Voltage control advancements in PMSM efficiency

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PMSM Voltage Control Evolution and Objectives

Permanent Magnet Synchronous Motors (PMSMs) have emerged as a cornerstone technology in various industries, particularly in electric vehicles and industrial automation. The evolution of voltage control in PMSMs represents a critical trajectory in the pursuit of enhanced motor efficiency and performance. This technological progression has been driven by the increasing demand for energy-efficient and high-performance motor systems across diverse applications.

The primary objective of voltage control advancements in PMSMs is to optimize motor efficiency while maintaining precise control over torque and speed. This involves developing sophisticated control algorithms and hardware solutions that can accurately regulate the voltage supplied to the motor windings. By doing so, these advancements aim to minimize power losses, improve dynamic response, and extend the operational range of PMSMs.

Over the past decades, voltage control techniques for PMSMs have evolved from simple scalar control methods to more complex vector control strategies. The introduction of field-oriented control (FOC) marked a significant milestone, enabling independent control of torque and flux. This breakthrough paved the way for more efficient and responsive PMSM systems, particularly in applications requiring high dynamic performance.

Recent technological trends have focused on further refining voltage control techniques to address the challenges posed by modern applications. These include the development of sensorless control algorithms, which eliminate the need for position sensors, thereby reducing system complexity and cost. Additionally, advancements in power electronics have enabled the implementation of more sophisticated pulse-width modulation (PWM) techniques, allowing for finer control over voltage waveforms and reduced harmonic distortion.

The integration of artificial intelligence and machine learning algorithms into voltage control systems represents another frontier in PMSM technology. These approaches promise to enhance adaptability to varying operating conditions and improve overall system efficiency through continuous optimization. Furthermore, the advent of wide-bandgap semiconductors, such as silicon carbide (SiC) and gallium nitride (GaN), is enabling the development of more compact and efficient power converters, which in turn facilitates more precise voltage control.

Looking ahead, the objectives for future voltage control advancements in PMSMs are multifaceted. They include achieving near-unity power factor operation across a wider speed range, further reducing torque ripple and acoustic noise, and improving fault tolerance and reliability. Additionally, there is a growing emphasis on developing control strategies that can optimize motor efficiency in real-time, adapting to changes in load and environmental conditions.

The primary objective of voltage control advancements in PMSMs is to optimize motor efficiency while maintaining precise control over torque and speed. This involves developing sophisticated control algorithms and hardware solutions that can accurately regulate the voltage supplied to the motor windings. By doing so, these advancements aim to minimize power losses, improve dynamic response, and extend the operational range of PMSMs.

Over the past decades, voltage control techniques for PMSMs have evolved from simple scalar control methods to more complex vector control strategies. The introduction of field-oriented control (FOC) marked a significant milestone, enabling independent control of torque and flux. This breakthrough paved the way for more efficient and responsive PMSM systems, particularly in applications requiring high dynamic performance.

Recent technological trends have focused on further refining voltage control techniques to address the challenges posed by modern applications. These include the development of sensorless control algorithms, which eliminate the need for position sensors, thereby reducing system complexity and cost. Additionally, advancements in power electronics have enabled the implementation of more sophisticated pulse-width modulation (PWM) techniques, allowing for finer control over voltage waveforms and reduced harmonic distortion.

The integration of artificial intelligence and machine learning algorithms into voltage control systems represents another frontier in PMSM technology. These approaches promise to enhance adaptability to varying operating conditions and improve overall system efficiency through continuous optimization. Furthermore, the advent of wide-bandgap semiconductors, such as silicon carbide (SiC) and gallium nitride (GaN), is enabling the development of more compact and efficient power converters, which in turn facilitates more precise voltage control.

Looking ahead, the objectives for future voltage control advancements in PMSMs are multifaceted. They include achieving near-unity power factor operation across a wider speed range, further reducing torque ripple and acoustic noise, and improving fault tolerance and reliability. Additionally, there is a growing emphasis on developing control strategies that can optimize motor efficiency in real-time, adapting to changes in load and environmental conditions.

Market Demand for Efficient PMSM Systems

The market demand for efficient Permanent Magnet Synchronous Motor (PMSM) systems has been steadily increasing across various industries. This surge is primarily driven by the global push for energy efficiency, stringent environmental regulations, and the need for high-performance motor systems in diverse applications.

In the automotive sector, the shift towards electric vehicles (EVs) has created a significant demand for efficient PMSM systems. These motors offer higher power density, improved efficiency, and better control compared to traditional induction motors. As major automakers commit to electrifying their fleets, the demand for advanced PMSM systems with optimized voltage control is expected to grow exponentially.

The industrial automation sector is another key driver for efficient PMSM systems. Manufacturing processes require precise control and high efficiency to reduce operational costs and improve productivity. PMSM systems with advanced voltage control techniques offer superior performance in variable speed applications, making them ideal for use in robotics, CNC machines, and conveyor systems.

In the renewable energy sector, particularly wind power generation, PMSM systems are gaining traction due to their high efficiency and reliability. Wind turbines equipped with PMSM generators can operate at variable speeds, maximizing energy capture across different wind conditions. The demand for more efficient and grid-friendly wind power systems is fueling research into advanced voltage control strategies for PMSM-based generators.

The HVAC industry is also experiencing a growing demand for efficient motor systems. As energy efficiency standards become more stringent, manufacturers are turning to PMSM systems with sophisticated voltage control to meet these requirements. These motors offer significant energy savings in air conditioning units, refrigeration systems, and heat pumps.

Market analysts project that the global PMSM market will continue to expand at a compound annual growth rate (CAGR) of over 8% in the coming years. This growth is attributed to the increasing adoption of PMSM systems in emerging applications such as aerospace, marine propulsion, and smart home appliances.

The demand for efficient PMSM systems is not limited to specific regions. While developed economies in North America and Europe are driving adoption through stringent energy efficiency regulations, emerging economies in Asia-Pacific are witnessing rapid industrialization and urbanization, creating new markets for advanced motor technologies.

As the market for efficient PMSM systems grows, there is an increasing focus on developing more sophisticated voltage control techniques. These advancements aim to further improve motor efficiency, reduce harmonics, and enhance overall system performance. The industry is witnessing a trend towards the integration of smart control algorithms, power electronics, and advanced sensing technologies to achieve these goals.

In the automotive sector, the shift towards electric vehicles (EVs) has created a significant demand for efficient PMSM systems. These motors offer higher power density, improved efficiency, and better control compared to traditional induction motors. As major automakers commit to electrifying their fleets, the demand for advanced PMSM systems with optimized voltage control is expected to grow exponentially.

The industrial automation sector is another key driver for efficient PMSM systems. Manufacturing processes require precise control and high efficiency to reduce operational costs and improve productivity. PMSM systems with advanced voltage control techniques offer superior performance in variable speed applications, making them ideal for use in robotics, CNC machines, and conveyor systems.

In the renewable energy sector, particularly wind power generation, PMSM systems are gaining traction due to their high efficiency and reliability. Wind turbines equipped with PMSM generators can operate at variable speeds, maximizing energy capture across different wind conditions. The demand for more efficient and grid-friendly wind power systems is fueling research into advanced voltage control strategies for PMSM-based generators.

The HVAC industry is also experiencing a growing demand for efficient motor systems. As energy efficiency standards become more stringent, manufacturers are turning to PMSM systems with sophisticated voltage control to meet these requirements. These motors offer significant energy savings in air conditioning units, refrigeration systems, and heat pumps.

Market analysts project that the global PMSM market will continue to expand at a compound annual growth rate (CAGR) of over 8% in the coming years. This growth is attributed to the increasing adoption of PMSM systems in emerging applications such as aerospace, marine propulsion, and smart home appliances.

The demand for efficient PMSM systems is not limited to specific regions. While developed economies in North America and Europe are driving adoption through stringent energy efficiency regulations, emerging economies in Asia-Pacific are witnessing rapid industrialization and urbanization, creating new markets for advanced motor technologies.

As the market for efficient PMSM systems grows, there is an increasing focus on developing more sophisticated voltage control techniques. These advancements aim to further improve motor efficiency, reduce harmonics, and enhance overall system performance. The industry is witnessing a trend towards the integration of smart control algorithms, power electronics, and advanced sensing technologies to achieve these goals.

Current PMSM Voltage Control Challenges

Permanent Magnet Synchronous Motors (PMSMs) have gained significant traction in various applications due to their high efficiency and power density. However, as the demand for even higher performance and energy efficiency grows, voltage control in PMSMs faces several challenges that need to be addressed.

One of the primary challenges in PMSM voltage control is the accurate estimation of rotor position and speed. Traditional methods often rely on mechanical sensors, which can be costly and prone to failure in harsh environments. Sensorless control techniques have emerged as a potential solution, but they still struggle with accuracy at low speeds and during startup conditions. This limitation affects the overall performance and reliability of the motor control system.

Another significant challenge is the management of voltage constraints, particularly in high-speed operations. As the motor speed increases, the back-EMF also rises, potentially exceeding the available DC bus voltage. This phenomenon, known as voltage saturation, can lead to a loss of torque control and reduced efficiency. Advanced control strategies are required to optimize the voltage utilization within these constraints while maintaining optimal performance.

The presence of parameter variations and uncertainties poses another hurdle in PMSM voltage control. Factors such as temperature changes, magnetic saturation, and manufacturing tolerances can cause fluctuations in motor parameters like resistance and inductance. These variations can significantly impact the accuracy of the control system, leading to suboptimal performance and reduced efficiency if not properly compensated for.

Harmonic distortion in the voltage waveform is an additional challenge that affects PMSM performance. Non-ideal inverter characteristics, such as dead-time effects and voltage drops across switching devices, can introduce harmonics into the voltage supply. These harmonics can cause torque ripples, increased losses, and acoustic noise, degrading the overall system efficiency and performance.

The need for faster dynamic response in voltage control is becoming increasingly critical, especially in applications requiring rapid torque changes or precise position control. Traditional PI controllers may struggle to meet these demands, necessitating the development of more advanced control algorithms that can provide quicker and more accurate voltage adjustments.

Lastly, the integration of PMSMs in complex systems, such as electric vehicles or industrial automation, introduces additional challenges in voltage control. These systems often require coordination between multiple motors and power electronic components, adding complexity to the control strategy. Ensuring stable and efficient operation across various operating conditions while maintaining system-level optimization becomes a significant challenge.

One of the primary challenges in PMSM voltage control is the accurate estimation of rotor position and speed. Traditional methods often rely on mechanical sensors, which can be costly and prone to failure in harsh environments. Sensorless control techniques have emerged as a potential solution, but they still struggle with accuracy at low speeds and during startup conditions. This limitation affects the overall performance and reliability of the motor control system.

Another significant challenge is the management of voltage constraints, particularly in high-speed operations. As the motor speed increases, the back-EMF also rises, potentially exceeding the available DC bus voltage. This phenomenon, known as voltage saturation, can lead to a loss of torque control and reduced efficiency. Advanced control strategies are required to optimize the voltage utilization within these constraints while maintaining optimal performance.

The presence of parameter variations and uncertainties poses another hurdle in PMSM voltage control. Factors such as temperature changes, magnetic saturation, and manufacturing tolerances can cause fluctuations in motor parameters like resistance and inductance. These variations can significantly impact the accuracy of the control system, leading to suboptimal performance and reduced efficiency if not properly compensated for.

Harmonic distortion in the voltage waveform is an additional challenge that affects PMSM performance. Non-ideal inverter characteristics, such as dead-time effects and voltage drops across switching devices, can introduce harmonics into the voltage supply. These harmonics can cause torque ripples, increased losses, and acoustic noise, degrading the overall system efficiency and performance.

The need for faster dynamic response in voltage control is becoming increasingly critical, especially in applications requiring rapid torque changes or precise position control. Traditional PI controllers may struggle to meet these demands, necessitating the development of more advanced control algorithms that can provide quicker and more accurate voltage adjustments.

Lastly, the integration of PMSMs in complex systems, such as electric vehicles or industrial automation, introduces additional challenges in voltage control. These systems often require coordination between multiple motors and power electronic components, adding complexity to the control strategy. Ensuring stable and efficient operation across various operating conditions while maintaining system-level optimization becomes a significant challenge.

State-of-the-Art Voltage Control Methods

01 Optimization of motor design for improved efficiency

Enhancing PMSM efficiency through optimized design parameters such as rotor configuration, stator winding patterns, and magnetic circuit layout. This includes reducing losses in the core and windings, optimizing air gap dimensions, and improving thermal management to maintain performance under various operating conditions.- Optimization of motor design for improved efficiency: Enhancing PMSM efficiency through optimized design parameters such as rotor geometry, magnet arrangement, and stator winding configuration. This includes reducing losses in the motor structure and improving magnetic flux distribution.

- Advanced control strategies for PMSM: Implementing sophisticated control algorithms and techniques to maximize PMSM efficiency. This includes vector control, sensorless control, and adaptive control methods to optimize motor performance under various operating conditions.

- Thermal management and cooling systems: Developing effective thermal management solutions to reduce heat losses and maintain optimal operating temperatures in PMSMs. This involves innovative cooling techniques and materials to enhance overall motor efficiency.

- Integration of power electronics and drive systems: Optimizing the integration of power electronics and drive systems with PMSMs to reduce losses and improve overall system efficiency. This includes advanced inverter designs and control strategies tailored for PMSM applications.

- Novel materials and manufacturing techniques: Utilizing advanced materials and manufacturing processes to enhance PMSM efficiency. This includes the use of high-performance magnetic materials, improved lamination techniques, and additive manufacturing for complex motor components.

02 Advanced control strategies for PMSM efficiency

Implementing sophisticated control algorithms and techniques to maximize PMSM efficiency across different speed and load ranges. This involves adaptive control methods, sensorless control techniques, and advanced vector control strategies to optimize torque production and minimize losses during operation.Expand Specific Solutions03 Innovative materials and manufacturing techniques

Utilizing advanced materials and manufacturing processes to enhance PMSM efficiency. This includes the use of high-performance magnetic materials, improved lamination techniques for the stator and rotor cores, and novel winding technologies to reduce losses and improve overall motor performance.Expand Specific Solutions04 Integration of power electronics for efficiency improvement

Incorporating advanced power electronic components and circuits to enhance PMSM efficiency. This involves the use of high-frequency inverters, regenerative braking systems, and intelligent power management techniques to optimize energy conversion and reduce losses in the motor drive system.Expand Specific Solutions05 Thermal management and cooling solutions

Developing effective thermal management and cooling strategies to maintain PMSM efficiency under various operating conditions. This includes innovative cooling designs, heat dissipation techniques, and temperature monitoring systems to prevent efficiency degradation due to overheating and ensure optimal performance across different load profiles.Expand Specific Solutions

Key PMSM Technology Players

The voltage control advancements in PMSM efficiency market is in a growth phase, driven by increasing demand for energy-efficient motor systems across various industries. The global market size is expanding, with projections indicating significant growth in the coming years. Technologically, the field is rapidly evolving, with companies like Infineon Technologies, Microchip Technology, and Texas Instruments leading innovation. These firms are developing advanced motor control solutions, integrating power electronics and digital control techniques to enhance PMSM efficiency. Academic institutions such as the University of Electronic Science & Technology of China and Hunan University are also contributing to research and development in this area, fostering industry-academia collaborations and pushing the boundaries of PMSM technology.

Microchip Technology, Inc.

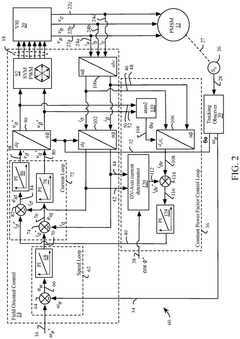

Technical Solution: Microchip Technology has developed innovative voltage control solutions for PMSM efficiency, centered around their dsPIC® Digital Signal Controllers. Their approach focuses on implementing advanced control algorithms directly on the microcontroller, enabling precise and responsive voltage regulation. Microchip's voltage control strategy incorporates adaptive flux weakening techniques, which allow for extended speed ranges while maintaining optimal efficiency[10]. They have also implemented advanced PWM schemes, such as discontinuous PWM, which reduce switching losses and improve overall system efficiency[11]. Microchip's solution includes sophisticated current measurement and reconstruction techniques, enabling accurate voltage control even at high switching frequencies. Additionally, their motor control development tools, like motorBench®, facilitate rapid prototyping and optimization of voltage control strategies for specific PMSM applications[12].

Strengths: Integrated DSC solutions for motor control, advanced flux weakening for extended speed range, comprehensive development tools for rapid implementation. Weaknesses: May require expertise in DSC programming, potential limitations in processing power compared to more advanced processors.

Infineon Technologies AG

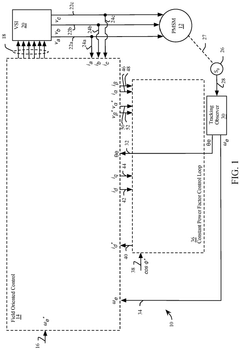

Technical Solution: Infineon has developed advanced voltage control techniques for PMSM efficiency, focusing on their iMOTION™ platform. This system integrates motor control ICs with power devices, enabling precise voltage regulation. Their approach utilizes Field Oriented Control (FOC) algorithms, which allow for dynamic adjustment of voltage and current vectors to optimize motor performance across various operating conditions[1]. Infineon's solution also incorporates adaptive voltage control mechanisms that respond to changes in load and speed, maintaining high efficiency throughout the motor's operational range[2]. The company has implemented sensorless control techniques, reducing system complexity while enhancing reliability and cost-effectiveness[3].

Strengths: Integrated solution combining control and power electronics, advanced FOC algorithms for precise control, adaptive voltage mechanisms for efficiency across operating ranges. Weaknesses: May require specialized knowledge for implementation, potentially higher initial cost compared to simpler control methods.

Innovative PMSM Efficiency Patents

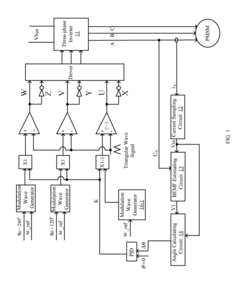

Driving circuit and driving method for permanent magnet synchronous motor

PatentActiveUS20170085196A1

Innovation

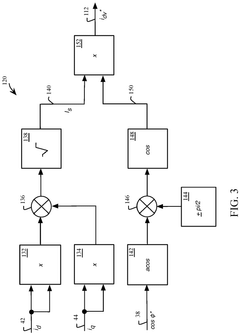

- A driving circuit and method that includes a current sampling circuit, back electromotive force (BEMF) circuit, and torque regulating circuit to estimate BEMF information and regulate the amplitude of a U-shaped modulation wave, allowing for maximum torque per ampere without a position sensor, using a sliding mode controller and PID regulator to synchronize rotor current with the modulation wave.

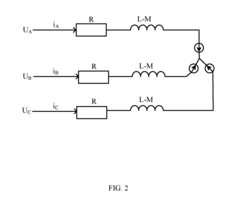

Field oriented control of permanent magnet synchronous motor with constant power factor control loop

PatentPendingEP4432548A1

Innovation

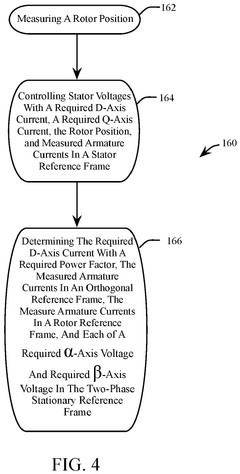

- Implementing a Field Oriented Control (FOC) system with a constant PFC loop that controls the direct-axis current to maintain a desired power factor, independent of motor parameters, using transformations like Clarke and Park to manage d-axis and q-axis currents, and PI controllers to suppress errors, thereby optimizing torque and flux control.

Energy Regulations Impact

The impact of energy regulations on voltage control advancements in PMSM efficiency is significant and multifaceted. As governments worldwide implement stricter energy efficiency standards, manufacturers of Permanent Magnet Synchronous Motors (PMSMs) are compelled to innovate and improve their voltage control techniques to meet these requirements.

Energy regulations, such as the European Union's Ecodesign Directive and the U.S. Department of Energy's efficiency standards, have set increasingly stringent targets for motor efficiency. These regulations have directly influenced the development of advanced voltage control strategies for PMSMs, pushing manufacturers to explore novel approaches to minimize energy losses and maximize overall system efficiency.

One key area of focus has been the reduction of harmonics in the voltage supply to PMSMs. Regulatory bodies have imposed limits on harmonic distortion, recognizing its detrimental effects on motor efficiency and power quality. This has led to the development of more sophisticated pulse width modulation (PWM) techniques and advanced filtering methods to ensure cleaner voltage waveforms and improved motor performance.

The push for higher efficiency has also driven research into more precise voltage control algorithms. Manufacturers have invested in developing adaptive control systems that can dynamically adjust voltage levels based on motor load and operating conditions. These systems help maintain optimal efficiency across a wide range of operating points, directly addressing the energy conservation goals set by regulatory frameworks.

Furthermore, energy regulations have accelerated the adoption of wide bandgap semiconductors, such as silicon carbide (SiC) and gallium nitride (GaN), in PMSM drive systems. These materials enable higher switching frequencies and lower losses, allowing for more efficient voltage control and meeting the stringent efficiency requirements imposed by regulations.

The emphasis on standby power consumption in energy regulations has also influenced voltage control strategies. Manufacturers have developed advanced sleep modes and rapid wake-up techniques for PMSM systems, ensuring minimal energy consumption during idle periods while maintaining quick responsiveness when needed.

As a result of these regulatory pressures, the industry has seen a shift towards more integrated and intelligent motor control systems. These systems often incorporate advanced sensors and real-time monitoring capabilities to optimize voltage control and ensure compliance with energy efficiency standards throughout the motor's operational life.

In conclusion, energy regulations have been a powerful catalyst for innovation in voltage control techniques for PMSMs. They have not only driven improvements in motor efficiency but also fostered the development of more sophisticated, adaptive, and intelligent control systems. As regulations continue to evolve, they will likely remain a key driver of technological advancements in this field, pushing the boundaries of what is possible in PMSM efficiency and performance.

Energy regulations, such as the European Union's Ecodesign Directive and the U.S. Department of Energy's efficiency standards, have set increasingly stringent targets for motor efficiency. These regulations have directly influenced the development of advanced voltage control strategies for PMSMs, pushing manufacturers to explore novel approaches to minimize energy losses and maximize overall system efficiency.

One key area of focus has been the reduction of harmonics in the voltage supply to PMSMs. Regulatory bodies have imposed limits on harmonic distortion, recognizing its detrimental effects on motor efficiency and power quality. This has led to the development of more sophisticated pulse width modulation (PWM) techniques and advanced filtering methods to ensure cleaner voltage waveforms and improved motor performance.

The push for higher efficiency has also driven research into more precise voltage control algorithms. Manufacturers have invested in developing adaptive control systems that can dynamically adjust voltage levels based on motor load and operating conditions. These systems help maintain optimal efficiency across a wide range of operating points, directly addressing the energy conservation goals set by regulatory frameworks.

Furthermore, energy regulations have accelerated the adoption of wide bandgap semiconductors, such as silicon carbide (SiC) and gallium nitride (GaN), in PMSM drive systems. These materials enable higher switching frequencies and lower losses, allowing for more efficient voltage control and meeting the stringent efficiency requirements imposed by regulations.

The emphasis on standby power consumption in energy regulations has also influenced voltage control strategies. Manufacturers have developed advanced sleep modes and rapid wake-up techniques for PMSM systems, ensuring minimal energy consumption during idle periods while maintaining quick responsiveness when needed.

As a result of these regulatory pressures, the industry has seen a shift towards more integrated and intelligent motor control systems. These systems often incorporate advanced sensors and real-time monitoring capabilities to optimize voltage control and ensure compliance with energy efficiency standards throughout the motor's operational life.

In conclusion, energy regulations have been a powerful catalyst for innovation in voltage control techniques for PMSMs. They have not only driven improvements in motor efficiency but also fostered the development of more sophisticated, adaptive, and intelligent control systems. As regulations continue to evolve, they will likely remain a key driver of technological advancements in this field, pushing the boundaries of what is possible in PMSM efficiency and performance.

PMSM Thermal Management

Thermal management is a critical aspect of Permanent Magnet Synchronous Motor (PMSM) design and operation, directly impacting the motor's efficiency and performance. As voltage control advancements continue to push the boundaries of PMSM efficiency, the importance of effective thermal management becomes increasingly paramount.

The primary sources of heat generation in PMSMs are copper losses in the stator windings, iron losses in the stator core, and to a lesser extent, rotor losses. These thermal loads can lead to decreased efficiency, reduced motor lifespan, and potential failure if not properly managed. Advanced thermal management techniques are essential to maintain optimal operating temperatures and ensure the longevity of the motor.

One of the key strategies in PMSM thermal management is the implementation of advanced cooling systems. Liquid cooling methods, such as oil or water jacket cooling, have shown significant improvements over traditional air cooling. These systems provide more efficient heat dissipation, allowing for higher power densities and improved overall performance. Additionally, innovative cooling channel designs and optimized flow patterns have further enhanced the effectiveness of liquid cooling systems.

Thermal modeling and simulation play a crucial role in the development of effective thermal management solutions. Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) tools enable engineers to predict temperature distributions and identify hotspots within the motor structure. These simulations guide the design process, allowing for optimized thermal management strategies tailored to specific motor configurations and operating conditions.

The selection of materials with superior thermal properties is another important aspect of PMSM thermal management. High thermal conductivity materials for stator laminations and advanced insulation materials for windings contribute to improved heat dissipation. Furthermore, the use of thermally conductive epoxy resins and innovative potting compounds enhances heat transfer from the windings to the motor housing.

Integration of thermal sensors and real-time temperature monitoring systems enables dynamic thermal management strategies. These systems can adjust motor operation parameters, such as current and voltage levels, to maintain optimal temperature ranges and prevent thermal overload. This adaptive approach ensures efficient operation across various load conditions and ambient temperatures.

As voltage control techniques continue to evolve, thermal management strategies must keep pace to fully leverage the potential efficiency gains. The synergy between advanced voltage control methods and sophisticated thermal management solutions is key to pushing the boundaries of PMSM performance and reliability in diverse applications, from electric vehicles to industrial automation.

The primary sources of heat generation in PMSMs are copper losses in the stator windings, iron losses in the stator core, and to a lesser extent, rotor losses. These thermal loads can lead to decreased efficiency, reduced motor lifespan, and potential failure if not properly managed. Advanced thermal management techniques are essential to maintain optimal operating temperatures and ensure the longevity of the motor.

One of the key strategies in PMSM thermal management is the implementation of advanced cooling systems. Liquid cooling methods, such as oil or water jacket cooling, have shown significant improvements over traditional air cooling. These systems provide more efficient heat dissipation, allowing for higher power densities and improved overall performance. Additionally, innovative cooling channel designs and optimized flow patterns have further enhanced the effectiveness of liquid cooling systems.

Thermal modeling and simulation play a crucial role in the development of effective thermal management solutions. Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) tools enable engineers to predict temperature distributions and identify hotspots within the motor structure. These simulations guide the design process, allowing for optimized thermal management strategies tailored to specific motor configurations and operating conditions.

The selection of materials with superior thermal properties is another important aspect of PMSM thermal management. High thermal conductivity materials for stator laminations and advanced insulation materials for windings contribute to improved heat dissipation. Furthermore, the use of thermally conductive epoxy resins and innovative potting compounds enhances heat transfer from the windings to the motor housing.

Integration of thermal sensors and real-time temperature monitoring systems enables dynamic thermal management strategies. These systems can adjust motor operation parameters, such as current and voltage levels, to maintain optimal temperature ranges and prevent thermal overload. This adaptive approach ensures efficient operation across various load conditions and ambient temperatures.

As voltage control techniques continue to evolve, thermal management strategies must keep pace to fully leverage the potential efficiency gains. The synergy between advanced voltage control methods and sophisticated thermal management solutions is key to pushing the boundaries of PMSM performance and reliability in diverse applications, from electric vehicles to industrial automation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!