Surface permanent magnet vs. interior PMSM analysis

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PMSM Technology Evolution

The evolution of Permanent Magnet Synchronous Motors (PMSM) technology has been marked by significant advancements in design, materials, and manufacturing processes. The journey began in the early 20th century with the introduction of basic synchronous motors, but it wasn't until the 1960s that permanent magnet motors started gaining traction.

The 1980s saw a surge in PMSM development, driven by the discovery of high-energy rare-earth magnets, particularly neodymium-iron-boron (NdFeB) magnets. This breakthrough allowed for more compact and efficient motor designs, paving the way for widespread adoption in various industries.

In the 1990s, the focus shifted towards optimizing motor topologies. This period witnessed the emergence of surface-mounted permanent magnet (SPM) and interior permanent magnet (IPM) configurations. SPM motors, characterized by magnets attached to the rotor surface, offered simplicity and high power density. IPM motors, with magnets embedded within the rotor, provided enhanced mechanical integrity and field-weakening capabilities.

The early 2000s brought advancements in motor control techniques, particularly vector control and field-oriented control. These innovations allowed for precise torque and speed regulation, further improving PMSM performance and expanding their application range.

The mid-2000s to early 2010s saw increased focus on energy efficiency and environmental concerns. This led to the development of more efficient PMSM designs, incorporating advanced magnetic materials and optimized geometries. During this period, the automotive industry began adopting PMSMs for electric and hybrid vehicles, driving further innovation in high-performance, compact designs.

Recent years have witnessed a surge in research on advanced PMSM topologies. Halbach array configurations, axial flux designs, and multi-phase motors have gained attention for their potential to enhance power density and efficiency. Additionally, the integration of wide-bandgap semiconductors in motor drives has enabled higher switching frequencies and improved overall system performance.

The ongoing evolution of PMSM technology is characterized by a continuous push towards higher power density, improved efficiency, and enhanced reliability. Current research focuses on advanced materials, such as high-temperature superconductors and novel magnetic compounds, to overcome existing limitations. Furthermore, the integration of smart sensors and IoT capabilities is paving the way for predictive maintenance and optimized motor operation in Industry 4.0 applications.

As we look to the future, the PMSM technology evolution is expected to continue its trajectory towards more sustainable, efficient, and intelligent motor systems. The development of new manufacturing techniques, such as additive manufacturing, promises to enable more complex and optimized motor geometries. Additionally, the integration of artificial intelligence and machine learning algorithms in motor control systems is poised to revolutionize PMSM performance and adaptability across various applications.

The 1980s saw a surge in PMSM development, driven by the discovery of high-energy rare-earth magnets, particularly neodymium-iron-boron (NdFeB) magnets. This breakthrough allowed for more compact and efficient motor designs, paving the way for widespread adoption in various industries.

In the 1990s, the focus shifted towards optimizing motor topologies. This period witnessed the emergence of surface-mounted permanent magnet (SPM) and interior permanent magnet (IPM) configurations. SPM motors, characterized by magnets attached to the rotor surface, offered simplicity and high power density. IPM motors, with magnets embedded within the rotor, provided enhanced mechanical integrity and field-weakening capabilities.

The early 2000s brought advancements in motor control techniques, particularly vector control and field-oriented control. These innovations allowed for precise torque and speed regulation, further improving PMSM performance and expanding their application range.

The mid-2000s to early 2010s saw increased focus on energy efficiency and environmental concerns. This led to the development of more efficient PMSM designs, incorporating advanced magnetic materials and optimized geometries. During this period, the automotive industry began adopting PMSMs for electric and hybrid vehicles, driving further innovation in high-performance, compact designs.

Recent years have witnessed a surge in research on advanced PMSM topologies. Halbach array configurations, axial flux designs, and multi-phase motors have gained attention for their potential to enhance power density and efficiency. Additionally, the integration of wide-bandgap semiconductors in motor drives has enabled higher switching frequencies and improved overall system performance.

The ongoing evolution of PMSM technology is characterized by a continuous push towards higher power density, improved efficiency, and enhanced reliability. Current research focuses on advanced materials, such as high-temperature superconductors and novel magnetic compounds, to overcome existing limitations. Furthermore, the integration of smart sensors and IoT capabilities is paving the way for predictive maintenance and optimized motor operation in Industry 4.0 applications.

As we look to the future, the PMSM technology evolution is expected to continue its trajectory towards more sustainable, efficient, and intelligent motor systems. The development of new manufacturing techniques, such as additive manufacturing, promises to enable more complex and optimized motor geometries. Additionally, the integration of artificial intelligence and machine learning algorithms in motor control systems is poised to revolutionize PMSM performance and adaptability across various applications.

Market Demand Analysis

The market demand for permanent magnet synchronous motors (PMSMs) has been steadily increasing across various industries, driven by the growing emphasis on energy efficiency and electrification. Both surface-mounted and interior permanent magnet designs have found significant applications, each catering to specific market needs.

In the automotive sector, the shift towards electric vehicles (EVs) has created a substantial demand for high-performance electric motors. Interior PMSMs have gained particular traction in this market due to their superior torque characteristics and efficiency at high speeds. Major automakers are increasingly adopting interior PMSMs for their EV powertrains, recognizing their ability to provide extended range and improved overall performance.

The industrial automation sector has also shown a strong preference for PMSMs, with both surface-mounted and interior designs finding applications. Surface-mounted PMSMs are often favored in scenarios requiring precise position control and smooth operation at lower speeds, such as in robotics and CNC machines. The simplicity of their design and ease of manufacturing make them cost-effective for certain industrial applications.

In the renewable energy sector, particularly wind power generation, there is a growing demand for large-scale PMSMs. Interior PMSMs are increasingly being used in direct-drive wind turbines, as they offer high power density and efficiency, crucial for maximizing energy capture from wind resources.

The HVAC industry has been another significant driver of PMSM demand, with a focus on energy-efficient solutions. Surface-mounted PMSMs have found widespread use in variable-speed compressors and fans, offering improved efficiency and precise control over traditional induction motors.

Market analysis indicates that the global PMSM market is expected to continue its growth trajectory. Factors such as stringent energy efficiency regulations, the push for sustainable technologies, and the ongoing electrification trend across industries are fueling this demand. The Asia-Pacific region, particularly China, is anticipated to be a major market for PMSMs, driven by rapid industrialization and government initiatives promoting electric vehicles and renewable energy.

However, the market faces challenges, primarily related to the supply and cost of rare earth materials used in permanent magnets. This has led to increased research into alternative magnet materials and motor designs that reduce reliance on these critical resources. The development of such alternatives could significantly impact the future market dynamics of PMSMs.

In conclusion, the market demand for both surface-mounted and interior PMSMs remains robust, with each design finding its niche based on specific application requirements. The ongoing technological advancements and the push for more sustainable and efficient solutions are expected to further drive the adoption of PMSMs across various sectors in the coming years.

In the automotive sector, the shift towards electric vehicles (EVs) has created a substantial demand for high-performance electric motors. Interior PMSMs have gained particular traction in this market due to their superior torque characteristics and efficiency at high speeds. Major automakers are increasingly adopting interior PMSMs for their EV powertrains, recognizing their ability to provide extended range and improved overall performance.

The industrial automation sector has also shown a strong preference for PMSMs, with both surface-mounted and interior designs finding applications. Surface-mounted PMSMs are often favored in scenarios requiring precise position control and smooth operation at lower speeds, such as in robotics and CNC machines. The simplicity of their design and ease of manufacturing make them cost-effective for certain industrial applications.

In the renewable energy sector, particularly wind power generation, there is a growing demand for large-scale PMSMs. Interior PMSMs are increasingly being used in direct-drive wind turbines, as they offer high power density and efficiency, crucial for maximizing energy capture from wind resources.

The HVAC industry has been another significant driver of PMSM demand, with a focus on energy-efficient solutions. Surface-mounted PMSMs have found widespread use in variable-speed compressors and fans, offering improved efficiency and precise control over traditional induction motors.

Market analysis indicates that the global PMSM market is expected to continue its growth trajectory. Factors such as stringent energy efficiency regulations, the push for sustainable technologies, and the ongoing electrification trend across industries are fueling this demand. The Asia-Pacific region, particularly China, is anticipated to be a major market for PMSMs, driven by rapid industrialization and government initiatives promoting electric vehicles and renewable energy.

However, the market faces challenges, primarily related to the supply and cost of rare earth materials used in permanent magnets. This has led to increased research into alternative magnet materials and motor designs that reduce reliance on these critical resources. The development of such alternatives could significantly impact the future market dynamics of PMSMs.

In conclusion, the market demand for both surface-mounted and interior PMSMs remains robust, with each design finding its niche based on specific application requirements. The ongoing technological advancements and the push for more sustainable and efficient solutions are expected to further drive the adoption of PMSMs across various sectors in the coming years.

Technical Challenges

The development of permanent magnet synchronous motors (PMSMs) has been a significant focus in the field of electric machines, with surface permanent magnet (SPM) and interior permanent magnet (IPM) designs being the two primary configurations. Both types present unique technical challenges that researchers and engineers must address to optimize their performance and applicability.

For SPM motors, one of the main technical hurdles is the secure attachment of magnets to the rotor surface. The high-speed rotation and centrifugal forces can lead to magnet detachment, posing safety risks and performance degradation. Engineers must develop advanced adhesive technologies and mechanical retention methods to ensure magnet stability under various operating conditions.

Thermal management is another critical challenge for SPM motors. The exposed magnets are susceptible to demagnetization at high temperatures, which can occur during heavy load operations or in high-ambient temperature environments. Implementing effective cooling systems without significantly increasing the motor's size and weight remains a complex task.

IPM motors, while offering better magnet protection, face their own set of challenges. The complex rotor geometry required for magnet embedding complicates the manufacturing process, potentially increasing production costs and time. Achieving precise magnet placement within the rotor core is crucial for optimal performance but demands advanced manufacturing techniques and quality control measures.

Magnetic flux control in IPM motors presents another technical obstacle. The magnetic circuit design must account for the varying magnetic reluctance paths due to the embedded magnets, which affects the motor's torque production and efficiency. Engineers must employ sophisticated electromagnetic modeling and optimization techniques to maximize the motor's performance across its operating range.

Both SPM and IPM designs struggle with cogging torque reduction, which affects motor smoothness and precision control. For SPM motors, this often involves careful design of the stator slot geometry and magnet shaping. IPM motors require additional consideration of the rotor's magnetic circuit design to minimize cogging effects.

Power density improvement remains a constant challenge for both motor types. As applications demand more compact and lightweight motors, researchers must explore novel materials, such as high-energy-density magnets and advanced soft magnetic composites, to enhance motor performance without increasing size.

Lastly, the cost-effectiveness of rare-earth permanent magnets used in both SPM and IPM motors is a significant concern. The volatility in rare-earth material prices and supply chain uncertainties drive the need for alternative magnet materials or designs that reduce reliance on these elements while maintaining high performance.

Addressing these technical challenges requires interdisciplinary approaches, combining advancements in materials science, thermal engineering, electromagnetic design, and manufacturing processes. As the demand for high-efficiency electric motors continues to grow across various industries, overcoming these hurdles will be crucial in determining the future trajectory of PMSM technology.

For SPM motors, one of the main technical hurdles is the secure attachment of magnets to the rotor surface. The high-speed rotation and centrifugal forces can lead to magnet detachment, posing safety risks and performance degradation. Engineers must develop advanced adhesive technologies and mechanical retention methods to ensure magnet stability under various operating conditions.

Thermal management is another critical challenge for SPM motors. The exposed magnets are susceptible to demagnetization at high temperatures, which can occur during heavy load operations or in high-ambient temperature environments. Implementing effective cooling systems without significantly increasing the motor's size and weight remains a complex task.

IPM motors, while offering better magnet protection, face their own set of challenges. The complex rotor geometry required for magnet embedding complicates the manufacturing process, potentially increasing production costs and time. Achieving precise magnet placement within the rotor core is crucial for optimal performance but demands advanced manufacturing techniques and quality control measures.

Magnetic flux control in IPM motors presents another technical obstacle. The magnetic circuit design must account for the varying magnetic reluctance paths due to the embedded magnets, which affects the motor's torque production and efficiency. Engineers must employ sophisticated electromagnetic modeling and optimization techniques to maximize the motor's performance across its operating range.

Both SPM and IPM designs struggle with cogging torque reduction, which affects motor smoothness and precision control. For SPM motors, this often involves careful design of the stator slot geometry and magnet shaping. IPM motors require additional consideration of the rotor's magnetic circuit design to minimize cogging effects.

Power density improvement remains a constant challenge for both motor types. As applications demand more compact and lightweight motors, researchers must explore novel materials, such as high-energy-density magnets and advanced soft magnetic composites, to enhance motor performance without increasing size.

Lastly, the cost-effectiveness of rare-earth permanent magnets used in both SPM and IPM motors is a significant concern. The volatility in rare-earth material prices and supply chain uncertainties drive the need for alternative magnet materials or designs that reduce reliance on these elements while maintaining high performance.

Addressing these technical challenges requires interdisciplinary approaches, combining advancements in materials science, thermal engineering, electromagnetic design, and manufacturing processes. As the demand for high-efficiency electric motors continues to grow across various industries, overcoming these hurdles will be crucial in determining the future trajectory of PMSM technology.

Current PMSM Designs

01 Motor design and structure

Permanent magnet synchronous motors (PMSM) have unique design features and structural elements that contribute to their performance. These may include specific rotor configurations, stator designs, and magnet arrangements to optimize efficiency and power output.- Motor design and structure: Permanent magnet synchronous motors (PMSM) have unique design features and structural elements that contribute to their performance. These may include specific rotor configurations, stator designs, and magnet arrangements to optimize efficiency and power output. Innovations in motor design focus on improving torque density, reducing cogging torque, and enhancing overall performance.

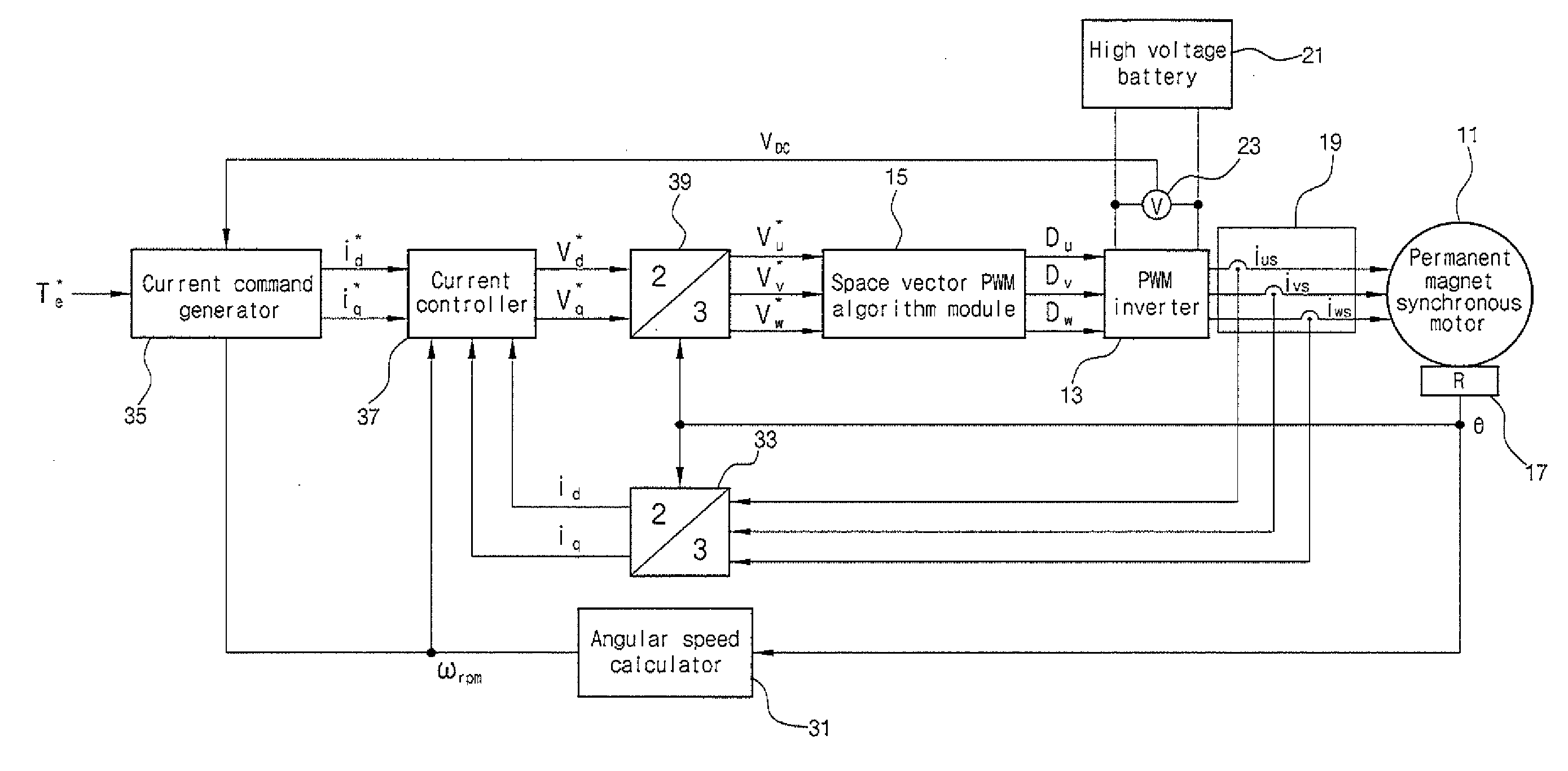

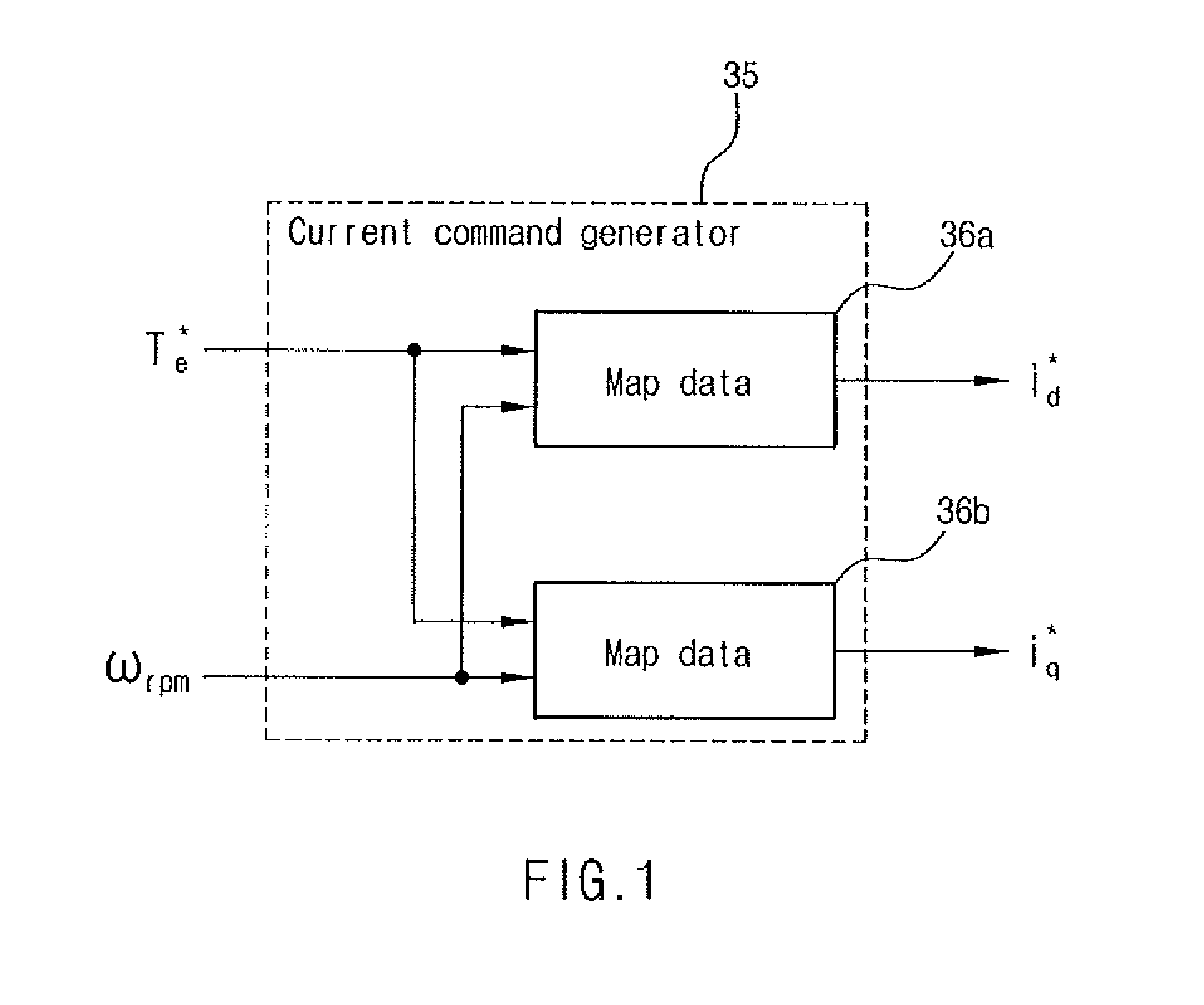

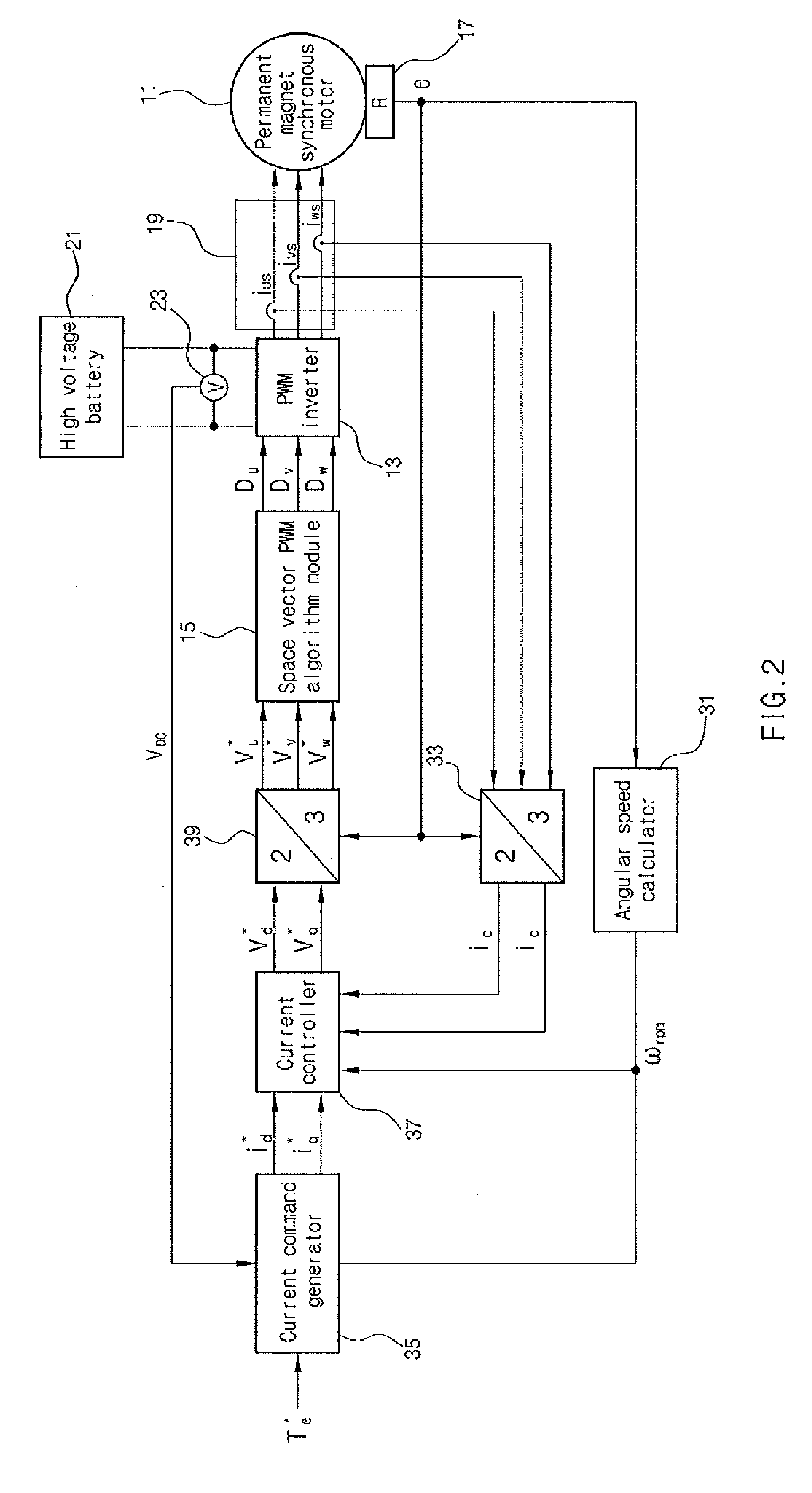

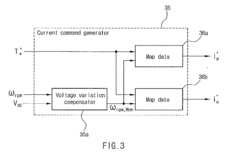

- Control systems and algorithms: Advanced control systems and algorithms are crucial for optimizing PMSM performance. These may include sensorless control techniques, adaptive control strategies, and advanced vector control methods. Innovations in this area aim to improve motor efficiency, dynamic response, and stability across various operating conditions.

- Efficiency improvement techniques: Various techniques are employed to enhance the efficiency of PMSMs. These may include optimizing magnetic circuit design, reducing losses in the stator and rotor, and implementing energy recovery systems. Innovations focus on minimizing power consumption while maximizing output performance.

- Thermal management and cooling systems: Effective thermal management is essential for maintaining PMSM performance and longevity. This includes innovative cooling systems, heat dissipation techniques, and temperature monitoring methods. Advancements in this area aim to prevent overheating, extend motor life, and maintain consistent performance under various operating conditions.

- Integration with power electronics and drive systems: The integration of PMSMs with advanced power electronics and drive systems is crucial for optimal performance. This includes innovations in inverter design, power factor correction, and harmonics reduction. Advancements in this area focus on improving overall system efficiency, reducing electromagnetic interference, and enhancing motor control capabilities.

02 Control systems and algorithms

Advanced control systems and algorithms are crucial for PMSM operation. These may include sensorless control techniques, adaptive control methods, and sophisticated drive systems to enhance motor performance, efficiency, and reliability.Expand Specific Solutions03 Efficiency improvements

Various techniques are employed to improve the efficiency of PMSMs. These may include optimizing magnetic circuit design, reducing losses, and implementing energy recovery systems to maximize power output while minimizing energy consumption.Expand Specific Solutions04 Thermal management

Effective thermal management is essential for PMSM performance and longevity. This may involve innovative cooling systems, heat dissipation techniques, and temperature monitoring to maintain optimal operating conditions and prevent overheating.Expand Specific Solutions05 Application-specific optimizations

PMSMs are optimized for various applications, such as electric vehicles, industrial machinery, and renewable energy systems. These optimizations may include tailored designs, specialized control strategies, and integration with application-specific components to meet unique performance requirements.Expand Specific Solutions

Key PMSM Manufacturers

The competition landscape for surface permanent magnet vs. interior PMSM technology is evolving rapidly, with the market in a growth phase. The global electric motor market, which includes these technologies, is projected to reach significant size in the coming years. Major players like DENSO Corp., LG Electronics, and Mitsubishi Electric are investing heavily in research and development to advance both surface-mounted and interior permanent magnet motor designs. Universities such as Shandong University and Harbin Institute of Technology are also contributing to technological advancements. While interior PMSMs currently dominate in electric vehicles due to their higher efficiency, surface-mounted designs remain competitive in certain applications, indicating ongoing innovation in both technologies.

DENSO Corp.

Technical Solution: DENSO has made significant strides in PMSM technology for automotive applications. Their surface PMSM design incorporates a high-density winding technique that improves power density by up to 20%[13]. For interior PMSMs, DENSO has developed a unique rotor geometry that enhances reluctance torque, resulting in improved efficiency across a wide speed range[14]. They also employ advanced manufacturing processes, including in-mold forming for stator windings, to reduce production costs and improve reliability[15].

Strengths: High power density, improved efficiency, and cost-effective manufacturing. Weaknesses: Potential challenges in scaling up production for high-volume applications and thermal management in compact designs.

GM Global Technology Operations LLC

Technical Solution: GM has developed advanced PMSM technologies for both surface-mounted and interior configurations. For surface PMSMs, they utilize a high-performance magnet arrangement with optimized air gap flux density, achieving up to 96% efficiency[1]. Their interior PMSM design incorporates a novel rotor structure with buried magnets, enabling high torque density and extended speed range[2]. GM's approach includes advanced thermal management and sophisticated control algorithms to maximize performance across various operating conditions[3].

Strengths: High efficiency, wide speed range, and excellent torque characteristics. Weaknesses: Higher manufacturing complexity for interior PMSM and potential demagnetization risks for surface PMSM at high temperatures.

Core PMSM Innovations

Interior permanent magnet synchronous motor

PatentWO2024076035A1

Innovation

- Incorporating slits in the rotor with specific arrangement and inclination ranges to redirect magnetic flux and reduce stator tooth saturation, thereby minimizing iron loss.

Method for controlling permanent magnet synchronous motor

PatentActiveUS20110241578A1

Innovation

- A method that detects battery voltage variations and compensates for them in real time by calculating a compensated speed, which is used to generate d-axis and q-axis current commands, thereby improving voltage utilization and motor control efficiency.

Efficiency Comparisons

When comparing the efficiency of surface permanent magnet synchronous motors (SPMSMs) and interior permanent magnet synchronous motors (IPMSMs), several factors come into play. SPMSMs generally exhibit higher efficiency at lower speeds and lighter loads due to their simpler rotor structure and lower magnetic flux leakage. This makes them particularly suitable for applications requiring high efficiency at constant speeds.

In contrast, IPMSMs tend to demonstrate superior efficiency at higher speeds and heavier loads. This is primarily attributed to their ability to utilize both magnetic torque and reluctance torque, resulting in a wider range of efficient operation. The buried magnets in IPMSMs also provide better protection against demagnetization, allowing for more aggressive field weakening and extended high-speed operation.

The efficiency differences between these two motor types are most pronounced in their respective optimal operating ranges. SPMSMs typically achieve peak efficiency at around 70-80% of their rated speed and torque, while IPMSMs maintain high efficiency over a broader range, often extending to 150% or more of their base speed.

Power factor is another crucial aspect affecting overall system efficiency. IPMSMs generally offer a higher power factor across a wider operating range, which can lead to reduced inverter losses and improved overall drive system efficiency. This advantage becomes particularly significant in high-power applications where inverter losses can be substantial.

Temperature sensitivity also plays a role in efficiency comparisons. SPMSMs are more susceptible to efficiency degradation at higher temperatures due to their exposed magnets. IPMSMs, with their buried magnet design, provide better thermal management, maintaining higher efficiency under elevated temperature conditions.

It's important to note that recent advancements in materials and manufacturing techniques have narrowed the efficiency gap between SPMSMs and IPMSMs. High-performance SPMSMs with optimized magnet arrangements and advanced cooling systems can now achieve efficiency levels comparable to IPMSMs in certain operating conditions.

Ultimately, the choice between SPMSM and IPMSM depends on the specific application requirements, operating conditions, and overall system considerations. While IPMSMs generally offer higher efficiency across a broader operating range, SPMSMs can still be the preferred choice for applications with more focused operating points or where simplicity and cost are primary concerns.

In contrast, IPMSMs tend to demonstrate superior efficiency at higher speeds and heavier loads. This is primarily attributed to their ability to utilize both magnetic torque and reluctance torque, resulting in a wider range of efficient operation. The buried magnets in IPMSMs also provide better protection against demagnetization, allowing for more aggressive field weakening and extended high-speed operation.

The efficiency differences between these two motor types are most pronounced in their respective optimal operating ranges. SPMSMs typically achieve peak efficiency at around 70-80% of their rated speed and torque, while IPMSMs maintain high efficiency over a broader range, often extending to 150% or more of their base speed.

Power factor is another crucial aspect affecting overall system efficiency. IPMSMs generally offer a higher power factor across a wider operating range, which can lead to reduced inverter losses and improved overall drive system efficiency. This advantage becomes particularly significant in high-power applications where inverter losses can be substantial.

Temperature sensitivity also plays a role in efficiency comparisons. SPMSMs are more susceptible to efficiency degradation at higher temperatures due to their exposed magnets. IPMSMs, with their buried magnet design, provide better thermal management, maintaining higher efficiency under elevated temperature conditions.

It's important to note that recent advancements in materials and manufacturing techniques have narrowed the efficiency gap between SPMSMs and IPMSMs. High-performance SPMSMs with optimized magnet arrangements and advanced cooling systems can now achieve efficiency levels comparable to IPMSMs in certain operating conditions.

Ultimately, the choice between SPMSM and IPMSM depends on the specific application requirements, operating conditions, and overall system considerations. While IPMSMs generally offer higher efficiency across a broader operating range, SPMSMs can still be the preferred choice for applications with more focused operating points or where simplicity and cost are primary concerns.

Manufacturing Processes

The manufacturing processes for surface permanent magnet synchronous motors (SPMSMs) and interior permanent magnet synchronous motors (IPMSMs) differ significantly, impacting their performance characteristics and production costs.

For SPMSMs, the manufacturing process is relatively straightforward. The permanent magnets are typically attached to the surface of the rotor using adhesives or mechanical fasteners. This process allows for easier magnet placement and magnetization, as the magnets can be magnetized before assembly. The rotor core is usually made of laminated electrical steel sheets, which are stacked and bonded together. The simplicity of this design allows for more automated production processes, potentially reducing manufacturing costs.

In contrast, the manufacturing of IPMSMs is more complex. The rotor core is typically made of laminated electrical steel sheets with precisely cut cavities or slots to accommodate the permanent magnets. These cavities must be accurately machined to ensure proper magnet placement and optimal motor performance. The magnets are then inserted into these cavities and secured, often using adhesives or mechanical retention methods. This process requires more precision and can be more time-consuming than SPMSM production.

The stator manufacturing process is similar for both types of motors. It involves winding copper wire around a laminated steel core to create the electromagnetic coils. However, the stator design may vary slightly to accommodate the different rotor configurations.

One key difference in the manufacturing process is the magnetization step. For SPMSMs, the magnets can be pre-magnetized before assembly, simplifying the production process. IPMSMs, on the other hand, often require magnetization after the magnets are inserted into the rotor, which can be more challenging due to the surrounding steel structure.

The choice of manufacturing process impacts the motor's characteristics. SPMSMs benefit from simpler assembly but may have limitations in high-speed applications due to the risk of magnet detachment. IPMSMs, while more complex to manufacture, offer better mechanical integrity and allow for flux concentration, potentially leading to higher torque density.

Material selection also plays a crucial role in the manufacturing process. Both motor types typically use rare-earth permanent magnets, such as neodymium-iron-boron (NdFeB) or samarium-cobalt (SmCo). However, the grade and shape of the magnets may differ based on the specific motor design and application requirements.

In terms of production scalability, SPMSMs generally have an advantage due to their simpler construction. This makes them more suitable for high-volume production. IPMSMs, while more challenging to manufacture at scale, offer performance benefits that can justify the additional complexity in certain applications.

For SPMSMs, the manufacturing process is relatively straightforward. The permanent magnets are typically attached to the surface of the rotor using adhesives or mechanical fasteners. This process allows for easier magnet placement and magnetization, as the magnets can be magnetized before assembly. The rotor core is usually made of laminated electrical steel sheets, which are stacked and bonded together. The simplicity of this design allows for more automated production processes, potentially reducing manufacturing costs.

In contrast, the manufacturing of IPMSMs is more complex. The rotor core is typically made of laminated electrical steel sheets with precisely cut cavities or slots to accommodate the permanent magnets. These cavities must be accurately machined to ensure proper magnet placement and optimal motor performance. The magnets are then inserted into these cavities and secured, often using adhesives or mechanical retention methods. This process requires more precision and can be more time-consuming than SPMSM production.

The stator manufacturing process is similar for both types of motors. It involves winding copper wire around a laminated steel core to create the electromagnetic coils. However, the stator design may vary slightly to accommodate the different rotor configurations.

One key difference in the manufacturing process is the magnetization step. For SPMSMs, the magnets can be pre-magnetized before assembly, simplifying the production process. IPMSMs, on the other hand, often require magnetization after the magnets are inserted into the rotor, which can be more challenging due to the surrounding steel structure.

The choice of manufacturing process impacts the motor's characteristics. SPMSMs benefit from simpler assembly but may have limitations in high-speed applications due to the risk of magnet detachment. IPMSMs, while more complex to manufacture, offer better mechanical integrity and allow for flux concentration, potentially leading to higher torque density.

Material selection also plays a crucial role in the manufacturing process. Both motor types typically use rare-earth permanent magnets, such as neodymium-iron-boron (NdFeB) or samarium-cobalt (SmCo). However, the grade and shape of the magnets may differ based on the specific motor design and application requirements.

In terms of production scalability, SPMSMs generally have an advantage due to their simpler construction. This makes them more suitable for high-volume production. IPMSMs, while more challenging to manufacture at scale, offer performance benefits that can justify the additional complexity in certain applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!