Actuation efficiency comparison in PMSM and servomotors

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PMSM and Servo Evolution

The evolution of Permanent Magnet Synchronous Motors (PMSM) and servomotors represents a significant advancement in electric motor technology. PMSMs emerged in the 1970s as a result of improvements in permanent magnet materials, particularly the development of rare-earth magnets. These motors offered higher efficiency and power density compared to traditional induction motors, making them attractive for various applications.

Servomotors, on the other hand, have a longer history dating back to the 1940s. Initially used in military and aerospace applications, they gained popularity in industrial automation during the 1960s and 1970s. Early servomotors were primarily based on DC motor technology, but the integration of PMSMs into servo systems marked a turning point in their evolution.

The 1980s and 1990s saw rapid advancements in both PMSM and servomotor technologies. For PMSMs, the focus was on improving magnet materials and optimizing motor design to enhance efficiency and reduce cogging torque. Neodymium-iron-boron (NdFeB) magnets, introduced in the 1980s, significantly boosted PMSM performance. Concurrently, servomotor development concentrated on enhancing control systems, incorporating digital electronics and microprocessors for more precise positioning and speed control.

In the 2000s, the convergence of PMSM and servomotor technologies accelerated. PMSM-based servomotors became increasingly common, offering superior performance in terms of efficiency, power density, and dynamic response. This period also saw advancements in motor design software and simulation tools, enabling more sophisticated optimization of motor parameters.

The past decade has witnessed further refinements in both technologies. For PMSMs, research has focused on reducing reliance on rare-earth materials, exploring alternative magnet compositions, and developing advanced control algorithms to maximize efficiency across a wide operating range. In the servomotor domain, emphasis has been placed on enhancing precision, developing more compact designs, and improving integration with digital control systems and industrial networks.

Recent trends include the development of high-speed PMSMs and servomotors for specialized applications, as well as the integration of smart features such as built-in sensors and predictive maintenance capabilities. The push towards Industry 4.0 and the Internet of Things (IoT) has also influenced the evolution of these motors, with increased focus on connectivity and data-driven optimization.

Looking ahead, the evolution of PMSMs and servomotors is likely to continue along several paths. These include further improvements in efficiency, the development of more environmentally friendly designs, and the integration of advanced materials and manufacturing techniques such as 3D printing for motor components. Additionally, the growing emphasis on electric vehicles and renewable energy systems is expected to drive innovation in high-performance, cost-effective motor solutions.

Servomotors, on the other hand, have a longer history dating back to the 1940s. Initially used in military and aerospace applications, they gained popularity in industrial automation during the 1960s and 1970s. Early servomotors were primarily based on DC motor technology, but the integration of PMSMs into servo systems marked a turning point in their evolution.

The 1980s and 1990s saw rapid advancements in both PMSM and servomotor technologies. For PMSMs, the focus was on improving magnet materials and optimizing motor design to enhance efficiency and reduce cogging torque. Neodymium-iron-boron (NdFeB) magnets, introduced in the 1980s, significantly boosted PMSM performance. Concurrently, servomotor development concentrated on enhancing control systems, incorporating digital electronics and microprocessors for more precise positioning and speed control.

In the 2000s, the convergence of PMSM and servomotor technologies accelerated. PMSM-based servomotors became increasingly common, offering superior performance in terms of efficiency, power density, and dynamic response. This period also saw advancements in motor design software and simulation tools, enabling more sophisticated optimization of motor parameters.

The past decade has witnessed further refinements in both technologies. For PMSMs, research has focused on reducing reliance on rare-earth materials, exploring alternative magnet compositions, and developing advanced control algorithms to maximize efficiency across a wide operating range. In the servomotor domain, emphasis has been placed on enhancing precision, developing more compact designs, and improving integration with digital control systems and industrial networks.

Recent trends include the development of high-speed PMSMs and servomotors for specialized applications, as well as the integration of smart features such as built-in sensors and predictive maintenance capabilities. The push towards Industry 4.0 and the Internet of Things (IoT) has also influenced the evolution of these motors, with increased focus on connectivity and data-driven optimization.

Looking ahead, the evolution of PMSMs and servomotors is likely to continue along several paths. These include further improvements in efficiency, the development of more environmentally friendly designs, and the integration of advanced materials and manufacturing techniques such as 3D printing for motor components. Additionally, the growing emphasis on electric vehicles and renewable energy systems is expected to drive innovation in high-performance, cost-effective motor solutions.

Market Demand Analysis

The market demand for efficient actuation systems in Permanent Magnet Synchronous Motors (PMSM) and servomotors has been steadily increasing across various industries. This growth is primarily driven by the rising need for precise motion control, energy efficiency, and improved performance in applications ranging from industrial automation to electric vehicles and robotics.

In the industrial automation sector, there is a growing demand for high-precision motion control systems that can enhance manufacturing processes and increase productivity. PMSMs and servomotors are increasingly being adopted in CNC machines, robotics, and packaging equipment due to their superior control capabilities and energy efficiency. The automotive industry, particularly in the electric vehicle (EV) segment, has also become a significant driver of demand for these motor technologies. As the EV market expands, the need for efficient and compact motor solutions that can maximize range and performance has intensified.

The aerospace and defense sectors are also contributing to the market demand for advanced actuation systems. These industries require highly reliable and efficient motors for applications such as flight control surfaces, weapon systems, and unmanned aerial vehicles. The compact size and high power density of PMSMs and servomotors make them particularly attractive for these applications.

In the renewable energy sector, there is an increasing demand for efficient motor solutions in wind turbines and solar tracking systems. PMSMs and servomotors offer advantages in terms of reliability, efficiency, and precise control, which are crucial for optimizing energy generation in these applications.

The healthcare industry is another significant market for these motor technologies. Medical equipment such as surgical robots, imaging systems, and prosthetics require precise and efficient actuation, driving the adoption of advanced motor solutions.

As industries continue to focus on energy efficiency and sustainability, the demand for motors with higher efficiency ratings is expected to grow. This trend is further supported by government regulations and incentives aimed at reducing energy consumption and carbon emissions in various sectors.

The market for PMSMs and servomotors is also being influenced by the broader trend of Industry 4.0 and the Industrial Internet of Things (IIoT). As manufacturing processes become more automated and interconnected, the need for intelligent motor systems that can integrate seamlessly with digital control systems and provide real-time performance data is increasing.

Overall, the market demand for efficient actuation systems in PMSMs and servomotors is expected to continue its upward trajectory. The combination of technological advancements, industry-specific requirements, and global trends towards efficiency and sustainability is likely to drive further innovation and adoption of these motor technologies across a wide range of applications.

In the industrial automation sector, there is a growing demand for high-precision motion control systems that can enhance manufacturing processes and increase productivity. PMSMs and servomotors are increasingly being adopted in CNC machines, robotics, and packaging equipment due to their superior control capabilities and energy efficiency. The automotive industry, particularly in the electric vehicle (EV) segment, has also become a significant driver of demand for these motor technologies. As the EV market expands, the need for efficient and compact motor solutions that can maximize range and performance has intensified.

The aerospace and defense sectors are also contributing to the market demand for advanced actuation systems. These industries require highly reliable and efficient motors for applications such as flight control surfaces, weapon systems, and unmanned aerial vehicles. The compact size and high power density of PMSMs and servomotors make them particularly attractive for these applications.

In the renewable energy sector, there is an increasing demand for efficient motor solutions in wind turbines and solar tracking systems. PMSMs and servomotors offer advantages in terms of reliability, efficiency, and precise control, which are crucial for optimizing energy generation in these applications.

The healthcare industry is another significant market for these motor technologies. Medical equipment such as surgical robots, imaging systems, and prosthetics require precise and efficient actuation, driving the adoption of advanced motor solutions.

As industries continue to focus on energy efficiency and sustainability, the demand for motors with higher efficiency ratings is expected to grow. This trend is further supported by government regulations and incentives aimed at reducing energy consumption and carbon emissions in various sectors.

The market for PMSMs and servomotors is also being influenced by the broader trend of Industry 4.0 and the Industrial Internet of Things (IIoT). As manufacturing processes become more automated and interconnected, the need for intelligent motor systems that can integrate seamlessly with digital control systems and provide real-time performance data is increasing.

Overall, the market demand for efficient actuation systems in PMSMs and servomotors is expected to continue its upward trajectory. The combination of technological advancements, industry-specific requirements, and global trends towards efficiency and sustainability is likely to drive further innovation and adoption of these motor technologies across a wide range of applications.

Technical Challenges

The comparison of actuation efficiency between Permanent Magnet Synchronous Motors (PMSM) and servomotors presents several technical challenges that researchers and engineers must address. These challenges stem from the inherent differences in design, operation, and application of these two motor types.

One of the primary challenges lies in establishing a standardized methodology for comparing efficiency across different motor architectures. PMSMs and servomotors operate on different principles, with PMSMs utilizing permanent magnets for field excitation and servomotors often employing wound field excitation. This fundamental difference makes direct comparisons complex, as the energy conversion mechanisms and loss profiles vary significantly between the two types.

Another significant challenge is accurately measuring and quantifying losses in both motor types under various operating conditions. PMSMs typically exhibit lower rotor losses due to the absence of rotor windings, but may suffer from eddy current losses in the permanent magnets. Servomotors, on the other hand, may have higher rotor losses but offer greater flexibility in field control. Developing precise measurement techniques and loss models that account for these differences is crucial for a fair comparison.

The impact of control strategies on efficiency poses another technical hurdle. Servomotors often employ sophisticated control algorithms to optimize performance, while PMSMs may rely on simpler control schemes. Evaluating the efficiency of these motors while considering the energy consumption of their respective control systems adds another layer of complexity to the comparison process.

Temperature management and its effect on efficiency is a critical challenge, particularly for PMSMs. The performance of permanent magnets can degrade at high temperatures, potentially leading to demagnetization and reduced efficiency. Servomotors may be less susceptible to this issue but may require more complex cooling systems. Developing accurate thermal models and cooling strategies for both motor types is essential for a comprehensive efficiency comparison.

The influence of motor size and power rating on efficiency comparisons presents another challenge. PMSMs tend to have higher efficiency in smaller sizes, while servomotors may offer advantages in larger power ranges. Creating a fair comparison methodology that accounts for these scaling effects requires careful consideration and standardization of test procedures.

Lastly, the application-specific nature of motor efficiency poses a significant challenge. The efficiency of both PMSMs and servomotors can vary greatly depending on the specific application requirements, such as duty cycle, speed range, and torque profile. Developing a comprehensive set of benchmark tests that accurately reflect real-world operating conditions across various applications is crucial for meaningful efficiency comparisons.

One of the primary challenges lies in establishing a standardized methodology for comparing efficiency across different motor architectures. PMSMs and servomotors operate on different principles, with PMSMs utilizing permanent magnets for field excitation and servomotors often employing wound field excitation. This fundamental difference makes direct comparisons complex, as the energy conversion mechanisms and loss profiles vary significantly between the two types.

Another significant challenge is accurately measuring and quantifying losses in both motor types under various operating conditions. PMSMs typically exhibit lower rotor losses due to the absence of rotor windings, but may suffer from eddy current losses in the permanent magnets. Servomotors, on the other hand, may have higher rotor losses but offer greater flexibility in field control. Developing precise measurement techniques and loss models that account for these differences is crucial for a fair comparison.

The impact of control strategies on efficiency poses another technical hurdle. Servomotors often employ sophisticated control algorithms to optimize performance, while PMSMs may rely on simpler control schemes. Evaluating the efficiency of these motors while considering the energy consumption of their respective control systems adds another layer of complexity to the comparison process.

Temperature management and its effect on efficiency is a critical challenge, particularly for PMSMs. The performance of permanent magnets can degrade at high temperatures, potentially leading to demagnetization and reduced efficiency. Servomotors may be less susceptible to this issue but may require more complex cooling systems. Developing accurate thermal models and cooling strategies for both motor types is essential for a comprehensive efficiency comparison.

The influence of motor size and power rating on efficiency comparisons presents another challenge. PMSMs tend to have higher efficiency in smaller sizes, while servomotors may offer advantages in larger power ranges. Creating a fair comparison methodology that accounts for these scaling effects requires careful consideration and standardization of test procedures.

Lastly, the application-specific nature of motor efficiency poses a significant challenge. The efficiency of both PMSMs and servomotors can vary greatly depending on the specific application requirements, such as duty cycle, speed range, and torque profile. Developing a comprehensive set of benchmark tests that accurately reflect real-world operating conditions across various applications is crucial for meaningful efficiency comparisons.

Current Efficiency Solutions

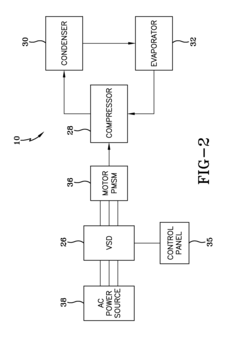

01 PMSM control strategies for improved efficiency

Various control strategies are employed to enhance the efficiency of Permanent Magnet Synchronous Motors (PMSM). These include advanced algorithms for torque control, flux weakening techniques, and optimized current vector control. Such strategies aim to minimize losses and maximize power output across different operating conditions.- PMSM control strategies for improved efficiency: Various control strategies are employed to enhance the efficiency of Permanent Magnet Synchronous Motors (PMSM). These include advanced algorithms for torque control, flux weakening techniques, and optimized current vector control. Such strategies aim to minimize losses and maximize power output across different operating conditions.

- Servo system design for high-performance actuation: Servo systems are designed with focus on high-performance actuation. This involves integrating precise position feedback mechanisms, implementing advanced control algorithms, and optimizing the mechanical design of the motor and drive system. These improvements lead to enhanced responsiveness and accuracy in motion control applications.

- Energy recovery and regenerative braking in PMSM systems: Energy efficiency in PMSM and servo systems is improved through energy recovery mechanisms and regenerative braking. These techniques capture and reuse kinetic energy during deceleration, reducing overall energy consumption and improving system efficiency, particularly in applications with frequent start-stop cycles.

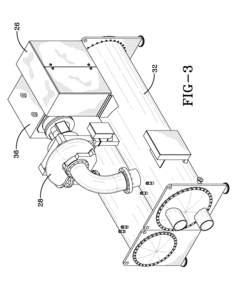

- Thermal management for improved motor efficiency: Effective thermal management strategies are crucial for maintaining high efficiency in PMSM and servo motors. This includes innovative cooling designs, use of advanced materials for heat dissipation, and temperature-based control algorithms. Proper thermal management prevents performance degradation and extends motor lifespan.

- Integration of power electronics for optimized drive performance: The integration of advanced power electronics with PMSM and servo motors leads to optimized drive performance. This includes the use of efficient inverter designs, implementation of sophisticated modulation techniques, and the development of compact, integrated motor-drive units. Such integration results in reduced losses, improved power density, and enhanced overall system efficiency.

02 Servo drive system optimization

Servo drive systems are optimized to improve actuation efficiency in PMSM-based servomotors. This involves enhancing power electronics, implementing intelligent control algorithms, and utilizing high-performance feedback systems. These optimizations result in better dynamic response, increased precision, and reduced energy consumption.Expand Specific Solutions03 Thermal management for efficiency improvement

Effective thermal management techniques are crucial for maintaining high efficiency in PMSM and servomotors. This includes innovative cooling systems, thermally optimized motor designs, and temperature-aware control strategies. Proper thermal management helps reduce losses and extends the operational range of the motors.Expand Specific Solutions04 Advanced materials and manufacturing techniques

The use of advanced materials and manufacturing techniques contributes to improved actuation efficiency in PMSM and servomotors. This includes the application of high-performance magnetic materials, optimized lamination designs, and precision manufacturing processes. These advancements result in reduced losses and enhanced power density.Expand Specific Solutions05 Integration of sensors and feedback systems

The integration of advanced sensors and feedback systems plays a crucial role in improving the actuation efficiency of PMSM and servomotors. High-resolution position sensors, current sensors, and temperature sensors provide accurate data for precise control and optimization of motor performance. This integration enables real-time adjustments and adaptive control strategies.Expand Specific Solutions

Key Motor Manufacturers

The competition landscape for actuation efficiency comparison in PMSM and servomotors is characterized by a mature market with established players and ongoing technological advancements. The industry is in a growth phase, driven by increasing demand for high-efficiency motors in various applications. Key players like ABB Group, Mitsubishi Electric Corp., and Infineon Technologies are investing heavily in R&D to improve motor efficiency and performance. The market size is substantial, with a global reach across industrial, automotive, and consumer sectors. Technological maturity is high, with companies like Microchip Technology and Samsung Electronics continuously innovating in motor control and power electronics to enhance actuation efficiency.

ABB Group

Technical Solution: ABB Group has developed advanced control algorithms for both PMSM and servomotors to optimize actuation efficiency. For PMSMs, they utilize field-oriented control (FOC) with space vector modulation, achieving up to 98% efficiency in certain applications[1]. Their servomotor solutions incorporate adaptive control techniques, compensating for load variations and minimizing energy losses. ABB's proprietary DTC (Direct Torque Control) technology, applied to both motor types, enables precise torque control and rapid response times, enhancing overall system efficiency[2]. The company has also implemented advanced thermal management systems, reducing heat-related losses and extending motor lifespan.

Strengths: High efficiency, precise control, and adaptability to various industrial applications. Weaknesses: Potentially higher initial costs and complexity in implementation for some users.

Infineon Technologies Americas Corp.

Technical Solution: Infineon Technologies has developed cutting-edge semiconductor solutions to enhance actuation efficiency in both PMSM and servomotors. Their iMOTION™ platform integrates advanced motor control algorithms with high-performance power devices, enabling efficiencies of up to 98% in PMSM applications[5]. For servomotors, Infineon's XMC™ microcontrollers provide precise position and speed control, utilizing field-oriented control (FOC) techniques to optimize energy consumption. The company's CoolMOS™ and OptiMOS™ power transistors offer ultra-low on-resistance, significantly reducing switching losses in motor drive systems[6]. Infineon has also introduced innovative gate driver ICs with integrated current sensing capabilities, allowing for more accurate and efficient motor control across various operating conditions.

Strengths: High-performance semiconductor solutions, integrated control systems, and low power losses. Weaknesses: Reliance on specific hardware platforms may limit flexibility for some applications.

Core Efficiency Innovations

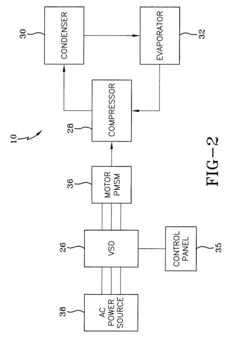

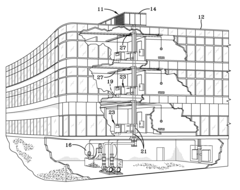

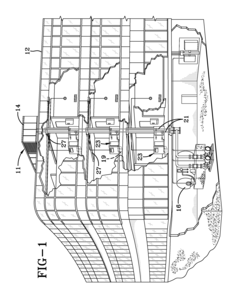

Variable speed drive with pulse-width modulated speed control

PatentActiveUS20100083693A1

Innovation

- A variable speed drive system using a converter, DC link, and inverter with a controller applying randomized Pulse-Width Modulation (PWM) to vary the switching frequency of transistors, enabling AC power output with variable voltage and frequency, and reducing harmonic components and noise.

Variable speed drive for permanent magnet motor

PatentActiveUS20100085000A1

Innovation

- A variable speed drive system incorporating an active filter and a passive filter, where the active filter generates high-frequency currents of opposite polarity to cancel out high-frequency currents, while the passive filter absorbs remaining harmonics, optimizing the system's efficiency and reducing costs.

Energy Regulations Impact

The impact of energy regulations on the comparison of actuation efficiency between Permanent Magnet Synchronous Motors (PMSM) and servomotors is significant and multifaceted. As global energy policies increasingly prioritize sustainability and efficiency, these regulations have become a driving force in motor technology development and selection.

Energy efficiency standards, such as those set by the International Electrotechnical Commission (IEC) and regional bodies like the European Union's Ecodesign Directive, have pushed manufacturers to improve motor performance. These regulations typically establish minimum efficiency levels for electric motors, which has led to advancements in both PMSM and servomotor technologies.

For PMSMs, energy regulations have accelerated the adoption of high-performance magnets and optimized motor designs. The use of rare-earth materials in PMSMs has been particularly influenced by these regulations, as they enable higher power densities and efficiencies. However, this has also raised concerns about the environmental impact and supply chain sustainability of these materials.

Servomotors, which are often used in precision control applications, have seen improvements in their control systems and power electronics to meet energy efficiency requirements. The integration of advanced feedback mechanisms and more sophisticated control algorithms has allowed servomotors to achieve higher levels of efficiency, particularly in dynamic operating conditions.

The comparison between PMSMs and servomotors in terms of actuation efficiency has been further complicated by these regulations. While PMSMs generally offer higher efficiency at steady-state operations, servomotors may provide better overall system efficiency in applications requiring frequent starts, stops, and position changes.

Energy regulations have also influenced the development of motor sizing and selection tools. These tools now incorporate efficiency metrics and lifecycle energy consumption calculations, allowing engineers to make more informed decisions when choosing between PMSMs and servomotors for specific applications.

Furthermore, the emphasis on system-level efficiency in energy regulations has led to a more holistic approach in motor selection. This includes considering factors such as the efficiency of associated drive systems, power transmission components, and the overall application requirements.

As energy regulations continue to evolve, they are likely to further shape the landscape of motor technology. This may lead to increased convergence between PMSM and servomotor technologies, with hybrid solutions emerging to meet both high efficiency and precise control requirements across a wider range of applications.

Energy efficiency standards, such as those set by the International Electrotechnical Commission (IEC) and regional bodies like the European Union's Ecodesign Directive, have pushed manufacturers to improve motor performance. These regulations typically establish minimum efficiency levels for electric motors, which has led to advancements in both PMSM and servomotor technologies.

For PMSMs, energy regulations have accelerated the adoption of high-performance magnets and optimized motor designs. The use of rare-earth materials in PMSMs has been particularly influenced by these regulations, as they enable higher power densities and efficiencies. However, this has also raised concerns about the environmental impact and supply chain sustainability of these materials.

Servomotors, which are often used in precision control applications, have seen improvements in their control systems and power electronics to meet energy efficiency requirements. The integration of advanced feedback mechanisms and more sophisticated control algorithms has allowed servomotors to achieve higher levels of efficiency, particularly in dynamic operating conditions.

The comparison between PMSMs and servomotors in terms of actuation efficiency has been further complicated by these regulations. While PMSMs generally offer higher efficiency at steady-state operations, servomotors may provide better overall system efficiency in applications requiring frequent starts, stops, and position changes.

Energy regulations have also influenced the development of motor sizing and selection tools. These tools now incorporate efficiency metrics and lifecycle energy consumption calculations, allowing engineers to make more informed decisions when choosing between PMSMs and servomotors for specific applications.

Furthermore, the emphasis on system-level efficiency in energy regulations has led to a more holistic approach in motor selection. This includes considering factors such as the efficiency of associated drive systems, power transmission components, and the overall application requirements.

As energy regulations continue to evolve, they are likely to further shape the landscape of motor technology. This may lead to increased convergence between PMSM and servomotor technologies, with hybrid solutions emerging to meet both high efficiency and precise control requirements across a wider range of applications.

Cost-Benefit Analysis

The cost-benefit analysis of PMSM (Permanent Magnet Synchronous Motors) and servomotors reveals significant differences in their actuation efficiency and overall economic impact. PMSMs generally offer higher efficiency and lower operating costs due to their superior power density and reduced energy consumption. The initial investment for PMSMs is typically higher, primarily due to the cost of rare earth magnets used in their construction. However, this is often offset by lower maintenance requirements and longer operational lifespans.

Servomotors, while potentially less expensive upfront, may incur higher long-term costs due to increased energy consumption and more frequent maintenance needs. Their efficiency can vary widely depending on the specific application and load conditions. In high-precision positioning tasks, servomotors may provide better cost-effectiveness due to their inherent feedback mechanisms.

When considering total cost of ownership, PMSMs often emerge as the more economical choice for continuous operation scenarios, particularly in industrial applications where energy costs are a significant factor. The energy savings over time can substantially outweigh the higher initial investment. Conversely, servomotors may prove more cost-effective in applications with intermittent use or where precise position control is paramount.

The environmental impact should also be factored into the cost-benefit analysis. PMSMs' higher efficiency translates to reduced carbon emissions and lower environmental costs, which may become increasingly important as environmental regulations tighten and carbon pricing mechanisms expand globally.

Scalability is another crucial consideration. PMSMs tend to maintain their efficiency advantages across a wider range of power outputs, making them more cost-effective for applications that require scaling. Servomotors, while versatile, may see diminishing returns in efficiency as they are scaled up, potentially leading to higher costs in larger systems.

In conclusion, while PMSMs generally offer better long-term cost benefits due to their superior efficiency, the optimal choice between PMSMs and servomotors depends heavily on the specific application requirements, operational patterns, and environmental considerations. A thorough analysis of these factors is essential for making an informed decision that balances initial costs against long-term operational expenses and performance benefits.

Servomotors, while potentially less expensive upfront, may incur higher long-term costs due to increased energy consumption and more frequent maintenance needs. Their efficiency can vary widely depending on the specific application and load conditions. In high-precision positioning tasks, servomotors may provide better cost-effectiveness due to their inherent feedback mechanisms.

When considering total cost of ownership, PMSMs often emerge as the more economical choice for continuous operation scenarios, particularly in industrial applications where energy costs are a significant factor. The energy savings over time can substantially outweigh the higher initial investment. Conversely, servomotors may prove more cost-effective in applications with intermittent use or where precise position control is paramount.

The environmental impact should also be factored into the cost-benefit analysis. PMSMs' higher efficiency translates to reduced carbon emissions and lower environmental costs, which may become increasingly important as environmental regulations tighten and carbon pricing mechanisms expand globally.

Scalability is another crucial consideration. PMSMs tend to maintain their efficiency advantages across a wider range of power outputs, making them more cost-effective for applications that require scaling. Servomotors, while versatile, may see diminishing returns in efficiency as they are scaled up, potentially leading to higher costs in larger systems.

In conclusion, while PMSMs generally offer better long-term cost benefits due to their superior efficiency, the optimal choice between PMSMs and servomotors depends heavily on the specific application requirements, operational patterns, and environmental considerations. A thorough analysis of these factors is essential for making an informed decision that balances initial costs against long-term operational expenses and performance benefits.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!