PMSM in disaster response robotic systems

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PMSM in Disaster Robotics: Background and Objectives

Permanent Magnet Synchronous Motors (PMSMs) have emerged as a critical component in disaster response robotic systems, revolutionizing the field of rescue operations. The evolution of PMSM technology in this context can be traced back to the early 2000s when researchers began exploring more efficient and reliable motor solutions for mobile robots operating in challenging environments.

The primary objective of integrating PMSMs into disaster response robots is to enhance their performance, efficiency, and reliability under extreme conditions. These motors offer superior power-to-weight ratios, precise control, and high torque capabilities, making them ideal for navigating through debris, climbing obstacles, and carrying heavy payloads in disaster-stricken areas.

Over the past two decades, the development of PMSMs for disaster robotics has been driven by several key factors. The increasing frequency and severity of natural disasters worldwide have necessitated more advanced and capable robotic systems. Additionally, the growing emphasis on sustainable and energy-efficient technologies has pushed researchers to optimize motor performance while minimizing power consumption.

The technological progression of PMSMs in disaster response robots has been marked by significant milestones. Early implementations focused on improving motor durability and waterproofing to withstand harsh environments. Subsequent advancements led to the development of compact, high-torque motors capable of operating in confined spaces and providing the necessary power for complex maneuvers.

Recent trends in PMSM research for disaster robotics include the integration of advanced control algorithms, such as sensorless control techniques, which enhance motor reliability by reducing the dependence on fragile sensor components. Furthermore, the incorporation of fault-tolerant designs and redundancy measures has become a priority to ensure continuous operation in critical situations.

The future direction of PMSM technology in disaster response robots aims to address several challenges. These include further miniaturization of motor components, improved thermal management for extended operation in extreme temperatures, and the development of adaptive control systems that can optimize motor performance based on real-time environmental conditions.

As we look ahead, the objectives for PMSM research in disaster robotics are multifaceted. Researchers are striving to increase motor efficiency to extend robot operational time, enhance torque density for improved payload capacity, and develop more robust designs capable of withstanding impacts and exposure to corrosive substances often encountered in disaster scenarios.

In conclusion, the background and objectives of PMSM research in disaster response robotic systems reflect a dynamic and rapidly evolving field. The continuous advancement of this technology promises to significantly enhance the capabilities of rescue robots, ultimately leading to more effective and efficient disaster response operations.

The primary objective of integrating PMSMs into disaster response robots is to enhance their performance, efficiency, and reliability under extreme conditions. These motors offer superior power-to-weight ratios, precise control, and high torque capabilities, making them ideal for navigating through debris, climbing obstacles, and carrying heavy payloads in disaster-stricken areas.

Over the past two decades, the development of PMSMs for disaster robotics has been driven by several key factors. The increasing frequency and severity of natural disasters worldwide have necessitated more advanced and capable robotic systems. Additionally, the growing emphasis on sustainable and energy-efficient technologies has pushed researchers to optimize motor performance while minimizing power consumption.

The technological progression of PMSMs in disaster response robots has been marked by significant milestones. Early implementations focused on improving motor durability and waterproofing to withstand harsh environments. Subsequent advancements led to the development of compact, high-torque motors capable of operating in confined spaces and providing the necessary power for complex maneuvers.

Recent trends in PMSM research for disaster robotics include the integration of advanced control algorithms, such as sensorless control techniques, which enhance motor reliability by reducing the dependence on fragile sensor components. Furthermore, the incorporation of fault-tolerant designs and redundancy measures has become a priority to ensure continuous operation in critical situations.

The future direction of PMSM technology in disaster response robots aims to address several challenges. These include further miniaturization of motor components, improved thermal management for extended operation in extreme temperatures, and the development of adaptive control systems that can optimize motor performance based on real-time environmental conditions.

As we look ahead, the objectives for PMSM research in disaster robotics are multifaceted. Researchers are striving to increase motor efficiency to extend robot operational time, enhance torque density for improved payload capacity, and develop more robust designs capable of withstanding impacts and exposure to corrosive substances often encountered in disaster scenarios.

In conclusion, the background and objectives of PMSM research in disaster response robotic systems reflect a dynamic and rapidly evolving field. The continuous advancement of this technology promises to significantly enhance the capabilities of rescue robots, ultimately leading to more effective and efficient disaster response operations.

Market Analysis for Disaster Response Robots

The market for disaster response robots has been experiencing significant growth in recent years, driven by the increasing frequency and severity of natural disasters worldwide. These robotic systems, equipped with Permanent Magnet Synchronous Motors (PMSMs), play a crucial role in enhancing the efficiency and effectiveness of disaster response operations.

The global disaster response robot market is projected to expand at a compound annual growth rate (CAGR) of over 20% during the forecast period of 2021-2026. This growth is primarily attributed to the rising investments in disaster management infrastructure and the growing adoption of advanced technologies in emergency response scenarios.

Key market segments for disaster response robots include search and rescue, firefighting, medical assistance, and debris removal. Among these, search and rescue applications currently dominate the market, accounting for the largest share due to the critical need for rapid and precise location of survivors in disaster-stricken areas.

Geographically, North America holds the largest market share, followed by Europe and Asia-Pacific. The United States, in particular, leads in terms of technological advancements and adoption of disaster response robots. However, the Asia-Pacific region is expected to witness the highest growth rate during the forecast period, driven by increasing government initiatives and investments in disaster management technologies.

The demand for PMSM-equipped disaster response robots is particularly strong in regions prone to natural disasters such as earthquakes, hurricanes, and floods. Countries like Japan, the United States, and China are at the forefront of developing and deploying these advanced robotic systems.

Key factors driving market growth include the need for improved safety of rescue personnel, the ability to access hazardous or hard-to-reach areas, and the potential for 24/7 operation in disaster zones. Additionally, the integration of artificial intelligence and machine learning technologies is enhancing the autonomous capabilities of these robots, further fueling market expansion.

However, the market faces challenges such as high initial costs, technical limitations in extreme environments, and the need for specialized training for operators. Despite these obstacles, ongoing research and development efforts are focused on addressing these issues, promising continued market growth and technological advancements in the coming years.

The global disaster response robot market is projected to expand at a compound annual growth rate (CAGR) of over 20% during the forecast period of 2021-2026. This growth is primarily attributed to the rising investments in disaster management infrastructure and the growing adoption of advanced technologies in emergency response scenarios.

Key market segments for disaster response robots include search and rescue, firefighting, medical assistance, and debris removal. Among these, search and rescue applications currently dominate the market, accounting for the largest share due to the critical need for rapid and precise location of survivors in disaster-stricken areas.

Geographically, North America holds the largest market share, followed by Europe and Asia-Pacific. The United States, in particular, leads in terms of technological advancements and adoption of disaster response robots. However, the Asia-Pacific region is expected to witness the highest growth rate during the forecast period, driven by increasing government initiatives and investments in disaster management technologies.

The demand for PMSM-equipped disaster response robots is particularly strong in regions prone to natural disasters such as earthquakes, hurricanes, and floods. Countries like Japan, the United States, and China are at the forefront of developing and deploying these advanced robotic systems.

Key factors driving market growth include the need for improved safety of rescue personnel, the ability to access hazardous or hard-to-reach areas, and the potential for 24/7 operation in disaster zones. Additionally, the integration of artificial intelligence and machine learning technologies is enhancing the autonomous capabilities of these robots, further fueling market expansion.

However, the market faces challenges such as high initial costs, technical limitations in extreme environments, and the need for specialized training for operators. Despite these obstacles, ongoing research and development efforts are focused on addressing these issues, promising continued market growth and technological advancements in the coming years.

Current PMSM Technology in Robotic Systems

Permanent Magnet Synchronous Motors (PMSMs) have become increasingly prevalent in robotic systems, particularly in disaster response applications. These motors offer high power density, excellent efficiency, and precise control, making them ideal for the demanding environments encountered in disaster scenarios.

In current robotic systems, PMSMs are primarily utilized for locomotion and actuation. For ground-based robots, PMSMs power the wheels or tracks, providing the necessary torque and speed control for navigating through debris and uneven terrain. In aerial drones, PMSMs drive the propellers, enabling stable flight and maneuverability in challenging conditions.

One of the key advantages of PMSMs in disaster response robots is their high torque-to-weight ratio. This allows for the development of compact yet powerful robotic systems that can carry heavy payloads or perform tasks requiring significant force, such as lifting debris or operating tools. The precise control offered by PMSMs also enables robots to perform delicate operations when necessary, such as handling fragile objects or interacting with survivors.

Advanced control techniques, such as field-oriented control (FOC) and direct torque control (DTC), are commonly employed to optimize PMSM performance in robotic systems. These methods allow for rapid torque response and accurate speed control, which are crucial for robots operating in dynamic and unpredictable environments.

Sensorless control techniques have gained traction in recent years, eliminating the need for position sensors and reducing system complexity. This is particularly beneficial for disaster response robots, as it enhances reliability and reduces potential points of failure in harsh conditions.

Energy efficiency is another critical aspect of PMSM technology in current robotic systems. The high efficiency of PMSMs contributes to extended battery life, allowing robots to operate for longer periods in the field. This is complemented by regenerative braking systems, which recover energy during deceleration and further improve overall system efficiency.

Thermal management remains a challenge in PMSM-powered robotic systems, especially in disaster scenarios where ambient temperatures may be extreme. Current solutions include advanced cooling systems, temperature-resistant materials, and intelligent control algorithms that optimize motor performance based on thermal conditions.

Researchers are also exploring the integration of PMSMs with other technologies to enhance robotic capabilities. For instance, the combination of PMSMs with artificial muscles or soft robotics is being investigated to create more adaptable and resilient robotic systems for disaster response applications.

In current robotic systems, PMSMs are primarily utilized for locomotion and actuation. For ground-based robots, PMSMs power the wheels or tracks, providing the necessary torque and speed control for navigating through debris and uneven terrain. In aerial drones, PMSMs drive the propellers, enabling stable flight and maneuverability in challenging conditions.

One of the key advantages of PMSMs in disaster response robots is their high torque-to-weight ratio. This allows for the development of compact yet powerful robotic systems that can carry heavy payloads or perform tasks requiring significant force, such as lifting debris or operating tools. The precise control offered by PMSMs also enables robots to perform delicate operations when necessary, such as handling fragile objects or interacting with survivors.

Advanced control techniques, such as field-oriented control (FOC) and direct torque control (DTC), are commonly employed to optimize PMSM performance in robotic systems. These methods allow for rapid torque response and accurate speed control, which are crucial for robots operating in dynamic and unpredictable environments.

Sensorless control techniques have gained traction in recent years, eliminating the need for position sensors and reducing system complexity. This is particularly beneficial for disaster response robots, as it enhances reliability and reduces potential points of failure in harsh conditions.

Energy efficiency is another critical aspect of PMSM technology in current robotic systems. The high efficiency of PMSMs contributes to extended battery life, allowing robots to operate for longer periods in the field. This is complemented by regenerative braking systems, which recover energy during deceleration and further improve overall system efficiency.

Thermal management remains a challenge in PMSM-powered robotic systems, especially in disaster scenarios where ambient temperatures may be extreme. Current solutions include advanced cooling systems, temperature-resistant materials, and intelligent control algorithms that optimize motor performance based on thermal conditions.

Researchers are also exploring the integration of PMSMs with other technologies to enhance robotic capabilities. For instance, the combination of PMSMs with artificial muscles or soft robotics is being investigated to create more adaptable and resilient robotic systems for disaster response applications.

PMSM Solutions for Disaster Response Robots

01 Motor design and structure

PMSM designs focus on optimizing the arrangement of permanent magnets, stator windings, and rotor configuration to enhance performance. Innovations include novel magnet shapes, improved cooling systems, and advanced materials to increase power density and efficiency.- Motor design and structure: Permanent Magnet Synchronous Motors (PMSMs) have unique design features and structural elements that contribute to their performance. This includes the arrangement of permanent magnets, rotor and stator configurations, and the use of specific materials to enhance magnetic properties and efficiency.

- Control systems and algorithms: Advanced control systems and algorithms are crucial for optimizing PMSM performance. These may include sensorless control techniques, adaptive control strategies, and advanced modulation methods to improve efficiency, reduce torque ripple, and enhance overall motor operation.

- Efficiency improvements: Various techniques are employed to improve the efficiency of PMSMs, such as optimizing magnetic circuit design, reducing losses, and implementing energy recovery systems. These improvements aim to enhance the motor's performance across different operating conditions and applications.

- Thermal management: Effective thermal management is essential for maintaining PMSM performance and longevity. This involves innovative cooling systems, heat dissipation techniques, and temperature monitoring to prevent overheating and ensure optimal operation under various load conditions.

- Application-specific optimizations: PMSMs are optimized for specific applications such as electric vehicles, industrial machinery, and renewable energy systems. These optimizations may include customized rotor designs, specialized winding configurations, and tailored control strategies to meet the unique requirements of each application.

02 Control strategies and algorithms

Advanced control techniques are developed for PMSMs to improve torque output, speed regulation, and overall system efficiency. These include sensorless control methods, adaptive algorithms, and model predictive control strategies to enhance motor performance across various operating conditions.Expand Specific Solutions03 Fault detection and diagnosis

Innovative methods for detecting and diagnosing faults in PMSMs are developed to improve reliability and maintenance. These include real-time monitoring systems, machine learning algorithms for predictive maintenance, and advanced sensor technologies to identify potential issues before they lead to motor failure.Expand Specific Solutions04 Efficiency improvement techniques

Research focuses on enhancing the energy efficiency of PMSMs through various methods. These include optimizing magnetic circuit design, reducing losses in core materials, improving thermal management, and developing high-performance power electronics for motor drives.Expand Specific Solutions05 Application-specific PMSM designs

Customized PMSM designs are developed for specific applications such as electric vehicles, industrial automation, and renewable energy systems. These designs focus on meeting unique requirements like high torque density, wide speed range operation, or integration with specific power systems.Expand Specific Solutions

Key Players in PMSM and Disaster Robotics

The research on PMSM in disaster response robotic systems is in an emerging stage, with growing market potential due to increasing natural disasters and the need for advanced robotic solutions. The technology is still evolving, with varying levels of maturity among key players. Companies like Mitsubishi Electric Corp. and ABB Oy are leading in industrial automation and robotics, while research institutions such as Harbin Institute of Technology and Shanghai Jiao Tong University are contributing significantly to PMSM advancements. The competitive landscape is diverse, including both established corporations and academic institutions, indicating a collaborative approach to technology development in this field.

Mitsubishi Electric Corp.

Technical Solution: Mitsubishi Electric has developed advanced PMSM (Permanent Magnet Synchronous Motor) technology for disaster response robotic systems. Their approach focuses on high-efficiency, compact designs suitable for mobile robots operating in challenging environments. The company's PMSM solutions incorporate advanced control algorithms that optimize torque output and energy efficiency, crucial for extended operation in disaster scenarios[1]. Mitsubishi's motors feature enhanced thermal management systems, allowing for sustained operation under extreme conditions often encountered in disaster zones[3]. Additionally, they have implemented robust position sensing technologies that maintain accurate motor control even in the presence of electromagnetic interference or physical shocks, which are common in disaster environments[5].

Strengths: High efficiency, compact design, and robust operation in extreme conditions. Weaknesses: Potentially higher cost compared to conventional motors, and reliance on rare earth materials for permanent magnets.

Beihang University

Technical Solution: Beihang University has conducted extensive research on PMSM technology for disaster response robotics, focusing on innovative control strategies and fault-tolerant designs. Their approach includes the development of adaptive control algorithms that can compensate for sudden changes in load or environmental conditions, crucial for robots navigating unstable disaster sites[13]. The university has also pioneered the use of multi-phase PMSM designs, which offer improved reliability through redundancy - if one phase fails, the motor can continue operating on the remaining phases[15]. Additionally, Beihang's researchers have developed novel sensorless control techniques that reduce the reliance on potentially vulnerable position sensors, enhancing the robustness of disaster response robots in harsh environments[17].

Strengths: Advanced control strategies, fault-tolerant designs, and innovative sensorless techniques. Weaknesses: Potential complexity in implementation and higher computational requirements for control systems.

Core PMSM Innovations for Harsh Environments

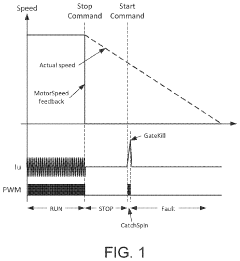

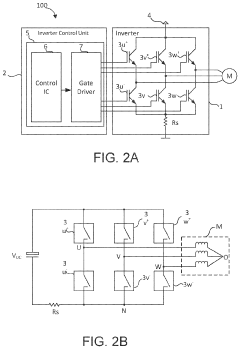

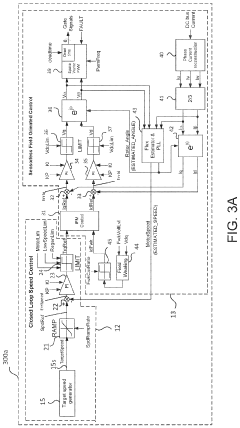

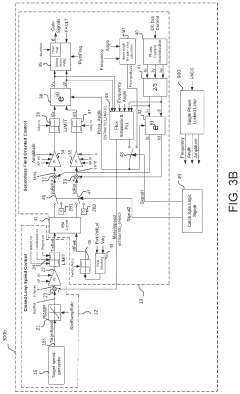

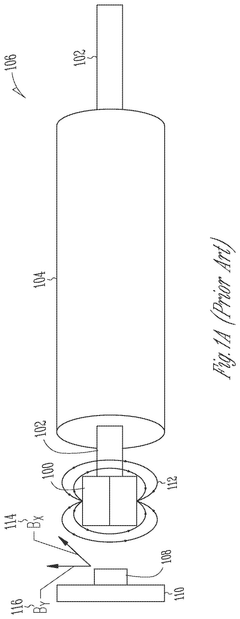

Catch spin method for permanent magnet synchronous motor with sensorless field oriented control

PatentActiveUS11594990B2

Innovation

- A motor control actuator and method that measures counter electro motive force (CEMF) or back electro motive force (BEMF) while the PMSM rotates, generates measurement signals, and performs a catch spin sequence using a multi-phase inverter to synchronize with the motor's voltage, including open loop and closed loop control to accurately restart the motor.

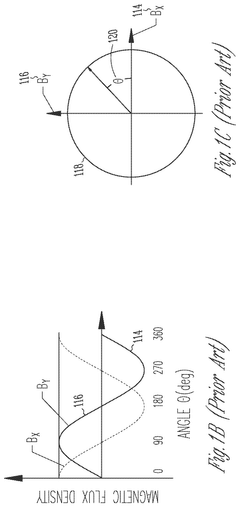

Permanent magnet synchronous motor (PMSM) integrated position sensing

PatentActiveUS12212257B2

Innovation

- The integration of analog magnetic flux sensors within the hollow cylindrical stator of the PMSM, arranged concentrically around the rotational axis at a constant mechanical angle relative to each other, allows for direct measurement of the magnetic flux from the rotor without external obstructions, enabling accurate rotor position sensing and reducing motor size and cost.

Safety Standards for Disaster Response Robots

Safety standards for disaster response robots are crucial for ensuring the effectiveness and reliability of these systems in high-risk environments. These standards encompass a wide range of considerations, including mechanical safety, electrical safety, operational safety, and human-robot interaction safety.

Mechanical safety standards focus on the physical design and construction of the robots. They address issues such as structural integrity, stability, and the prevention of pinch points or sharp edges that could cause injury. For disaster response robots, these standards must account for the challenging and unpredictable environments in which they operate, ensuring that the robots can withstand impacts, debris, and extreme conditions without compromising their functionality or safety.

Electrical safety standards are particularly important for robots operating in disaster scenarios, where they may encounter water, fire, or other hazardous conditions. These standards cover aspects such as insulation, grounding, and protection against short circuits and overloads. They also address the safety of power sources, including batteries and charging systems, to prevent electrical fires or explosions that could exacerbate the disaster situation.

Operational safety standards focus on the robot's behavior and control systems. They include requirements for fail-safe mechanisms, emergency stop functions, and redundant systems to ensure that the robot can be safely controlled and shut down if necessary. These standards also cover the robot's autonomous capabilities, setting guidelines for decision-making algorithms and sensor systems to prevent unintended or dangerous actions.

Human-robot interaction safety is a critical aspect of disaster response robotics. Standards in this area address the interface between human operators and the robots, ensuring clear communication and control. They also cover safety measures for situations where robots may need to interact directly with disaster victims or rescue personnel, including proximity sensors and force-limiting mechanisms to prevent accidental injuries.

Specific to PMSM (Permanent Magnet Synchronous Motors) in disaster response robotic systems, safety standards must address the unique characteristics of these motors. This includes guidelines for thermal management to prevent overheating in extreme conditions, as well as standards for the enclosure and protection of the motor components to maintain their integrity in harsh environments.

Furthermore, safety standards for disaster response robots must be regularly updated to keep pace with technological advancements and lessons learned from real-world deployments. This involves a collaborative effort between robotics engineers, safety experts, and first responders to ensure that the standards remain relevant and effective in protecting both the operators and the individuals they aim to assist in disaster scenarios.

Mechanical safety standards focus on the physical design and construction of the robots. They address issues such as structural integrity, stability, and the prevention of pinch points or sharp edges that could cause injury. For disaster response robots, these standards must account for the challenging and unpredictable environments in which they operate, ensuring that the robots can withstand impacts, debris, and extreme conditions without compromising their functionality or safety.

Electrical safety standards are particularly important for robots operating in disaster scenarios, where they may encounter water, fire, or other hazardous conditions. These standards cover aspects such as insulation, grounding, and protection against short circuits and overloads. They also address the safety of power sources, including batteries and charging systems, to prevent electrical fires or explosions that could exacerbate the disaster situation.

Operational safety standards focus on the robot's behavior and control systems. They include requirements for fail-safe mechanisms, emergency stop functions, and redundant systems to ensure that the robot can be safely controlled and shut down if necessary. These standards also cover the robot's autonomous capabilities, setting guidelines for decision-making algorithms and sensor systems to prevent unintended or dangerous actions.

Human-robot interaction safety is a critical aspect of disaster response robotics. Standards in this area address the interface between human operators and the robots, ensuring clear communication and control. They also cover safety measures for situations where robots may need to interact directly with disaster victims or rescue personnel, including proximity sensors and force-limiting mechanisms to prevent accidental injuries.

Specific to PMSM (Permanent Magnet Synchronous Motors) in disaster response robotic systems, safety standards must address the unique characteristics of these motors. This includes guidelines for thermal management to prevent overheating in extreme conditions, as well as standards for the enclosure and protection of the motor components to maintain their integrity in harsh environments.

Furthermore, safety standards for disaster response robots must be regularly updated to keep pace with technological advancements and lessons learned from real-world deployments. This involves a collaborative effort between robotics engineers, safety experts, and first responders to ensure that the standards remain relevant and effective in protecting both the operators and the individuals they aim to assist in disaster scenarios.

Energy Efficiency in Disaster Robotic Systems

Energy efficiency is a critical factor in the design and operation of disaster response robotic systems, particularly those utilizing Permanent Magnet Synchronous Motors (PMSM). In disaster scenarios, where power sources may be limited or unreliable, maximizing energy efficiency becomes paramount to ensure prolonged operation and effective mission completion.

The integration of PMSM in disaster response robots offers several advantages in terms of energy efficiency. These motors are known for their high power density, excellent control characteristics, and superior efficiency compared to other motor types. By leveraging the inherent efficiency of PMSM, robotic systems can operate for extended periods on limited power supplies, a crucial feature in disaster environments where recharging opportunities may be scarce.

Advanced control strategies play a vital role in optimizing the energy efficiency of PMSM-driven robotic systems. Field-oriented control (FOC) and direct torque control (DTC) techniques enable precise regulation of motor torque and speed, minimizing energy losses during operation. Additionally, implementing regenerative braking systems allows the robot to recover and store energy during deceleration, further enhancing overall efficiency.

Power management systems are essential components in disaster response robots, working in tandem with PMSM to maximize energy utilization. Intelligent power distribution algorithms can prioritize critical functions while temporarily reducing power to non-essential systems, extending operational time without compromising core capabilities. Furthermore, adaptive power management strategies can dynamically adjust motor parameters based on terrain conditions and mission requirements, ensuring optimal energy consumption across various scenarios.

The development of lightweight materials and streamlined designs contributes significantly to energy efficiency in disaster robotic systems. By reducing the overall weight of the robot, less energy is required for locomotion, allowing for longer operational times or increased payload capacity. Advanced composite materials and innovative structural designs can achieve this weight reduction without compromising the robot's strength or functionality.

Energy harvesting technologies present promising opportunities for enhancing the self-sufficiency of disaster response robots. Integrating solar panels, piezoelectric elements, or thermoelectric generators can supplement the robot's primary power source, extending operational duration in the field. These technologies are particularly valuable in scenarios where traditional power sources are unavailable or compromised.

In conclusion, the focus on energy efficiency in disaster robotic systems, particularly those employing PMSM, is crucial for enhancing their effectiveness and reliability in challenging environments. Through a combination of advanced motor technology, intelligent control strategies, and innovative power management solutions, these robotic systems can achieve extended operational capabilities, ultimately improving their ability to assist in disaster response and recovery efforts.

The integration of PMSM in disaster response robots offers several advantages in terms of energy efficiency. These motors are known for their high power density, excellent control characteristics, and superior efficiency compared to other motor types. By leveraging the inherent efficiency of PMSM, robotic systems can operate for extended periods on limited power supplies, a crucial feature in disaster environments where recharging opportunities may be scarce.

Advanced control strategies play a vital role in optimizing the energy efficiency of PMSM-driven robotic systems. Field-oriented control (FOC) and direct torque control (DTC) techniques enable precise regulation of motor torque and speed, minimizing energy losses during operation. Additionally, implementing regenerative braking systems allows the robot to recover and store energy during deceleration, further enhancing overall efficiency.

Power management systems are essential components in disaster response robots, working in tandem with PMSM to maximize energy utilization. Intelligent power distribution algorithms can prioritize critical functions while temporarily reducing power to non-essential systems, extending operational time without compromising core capabilities. Furthermore, adaptive power management strategies can dynamically adjust motor parameters based on terrain conditions and mission requirements, ensuring optimal energy consumption across various scenarios.

The development of lightweight materials and streamlined designs contributes significantly to energy efficiency in disaster robotic systems. By reducing the overall weight of the robot, less energy is required for locomotion, allowing for longer operational times or increased payload capacity. Advanced composite materials and innovative structural designs can achieve this weight reduction without compromising the robot's strength or functionality.

Energy harvesting technologies present promising opportunities for enhancing the self-sufficiency of disaster response robots. Integrating solar panels, piezoelectric elements, or thermoelectric generators can supplement the robot's primary power source, extending operational duration in the field. These technologies are particularly valuable in scenarios where traditional power sources are unavailable or compromised.

In conclusion, the focus on energy efficiency in disaster robotic systems, particularly those employing PMSM, is crucial for enhancing their effectiveness and reliability in challenging environments. Through a combination of advanced motor technology, intelligent control strategies, and innovative power management solutions, these robotic systems can achieve extended operational capabilities, ultimately improving their ability to assist in disaster response and recovery efforts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!