid PMSM systems: Innovative thermal management solutions for hybrid PMSM systems, addressing heat dissipation challenges in high-performance electric motors. These approaches may include advanced cooling techniques, thermal modeling, and temperature-aware control strategies to optimize motor efficiency and extend component lifespan.

- Integration of hybrid PMSM systems with renewable energy sources: Novel approaches for integrating hybrid PMSM systems with renewable energy sources such as solar and wind power. These solutions focus on optimizing power conversion, storage, and distribution to enhance overall system efficiency and sustainability in various applications, including electric vehicles and smart grid systems.

02 PMSM-based hybrid powertrains

Hybrid powertrain configurations incorporating PMSMs for improved vehicle performance and energy efficiency. These systems typically combine a PMSM with an internal combustion engine or other electric motors to provide optimal power distribution and energy management in hybrid electric vehicles.Expand Specific Solutions03 Hybrid excitation PMSM designs

Novel PMSM designs that incorporate both permanent magnets and electromagnetic excitation to achieve variable flux control. These hybrid excitation systems allow for improved efficiency and wider operating range by adjusting the magnetic field strength based on load conditions.Expand Specific Solutions04 Fault-tolerant hybrid PMSM systems

Hybrid PMSM configurations designed to maintain operation under fault conditions. These systems may include redundant windings, modular designs, or adaptive control strategies to ensure continued functionality in the event of component failures or electrical faults.Expand Specific Solutions05 Energy storage integration in hybrid PMSM systems

Hybrid PMSM systems that incorporate energy storage elements such as batteries or supercapacitors. These integrated systems enable improved power management, regenerative braking capabilities, and enhanced overall system efficiency in applications like electric vehicles or renewable energy systems.Expand Specific Solutions

Satellite PMSM Players

The research on Hybrid PMSM systems for multi-mission satellites is in a developing stage, with growing market potential due to increasing demand for versatile satellite platforms. The technology is advancing rapidly, but still requires further refinement for widespread adoption. Key players like China Academy of Space Technology, Harbin Institute of Technology, and Nanjing University of Aeronautics & Astronautics are leading research efforts, while companies such as Thales SA and Hughes Network Systems are exploring commercial applications. The competitive landscape is characterized by a mix of academic institutions and aerospace companies collaborating to overcome technical challenges and improve system performance for diverse satellite missions.

Nanjing University of Aeronautics & Astronautics

Technical Solution: Nanjing University of Aeronautics & Astronautics (NUAA) has conducted extensive research on Hybrid PMSM systems for multi-mission satellites, focusing on improving efficiency and reliability. Their approach involves a novel hybrid excitation topology that combines permanent magnets with a superconducting field winding, allowing for dynamic flux control and high power density[13]. NUAA has developed advanced control algorithms that utilize artificial intelligence techniques, such as reinforcement learning, to optimize motor performance across various operating conditions. The system also incorporates a unique thermal management solution using heat pipes and phase change materials, ensuring stable operation in the extreme temperature variations of space[15]. Additionally, NUAA has implemented a fault-tolerant control strategy that can reconfigure the motor windings in real-time to maintain operation even in the event of partial winding failures. The university has also explored the use of additive manufacturing techniques to create complex rotor and stator geometries, further improving motor performance and reducing mass[17].

Strengths: High power density, advanced AI-based control, and excellent fault tolerance. Weaknesses: The use of superconducting materials may increase system complexity and cost, potentially limiting practical implementation in the near term.

China Academy of Space Technology

Technical Solution: China Academy of Space Technology (CAST) has developed advanced Hybrid Permanent Magnet Synchronous Motor (PMSM) systems for multi-mission satellites. Their approach integrates high-efficiency PMSMs with sophisticated control algorithms to optimize power consumption and torque output. The system employs a hybrid configuration combining permanent magnets and electromagnets, allowing for dynamic flux control[1]. This enables the motor to adapt to various mission requirements, from high-torque maneuvers to low-power station-keeping. CAST has also implemented advanced thermal management techniques, utilizing phase-change materials and heat pipes to maintain optimal motor performance in the harsh space environment[3]. The control system incorporates adaptive algorithms that can compensate for motor parameter variations due to temperature fluctuations and aging effects, ensuring consistent performance throughout the satellite's lifespan[5].

Strengths: Highly adaptable to different mission profiles, excellent power efficiency, and robust performance in space environments. Weaknesses: Complexity of the hybrid system may increase manufacturing costs and potential points of failure.

PMSM Innovations

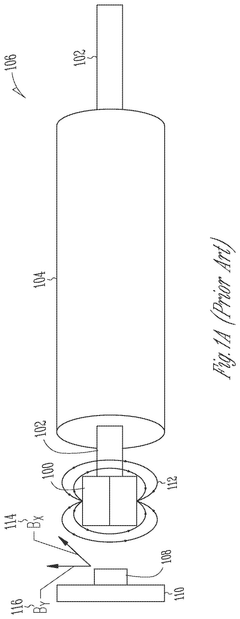

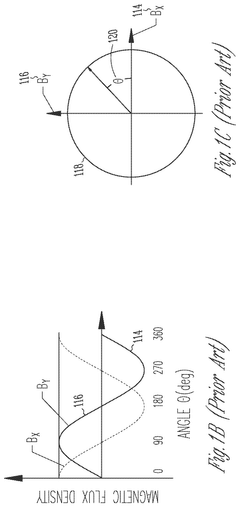

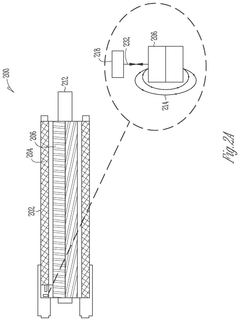

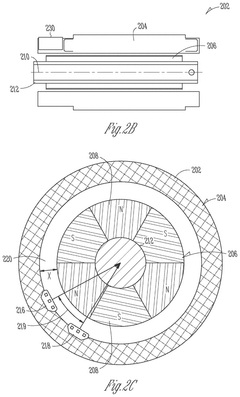

Permanent magnet synchronous motor (PMSM) integrated position sensing

PatentActiveUS12212257B2

Innovation

- The integration of analog magnetic flux sensors within the hollow cylindrical stator of the PMSM, arranged concentrically around the rotational axis at a constant mechanical angle relative to each other, allows for direct measurement of the magnetic flux from the rotor without external obstructions, enabling accurate rotor position sensing and reducing motor size and cost.

Permanent magnet synchronous motor

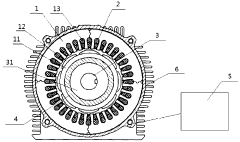

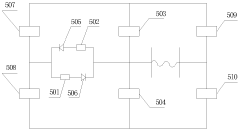

PatentWO2017201991A1

Innovation

- 采用不对称椭球形永磁体槽和环氧酚醛树脂塑封树脂壳,提高磁性集中性和密封性,并通过逆变器将直流电能转变为交流电能,增强适用性和安全性。

Space Regulations

Space regulations play a crucial role in the development and implementation of hybrid Permanent Magnet Synchronous Motor (PMSM) systems for multi-mission satellites. These regulations encompass a wide range of guidelines and standards that govern the design, manufacturing, testing, and operation of satellite components in space environments.

International space agencies, such as NASA and ESA, have established comprehensive regulatory frameworks to ensure the safety, reliability, and compatibility of satellite systems. These regulations address various aspects of hybrid PMSM systems, including electromagnetic compatibility, thermal management, radiation hardness, and mechanical stability.

One key area of focus in space regulations is the electromagnetic compatibility of hybrid PMSM systems. Strict guidelines are in place to minimize electromagnetic interference (EMI) between different satellite subsystems and to prevent potential disruptions to communication and navigation systems. Manufacturers must adhere to specific EMI emission and susceptibility limits, as well as implement appropriate shielding and grounding techniques.

Thermal management regulations are another critical aspect of space regulations for hybrid PMSM systems. These regulations specify the acceptable temperature ranges for motor operation and require the implementation of effective cooling mechanisms to prevent overheating in the vacuum of space. Thermal cycling tests and thermal analysis are mandatory to ensure the long-term reliability of the motor system.

Radiation hardness is a paramount concern in space applications, and regulations mandate rigorous testing and qualification procedures for hybrid PMSM systems. Components must be designed to withstand the harsh radiation environment of space, including exposure to high-energy particles and cosmic rays. Radiation-hardened materials and shielding techniques are often required to meet these stringent regulations.

Mechanical stability regulations address the structural integrity of hybrid PMSM systems during launch and in-orbit operations. Vibration testing, shock testing, and structural analysis are essential components of the regulatory compliance process. These regulations ensure that the motor system can withstand the extreme forces experienced during launch and maintain proper functionality throughout the satellite's operational lifetime.

Space regulations also cover the reliability and redundancy requirements for critical satellite components, including hybrid PMSM systems. Manufacturers must demonstrate compliance with specific reliability standards and implement redundancy measures to mitigate potential single-point failures. Extensive qualification testing and documentation are necessary to meet these regulatory requirements.

In conclusion, space regulations for hybrid PMSM systems in multi-mission satellites encompass a comprehensive set of guidelines and standards. Compliance with these regulations is essential for ensuring the safety, reliability, and performance of satellite systems in the challenging space environment. As technology advances, regulatory frameworks continue to evolve, necessitating ongoing collaboration between manufacturers, space agencies, and regulatory bodies to maintain the highest standards of safety and reliability in satellite operations.

International space agencies, such as NASA and ESA, have established comprehensive regulatory frameworks to ensure the safety, reliability, and compatibility of satellite systems. These regulations address various aspects of hybrid PMSM systems, including electromagnetic compatibility, thermal management, radiation hardness, and mechanical stability.

One key area of focus in space regulations is the electromagnetic compatibility of hybrid PMSM systems. Strict guidelines are in place to minimize electromagnetic interference (EMI) between different satellite subsystems and to prevent potential disruptions to communication and navigation systems. Manufacturers must adhere to specific EMI emission and susceptibility limits, as well as implement appropriate shielding and grounding techniques.

Thermal management regulations are another critical aspect of space regulations for hybrid PMSM systems. These regulations specify the acceptable temperature ranges for motor operation and require the implementation of effective cooling mechanisms to prevent overheating in the vacuum of space. Thermal cycling tests and thermal analysis are mandatory to ensure the long-term reliability of the motor system.

Radiation hardness is a paramount concern in space applications, and regulations mandate rigorous testing and qualification procedures for hybrid PMSM systems. Components must be designed to withstand the harsh radiation environment of space, including exposure to high-energy particles and cosmic rays. Radiation-hardened materials and shielding techniques are often required to meet these stringent regulations.

Mechanical stability regulations address the structural integrity of hybrid PMSM systems during launch and in-orbit operations. Vibration testing, shock testing, and structural analysis are essential components of the regulatory compliance process. These regulations ensure that the motor system can withstand the extreme forces experienced during launch and maintain proper functionality throughout the satellite's operational lifetime.

Space regulations also cover the reliability and redundancy requirements for critical satellite components, including hybrid PMSM systems. Manufacturers must demonstrate compliance with specific reliability standards and implement redundancy measures to mitigate potential single-point failures. Extensive qualification testing and documentation are necessary to meet these regulatory requirements.

In conclusion, space regulations for hybrid PMSM systems in multi-mission satellites encompass a comprehensive set of guidelines and standards. Compliance with these regulations is essential for ensuring the safety, reliability, and performance of satellite systems in the challenging space environment. As technology advances, regulatory frameworks continue to evolve, necessitating ongoing collaboration between manufacturers, space agencies, and regulatory bodies to maintain the highest standards of safety and reliability in satellite operations.

Thermal Management

Thermal management is a critical aspect of hybrid Permanent Magnet Synchronous Motor (PMSM) systems for multi-mission satellites. The space environment presents unique challenges, including extreme temperature fluctuations and the absence of convective cooling. Effective thermal control is essential to maintain optimal performance and longevity of the PMSM systems.

In hybrid PMSM systems, heat generation occurs primarily in the stator windings, rotor magnets, and power electronics. The thermal design must account for both steady-state and transient thermal loads, considering the varying operational modes of multi-mission satellites. Passive thermal control techniques, such as heat pipes and radiators, are often employed to dissipate excess heat to space.

Advanced thermal management solutions incorporate active cooling systems, including thermoelectric coolers and miniature pumped fluid loops. These systems provide precise temperature control for sensitive components, ensuring consistent performance across diverse mission profiles. The integration of phase change materials (PCMs) in the thermal design offers an effective means of temperature stabilization during peak load periods.

Thermal modeling and simulation play a crucial role in optimizing the thermal management strategy for hybrid PMSM systems. Finite element analysis (FEA) and computational fluid dynamics (CFD) tools enable engineers to predict temperature distributions and identify potential hotspots. These simulations inform the placement of thermal sensors and the design of thermal interfaces between components.

The selection of materials with appropriate thermal properties is paramount in managing heat flow within the system. High thermal conductivity materials, such as aluminum nitride and boron nitride, are utilized in substrates and thermal interface materials to enhance heat spreading. Conversely, thermal isolation materials are strategically employed to protect temperature-sensitive components from heat sources.

Innovative cooling techniques, such as direct chip cooling and two-phase cooling systems, are being explored to address the increasing power densities in advanced hybrid PMSM designs. These methods offer improved heat transfer efficiency and reduced thermal gradients, contributing to enhanced system reliability and performance.

Thermal vacuum testing is an essential step in validating the thermal management system's effectiveness. This testing simulates the space environment and verifies the system's ability to maintain component temperatures within specified limits under various operational scenarios. The results of these tests inform final design optimizations and provide confidence in the system's thermal performance during actual space missions.

In hybrid PMSM systems, heat generation occurs primarily in the stator windings, rotor magnets, and power electronics. The thermal design must account for both steady-state and transient thermal loads, considering the varying operational modes of multi-mission satellites. Passive thermal control techniques, such as heat pipes and radiators, are often employed to dissipate excess heat to space.

Advanced thermal management solutions incorporate active cooling systems, including thermoelectric coolers and miniature pumped fluid loops. These systems provide precise temperature control for sensitive components, ensuring consistent performance across diverse mission profiles. The integration of phase change materials (PCMs) in the thermal design offers an effective means of temperature stabilization during peak load periods.

Thermal modeling and simulation play a crucial role in optimizing the thermal management strategy for hybrid PMSM systems. Finite element analysis (FEA) and computational fluid dynamics (CFD) tools enable engineers to predict temperature distributions and identify potential hotspots. These simulations inform the placement of thermal sensors and the design of thermal interfaces between components.

The selection of materials with appropriate thermal properties is paramount in managing heat flow within the system. High thermal conductivity materials, such as aluminum nitride and boron nitride, are utilized in substrates and thermal interface materials to enhance heat spreading. Conversely, thermal isolation materials are strategically employed to protect temperature-sensitive components from heat sources.

Innovative cooling techniques, such as direct chip cooling and two-phase cooling systems, are being explored to address the increasing power densities in advanced hybrid PMSM designs. These methods offer improved heat transfer efficiency and reduced thermal gradients, contributing to enhanced system reliability and performance.

Thermal vacuum testing is an essential step in validating the thermal management system's effectiveness. This testing simulates the space environment and verifies the system's ability to maintain component temperatures within specified limits under various operational scenarios. The results of these tests inform final design optimizations and provide confidence in the system's thermal performance during actual space missions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!