The role of PMSM in modern powertrain designs

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PMSM Evolution in Powertrains

The evolution of Permanent Magnet Synchronous Motors (PMSM) in powertrains represents a significant technological advancement in the automotive industry. This progression can be traced through several key stages, each marked by notable improvements in performance, efficiency, and integration within vehicle systems.

In the early stages of PMSM adoption, these motors were primarily used in hybrid electric vehicles (HEVs) as auxiliary power sources. The initial designs focused on compact size and moderate power output, complementing traditional internal combustion engines. This phase saw the introduction of basic PMSM configurations, often with surface-mounted magnets and simple control systems.

As technology advanced, the mid-2000s witnessed a shift towards more sophisticated PMSM designs. Manufacturers began incorporating interior permanent magnet (IPM) configurations, which offered higher power density and improved efficiency. This period also saw the development of more advanced control algorithms, enabling better torque control and wider speed ranges.

The late 2000s and early 2010s marked a turning point in PMSM evolution for powertrains. With the rise of fully electric vehicles (EVs), PMSMs became the primary propulsion system. This shift drove significant improvements in power output, thermal management, and integration with power electronics. Manufacturers focused on optimizing magnet arrangements and rotor designs to achieve higher torque densities and extended speed ranges.

Recent years have seen a focus on enhancing PMSM efficiency and reducing reliance on rare earth materials. Innovations in magnet technology, such as the development of dysprosium-free magnets, have addressed concerns about material scarcity and cost. Additionally, advancements in motor design have led to the creation of hybrid excited PMSMs, combining permanent magnets with wound field excitation for improved performance across a wider operating range.

The latest developments in PMSM technology for powertrains include the integration of advanced cooling systems, enabling higher continuous power output and improved reliability. There's also a trend towards modular designs that allow for easier manufacturing and integration into various vehicle platforms. Furthermore, the advent of silicon carbide (SiC) power electronics has enabled higher switching frequencies, resulting in more compact and efficient motor-inverter systems.

Looking forward, the evolution of PMSMs in powertrains is likely to continue with a focus on increased power density, improved efficiency across a wider operating range, and enhanced integration with vehicle systems. Emerging technologies such as 3D printing for motor components and the use of artificial intelligence for real-time motor optimization are expected to drive the next phase of PMSM evolution in modern powertrain designs.

In the early stages of PMSM adoption, these motors were primarily used in hybrid electric vehicles (HEVs) as auxiliary power sources. The initial designs focused on compact size and moderate power output, complementing traditional internal combustion engines. This phase saw the introduction of basic PMSM configurations, often with surface-mounted magnets and simple control systems.

As technology advanced, the mid-2000s witnessed a shift towards more sophisticated PMSM designs. Manufacturers began incorporating interior permanent magnet (IPM) configurations, which offered higher power density and improved efficiency. This period also saw the development of more advanced control algorithms, enabling better torque control and wider speed ranges.

The late 2000s and early 2010s marked a turning point in PMSM evolution for powertrains. With the rise of fully electric vehicles (EVs), PMSMs became the primary propulsion system. This shift drove significant improvements in power output, thermal management, and integration with power electronics. Manufacturers focused on optimizing magnet arrangements and rotor designs to achieve higher torque densities and extended speed ranges.

Recent years have seen a focus on enhancing PMSM efficiency and reducing reliance on rare earth materials. Innovations in magnet technology, such as the development of dysprosium-free magnets, have addressed concerns about material scarcity and cost. Additionally, advancements in motor design have led to the creation of hybrid excited PMSMs, combining permanent magnets with wound field excitation for improved performance across a wider operating range.

The latest developments in PMSM technology for powertrains include the integration of advanced cooling systems, enabling higher continuous power output and improved reliability. There's also a trend towards modular designs that allow for easier manufacturing and integration into various vehicle platforms. Furthermore, the advent of silicon carbide (SiC) power electronics has enabled higher switching frequencies, resulting in more compact and efficient motor-inverter systems.

Looking forward, the evolution of PMSMs in powertrains is likely to continue with a focus on increased power density, improved efficiency across a wider operating range, and enhanced integration with vehicle systems. Emerging technologies such as 3D printing for motor components and the use of artificial intelligence for real-time motor optimization are expected to drive the next phase of PMSM evolution in modern powertrain designs.

Market Demand Analysis

The market demand for Permanent Magnet Synchronous Motors (PMSMs) in modern powertrain designs has been experiencing significant growth, driven by the rapid expansion of the electric vehicle (EV) industry and the increasing focus on energy efficiency across various sectors. As governments worldwide implement stricter emissions regulations and push for electrification, automotive manufacturers are increasingly turning to PMSMs as a key component in their electric and hybrid vehicle powertrains.

In the automotive sector, PMSMs are preferred for their high power density, excellent efficiency, and compact design. These characteristics make them ideal for use in electric vehicles, where space and weight considerations are crucial. The growing consumer demand for EVs with longer range and better performance has further accelerated the adoption of PMSMs in powertrain systems.

Beyond the automotive industry, PMSMs are gaining traction in industrial applications, renewable energy systems, and aerospace. In industrial settings, the demand for high-efficiency motors to reduce energy consumption and operational costs is driving the adoption of PMSMs in various machinery and equipment. The renewable energy sector, particularly wind turbines, is another area where PMSMs are seeing increased demand due to their ability to operate efficiently at variable speeds.

The market for PMSMs is also benefiting from advancements in power electronics and control systems, which enable better motor performance and integration into complex powertrain designs. As these technologies continue to evolve, the capabilities and applications of PMSMs are expected to expand further, opening up new market opportunities.

However, the market demand for PMSMs is not without challenges. The reliance on rare earth materials for permanent magnets has raised concerns about supply chain stability and cost fluctuations. This has led to increased research into alternative motor designs and materials, which could potentially impact the long-term market dynamics for PMSMs.

Despite these challenges, industry analysts project continued growth in the PMSM market, particularly in the EV sector. The increasing focus on sustainability and energy efficiency across industries is expected to sustain this growth trend in the foreseeable future. As manufacturers continue to innovate and improve PMSM designs, addressing challenges such as cost reduction and material sustainability, the market demand is likely to expand further, solidifying the role of PMSMs as a critical component in modern powertrain designs.

In the automotive sector, PMSMs are preferred for their high power density, excellent efficiency, and compact design. These characteristics make them ideal for use in electric vehicles, where space and weight considerations are crucial. The growing consumer demand for EVs with longer range and better performance has further accelerated the adoption of PMSMs in powertrain systems.

Beyond the automotive industry, PMSMs are gaining traction in industrial applications, renewable energy systems, and aerospace. In industrial settings, the demand for high-efficiency motors to reduce energy consumption and operational costs is driving the adoption of PMSMs in various machinery and equipment. The renewable energy sector, particularly wind turbines, is another area where PMSMs are seeing increased demand due to their ability to operate efficiently at variable speeds.

The market for PMSMs is also benefiting from advancements in power electronics and control systems, which enable better motor performance and integration into complex powertrain designs. As these technologies continue to evolve, the capabilities and applications of PMSMs are expected to expand further, opening up new market opportunities.

However, the market demand for PMSMs is not without challenges. The reliance on rare earth materials for permanent magnets has raised concerns about supply chain stability and cost fluctuations. This has led to increased research into alternative motor designs and materials, which could potentially impact the long-term market dynamics for PMSMs.

Despite these challenges, industry analysts project continued growth in the PMSM market, particularly in the EV sector. The increasing focus on sustainability and energy efficiency across industries is expected to sustain this growth trend in the foreseeable future. As manufacturers continue to innovate and improve PMSM designs, addressing challenges such as cost reduction and material sustainability, the market demand is likely to expand further, solidifying the role of PMSMs as a critical component in modern powertrain designs.

PMSM Tech Challenges

Permanent Magnet Synchronous Motors (PMSMs) have become a cornerstone in modern powertrain designs, offering superior efficiency and power density. However, their widespread adoption faces several technical challenges that require innovative solutions.

One of the primary challenges is the optimization of motor design for high-speed operation. As powertrains demand higher rotational speeds to improve overall system efficiency, PMSMs must overcome issues related to mechanical stress, rotor dynamics, and thermal management. The centrifugal forces acting on the rotor at high speeds can lead to deformation or even failure of the permanent magnets, necessitating advanced rotor designs and material solutions.

Thermal management presents another significant hurdle. The compact nature of modern powertrains leaves limited space for cooling systems, yet PMSMs generate considerable heat during operation. Efficient heat dissipation is crucial to maintain motor performance and prevent demagnetization of the permanent magnets. Innovative cooling techniques, such as oil spray cooling or integrated liquid cooling channels, are being explored to address this challenge.

The control of PMSMs at high speeds and under varying load conditions poses complex challenges in power electronics and control algorithms. Field weakening techniques are essential to extend the speed range beyond the base speed, but they come with the trade-off of reduced torque capability. Developing robust control strategies that can handle the nonlinear characteristics of PMSMs across their entire operating range remains an active area of research.

Material limitations also present ongoing challenges. While rare-earth permanent magnets offer excellent magnetic properties, their cost and supply chain vulnerabilities have spurred research into alternative magnet materials or magnet-free designs. Balancing performance with cost-effectiveness and sustainability is a key consideration in PMSM development for powertrains.

Manufacturing complexities associated with PMSMs, particularly in mass production scenarios, pose additional challenges. Achieving consistent quality in magnet placement, rotor balancing, and overall assembly requires advanced manufacturing techniques and stringent quality control measures. The integration of PMSMs into complex powertrain systems also demands careful consideration of packaging, vibration isolation, and electromagnetic compatibility.

Lastly, the drive towards higher power density and efficiency pushes the boundaries of current PMSM designs. Incremental improvements in materials, manufacturing processes, and design optimization are being pursued to extract maximum performance from these motors. However, breakthrough innovations may be necessary to meet the ever-increasing demands of future powertrain applications.

One of the primary challenges is the optimization of motor design for high-speed operation. As powertrains demand higher rotational speeds to improve overall system efficiency, PMSMs must overcome issues related to mechanical stress, rotor dynamics, and thermal management. The centrifugal forces acting on the rotor at high speeds can lead to deformation or even failure of the permanent magnets, necessitating advanced rotor designs and material solutions.

Thermal management presents another significant hurdle. The compact nature of modern powertrains leaves limited space for cooling systems, yet PMSMs generate considerable heat during operation. Efficient heat dissipation is crucial to maintain motor performance and prevent demagnetization of the permanent magnets. Innovative cooling techniques, such as oil spray cooling or integrated liquid cooling channels, are being explored to address this challenge.

The control of PMSMs at high speeds and under varying load conditions poses complex challenges in power electronics and control algorithms. Field weakening techniques are essential to extend the speed range beyond the base speed, but they come with the trade-off of reduced torque capability. Developing robust control strategies that can handle the nonlinear characteristics of PMSMs across their entire operating range remains an active area of research.

Material limitations also present ongoing challenges. While rare-earth permanent magnets offer excellent magnetic properties, their cost and supply chain vulnerabilities have spurred research into alternative magnet materials or magnet-free designs. Balancing performance with cost-effectiveness and sustainability is a key consideration in PMSM development for powertrains.

Manufacturing complexities associated with PMSMs, particularly in mass production scenarios, pose additional challenges. Achieving consistent quality in magnet placement, rotor balancing, and overall assembly requires advanced manufacturing techniques and stringent quality control measures. The integration of PMSMs into complex powertrain systems also demands careful consideration of packaging, vibration isolation, and electromagnetic compatibility.

Lastly, the drive towards higher power density and efficiency pushes the boundaries of current PMSM designs. Incremental improvements in materials, manufacturing processes, and design optimization are being pursued to extract maximum performance from these motors. However, breakthrough innovations may be necessary to meet the ever-increasing demands of future powertrain applications.

Current PMSM Solutions

01 Motor design and structure

Permanent Magnet Synchronous Motors (PMSMs) have specific design features and structural elements that enhance their performance. These may include optimized rotor configurations, stator winding arrangements, and magnetic circuit designs. Innovations in motor structure can lead to improved efficiency, power density, and overall performance of PMSMs.- Control and optimization of PMSM: Advanced control strategies and optimization techniques for Permanent Magnet Synchronous Motors (PMSM) to improve performance, efficiency, and reliability. This includes methods for precise speed and torque control, sensorless operation, and adaptive control algorithms to handle various operating conditions.

- PMSM design and construction: Innovative approaches in the design and construction of PMSMs, focusing on enhancing magnetic flux distribution, reducing cogging torque, and improving overall motor efficiency. This includes novel rotor and stator configurations, advanced materials for permanent magnets, and optimized winding patterns.

- Thermal management in PMSM: Techniques for effective thermal management in PMSMs to prevent overheating and maintain optimal performance. This involves innovative cooling systems, heat dissipation methods, and temperature monitoring strategies to ensure longevity and reliability of the motor under various operating conditions.

- PMSM for electric vehicle applications: Specialized PMSM designs and control strategies tailored for electric vehicle (EV) applications. This includes high-efficiency motors with extended range capabilities, regenerative braking systems, and integration with vehicle power management systems for optimal performance and energy utilization in EVs.

- Fault diagnosis and condition monitoring in PMSM: Advanced techniques for real-time fault diagnosis and condition monitoring in PMSMs. This encompasses methods for detecting and identifying various faults such as demagnetization, bearing failures, and winding issues, as well as predictive maintenance strategies to enhance motor reliability and longevity.

02 Control systems and algorithms

Advanced control systems and algorithms are crucial for optimizing PMSM operation. These may include sensorless control techniques, adaptive control strategies, and advanced modulation methods. Improved control systems can enhance motor efficiency, reduce torque ripple, and provide better dynamic performance across various operating conditions.Expand Specific Solutions03 Thermal management and cooling

Effective thermal management is essential for maintaining PMSM performance and longevity. Innovations in cooling systems, heat dissipation techniques, and temperature monitoring can help prevent overheating, reduce losses, and improve overall motor reliability. This may include novel cooling channel designs or advanced thermal materials.Expand Specific Solutions04 Magnet materials and configurations

The choice and arrangement of permanent magnets significantly impact PMSM performance. Research focuses on developing new magnetic materials, optimizing magnet shapes and placements, and exploring alternative magnet configurations. These advancements aim to improve motor torque density, reduce cogging torque, and enhance overall efficiency.Expand Specific Solutions05 Integration with power electronics

Integrating PMSMs with advanced power electronic systems is crucial for optimal performance in various applications. This includes developing efficient inverter topologies, implementing sophisticated modulation techniques, and designing integrated motor-drive systems. Such integration can lead to improved system efficiency, reduced size, and enhanced controllability.Expand Specific Solutions

Key PMSM Manufacturers

The market for Permanent Magnet Synchronous Motors (PMSM) in modern powertrain designs is experiencing rapid growth and technological advancement. The industry is in a mature growth phase, with increasing adoption across automotive, industrial, and renewable energy sectors. Market size is expanding significantly due to the rising demand for energy-efficient and high-performance electric motors. Companies like Infineon Technologies, GM Global Technology Operations, and NXP USA are at the forefront of PMSM technology development, focusing on improving power density, efficiency, and control systems. The technology's maturity is evident in its widespread implementation, with automotive giants such as Hyundai Motor, Kia, and Toyota Motor Corp. integrating PMSMs into their electric and hybrid vehicle powertrains, signaling a shift towards more sustainable transportation solutions.

Infineon Technologies Americas Corp.

Technical Solution: Infineon has developed cutting-edge power electronics and control solutions specifically tailored for PMSM applications in modern powertrains. Their HybridPACK™ Drive CoolSiC™ module integrates advanced silicon carbide (SiC) MOSFETs with optimized gate drivers, enabling higher switching frequencies and improved efficiency in PMSM control [7]. Infineon's motor control ICs, such as the AURIX™ family, provide sophisticated sensorless field-oriented control algorithms that enhance PMSM performance across a wide speed range. The company's solutions also incorporate advanced current sensing and thermal management techniques, allowing for precise torque control and improved reliability in automotive applications [8].

Strengths: Advanced power electronics integration, high-performance control solutions, wide range of automotive-qualified products. Weaknesses: Reliance on external motor manufacturers for complete powertrain solutions.

GM Global Technology Operations LLC

Technical Solution: GM has developed advanced PMSM technology for their electric vehicle powertrains. Their design focuses on high power density and efficiency, utilizing rare-earth magnets and innovative cooling systems. GM's PMSM motors achieve peak efficiency of over 97% [1], with power outputs ranging from 150 kW to 255 kW depending on the vehicle model [2]. The company has also implemented a unique stator winding design that reduces copper losses and improves thermal management. GM's PMSM motors are integrated into a modular electric drive unit, which combines the electric motor, power electronics, and gearbox into a single, compact package [3].

Strengths: High efficiency, compact design, scalable power output. Weaknesses: Reliance on rare-earth materials, potentially higher production costs.

PMSM Core Innovations

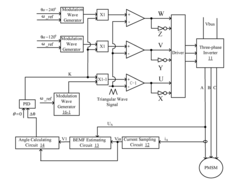

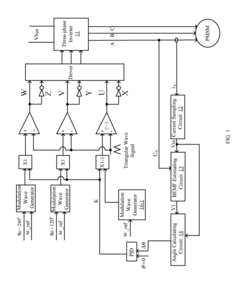

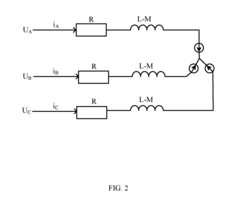

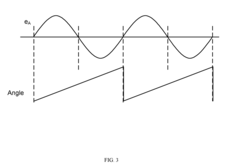

Driving circuit and driving method for permanent magnet synchronous motor

PatentActiveUS20170085196A1

Innovation

- A driving circuit and method that includes a current sampling circuit, back electromotive force (BEMF) circuit, and torque regulating circuit to estimate BEMF information and regulate the amplitude of a U-shaped modulation wave, allowing for maximum torque per ampere without a position sensor, using a sliding mode controller and PID regulator to synchronize rotor current with the modulation wave.

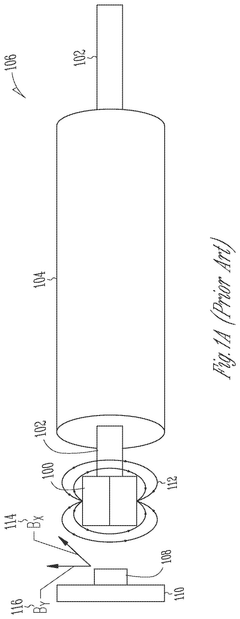

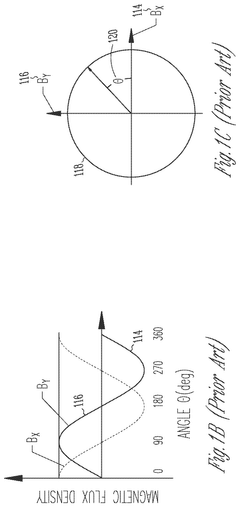

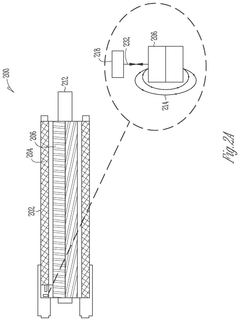

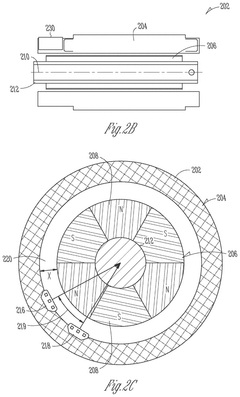

Permanent magnet synchronous motor (PMSM) integrated position sensing

PatentActiveUS12212257B2

Innovation

- The integration of analog magnetic flux sensors within the hollow cylindrical stator of the PMSM, arranged concentrically around the rotational axis at a constant mechanical angle relative to each other, allows for direct measurement of the magnetic flux from the rotor without external obstructions, enabling accurate rotor position sensing and reducing motor size and cost.

Energy Efficiency Impact

The integration of Permanent Magnet Synchronous Motors (PMSM) in modern powertrain designs has significantly impacted energy efficiency in electric and hybrid vehicles. PMSMs offer superior power density and efficiency compared to traditional induction motors, leading to improved overall vehicle performance and reduced energy consumption.

One of the primary advantages of PMSMs is their high efficiency across a wide range of operating speeds. This characteristic is particularly beneficial in automotive applications, where vehicles frequently operate at varying speeds and loads. The efficiency of PMSMs can exceed 95% in optimal conditions, resulting in less energy loss during power conversion and transmission.

The compact design of PMSMs allows for better space utilization within the powertrain, contributing to overall vehicle weight reduction. This weight savings directly translates to improved energy efficiency, as less energy is required to propel the vehicle. Additionally, the reduced size enables more flexible powertrain configurations, potentially leading to further optimization of vehicle dynamics and energy management systems.

PMSMs exhibit excellent torque characteristics, providing high torque at low speeds and maintaining good performance at higher speeds. This torque profile aligns well with the requirements of electric vehicles, enabling rapid acceleration and smooth operation across various driving conditions. The ability to deliver high torque efficiently contributes to reduced energy consumption during acceleration and hill climbing scenarios.

The use of permanent magnets in PMSMs eliminates the need for external excitation, reducing electrical losses associated with field windings. This feature not only improves efficiency but also simplifies the motor control system, potentially leading to more reliable and cost-effective powertrain solutions.

Advanced control strategies for PMSMs, such as field-oriented control and model predictive control, further enhance energy efficiency by optimizing motor operation based on real-time driving conditions. These control techniques allow for precise torque and speed regulation, minimizing energy waste and maximizing power utilization.

The integration of PMSMs with regenerative braking systems has a significant impact on overall energy efficiency. During deceleration or downhill driving, PMSMs can function as generators, converting kinetic energy back into electrical energy to recharge the vehicle's battery. This energy recovery process substantially improves the overall efficiency of the powertrain system, extending the vehicle's range and reducing energy consumption.

One of the primary advantages of PMSMs is their high efficiency across a wide range of operating speeds. This characteristic is particularly beneficial in automotive applications, where vehicles frequently operate at varying speeds and loads. The efficiency of PMSMs can exceed 95% in optimal conditions, resulting in less energy loss during power conversion and transmission.

The compact design of PMSMs allows for better space utilization within the powertrain, contributing to overall vehicle weight reduction. This weight savings directly translates to improved energy efficiency, as less energy is required to propel the vehicle. Additionally, the reduced size enables more flexible powertrain configurations, potentially leading to further optimization of vehicle dynamics and energy management systems.

PMSMs exhibit excellent torque characteristics, providing high torque at low speeds and maintaining good performance at higher speeds. This torque profile aligns well with the requirements of electric vehicles, enabling rapid acceleration and smooth operation across various driving conditions. The ability to deliver high torque efficiently contributes to reduced energy consumption during acceleration and hill climbing scenarios.

The use of permanent magnets in PMSMs eliminates the need for external excitation, reducing electrical losses associated with field windings. This feature not only improves efficiency but also simplifies the motor control system, potentially leading to more reliable and cost-effective powertrain solutions.

Advanced control strategies for PMSMs, such as field-oriented control and model predictive control, further enhance energy efficiency by optimizing motor operation based on real-time driving conditions. These control techniques allow for precise torque and speed regulation, minimizing energy waste and maximizing power utilization.

The integration of PMSMs with regenerative braking systems has a significant impact on overall energy efficiency. During deceleration or downhill driving, PMSMs can function as generators, converting kinetic energy back into electrical energy to recharge the vehicle's battery. This energy recovery process substantially improves the overall efficiency of the powertrain system, extending the vehicle's range and reducing energy consumption.

PMSM Manufacturing Trends

The manufacturing trends of Permanent Magnet Synchronous Motors (PMSM) have been evolving rapidly in response to the increasing demand for high-efficiency powertrains in modern vehicles. One significant trend is the shift towards more automated and precise manufacturing processes. Advanced robotics and computer-controlled systems are being increasingly employed in PMSM production lines, ensuring higher consistency and quality in motor assembly.

Another notable trend is the focus on materials innovation. Manufacturers are exploring new magnetic materials and improved lamination steels to enhance motor performance and efficiency. The use of rare-earth magnets, particularly neodymium-iron-boron (NdFeB) magnets, has become more prevalent due to their superior magnetic properties. However, concerns about the supply chain stability of rare-earth elements have also led to research into alternative magnetic materials.

Additive manufacturing techniques are gaining traction in PMSM production. 3D printing of certain motor components allows for more complex geometries and potentially reduces material waste. This technology is particularly useful for prototyping and small-scale production runs, enabling faster iteration and customization of motor designs.

The integration of sensors and smart technologies into the manufacturing process is another emerging trend. In-line quality control systems using advanced sensors and machine learning algorithms are being implemented to detect defects and ensure consistent motor performance. This trend aligns with the broader Industry 4.0 movement, emphasizing data-driven manufacturing and predictive maintenance.

Environmental considerations are also shaping PMSM manufacturing trends. There is a growing emphasis on sustainable production methods, including the use of recycled materials and the development of more energy-efficient manufacturing processes. Some manufacturers are exploring ways to reduce or eliminate the use of heavy rare-earth elements in magnets, addressing both environmental and supply chain concerns.

Miniaturization and increased power density are driving changes in manufacturing techniques. As electric powertrains become more compact and powerful, manufacturers are developing new methods to produce smaller, more precise motor components without compromising performance. This includes advancements in winding techniques and thermal management solutions.

Lastly, there is a trend towards greater vertical integration in PMSM manufacturing. Some major automotive and industrial companies are bringing motor production in-house or forming strategic partnerships with specialized motor manufacturers. This approach aims to secure supply chains, reduce costs, and maintain tighter control over motor design and quality.

Another notable trend is the focus on materials innovation. Manufacturers are exploring new magnetic materials and improved lamination steels to enhance motor performance and efficiency. The use of rare-earth magnets, particularly neodymium-iron-boron (NdFeB) magnets, has become more prevalent due to their superior magnetic properties. However, concerns about the supply chain stability of rare-earth elements have also led to research into alternative magnetic materials.

Additive manufacturing techniques are gaining traction in PMSM production. 3D printing of certain motor components allows for more complex geometries and potentially reduces material waste. This technology is particularly useful for prototyping and small-scale production runs, enabling faster iteration and customization of motor designs.

The integration of sensors and smart technologies into the manufacturing process is another emerging trend. In-line quality control systems using advanced sensors and machine learning algorithms are being implemented to detect defects and ensure consistent motor performance. This trend aligns with the broader Industry 4.0 movement, emphasizing data-driven manufacturing and predictive maintenance.

Environmental considerations are also shaping PMSM manufacturing trends. There is a growing emphasis on sustainable production methods, including the use of recycled materials and the development of more energy-efficient manufacturing processes. Some manufacturers are exploring ways to reduce or eliminate the use of heavy rare-earth elements in magnets, addressing both environmental and supply chain concerns.

Miniaturization and increased power density are driving changes in manufacturing techniques. As electric powertrains become more compact and powerful, manufacturers are developing new methods to produce smaller, more precise motor components without compromising performance. This includes advancements in winding techniques and thermal management solutions.

Lastly, there is a trend towards greater vertical integration in PMSM manufacturing. Some major automotive and industrial companies are bringing motor production in-house or forming strategic partnerships with specialized motor manufacturers. This approach aims to secure supply chains, reduce costs, and maintain tighter control over motor design and quality.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!