Analyzing power-to-weight ratios in modern PMSM

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PMSM Power-Weight Evolution

The evolution of power-to-weight ratios in Permanent Magnet Synchronous Motors (PMSMs) has been a critical factor in their widespread adoption across various industries. This progression can be traced through several key developmental stages, each marked by significant technological advancements and innovative solutions.

In the early stages of PMSM development, the focus was primarily on improving overall efficiency and torque density. However, as applications in electric vehicles, aerospace, and robotics emerged, the emphasis shifted towards optimizing the power-to-weight ratio. This shift was driven by the need for more compact and lightweight motors that could deliver high performance in space-constrained environments.

The 1990s saw the introduction of rare-earth magnets, particularly neodymium-iron-boron (NdFeB) magnets, which revolutionized PMSM design. These magnets offered significantly higher magnetic flux densities compared to traditional ferrite magnets, allowing for substantial reductions in motor size and weight while maintaining or even increasing power output. This breakthrough marked a pivotal moment in the power-to-weight evolution of PMSMs.

As we entered the 21st century, advancements in materials science and manufacturing techniques further propelled the improvement of power-to-weight ratios. The development of high-strength, lightweight alloys for motor housings and the implementation of advanced cooling systems enabled motors to operate at higher power densities without compromising reliability or lifespan.

The integration of sophisticated control algorithms and power electronics in the 2010s brought about another leap in PMSM performance. Field-oriented control (FOC) and model predictive control (MPC) techniques allowed for more precise and efficient motor operation, effectively increasing the usable power output without necessitating physical changes to the motor's design.

Recent years have seen a focus on optimizing motor topology and magnetic circuit design. Techniques such as halbach array configurations and the use of concentrated windings have further enhanced power density while reducing overall motor mass. Additionally, the exploration of new magnetic materials, such as cerium-based magnets, promises to address concerns about the availability and cost of rare-earth elements while maintaining high performance.

Looking towards the future, emerging technologies like additive manufacturing and nanotechnology are poised to drive the next wave of innovations in PMSM power-to-weight ratios. These advancements may enable the creation of complex, lightweight structures and novel magnetic materials that were previously impossible to produce using traditional manufacturing methods.

In the early stages of PMSM development, the focus was primarily on improving overall efficiency and torque density. However, as applications in electric vehicles, aerospace, and robotics emerged, the emphasis shifted towards optimizing the power-to-weight ratio. This shift was driven by the need for more compact and lightweight motors that could deliver high performance in space-constrained environments.

The 1990s saw the introduction of rare-earth magnets, particularly neodymium-iron-boron (NdFeB) magnets, which revolutionized PMSM design. These magnets offered significantly higher magnetic flux densities compared to traditional ferrite magnets, allowing for substantial reductions in motor size and weight while maintaining or even increasing power output. This breakthrough marked a pivotal moment in the power-to-weight evolution of PMSMs.

As we entered the 21st century, advancements in materials science and manufacturing techniques further propelled the improvement of power-to-weight ratios. The development of high-strength, lightweight alloys for motor housings and the implementation of advanced cooling systems enabled motors to operate at higher power densities without compromising reliability or lifespan.

The integration of sophisticated control algorithms and power electronics in the 2010s brought about another leap in PMSM performance. Field-oriented control (FOC) and model predictive control (MPC) techniques allowed for more precise and efficient motor operation, effectively increasing the usable power output without necessitating physical changes to the motor's design.

Recent years have seen a focus on optimizing motor topology and magnetic circuit design. Techniques such as halbach array configurations and the use of concentrated windings have further enhanced power density while reducing overall motor mass. Additionally, the exploration of new magnetic materials, such as cerium-based magnets, promises to address concerns about the availability and cost of rare-earth elements while maintaining high performance.

Looking towards the future, emerging technologies like additive manufacturing and nanotechnology are poised to drive the next wave of innovations in PMSM power-to-weight ratios. These advancements may enable the creation of complex, lightweight structures and novel magnetic materials that were previously impossible to produce using traditional manufacturing methods.

Market Demand for Efficient PMSMs

The market demand for efficient Permanent Magnet Synchronous Motors (PMSMs) has been steadily increasing across various industries due to their superior performance characteristics, particularly in applications where power-to-weight ratio is crucial. This growing demand is driven by several factors, including the push for energy efficiency, the rise of electric vehicles, and the need for compact, high-performance motors in industrial automation.

In the automotive sector, the shift towards electrification has created a significant market for PMSMs. Electric and hybrid vehicles require motors with high power density and efficiency, making PMSMs an ideal choice. The global electric vehicle market is expected to grow rapidly in the coming years, further boosting the demand for efficient PMSMs with optimized power-to-weight ratios.

The aerospace industry is another key driver of demand for high-performance PMSMs. As aircraft manufacturers strive to reduce weight and improve fuel efficiency, there is a growing interest in electric propulsion systems and more electric aircraft concepts. PMSMs with excellent power-to-weight ratios are essential for these applications, from electric taxiing systems to auxiliary power units.

Industrial automation and robotics represent another significant market for efficient PMSMs. As factories become increasingly automated, there is a need for compact, powerful motors that can operate with high precision and energy efficiency. PMSMs with optimized power-to-weight ratios are well-suited for robotic arms, conveyor systems, and other automated manufacturing equipment.

The renewable energy sector, particularly wind power generation, is also driving demand for efficient PMSMs. Direct-drive wind turbines using PMSMs are gaining popularity due to their higher efficiency and lower maintenance requirements compared to geared systems. As wind farms continue to expand globally, the demand for large-scale PMSMs with favorable power-to-weight ratios is expected to grow.

In the consumer electronics and appliance market, there is a trend towards more compact and energy-efficient devices. PMSMs are finding applications in high-end washing machines, air conditioners, and other household appliances where space is at a premium and energy efficiency is a key selling point.

The healthcare industry is another emerging market for PMSMs, particularly in medical imaging equipment and surgical robots. These applications require motors with precise control, low noise, and high reliability, making PMSMs an attractive option.

As industries continue to prioritize energy efficiency and performance, the market for PMSMs with optimized power-to-weight ratios is expected to expand further. Manufacturers are likely to focus on developing motors with higher power densities, improved thermal management, and advanced control systems to meet the evolving demands of various sectors.

In the automotive sector, the shift towards electrification has created a significant market for PMSMs. Electric and hybrid vehicles require motors with high power density and efficiency, making PMSMs an ideal choice. The global electric vehicle market is expected to grow rapidly in the coming years, further boosting the demand for efficient PMSMs with optimized power-to-weight ratios.

The aerospace industry is another key driver of demand for high-performance PMSMs. As aircraft manufacturers strive to reduce weight and improve fuel efficiency, there is a growing interest in electric propulsion systems and more electric aircraft concepts. PMSMs with excellent power-to-weight ratios are essential for these applications, from electric taxiing systems to auxiliary power units.

Industrial automation and robotics represent another significant market for efficient PMSMs. As factories become increasingly automated, there is a need for compact, powerful motors that can operate with high precision and energy efficiency. PMSMs with optimized power-to-weight ratios are well-suited for robotic arms, conveyor systems, and other automated manufacturing equipment.

The renewable energy sector, particularly wind power generation, is also driving demand for efficient PMSMs. Direct-drive wind turbines using PMSMs are gaining popularity due to their higher efficiency and lower maintenance requirements compared to geared systems. As wind farms continue to expand globally, the demand for large-scale PMSMs with favorable power-to-weight ratios is expected to grow.

In the consumer electronics and appliance market, there is a trend towards more compact and energy-efficient devices. PMSMs are finding applications in high-end washing machines, air conditioners, and other household appliances where space is at a premium and energy efficiency is a key selling point.

The healthcare industry is another emerging market for PMSMs, particularly in medical imaging equipment and surgical robots. These applications require motors with precise control, low noise, and high reliability, making PMSMs an attractive option.

As industries continue to prioritize energy efficiency and performance, the market for PMSMs with optimized power-to-weight ratios is expected to expand further. Manufacturers are likely to focus on developing motors with higher power densities, improved thermal management, and advanced control systems to meet the evolving demands of various sectors.

Current PMSM Power-Weight Challenges

Permanent Magnet Synchronous Motors (PMSMs) have become increasingly prevalent in various industries due to their high efficiency and power density. However, as applications demand ever-higher performance, the power-to-weight ratio of PMSMs has become a critical challenge. Current PMSMs face several obstacles in achieving optimal power-to-weight ratios, which are essential for applications such as electric vehicles, aerospace, and robotics.

One of the primary challenges is the limitation of magnetic materials. While rare-earth magnets like neodymium-iron-boron (NdFeB) offer high magnetic flux density, they are heavy and expensive. This creates a trade-off between motor performance and weight, as well as cost considerations. Researchers are exploring alternative magnetic materials and configurations to overcome this limitation, but progress has been incremental.

Thermal management presents another significant hurdle. As PMSMs are pushed to deliver higher power outputs, heat generation increases substantially. Conventional cooling methods often add considerable weight to the motor system, negatively impacting the power-to-weight ratio. Innovative cooling solutions that are both effective and lightweight are needed to address this issue.

The design of motor windings also poses challenges. While increasing the number of turns in the windings can enhance torque production, it also increases copper losses and overall motor weight. Balancing these factors to achieve an optimal power-to-weight ratio requires sophisticated design techniques and potentially new winding technologies.

Structural integrity is another critical concern. As motors are designed to be lighter, ensuring they can withstand the mechanical stresses associated with high-speed operation becomes more challenging. This is particularly important in applications like electric aircraft, where safety is paramount.

Furthermore, the integration of power electronics and control systems adds complexity to the power-to-weight optimization problem. While these components are essential for motor operation, they contribute additional weight that must be considered in the overall system design.

Manufacturing processes also play a role in the current challenges. Achieving tight tolerances and optimal material properties while keeping production costs reasonable is a delicate balance. Advanced manufacturing techniques, such as additive manufacturing, show promise but are not yet fully mature for large-scale PMSM production.

Lastly, the interdependence of various motor components makes optimization a complex task. Improvements in one area often lead to compromises in another, necessitating a holistic approach to motor design and optimization. This complexity is further compounded by the diverse requirements of different applications, making it difficult to develop a one-size-fits-all solution for power-to-weight ratio improvement in PMSMs.

One of the primary challenges is the limitation of magnetic materials. While rare-earth magnets like neodymium-iron-boron (NdFeB) offer high magnetic flux density, they are heavy and expensive. This creates a trade-off between motor performance and weight, as well as cost considerations. Researchers are exploring alternative magnetic materials and configurations to overcome this limitation, but progress has been incremental.

Thermal management presents another significant hurdle. As PMSMs are pushed to deliver higher power outputs, heat generation increases substantially. Conventional cooling methods often add considerable weight to the motor system, negatively impacting the power-to-weight ratio. Innovative cooling solutions that are both effective and lightweight are needed to address this issue.

The design of motor windings also poses challenges. While increasing the number of turns in the windings can enhance torque production, it also increases copper losses and overall motor weight. Balancing these factors to achieve an optimal power-to-weight ratio requires sophisticated design techniques and potentially new winding technologies.

Structural integrity is another critical concern. As motors are designed to be lighter, ensuring they can withstand the mechanical stresses associated with high-speed operation becomes more challenging. This is particularly important in applications like electric aircraft, where safety is paramount.

Furthermore, the integration of power electronics and control systems adds complexity to the power-to-weight optimization problem. While these components are essential for motor operation, they contribute additional weight that must be considered in the overall system design.

Manufacturing processes also play a role in the current challenges. Achieving tight tolerances and optimal material properties while keeping production costs reasonable is a delicate balance. Advanced manufacturing techniques, such as additive manufacturing, show promise but are not yet fully mature for large-scale PMSM production.

Lastly, the interdependence of various motor components makes optimization a complex task. Improvements in one area often lead to compromises in another, necessitating a holistic approach to motor design and optimization. This complexity is further compounded by the diverse requirements of different applications, making it difficult to develop a one-size-fits-all solution for power-to-weight ratio improvement in PMSMs.

State-of-Art PMSM Designs

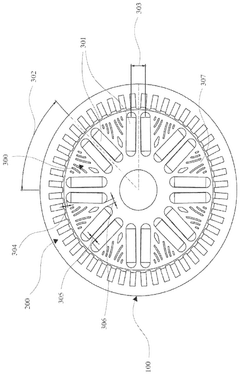

01 Optimizing motor design for high power-to-weight ratio

PMSM designs focus on reducing weight while maintaining or increasing power output. This involves using lightweight materials, optimizing the rotor and stator designs, and improving magnetic circuit efficiency. Advanced manufacturing techniques and novel geometries are employed to achieve a higher power density.- Optimizing PMSM design for high power-to-weight ratio: Improving the power-to-weight ratio of Permanent Magnet Synchronous Motors (PMSMs) through optimized design techniques. This includes using lightweight materials, efficient magnetic circuit designs, and advanced cooling systems to reduce overall motor weight while maintaining or increasing power output.

- Advanced magnet materials for PMSM performance: Utilizing high-performance magnetic materials, such as rare-earth magnets or novel composite materials, to enhance the power density of PMSMs. These advanced materials allow for stronger magnetic fields in a compact design, contributing to improved power-to-weight ratios.

- Innovative rotor and stator configurations: Developing new rotor and stator designs to optimize the power-to-weight ratio of PMSMs. This includes novel geometries, improved winding techniques, and integration of lightweight structural components to reduce mass while maintaining electromagnetic performance.

- Thermal management for high-performance PMSMs: Implementing advanced cooling techniques and thermal management systems to allow for higher power outputs without increasing motor size or weight. This includes innovative heat dissipation methods and temperature-resistant materials to maintain efficiency and reliability.

- Integration of power electronics for compact PMSM systems: Combining power electronics and control systems with the PMSM in integrated packages to reduce overall system weight and size. This approach optimizes the entire drivetrain, leading to improved power-to-weight ratios for the complete motor system.

02 Enhancing magnetic materials and configurations

Improvements in permanent magnet materials and their configurations within the motor structure contribute to increased power-to-weight ratios. This includes using high-performance magnets, optimizing magnet shapes and arrangements, and developing novel magnetic circuit designs to maximize flux density while minimizing motor weight.Expand Specific Solutions03 Thermal management for improved power density

Effective thermal management systems are crucial for maintaining high power-to-weight ratios in PMSMs. Advanced cooling techniques, heat-resistant materials, and optimized heat dissipation designs allow for higher power outputs without increasing motor size or weight significantly.Expand Specific Solutions04 Integration of power electronics and control systems

Integrating advanced power electronics and control systems directly into the motor design can lead to improved overall power-to-weight ratios. This approach reduces the need for external components, optimizes power flow, and allows for more precise motor control, resulting in higher efficiency and power density.Expand Specific Solutions05 Novel winding techniques and materials

Innovative winding techniques and materials are employed to increase the power-to-weight ratio of PMSMs. This includes using high-performance conductors, advanced insulation materials, and optimized winding patterns to maximize current capacity and reduce losses while minimizing the overall weight of the motor.Expand Specific Solutions

Key PMSM Manufacturers

The power-to-weight ratio analysis in modern Permanent Magnet Synchronous Motors (PMSM) is currently in a mature development stage, with significant market growth driven by increasing demand for high-efficiency electric motors. The global PMSM market size is projected to reach billions of dollars by 2025. Technologically, companies like Intel, LG Chem, and Fujitsu are at the forefront, developing advanced materials and control systems to enhance power density. Academic institutions such as Harbin Institute of Technology and Northwestern Polytechnical University are contributing to fundamental research, while industry players like Volvo Lastvagnar and Gree Electric Appliances are focusing on practical applications in automotive and consumer electronics sectors.

Intel Corp.

Technical Solution: Intel has developed advanced PMSM (Permanent Magnet Synchronous Motor) solutions with improved power-to-weight ratios. Their approach involves using high-performance magnets and optimized motor designs. Intel's PMSMs utilize neodymium-iron-boron (NdFeB) magnets, which offer high magnetic flux density, contributing to increased power density[1]. They have also implemented advanced cooling systems, allowing for higher current densities and improved overall performance. Intel's motor designs incorporate lightweight materials such as aluminum alloys for the stator housing, reducing overall weight while maintaining structural integrity[3]. Additionally, they have optimized the stator winding configuration to minimize copper losses and improve efficiency, further enhancing the power-to-weight ratio[5].

Strengths: High power density, improved efficiency, and reduced weight. Weaknesses: Potential higher costs due to premium materials and complex manufacturing processes.

Fujitsu Ltd.

Technical Solution: Fujitsu has made significant strides in PMSM technology, focusing on enhancing power-to-weight ratios through innovative design and material choices. Their approach involves the use of advanced magnetic materials, such as samarium-cobalt (SmCo) magnets, which offer high temperature stability and strong magnetic properties[2]. Fujitsu has also developed a unique rotor design that minimizes eddy current losses, thereby improving overall efficiency. Their PMSMs feature a segmented stator core design, which allows for better heat dissipation and reduced core losses[4]. Furthermore, Fujitsu has implemented advanced control algorithms that optimize motor performance across various operating conditions, contributing to improved power output relative to motor weight[6].

Strengths: High temperature stability, improved efficiency, and advanced control systems. Weaknesses: Potentially higher production costs and complexity in manufacturing.

Core PMSM Power-Weight Innovations

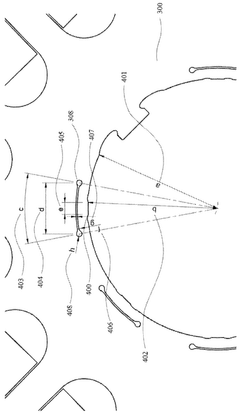

Permanent magnet synchronous machine rotor geometries with a maximized torque-speed density

PatentWO2025104500A1

Innovation

- The development of a radial-field electric motor geometry with a multi-pole rotor, optimized parameters such as magnet thickness, rotor bridge, flux return path, and magnet post, and inclusion of slots to reduce weight and maintain structural integrity, achieving a magnet aspect ratio of 45-70%.

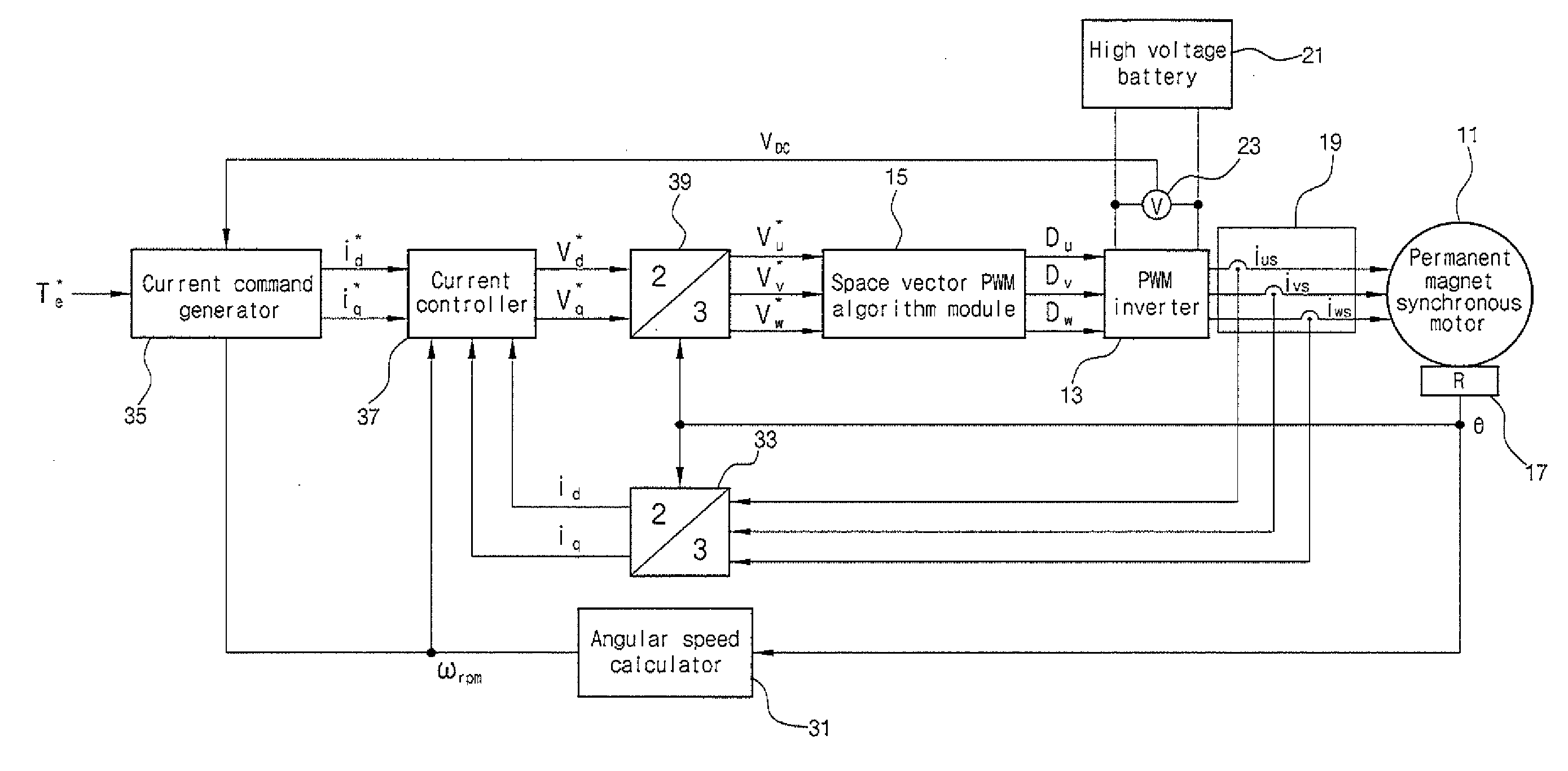

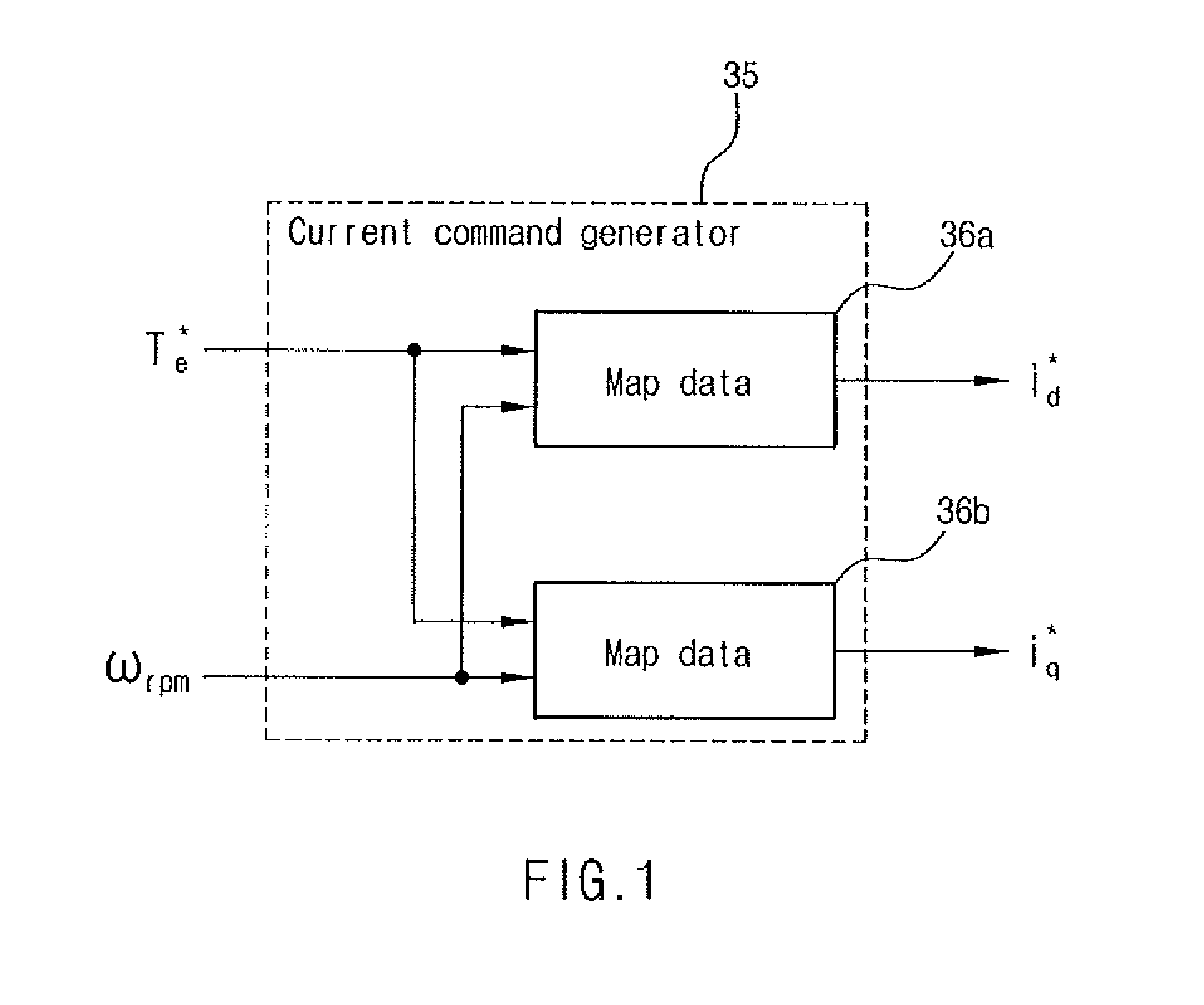

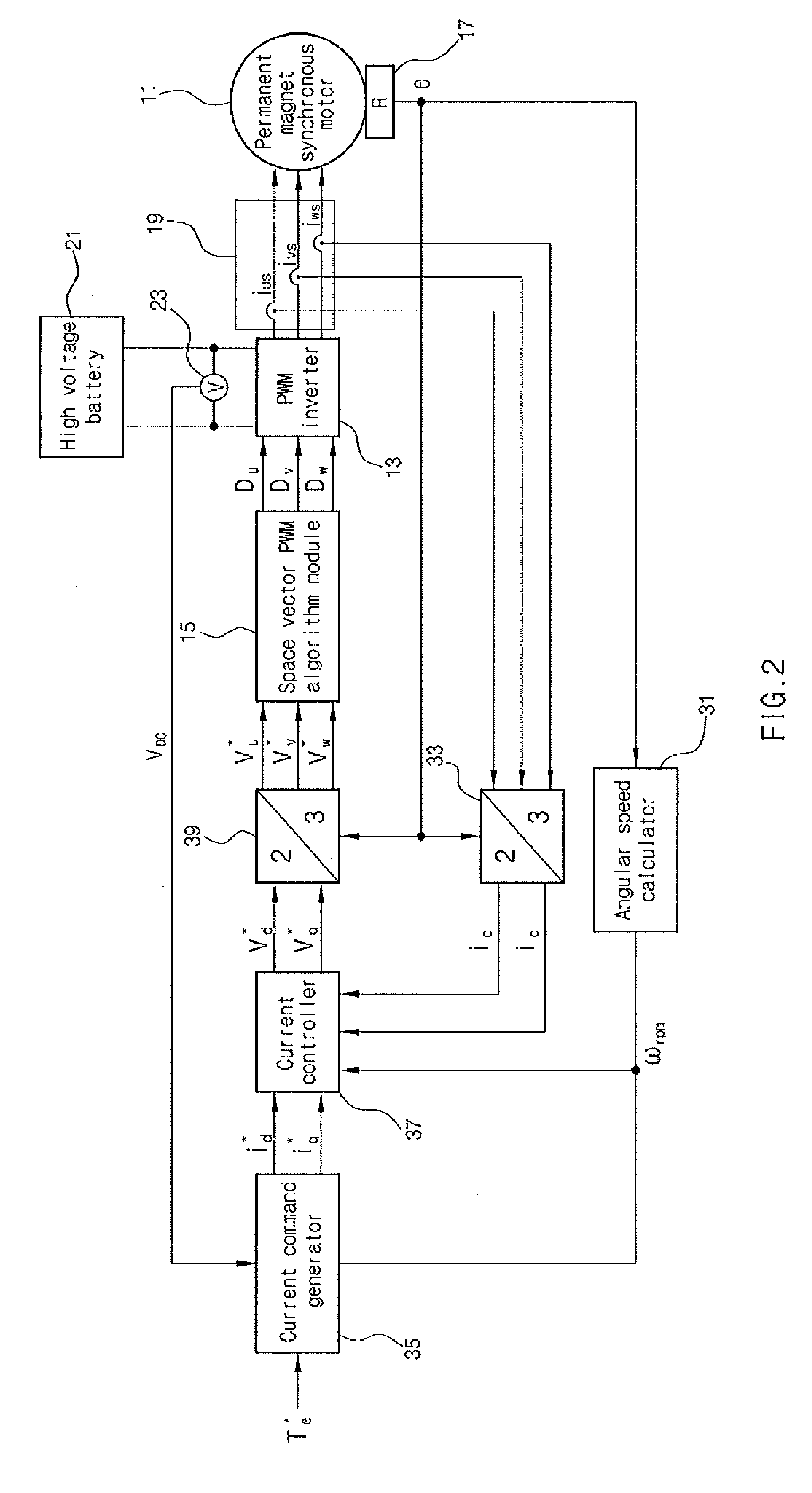

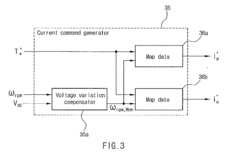

Method for controlling permanent magnet synchronous motor

PatentActiveUS20110241578A1

Innovation

- A method that detects battery voltage variations and compensates for them in real time by calculating a compensated speed, which is used to generate d-axis and q-axis current commands, thereby improving voltage utilization and motor control efficiency.

PMSM Materials Advancements

The advancements in materials for Permanent Magnet Synchronous Motors (PMSMs) have played a crucial role in improving their power-to-weight ratios. Over the past decade, significant progress has been made in developing high-performance magnetic materials and innovative motor designs, leading to more efficient and compact PMSMs.

One of the key areas of focus has been the development of rare-earth permanent magnets, particularly neodymium-iron-boron (NdFeB) magnets. These magnets offer superior magnetic properties, including high remanence and coercivity, which directly contribute to increased power density in PMSMs. Recent research has focused on optimizing the composition and manufacturing processes of NdFeB magnets to further enhance their performance.

Advancements in soft magnetic materials have also contributed to improved power-to-weight ratios. The development of high-silicon electrical steels and amorphous alloys has led to reduced core losses and improved magnetic flux density. These materials allow for thinner laminations and more efficient magnetic circuits, resulting in lighter and more compact motor designs.

Thermal management materials have seen significant improvements as well. The introduction of advanced thermal interface materials and high-performance insulation systems has enabled better heat dissipation, allowing PMSMs to operate at higher power levels without compromising reliability or increasing weight.

Innovations in winding technologies have further enhanced power-to-weight ratios. The use of high-density copper windings and advanced insulation materials has led to increased current-carrying capacity and improved thermal performance. Additionally, the development of hairpin windings has allowed for higher slot fill factors, resulting in more compact and efficient motor designs.

Composite materials have also played a role in reducing the overall weight of PMSMs. The use of carbon fiber reinforced plastics (CFRP) in motor housings and structural components has led to significant weight reductions without compromising structural integrity. This has been particularly beneficial in applications where weight is a critical factor, such as electric vehicles and aerospace.

The integration of these material advancements has resulted in PMSMs with significantly improved power-to-weight ratios. Modern PMSMs can achieve power densities of up to 5 kW/kg, a substantial increase from the 1-2 kW/kg typical of earlier designs. This improvement has enabled the widespread adoption of PMSMs in various applications, from electric vehicles to industrial automation, where high performance and compact design are essential.

Looking ahead, ongoing research in nanomaterials and advanced manufacturing techniques promises further improvements in PMSM materials. The development of nanocomposite magnets and 3D-printed soft magnetic cores are areas of particular interest, potentially leading to even higher power-to-weight ratios in future PMSM designs.

One of the key areas of focus has been the development of rare-earth permanent magnets, particularly neodymium-iron-boron (NdFeB) magnets. These magnets offer superior magnetic properties, including high remanence and coercivity, which directly contribute to increased power density in PMSMs. Recent research has focused on optimizing the composition and manufacturing processes of NdFeB magnets to further enhance their performance.

Advancements in soft magnetic materials have also contributed to improved power-to-weight ratios. The development of high-silicon electrical steels and amorphous alloys has led to reduced core losses and improved magnetic flux density. These materials allow for thinner laminations and more efficient magnetic circuits, resulting in lighter and more compact motor designs.

Thermal management materials have seen significant improvements as well. The introduction of advanced thermal interface materials and high-performance insulation systems has enabled better heat dissipation, allowing PMSMs to operate at higher power levels without compromising reliability or increasing weight.

Innovations in winding technologies have further enhanced power-to-weight ratios. The use of high-density copper windings and advanced insulation materials has led to increased current-carrying capacity and improved thermal performance. Additionally, the development of hairpin windings has allowed for higher slot fill factors, resulting in more compact and efficient motor designs.

Composite materials have also played a role in reducing the overall weight of PMSMs. The use of carbon fiber reinforced plastics (CFRP) in motor housings and structural components has led to significant weight reductions without compromising structural integrity. This has been particularly beneficial in applications where weight is a critical factor, such as electric vehicles and aerospace.

The integration of these material advancements has resulted in PMSMs with significantly improved power-to-weight ratios. Modern PMSMs can achieve power densities of up to 5 kW/kg, a substantial increase from the 1-2 kW/kg typical of earlier designs. This improvement has enabled the widespread adoption of PMSMs in various applications, from electric vehicles to industrial automation, where high performance and compact design are essential.

Looking ahead, ongoing research in nanomaterials and advanced manufacturing techniques promises further improvements in PMSM materials. The development of nanocomposite magnets and 3D-printed soft magnetic cores are areas of particular interest, potentially leading to even higher power-to-weight ratios in future PMSM designs.

Environmental Impact of PMSMs

The environmental impact of Permanent Magnet Synchronous Motors (PMSMs) is a critical consideration in the context of analyzing power-to-weight ratios in modern PMSMs. As these motors become increasingly prevalent in various applications, particularly in electric vehicles and renewable energy systems, their ecological footprint demands careful examination.

PMSMs offer significant advantages in terms of efficiency and power density compared to other motor types. This improved efficiency translates to reduced energy consumption over the motor's lifetime, potentially lowering greenhouse gas emissions associated with electricity generation. The high power-to-weight ratio of PMSMs also contributes to overall system efficiency, especially in transportation applications where weight reduction leads to decreased energy requirements.

However, the production and disposal of PMSMs present environmental challenges. The rare earth elements used in permanent magnets, such as neodymium and dysprosium, are associated with resource-intensive and potentially polluting mining and refining processes. The extraction of these materials can lead to soil erosion, water contamination, and habitat destruction in mining areas.

The manufacturing process of PMSMs involves energy-intensive steps, including the production of high-purity metals and the precise assembly of motor components. While the energy efficiency of PMSMs during operation may offset some of these production-related impacts, the overall life cycle assessment must be considered for a comprehensive environmental evaluation.

End-of-life management for PMSMs is another crucial environmental consideration. The recycling of rare earth magnets is technically challenging and not yet widely implemented on a commercial scale. Improper disposal can lead to the loss of valuable materials and potential environmental contamination.

Efforts to mitigate the environmental impact of PMSMs are ongoing. Research into alternative magnet materials, such as those using fewer or no rare earth elements, aims to reduce the reliance on environmentally problematic resources. Additionally, advancements in recycling technologies for rare earth magnets show promise for improving the circularity of PMSM materials.

The development of more efficient PMSMs with higher power-to-weight ratios can indirectly benefit the environment by enabling the broader adoption of electric vehicles and renewable energy technologies. This transition away from fossil fuel-dependent systems has the potential to significantly reduce global carbon emissions and air pollution.

In conclusion, while PMSMs offer substantial environmental benefits through their high efficiency and power density, their production and end-of-life management present notable ecological challenges. Balancing these factors is crucial for the sustainable development and deployment of PMSM technology in various applications.

PMSMs offer significant advantages in terms of efficiency and power density compared to other motor types. This improved efficiency translates to reduced energy consumption over the motor's lifetime, potentially lowering greenhouse gas emissions associated with electricity generation. The high power-to-weight ratio of PMSMs also contributes to overall system efficiency, especially in transportation applications where weight reduction leads to decreased energy requirements.

However, the production and disposal of PMSMs present environmental challenges. The rare earth elements used in permanent magnets, such as neodymium and dysprosium, are associated with resource-intensive and potentially polluting mining and refining processes. The extraction of these materials can lead to soil erosion, water contamination, and habitat destruction in mining areas.

The manufacturing process of PMSMs involves energy-intensive steps, including the production of high-purity metals and the precise assembly of motor components. While the energy efficiency of PMSMs during operation may offset some of these production-related impacts, the overall life cycle assessment must be considered for a comprehensive environmental evaluation.

End-of-life management for PMSMs is another crucial environmental consideration. The recycling of rare earth magnets is technically challenging and not yet widely implemented on a commercial scale. Improper disposal can lead to the loss of valuable materials and potential environmental contamination.

Efforts to mitigate the environmental impact of PMSMs are ongoing. Research into alternative magnet materials, such as those using fewer or no rare earth elements, aims to reduce the reliance on environmentally problematic resources. Additionally, advancements in recycling technologies for rare earth magnets show promise for improving the circularity of PMSM materials.

The development of more efficient PMSMs with higher power-to-weight ratios can indirectly benefit the environment by enabling the broader adoption of electric vehicles and renewable energy technologies. This transition away from fossil fuel-dependent systems has the potential to significantly reduce global carbon emissions and air pollution.

In conclusion, while PMSMs offer substantial environmental benefits through their high efficiency and power density, their production and end-of-life management present notable ecological challenges. Balancing these factors is crucial for the sustainable development and deployment of PMSM technology in various applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!