Power electronics advancements for PMSM drives

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PMSM Drive Evolution

The evolution of Permanent Magnet Synchronous Motor (PMSM) drives has been marked by significant advancements in power electronics over the past few decades. This progression has been driven by the increasing demand for high-efficiency, compact, and reliable motor drive systems across various industries.

In the early stages of PMSM drive development, the focus was primarily on improving the basic control algorithms and motor design. However, as power electronic technologies advanced, the emphasis shifted towards enhancing the performance and efficiency of the entire drive system.

One of the key milestones in PMSM drive evolution was the introduction of vector control techniques in the 1980s. This breakthrough allowed for precise control of motor torque and speed, significantly improving the dynamic performance of PMSM drives. The implementation of these techniques was made possible by the development of more powerful microprocessors and digital signal processors.

The 1990s saw the emergence of advanced power semiconductor devices, such as Insulated Gate Bipolar Transistors (IGBTs). These devices offered higher switching frequencies and lower losses compared to their predecessors, enabling the design of more efficient and compact inverters for PMSM drives.

As we entered the 21st century, the focus shifted towards further improving the efficiency and power density of PMSM drives. This led to the development of wide bandgap semiconductor devices, such as Silicon Carbide (SiC) and Gallium Nitride (GaN). These materials allowed for even higher switching frequencies, lower losses, and improved thermal management, resulting in more compact and efficient drive systems.

In recent years, the integration of advanced control algorithms and artificial intelligence has pushed the boundaries of PMSM drive performance. Techniques such as model predictive control and adaptive control have been implemented to optimize drive performance under varying operating conditions.

The ongoing trend in PMSM drive evolution is towards more integrated and intelligent systems. This includes the development of modular and scalable drive architectures, as well as the incorporation of advanced sensing and communication technologies for improved diagnostics and predictive maintenance.

Looking ahead, the future of PMSM drives is likely to be shaped by emerging technologies such as wide bandgap semiconductors, advanced magnetic materials, and innovative cooling solutions. These advancements will continue to push the boundaries of power density, efficiency, and reliability in PMSM drive systems.

In the early stages of PMSM drive development, the focus was primarily on improving the basic control algorithms and motor design. However, as power electronic technologies advanced, the emphasis shifted towards enhancing the performance and efficiency of the entire drive system.

One of the key milestones in PMSM drive evolution was the introduction of vector control techniques in the 1980s. This breakthrough allowed for precise control of motor torque and speed, significantly improving the dynamic performance of PMSM drives. The implementation of these techniques was made possible by the development of more powerful microprocessors and digital signal processors.

The 1990s saw the emergence of advanced power semiconductor devices, such as Insulated Gate Bipolar Transistors (IGBTs). These devices offered higher switching frequencies and lower losses compared to their predecessors, enabling the design of more efficient and compact inverters for PMSM drives.

As we entered the 21st century, the focus shifted towards further improving the efficiency and power density of PMSM drives. This led to the development of wide bandgap semiconductor devices, such as Silicon Carbide (SiC) and Gallium Nitride (GaN). These materials allowed for even higher switching frequencies, lower losses, and improved thermal management, resulting in more compact and efficient drive systems.

In recent years, the integration of advanced control algorithms and artificial intelligence has pushed the boundaries of PMSM drive performance. Techniques such as model predictive control and adaptive control have been implemented to optimize drive performance under varying operating conditions.

The ongoing trend in PMSM drive evolution is towards more integrated and intelligent systems. This includes the development of modular and scalable drive architectures, as well as the incorporation of advanced sensing and communication technologies for improved diagnostics and predictive maintenance.

Looking ahead, the future of PMSM drives is likely to be shaped by emerging technologies such as wide bandgap semiconductors, advanced magnetic materials, and innovative cooling solutions. These advancements will continue to push the boundaries of power density, efficiency, and reliability in PMSM drive systems.

Market Demand Analysis

The market demand for power electronics advancements in Permanent Magnet Synchronous Motor (PMSM) drives has been experiencing significant growth in recent years. This surge is primarily driven by the increasing adoption of electric vehicles (EVs) and the growing emphasis on energy efficiency across various industrial sectors.

In the automotive industry, the shift towards electrification has created a substantial demand for high-performance PMSM drives. As major automakers worldwide commit to expanding their EV lineups, the need for more efficient and compact power electronic systems has become paramount. This trend is expected to continue, with the global EV market projected to grow at a compound annual growth rate (CAGR) of over 20% in the coming years.

The industrial sector is another key driver of market demand for advanced PMSM drives. Industries such as manufacturing, robotics, and automation are increasingly adopting PMSM technology due to its superior efficiency and precise control capabilities. The push for energy-efficient solutions in industrial processes has led to a growing replacement of traditional induction motors with PMSM drives, further fueling the demand for power electronics advancements.

In the renewable energy sector, particularly in wind power generation, PMSM drives are gaining traction due to their ability to operate at variable speeds and their high power density. As countries worldwide invest in expanding their renewable energy capacities, the demand for advanced power electronics in PMSM drives for wind turbines is expected to rise significantly.

The HVAC (Heating, Ventilation, and Air Conditioning) industry is also contributing to the market demand. With stringent energy efficiency regulations being implemented globally, HVAC manufacturers are turning to PMSM drives to meet these standards. This shift is creating a substantial market for power electronics that can deliver improved performance and energy savings in HVAC systems.

Furthermore, the aerospace and defense sectors are showing increased interest in PMSM drives for various applications, including electric propulsion systems and actuators. The need for lightweight, high-power-density solutions in these industries is driving innovation in power electronics for PMSM drives.

The market demand is not limited to hardware advancements alone. There is a growing need for sophisticated control algorithms and software solutions that can optimize the performance of PMSM drives. This includes advancements in sensorless control techniques, predictive maintenance algorithms, and real-time optimization strategies.

As the Internet of Things (IoT) and Industry 4.0 concepts gain momentum, there is an emerging demand for power electronics that can seamlessly integrate with digital platforms. This integration enables remote monitoring, predictive maintenance, and data-driven optimization of PMSM drives, adding another layer to the market demand for advanced power electronics solutions.

In the automotive industry, the shift towards electrification has created a substantial demand for high-performance PMSM drives. As major automakers worldwide commit to expanding their EV lineups, the need for more efficient and compact power electronic systems has become paramount. This trend is expected to continue, with the global EV market projected to grow at a compound annual growth rate (CAGR) of over 20% in the coming years.

The industrial sector is another key driver of market demand for advanced PMSM drives. Industries such as manufacturing, robotics, and automation are increasingly adopting PMSM technology due to its superior efficiency and precise control capabilities. The push for energy-efficient solutions in industrial processes has led to a growing replacement of traditional induction motors with PMSM drives, further fueling the demand for power electronics advancements.

In the renewable energy sector, particularly in wind power generation, PMSM drives are gaining traction due to their ability to operate at variable speeds and their high power density. As countries worldwide invest in expanding their renewable energy capacities, the demand for advanced power electronics in PMSM drives for wind turbines is expected to rise significantly.

The HVAC (Heating, Ventilation, and Air Conditioning) industry is also contributing to the market demand. With stringent energy efficiency regulations being implemented globally, HVAC manufacturers are turning to PMSM drives to meet these standards. This shift is creating a substantial market for power electronics that can deliver improved performance and energy savings in HVAC systems.

Furthermore, the aerospace and defense sectors are showing increased interest in PMSM drives for various applications, including electric propulsion systems and actuators. The need for lightweight, high-power-density solutions in these industries is driving innovation in power electronics for PMSM drives.

The market demand is not limited to hardware advancements alone. There is a growing need for sophisticated control algorithms and software solutions that can optimize the performance of PMSM drives. This includes advancements in sensorless control techniques, predictive maintenance algorithms, and real-time optimization strategies.

As the Internet of Things (IoT) and Industry 4.0 concepts gain momentum, there is an emerging demand for power electronics that can seamlessly integrate with digital platforms. This integration enables remote monitoring, predictive maintenance, and data-driven optimization of PMSM drives, adding another layer to the market demand for advanced power electronics solutions.

Technical Challenges

The advancement of power electronics for Permanent Magnet Synchronous Motor (PMSM) drives faces several significant technical challenges. These challenges stem from the increasing demands for higher efficiency, power density, and reliability in electric drive systems.

One of the primary challenges is the development of more efficient and compact power converters. As PMSM drives are used in applications ranging from electric vehicles to industrial automation, there is a constant push for smaller, lighter, and more efficient power electronic systems. This requires innovations in semiconductor technology, particularly in wide bandgap materials such as Silicon Carbide (SiC) and Gallium Nitride (GaN). While these materials offer superior performance, their integration into power electronic systems presents challenges in terms of thermal management, electromagnetic interference (EMI), and cost-effective manufacturing processes.

Another significant challenge lies in the control algorithms for PMSM drives. As the demand for precise motor control increases, especially in high-performance applications, there is a need for more sophisticated control strategies. This includes the development of advanced sensorless control techniques, which eliminate the need for position sensors, reducing system cost and complexity. However, implementing these algorithms requires high-speed digital signal processors and field-programmable gate arrays (FPGAs) with sufficient computational power, presenting challenges in terms of system integration and cost.

The thermal management of power electronic systems for PMSM drives is another critical challenge. As power densities increase, managing heat dissipation becomes more complex. This requires innovations in cooling technologies, including advanced heat sink designs, phase-change materials, and liquid cooling systems. The challenge lies not only in developing these cooling solutions but also in integrating them effectively into compact drive systems without compromising reliability or increasing costs significantly.

Reliability and robustness of power electronic systems in harsh environments pose another set of challenges. PMSM drives are often used in applications exposed to vibration, temperature extremes, and electromagnetic interference. Ensuring the long-term reliability of power electronic components, especially in automotive and aerospace applications, requires advancements in packaging technologies, thermal cycling resistance, and EMI shielding techniques.

Furthermore, the integration of power electronics with communication and IoT technologies presents new challenges. As PMSM drives become part of larger, interconnected systems, there is a need for seamless integration of power electronic controllers with industrial communication protocols and cloud-based monitoring systems. This requires advancements in embedded systems design, cybersecurity measures, and the development of standardized communication interfaces for power electronic systems.

Lastly, the challenge of reducing the environmental impact of power electronic systems cannot be overlooked. This includes the development of more sustainable manufacturing processes, the use of recyclable materials, and the design of power electronic systems that are easily recyclable at the end of their life cycle. Additionally, improving the energy efficiency of PMSM drives throughout their operational life remains a constant challenge, requiring continuous innovations in circuit design, control strategies, and materials science.

One of the primary challenges is the development of more efficient and compact power converters. As PMSM drives are used in applications ranging from electric vehicles to industrial automation, there is a constant push for smaller, lighter, and more efficient power electronic systems. This requires innovations in semiconductor technology, particularly in wide bandgap materials such as Silicon Carbide (SiC) and Gallium Nitride (GaN). While these materials offer superior performance, their integration into power electronic systems presents challenges in terms of thermal management, electromagnetic interference (EMI), and cost-effective manufacturing processes.

Another significant challenge lies in the control algorithms for PMSM drives. As the demand for precise motor control increases, especially in high-performance applications, there is a need for more sophisticated control strategies. This includes the development of advanced sensorless control techniques, which eliminate the need for position sensors, reducing system cost and complexity. However, implementing these algorithms requires high-speed digital signal processors and field-programmable gate arrays (FPGAs) with sufficient computational power, presenting challenges in terms of system integration and cost.

The thermal management of power electronic systems for PMSM drives is another critical challenge. As power densities increase, managing heat dissipation becomes more complex. This requires innovations in cooling technologies, including advanced heat sink designs, phase-change materials, and liquid cooling systems. The challenge lies not only in developing these cooling solutions but also in integrating them effectively into compact drive systems without compromising reliability or increasing costs significantly.

Reliability and robustness of power electronic systems in harsh environments pose another set of challenges. PMSM drives are often used in applications exposed to vibration, temperature extremes, and electromagnetic interference. Ensuring the long-term reliability of power electronic components, especially in automotive and aerospace applications, requires advancements in packaging technologies, thermal cycling resistance, and EMI shielding techniques.

Furthermore, the integration of power electronics with communication and IoT technologies presents new challenges. As PMSM drives become part of larger, interconnected systems, there is a need for seamless integration of power electronic controllers with industrial communication protocols and cloud-based monitoring systems. This requires advancements in embedded systems design, cybersecurity measures, and the development of standardized communication interfaces for power electronic systems.

Lastly, the challenge of reducing the environmental impact of power electronic systems cannot be overlooked. This includes the development of more sustainable manufacturing processes, the use of recyclable materials, and the design of power electronic systems that are easily recyclable at the end of their life cycle. Additionally, improving the energy efficiency of PMSM drives throughout their operational life remains a constant challenge, requiring continuous innovations in circuit design, control strategies, and materials science.

Current PMSM Solutions

01 Advanced power conversion techniques

Recent advancements in power electronics focus on improving power conversion efficiency and reliability. This includes the development of new topologies for DC-DC converters, AC-DC rectifiers, and inverters. These innovations aim to reduce energy losses, increase power density, and enhance overall system performance in various applications such as renewable energy systems, electric vehicles, and industrial drives.- Advanced power conversion techniques: Recent advancements in power electronics focus on improving power conversion efficiency and reliability. This includes the development of new topologies for DC-DC converters, AC-DC rectifiers, and inverters. These innovations aim to reduce energy losses, increase power density, and enhance overall system performance in various applications such as renewable energy systems, electric vehicles, and industrial drives.

- Wide bandgap semiconductor devices: The adoption of wide bandgap semiconductor materials, such as Silicon Carbide (SiC) and Gallium Nitride (GaN), is revolutionizing power electronics. These materials offer superior properties including higher breakdown voltage, faster switching speeds, and better thermal conductivity compared to traditional silicon. This enables the design of more compact, efficient, and reliable power electronic systems for high-frequency and high-power applications.

- Smart grid and energy management systems: Power electronics play a crucial role in the development of smart grid technologies and advanced energy management systems. This includes innovations in bidirectional power flow control, real-time monitoring and diagnostics, and intelligent load management. These advancements contribute to improved grid stability, increased integration of renewable energy sources, and enhanced energy efficiency in both residential and industrial settings.

- Wireless power transfer technologies: Advancements in wireless power transfer systems are expanding the capabilities of power electronics. This includes developments in resonant inductive coupling, capacitive power transfer, and radio frequency (RF) power transmission. These technologies enable contactless charging for electric vehicles, consumer electronics, and medical implants, offering increased convenience and new application possibilities.

- Miniaturization and integration of power electronic systems: Ongoing efforts in power electronics focus on miniaturization and integration of components and subsystems. This includes advancements in packaging technologies, thermal management solutions, and the development of power system-on-chip (PSoC) designs. These innovations lead to more compact, cost-effective, and reliable power electronic solutions for a wide range of applications, from portable devices to industrial equipment.

02 Wide bandgap semiconductor devices

The adoption of wide bandgap semiconductor materials, such as Silicon Carbide (SiC) and Gallium Nitride (GaN), is revolutionizing power electronics. These materials offer higher breakdown voltage, faster switching speeds, and better thermal conductivity compared to traditional silicon-based devices. This enables the design of more compact, efficient, and reliable power electronic systems for high-frequency and high-power applications.Expand Specific Solutions03 Smart grid and energy management systems

Power electronics play a crucial role in the development of smart grid technologies and advanced energy management systems. These innovations include bidirectional power flow control, real-time monitoring and diagnostics, and intelligent load management. Such advancements contribute to improved grid stability, increased integration of renewable energy sources, and enhanced energy efficiency in both residential and industrial settings.Expand Specific Solutions04 Wireless power transfer technologies

Advancements in wireless power transfer systems are expanding the capabilities of power electronics. These technologies enable contactless charging for electric vehicles, consumer electronics, and industrial equipment. Recent developments focus on improving transfer efficiency, increasing power levels, and enhancing safety features, paving the way for more widespread adoption of wireless charging solutions.Expand Specific Solutions05 Miniaturization and integration of power electronic components

Ongoing research in power electronics aims to reduce the size and weight of power conversion systems while increasing their functionality. This includes the development of integrated power modules, advanced packaging techniques, and 3D integration of power electronic components. These advancements lead to more compact and efficient power electronic solutions for various applications, from portable devices to large-scale industrial systems.Expand Specific Solutions

Key Industry Players

The power electronics advancements for PMSM drives market is in a growth phase, driven by increasing demand for energy-efficient motor systems across various industries. The market size is expanding rapidly, with a projected CAGR of over 8% in the coming years. Technologically, the field is advancing quickly, with companies like Infineon Technologies, Silergy Semiconductor, and Midea Group leading innovation. Universities such as Jiangsu University, Shanghai University, and IIT Delhi are contributing significantly to research and development. The technology is maturing, with focus areas including improved control algorithms, wide bandgap semiconductors, and advanced thermal management solutions for higher power density and efficiency in PMSM drives.

GM Global Technology Operations LLC

Technical Solution: GM has made significant advancements in power electronics for PMSM drives, particularly in the context of electric vehicle (EV) applications. They have developed a proprietary inverter design that utilizes wide bandgap semiconductors, specifically silicon carbide (SiC) MOSFETs, to achieve higher power density and efficiency[4]. This inverter technology, integrated with their PMSM designs, allows for improved thermal management and reduced overall system size. GM has also implemented advanced control algorithms that optimize torque production and minimize losses across the entire operating range of their electric motors[5].

Strengths: High power density, improved efficiency, and optimized control. Weaknesses: Potentially higher component costs and complexity in manufacturing.

Infineon Technologies Americas Corp.

Technical Solution: Infineon has developed advanced power electronics solutions for PMSM drives, focusing on high-efficiency and compact designs. Their latest SiC-based power modules offer improved thermal management and higher switching frequencies, enabling more efficient PMSM control[1]. They have also introduced intelligent power modules (IPMs) specifically designed for PMSM drives, integrating gate drivers, protection circuits, and power devices in a single package. These IPMs feature advanced current sensing technology and built-in overcurrent protection, enhancing the overall reliability and performance of PMSM drives[2][3].

Strengths: High integration, improved efficiency, and enhanced reliability. Weaknesses: Potentially higher initial cost compared to traditional solutions.

Core Innovations

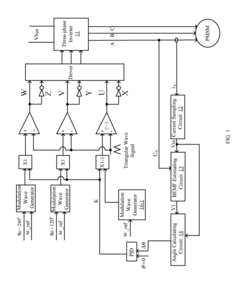

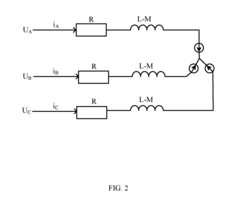

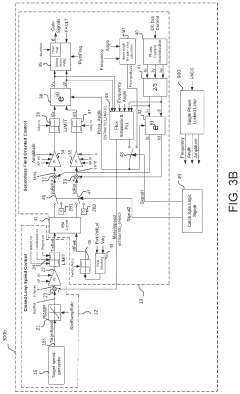

Driving circuit and driving method for permanent magnet synchronous motor

PatentActiveUS20170085196A1

Innovation

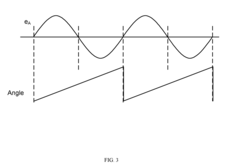

- A driving circuit and method that includes a current sampling circuit, back electromotive force (BEMF) circuit, and torque regulating circuit to estimate BEMF information and regulate the amplitude of a U-shaped modulation wave, allowing for maximum torque per ampere without a position sensor, using a sliding mode controller and PID regulator to synchronize rotor current with the modulation wave.

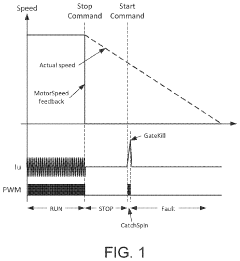

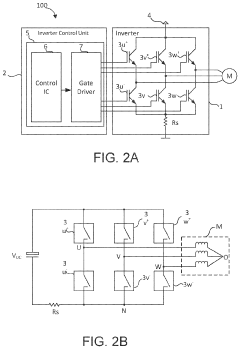

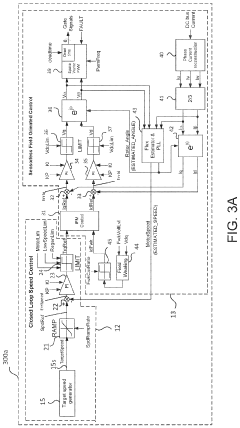

Catch spin method for permanent magnet synchronous motor with sensorless field oriented control

PatentActiveUS11594990B2

Innovation

- A motor control actuator and method that measures counter electro motive force (CEMF) or back electro motive force (BEMF) while the PMSM rotates, generates measurement signals, and performs a catch spin sequence using a multi-phase inverter to synchronize with the motor's voltage, including open loop and closed loop control to accurately restart the motor.

Efficiency Regulations

Efficiency regulations play a crucial role in shaping the development of power electronics for Permanent Magnet Synchronous Motor (PMSM) drives. These regulations are designed to promote energy conservation, reduce environmental impact, and drive technological innovation in the field of electric motor systems.

The International Electrotechnical Commission (IEC) has established global standards for motor efficiency, with IEC 60034-30-1 defining efficiency classes for electric motors. These classes, ranging from IE1 to IE4, set increasingly stringent efficiency requirements. The most recent addition, IE5, represents ultra-premium efficiency levels, pushing the boundaries of what is achievable with current technology.

In the United States, the Department of Energy (DOE) has implemented mandatory efficiency standards for electric motors through the Energy Policy and Conservation Act. These standards have been periodically updated, with the most recent revision in 2016 requiring most motors to meet Premium Efficiency (IE3) levels.

The European Union has also taken significant steps in regulating motor efficiency through the Ecodesign Directive. This directive mandates minimum efficiency performance standards (MEPS) for various types of electric motors, including those used in PMSM drives. The latest regulations require IE3 efficiency levels for most motor types, with plans to further increase these requirements in the coming years.

These efficiency regulations have had a profound impact on the development of power electronics for PMSM drives. Manufacturers are compelled to invest in research and development to create more efficient motor systems, leading to advancements in materials, design, and control strategies. For instance, the use of advanced semiconductor materials like silicon carbide (SiC) and gallium nitride (GaN) in power electronic devices has enabled higher switching frequencies and reduced losses, contributing to overall system efficiency improvements.

Furthermore, these regulations have spurred innovation in motor control algorithms and power converter topologies. Advanced control techniques such as field-oriented control (FOC) and model predictive control (MPC) have been refined to maximize motor efficiency across a wide operating range. Similarly, multilevel inverter topologies and resonant converters have been developed to reduce harmonic distortion and switching losses, further enhancing system efficiency.

The impact of efficiency regulations extends beyond the motor itself, encompassing the entire drive system. This holistic approach has led to the development of integrated motor-drive systems, where the power electronics and motor are optimized as a single unit. Such integrated solutions offer improved efficiency, reduced size, and enhanced reliability compared to traditional separate motor and drive configurations.

The International Electrotechnical Commission (IEC) has established global standards for motor efficiency, with IEC 60034-30-1 defining efficiency classes for electric motors. These classes, ranging from IE1 to IE4, set increasingly stringent efficiency requirements. The most recent addition, IE5, represents ultra-premium efficiency levels, pushing the boundaries of what is achievable with current technology.

In the United States, the Department of Energy (DOE) has implemented mandatory efficiency standards for electric motors through the Energy Policy and Conservation Act. These standards have been periodically updated, with the most recent revision in 2016 requiring most motors to meet Premium Efficiency (IE3) levels.

The European Union has also taken significant steps in regulating motor efficiency through the Ecodesign Directive. This directive mandates minimum efficiency performance standards (MEPS) for various types of electric motors, including those used in PMSM drives. The latest regulations require IE3 efficiency levels for most motor types, with plans to further increase these requirements in the coming years.

These efficiency regulations have had a profound impact on the development of power electronics for PMSM drives. Manufacturers are compelled to invest in research and development to create more efficient motor systems, leading to advancements in materials, design, and control strategies. For instance, the use of advanced semiconductor materials like silicon carbide (SiC) and gallium nitride (GaN) in power electronic devices has enabled higher switching frequencies and reduced losses, contributing to overall system efficiency improvements.

Furthermore, these regulations have spurred innovation in motor control algorithms and power converter topologies. Advanced control techniques such as field-oriented control (FOC) and model predictive control (MPC) have been refined to maximize motor efficiency across a wide operating range. Similarly, multilevel inverter topologies and resonant converters have been developed to reduce harmonic distortion and switching losses, further enhancing system efficiency.

The impact of efficiency regulations extends beyond the motor itself, encompassing the entire drive system. This holistic approach has led to the development of integrated motor-drive systems, where the power electronics and motor are optimized as a single unit. Such integrated solutions offer improved efficiency, reduced size, and enhanced reliability compared to traditional separate motor and drive configurations.

Thermal Management

Thermal management is a critical aspect of power electronics advancements for PMSM drives. As the power density and switching frequency of these drives increase, the heat generated within the system becomes a significant challenge. Effective thermal management is essential to ensure the reliability, efficiency, and longevity of PMSM drive systems.

One of the primary focuses of thermal management in PMSM drives is the development of advanced cooling techniques. Traditional air cooling methods are often insufficient for high-power density applications. Liquid cooling systems, utilizing coolants such as water or dielectric fluids, have gained popularity due to their superior heat dissipation capabilities. These systems can be designed with cold plates or direct chip cooling to efficiently remove heat from power electronic components.

The integration of wide bandgap (WBG) semiconductors, such as silicon carbide (SiC) and gallium nitride (GaN), has introduced new thermal challenges and opportunities. While these materials offer higher temperature operation and reduced switching losses, they also require careful thermal design to manage localized hot spots and ensure optimal performance.

Advanced thermal interface materials (TIMs) play a crucial role in improving heat transfer between components and heat sinks. Research in this area has led to the development of novel materials with enhanced thermal conductivity, such as graphene-based TIMs and phase-change materials, which can significantly reduce thermal resistance in the system.

Thermal modeling and simulation tools have become indispensable in the design process of PMSM drives. Computational fluid dynamics (CFD) and finite element analysis (FEA) enable engineers to predict thermal behavior, identify potential hot spots, and optimize cooling strategies before physical prototyping. These tools help in reducing development time and costs while improving overall system performance.

The concept of thermal management extends beyond component-level cooling to system-level design considerations. This includes optimizing the layout of power electronic components, implementing intelligent thermal management strategies, and utilizing advanced packaging techniques. For instance, 3D packaging and embedded cooling technologies are being explored to achieve more compact and thermally efficient designs.

Monitoring and control of thermal conditions in real-time have also become important aspects of thermal management in PMSM drives. The integration of temperature sensors and intelligent control algorithms allows for dynamic adjustment of operating parameters to maintain optimal thermal conditions and prevent overheating.

As PMSM drives continue to evolve, research in thermal management is focusing on developing more efficient, compact, and cost-effective cooling solutions. This includes exploring novel cooling technologies such as two-phase cooling systems, thermoelectric coolers, and even the use of artificial intelligence for predictive thermal management.

One of the primary focuses of thermal management in PMSM drives is the development of advanced cooling techniques. Traditional air cooling methods are often insufficient for high-power density applications. Liquid cooling systems, utilizing coolants such as water or dielectric fluids, have gained popularity due to their superior heat dissipation capabilities. These systems can be designed with cold plates or direct chip cooling to efficiently remove heat from power electronic components.

The integration of wide bandgap (WBG) semiconductors, such as silicon carbide (SiC) and gallium nitride (GaN), has introduced new thermal challenges and opportunities. While these materials offer higher temperature operation and reduced switching losses, they also require careful thermal design to manage localized hot spots and ensure optimal performance.

Advanced thermal interface materials (TIMs) play a crucial role in improving heat transfer between components and heat sinks. Research in this area has led to the development of novel materials with enhanced thermal conductivity, such as graphene-based TIMs and phase-change materials, which can significantly reduce thermal resistance in the system.

Thermal modeling and simulation tools have become indispensable in the design process of PMSM drives. Computational fluid dynamics (CFD) and finite element analysis (FEA) enable engineers to predict thermal behavior, identify potential hot spots, and optimize cooling strategies before physical prototyping. These tools help in reducing development time and costs while improving overall system performance.

The concept of thermal management extends beyond component-level cooling to system-level design considerations. This includes optimizing the layout of power electronic components, implementing intelligent thermal management strategies, and utilizing advanced packaging techniques. For instance, 3D packaging and embedded cooling technologies are being explored to achieve more compact and thermally efficient designs.

Monitoring and control of thermal conditions in real-time have also become important aspects of thermal management in PMSM drives. The integration of temperature sensors and intelligent control algorithms allows for dynamic adjustment of operating parameters to maintain optimal thermal conditions and prevent overheating.

As PMSM drives continue to evolve, research in thermal management is focusing on developing more efficient, compact, and cost-effective cooling solutions. This includes exploring novel cooling technologies such as two-phase cooling systems, thermoelectric coolers, and even the use of artificial intelligence for predictive thermal management.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!