Dual-coil configurations for hybrid PMSM systems

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PMSM Dual-Coil Evolution

The evolution of dual-coil configurations in hybrid Permanent Magnet Synchronous Motor (PMSM) systems represents a significant advancement in electric motor technology. This progression can be traced through several key developmental stages, each marked by notable technological achievements and innovative solutions.

In the early stages of PMSM development, single-coil configurations were the norm. However, as demands for higher efficiency and performance increased, researchers began exploring dual-coil designs. The initial dual-coil configurations emerged in the late 1990s, primarily focusing on improving torque density and reducing torque ripple.

The early 2000s saw a shift towards more sophisticated dual-coil arrangements. Engineers experimented with various winding patterns and coil placements to optimize magnetic field distribution. This period was characterized by the introduction of fractional-slot concentrated winding (FSCW) techniques in dual-coil setups, which significantly enhanced power density and efficiency.

A major breakthrough came in the mid-2000s with the development of hybrid excitation systems. These systems combined permanent magnets with electromagnetic excitation, utilizing dual-coil configurations to achieve variable flux control. This innovation allowed for a wider operating range and improved efficiency across different speed profiles.

The late 2000s and early 2010s witnessed advancements in materials science that further propelled dual-coil PMSM evolution. The introduction of high-performance magnetic materials and advanced insulation systems enabled the design of more compact and efficient dual-coil arrangements.

Recent years have seen a focus on integrating dual-coil PMSM systems with advanced control strategies. The development of sophisticated sensorless control algorithms and the application of artificial intelligence have led to more adaptive and efficient motor operation. These advancements have particularly benefited hybrid and electric vehicle applications, where dual-coil PMSMs have become increasingly prevalent.

The latest trend in dual-coil PMSM evolution involves the exploration of modular and reconfigurable designs. These innovative approaches allow for dynamic adjustment of motor characteristics, adapting to varying load conditions and operational requirements. This flexibility represents a significant step towards more versatile and efficient electric drive systems.

Throughout this evolutionary journey, dual-coil configurations in hybrid PMSM systems have consistently demonstrated improvements in power density, efficiency, and controllability. The technology continues to evolve, driven by the growing demands of various industries, particularly in the automotive and renewable energy sectors.

In the early stages of PMSM development, single-coil configurations were the norm. However, as demands for higher efficiency and performance increased, researchers began exploring dual-coil designs. The initial dual-coil configurations emerged in the late 1990s, primarily focusing on improving torque density and reducing torque ripple.

The early 2000s saw a shift towards more sophisticated dual-coil arrangements. Engineers experimented with various winding patterns and coil placements to optimize magnetic field distribution. This period was characterized by the introduction of fractional-slot concentrated winding (FSCW) techniques in dual-coil setups, which significantly enhanced power density and efficiency.

A major breakthrough came in the mid-2000s with the development of hybrid excitation systems. These systems combined permanent magnets with electromagnetic excitation, utilizing dual-coil configurations to achieve variable flux control. This innovation allowed for a wider operating range and improved efficiency across different speed profiles.

The late 2000s and early 2010s witnessed advancements in materials science that further propelled dual-coil PMSM evolution. The introduction of high-performance magnetic materials and advanced insulation systems enabled the design of more compact and efficient dual-coil arrangements.

Recent years have seen a focus on integrating dual-coil PMSM systems with advanced control strategies. The development of sophisticated sensorless control algorithms and the application of artificial intelligence have led to more adaptive and efficient motor operation. These advancements have particularly benefited hybrid and electric vehicle applications, where dual-coil PMSMs have become increasingly prevalent.

The latest trend in dual-coil PMSM evolution involves the exploration of modular and reconfigurable designs. These innovative approaches allow for dynamic adjustment of motor characteristics, adapting to varying load conditions and operational requirements. This flexibility represents a significant step towards more versatile and efficient electric drive systems.

Throughout this evolutionary journey, dual-coil configurations in hybrid PMSM systems have consistently demonstrated improvements in power density, efficiency, and controllability. The technology continues to evolve, driven by the growing demands of various industries, particularly in the automotive and renewable energy sectors.

Hybrid PMSM Market Trends

The hybrid Permanent Magnet Synchronous Motor (PMSM) market is experiencing significant growth and transformation, driven by the increasing demand for energy-efficient and high-performance electric motors across various industries. This market trend is particularly evident in automotive, industrial automation, and renewable energy sectors, where the need for compact, powerful, and efficient motor systems is paramount.

In the automotive industry, the shift towards electric and hybrid vehicles has been a major catalyst for the adoption of hybrid PMSM systems. As governments worldwide implement stricter emissions regulations and consumers become more environmentally conscious, automakers are increasingly incorporating hybrid PMSM technology into their electric powertrains. This trend is expected to continue, with the global electric vehicle market projected to grow at a compound annual growth rate (CAGR) of over 20% in the coming years.

The industrial automation sector is another key driver of the hybrid PMSM market. As manufacturers strive for greater efficiency and precision in their production processes, the demand for advanced motor systems has surged. Hybrid PMSM systems offer superior control, higher power density, and improved energy efficiency compared to traditional motor technologies. This has led to their widespread adoption in robotics, CNC machines, and other industrial applications.

In the renewable energy sector, particularly wind power generation, hybrid PMSM systems are gaining traction due to their ability to operate efficiently at variable speeds. Wind turbine manufacturers are increasingly opting for these motors to enhance energy capture and reduce maintenance requirements. The global wind energy market's steady growth is expected to further boost the demand for hybrid PMSM systems in this sector.

The Asia-Pacific region, led by China and Japan, is emerging as a major market for hybrid PMSM systems. The region's robust manufacturing sector, coupled with government initiatives promoting electric vehicles and industrial automation, is driving significant growth. North America and Europe are also witnessing strong market expansion, primarily fueled by the automotive and renewable energy sectors.

Technological advancements in materials science and power electronics are further propelling the hybrid PMSM market. Innovations in magnet materials, such as the development of high-performance rare-earth magnets, are enhancing motor efficiency and power density. Additionally, improvements in motor control algorithms and power electronic devices are enabling more precise and efficient operation of hybrid PMSM systems.

The market is also seeing a trend towards customization and modular design approaches. Motor manufacturers are developing flexible hybrid PMSM platforms that can be easily adapted to different applications and performance requirements. This trend is particularly beneficial for OEMs looking to integrate these motors into diverse product lines without significant redesign efforts.

In the automotive industry, the shift towards electric and hybrid vehicles has been a major catalyst for the adoption of hybrid PMSM systems. As governments worldwide implement stricter emissions regulations and consumers become more environmentally conscious, automakers are increasingly incorporating hybrid PMSM technology into their electric powertrains. This trend is expected to continue, with the global electric vehicle market projected to grow at a compound annual growth rate (CAGR) of over 20% in the coming years.

The industrial automation sector is another key driver of the hybrid PMSM market. As manufacturers strive for greater efficiency and precision in their production processes, the demand for advanced motor systems has surged. Hybrid PMSM systems offer superior control, higher power density, and improved energy efficiency compared to traditional motor technologies. This has led to their widespread adoption in robotics, CNC machines, and other industrial applications.

In the renewable energy sector, particularly wind power generation, hybrid PMSM systems are gaining traction due to their ability to operate efficiently at variable speeds. Wind turbine manufacturers are increasingly opting for these motors to enhance energy capture and reduce maintenance requirements. The global wind energy market's steady growth is expected to further boost the demand for hybrid PMSM systems in this sector.

The Asia-Pacific region, led by China and Japan, is emerging as a major market for hybrid PMSM systems. The region's robust manufacturing sector, coupled with government initiatives promoting electric vehicles and industrial automation, is driving significant growth. North America and Europe are also witnessing strong market expansion, primarily fueled by the automotive and renewable energy sectors.

Technological advancements in materials science and power electronics are further propelling the hybrid PMSM market. Innovations in magnet materials, such as the development of high-performance rare-earth magnets, are enhancing motor efficiency and power density. Additionally, improvements in motor control algorithms and power electronic devices are enabling more precise and efficient operation of hybrid PMSM systems.

The market is also seeing a trend towards customization and modular design approaches. Motor manufacturers are developing flexible hybrid PMSM platforms that can be easily adapted to different applications and performance requirements. This trend is particularly beneficial for OEMs looking to integrate these motors into diverse product lines without significant redesign efforts.

Dual-Coil Challenges

The implementation of dual-coil configurations in hybrid Permanent Magnet Synchronous Motor (PMSM) systems presents several significant challenges that researchers and engineers must address. These challenges stem from the complex interactions between the two coil systems and their impact on the overall performance of the motor.

One of the primary challenges is the electromagnetic interference between the two coils. As both coils operate simultaneously within the same motor structure, they can potentially create conflicting magnetic fields. This interference may lead to reduced efficiency, increased losses, and compromised torque production. Mitigating these electromagnetic interactions requires sophisticated design strategies and advanced control algorithms.

Another critical challenge lies in the thermal management of the dual-coil system. The presence of two coils in close proximity generates more heat than traditional single-coil configurations. This increased heat production can lead to accelerated degradation of motor components, reduced efficiency, and potential failure if not properly managed. Developing effective cooling solutions and optimizing the thermal distribution within the motor becomes crucial for ensuring long-term reliability and performance.

The mechanical design and integration of dual coils within the limited space of a PMSM system pose significant challenges. Engineers must find innovative ways to accommodate both coils while maintaining the motor's compact form factor. This often requires rethinking traditional motor geometries and exploring novel winding techniques to maximize space utilization without compromising performance.

Control complexity is another major hurdle in dual-coil PMSM systems. Coordinating the operation of two coils to achieve optimal performance across various operating conditions requires sophisticated control strategies. This includes managing the current distribution between coils, optimizing switching sequences, and implementing advanced sensorless control techniques. The increased complexity of the control system can lead to higher computational requirements and potential stability issues.

Power electronics design for dual-coil systems presents its own set of challenges. The need for separate or more complex inverter topologies to drive the two coils independently can increase system cost and complexity. Additionally, ensuring proper current sharing and balancing between the coils requires careful consideration in the design of power electronic components and control algorithms.

Lastly, the manufacturing and assembly processes for dual-coil PMSM systems are more intricate compared to traditional single-coil designs. Achieving consistent quality and performance across production units becomes more challenging due to the increased number of components and potential for variations in coil characteristics. This necessitates the development of advanced manufacturing techniques and stringent quality control measures to ensure reliability and performance consistency in mass production scenarios.

One of the primary challenges is the electromagnetic interference between the two coils. As both coils operate simultaneously within the same motor structure, they can potentially create conflicting magnetic fields. This interference may lead to reduced efficiency, increased losses, and compromised torque production. Mitigating these electromagnetic interactions requires sophisticated design strategies and advanced control algorithms.

Another critical challenge lies in the thermal management of the dual-coil system. The presence of two coils in close proximity generates more heat than traditional single-coil configurations. This increased heat production can lead to accelerated degradation of motor components, reduced efficiency, and potential failure if not properly managed. Developing effective cooling solutions and optimizing the thermal distribution within the motor becomes crucial for ensuring long-term reliability and performance.

The mechanical design and integration of dual coils within the limited space of a PMSM system pose significant challenges. Engineers must find innovative ways to accommodate both coils while maintaining the motor's compact form factor. This often requires rethinking traditional motor geometries and exploring novel winding techniques to maximize space utilization without compromising performance.

Control complexity is another major hurdle in dual-coil PMSM systems. Coordinating the operation of two coils to achieve optimal performance across various operating conditions requires sophisticated control strategies. This includes managing the current distribution between coils, optimizing switching sequences, and implementing advanced sensorless control techniques. The increased complexity of the control system can lead to higher computational requirements and potential stability issues.

Power electronics design for dual-coil systems presents its own set of challenges. The need for separate or more complex inverter topologies to drive the two coils independently can increase system cost and complexity. Additionally, ensuring proper current sharing and balancing between the coils requires careful consideration in the design of power electronic components and control algorithms.

Lastly, the manufacturing and assembly processes for dual-coil PMSM systems are more intricate compared to traditional single-coil designs. Achieving consistent quality and performance across production units becomes more challenging due to the increased number of components and potential for variations in coil characteristics. This necessitates the development of advanced manufacturing techniques and stringent quality control measures to ensure reliability and performance consistency in mass production scenarios.

Dual-Coil Configurations

01 Dual-coil winding configurations

Hybrid PMSM systems can utilize dual-coil winding configurations to enhance performance and efficiency. These configurations involve two separate coil windings in the stator, which can be independently controlled or operated in different modes. This arrangement allows for improved torque production, better power factor control, and increased flexibility in motor operation.- Dual-coil winding configurations: Hybrid PMSM systems can utilize dual-coil winding configurations to enhance performance and efficiency. These configurations involve two separate coil windings in the stator, which can be independently controlled or operated in different modes. This arrangement allows for improved torque production, better power factor control, and increased flexibility in motor operation.

- Hybrid excitation techniques: Dual-coil configurations in hybrid PMSM systems can incorporate both permanent magnet and electromagnetic excitation. This hybrid excitation approach combines the advantages of both excitation methods, allowing for improved flux control, extended speed range, and enhanced overall system efficiency. The dual-coil arrangement facilitates seamless switching between different excitation modes.

- Fault-tolerant design: Dual-coil configurations can be designed to provide fault tolerance in hybrid PMSM systems. By having two independent coil sets, the motor can continue to operate even if one coil set fails. This redundancy improves system reliability and allows for continued operation in critical applications, albeit at reduced performance levels.

- Control strategies for dual-coil systems: Advanced control strategies are developed specifically for dual-coil configurations in hybrid PMSM systems. These strategies optimize the current distribution between the two coil sets, manage the flux weakening capabilities, and coordinate the switching between different operating modes. Such control techniques aim to maximize efficiency, torque production, and overall system performance across various operating conditions.

- Thermal management in dual-coil configurations: Dual-coil configurations in hybrid PMSM systems present unique thermal management challenges and opportunities. The design allows for better heat distribution and cooling strategies, as the heat generation can be spread across two coil sets. Innovative cooling techniques and thermal design considerations are implemented to maintain optimal operating temperatures and prevent overheating in these dual-coil systems.

02 Hybrid excitation techniques

Dual-coil configurations in hybrid PMSM systems can incorporate both permanent magnet and electromagnetic excitation. This hybrid excitation approach combines the advantages of both excitation methods, allowing for improved efficiency, wider speed range, and better flux weakening capabilities. The dual-coil arrangement enables dynamic adjustment of the excitation field strength based on operating conditions.Expand Specific Solutions03 Control strategies for dual-coil PMSMs

Advanced control strategies are developed for dual-coil configurations in hybrid PMSM systems. These strategies focus on optimizing the current distribution between the two coils, implementing vector control techniques, and managing the interaction between permanent magnet and electromagnetic excitation. The control algorithms aim to maximize efficiency, torque production, and overall system performance across various operating conditions.Expand Specific Solutions04 Fault-tolerant operation

Dual-coil configurations in hybrid PMSM systems offer enhanced fault-tolerant capabilities. In the event of a fault in one coil, the motor can continue to operate using the remaining healthy coil, albeit at reduced performance. This feature improves the reliability and availability of the motor system, making it suitable for critical applications where continuous operation is essential.Expand Specific Solutions05 Thermal management and efficiency improvements

The dual-coil configuration in hybrid PMSM systems allows for improved thermal management and efficiency. By distributing the current between two coils, the heat generation can be more evenly spread, reducing hotspots and improving overall cooling. This arrangement also enables selective activation of coils based on load conditions, potentially leading to reduced copper losses and increased system efficiency.Expand Specific Solutions

Hybrid PMSM Competitors

The research on dual-coil configurations for hybrid PMSM systems is in a competitive and evolving landscape. The industry is in a growth phase, with increasing market size driven by the rising demand for efficient electric motors in various applications. The technology is advancing rapidly, with several key players contributing to its development. Companies like Mitsubishi Electric Corp., Hitachi Ltd., and Siemens Plc are leading the charge with their extensive R&D capabilities. Academic institutions such as Harbin Institute of Technology, Southeast University, and Nanjing University of Aeronautics & Astronautics are also making significant contributions, bridging the gap between theoretical research and practical applications. The technology's maturity is progressing, but there's still room for innovation and optimization in dual-coil configurations for hybrid PMSM systems.

Mitsubishi Electric Corp.

Technical Solution: Mitsubishi Electric has developed advanced dual-coil configurations for hybrid Permanent Magnet Synchronous Motor (PMSM) systems. Their approach involves using two separate stator windings, each powered by its own inverter, allowing for independent control of magnetic fields[1]. This configuration enables improved torque production and efficiency across a wide speed range. The company has implemented a novel control strategy that optimizes the current distribution between the two coils based on operating conditions, resulting in reduced losses and enhanced overall system performance[3]. Mitsubishi's dual-coil PMSM design also incorporates advanced magnetic materials and optimized rotor geometry to maximize power density and minimize cogging torque[5].

Strengths: Enhanced torque control, improved efficiency, and wider operating range. Weaknesses: Increased system complexity and potentially higher manufacturing costs.

Hitachi Ltd.

Technical Solution: Hitachi has pioneered a unique dual-coil configuration for hybrid PMSM systems, focusing on high-efficiency electric vehicle applications. Their design features a split stator with two independent windings, allowing for flexible control of magnetic field distribution[2]. Hitachi's approach includes an innovative flux-weakening technique that leverages the dual-coil structure to extend the constant power speed range of the motor. The company has also developed sophisticated control algorithms that dynamically adjust the current ratio between the two coils to optimize efficiency and torque output under varying load conditions[4]. Additionally, Hitachi's dual-coil PMSM incorporates advanced thermal management techniques to maintain optimal performance in high-power density applications[6].

Strengths: Extended speed range, improved efficiency in electric vehicles, and advanced thermal management. Weaknesses: Potential increase in motor size and weight due to dual-coil configuration.

Dual-Coil Innovations

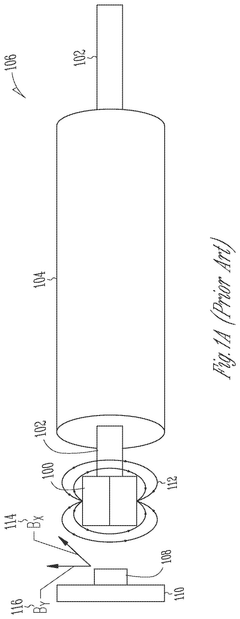

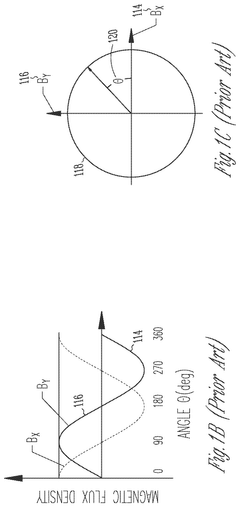

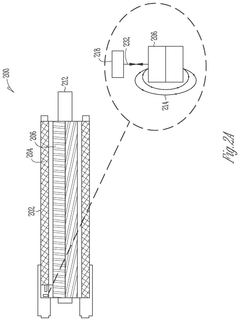

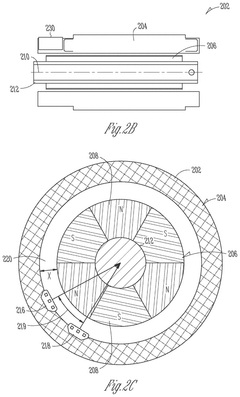

Permanent magnet synchronous motor (PMSM) integrated position sensing

PatentActiveUS12212257B2

Innovation

- The integration of analog magnetic flux sensors within the hollow cylindrical stator of the PMSM, arranged concentrically around the rotational axis at a constant mechanical angle relative to each other, allows for direct measurement of the magnetic flux from the rotor without external obstructions, enabling accurate rotor position sensing and reducing motor size and cost.

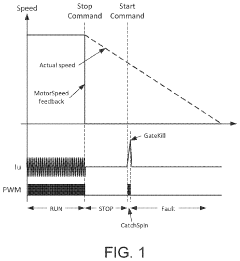

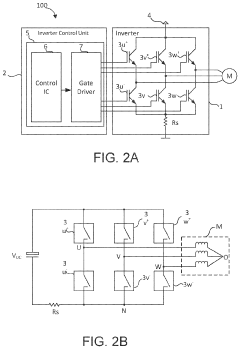

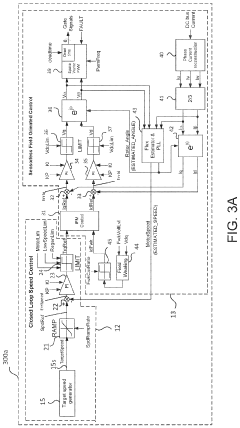

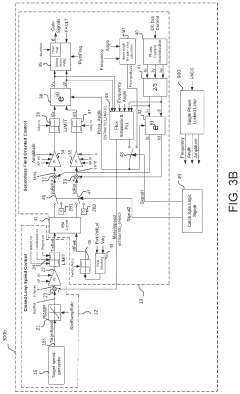

Catch spin method for permanent magnet synchronous motor with sensorless field oriented control

PatentActiveUS11594990B2

Innovation

- A motor control actuator and method that measures counter electro motive force (CEMF) or back electro motive force (BEMF) while the PMSM rotates, generates measurement signals, and performs a catch spin sequence using a multi-phase inverter to synchronize with the motor's voltage, including open loop and closed loop control to accurately restart the motor.

Energy Efficiency Impact

The implementation of dual-coil configurations in hybrid Permanent Magnet Synchronous Motor (PMSM) systems has shown significant potential for enhancing energy efficiency in various applications. This innovative approach addresses the growing demand for more sustainable and cost-effective motor solutions across industries.

Dual-coil configurations in hybrid PMSM systems offer several advantages that contribute to improved energy efficiency. By utilizing two separate coil systems, these motors can optimize power distribution and reduce overall energy consumption. The primary coil typically handles the main power requirements, while the secondary coil manages auxiliary functions or provides additional power during peak demand periods.

One of the key benefits of this configuration is the ability to minimize copper losses. By strategically distributing the current between the two coils, the system can reduce resistive losses and improve overall efficiency. This is particularly advantageous in applications with varying load conditions, where the motor can adapt its power output to match the demand more precisely.

Furthermore, dual-coil configurations enable better thermal management within the motor. The distribution of heat generation across two coil systems allows for more effective cooling, reducing the risk of overheating and extending the motor's lifespan. This improved thermal performance contributes to sustained efficiency over time and reduces maintenance requirements.

The impact on energy efficiency is also evident in the motor's ability to operate at higher frequencies. Dual-coil configurations can support increased switching frequencies, leading to smoother operation and reduced harmonic losses. This results in improved power quality and reduced electromagnetic interference, further enhancing the overall system efficiency.

In applications requiring frequent start-stop cycles or rapid speed changes, dual-coil hybrid PMSM systems demonstrate superior performance. The secondary coil can be utilized to provide additional torque during acceleration or deceleration phases, reducing the energy required for these transient operations. This feature is particularly beneficial in electric vehicle applications, where energy recovery during braking can be optimized.

Moreover, the flexibility offered by dual-coil configurations allows for more precise control of the motor's magnetic field. This enhanced control capability enables the system to maintain optimal efficiency across a wider range of operating conditions, adapting to varying loads and speeds with minimal energy waste.

Dual-coil configurations in hybrid PMSM systems offer several advantages that contribute to improved energy efficiency. By utilizing two separate coil systems, these motors can optimize power distribution and reduce overall energy consumption. The primary coil typically handles the main power requirements, while the secondary coil manages auxiliary functions or provides additional power during peak demand periods.

One of the key benefits of this configuration is the ability to minimize copper losses. By strategically distributing the current between the two coils, the system can reduce resistive losses and improve overall efficiency. This is particularly advantageous in applications with varying load conditions, where the motor can adapt its power output to match the demand more precisely.

Furthermore, dual-coil configurations enable better thermal management within the motor. The distribution of heat generation across two coil systems allows for more effective cooling, reducing the risk of overheating and extending the motor's lifespan. This improved thermal performance contributes to sustained efficiency over time and reduces maintenance requirements.

The impact on energy efficiency is also evident in the motor's ability to operate at higher frequencies. Dual-coil configurations can support increased switching frequencies, leading to smoother operation and reduced harmonic losses. This results in improved power quality and reduced electromagnetic interference, further enhancing the overall system efficiency.

In applications requiring frequent start-stop cycles or rapid speed changes, dual-coil hybrid PMSM systems demonstrate superior performance. The secondary coil can be utilized to provide additional torque during acceleration or deceleration phases, reducing the energy required for these transient operations. This feature is particularly beneficial in electric vehicle applications, where energy recovery during braking can be optimized.

Moreover, the flexibility offered by dual-coil configurations allows for more precise control of the motor's magnetic field. This enhanced control capability enables the system to maintain optimal efficiency across a wider range of operating conditions, adapting to varying loads and speeds with minimal energy waste.

Manufacturing Scalability

The manufacturing scalability of dual-coil configurations for hybrid Permanent Magnet Synchronous Motor (PMSM) systems presents both opportunities and challenges in the realm of electric motor production. As the demand for more efficient and powerful electric motors continues to grow, particularly in the automotive and industrial sectors, the ability to scale up production of these advanced motor designs becomes crucial.

Dual-coil configurations offer several advantages in terms of performance and efficiency, but their complexity can pose hurdles in large-scale manufacturing. The intricate winding patterns and the need for precise placement of multiple coils require advanced manufacturing techniques and specialized equipment. However, recent advancements in automated winding technologies have significantly improved the feasibility of mass-producing dual-coil PMSM systems.

One of the key factors enhancing manufacturing scalability is the development of modular coil designs. These allow for the separate production of coil units that can be easily assembled into the final motor structure. This modular approach not only streamlines the manufacturing process but also enables greater flexibility in motor customization to meet diverse application requirements.

Advancements in 3D printing technology have also contributed to improved scalability. Rapid prototyping of complex stator structures and coil formers allows for quicker design iterations and validation, reducing the time from concept to production. Additionally, 3D printing enables the creation of optimized cooling channels within the motor structure, addressing thermal management challenges associated with high-performance dual-coil configurations.

The integration of Industry 4.0 principles in motor manufacturing facilities has further enhanced scalability. Smart factories equipped with IoT sensors and AI-driven quality control systems can ensure consistent production quality even at high volumes. These technologies enable real-time monitoring of the winding process, immediate detection of defects, and adaptive control of manufacturing parameters to maintain optimal production efficiency.

However, challenges remain in scaling up the production of dual-coil PMSM systems. The increased complexity of these motors often results in higher material costs and longer production times compared to conventional single-coil designs. To address this, manufacturers are investing in research to develop more cost-effective materials and streamlined production processes specifically tailored for dual-coil configurations.

Supply chain management also plays a critical role in manufacturing scalability. The dual-coil design requires a reliable supply of specialized components, including high-grade magnetic materials and precision-wound coils. Establishing robust supplier networks and potentially bringing critical component production in-house are strategies being explored by manufacturers to ensure consistent supply and quality control.

As the technology matures and production techniques evolve, the scalability of dual-coil PMSM manufacturing is expected to improve significantly. This will likely lead to wider adoption of these high-performance motor systems across various industries, driving further innovation and efficiency improvements in electric motor applications.

Dual-coil configurations offer several advantages in terms of performance and efficiency, but their complexity can pose hurdles in large-scale manufacturing. The intricate winding patterns and the need for precise placement of multiple coils require advanced manufacturing techniques and specialized equipment. However, recent advancements in automated winding technologies have significantly improved the feasibility of mass-producing dual-coil PMSM systems.

One of the key factors enhancing manufacturing scalability is the development of modular coil designs. These allow for the separate production of coil units that can be easily assembled into the final motor structure. This modular approach not only streamlines the manufacturing process but also enables greater flexibility in motor customization to meet diverse application requirements.

Advancements in 3D printing technology have also contributed to improved scalability. Rapid prototyping of complex stator structures and coil formers allows for quicker design iterations and validation, reducing the time from concept to production. Additionally, 3D printing enables the creation of optimized cooling channels within the motor structure, addressing thermal management challenges associated with high-performance dual-coil configurations.

The integration of Industry 4.0 principles in motor manufacturing facilities has further enhanced scalability. Smart factories equipped with IoT sensors and AI-driven quality control systems can ensure consistent production quality even at high volumes. These technologies enable real-time monitoring of the winding process, immediate detection of defects, and adaptive control of manufacturing parameters to maintain optimal production efficiency.

However, challenges remain in scaling up the production of dual-coil PMSM systems. The increased complexity of these motors often results in higher material costs and longer production times compared to conventional single-coil designs. To address this, manufacturers are investing in research to develop more cost-effective materials and streamlined production processes specifically tailored for dual-coil configurations.

Supply chain management also plays a critical role in manufacturing scalability. The dual-coil design requires a reliable supply of specialized components, including high-grade magnetic materials and precision-wound coils. Establishing robust supplier networks and potentially bringing critical component production in-house are strategies being explored by manufacturers to ensure consistent supply and quality control.

As the technology matures and production techniques evolve, the scalability of dual-coil PMSM manufacturing is expected to improve significantly. This will likely lead to wider adoption of these high-performance motor systems across various industries, driving further innovation and efficiency improvements in electric motor applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!