Electronically commutated drive systems with PMSM integration

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PMSM Drive Evolution

The evolution of Permanent Magnet Synchronous Motor (PMSM) drive systems represents a significant advancement in electric motor technology. This progression can be traced through several key stages, each marked by technological breakthroughs and improvements in performance, efficiency, and control.

In the early stages of PMSM development, the focus was primarily on improving the basic motor design and materials. The introduction of rare-earth permanent magnets, particularly neodymium-iron-boron (NdFeB) magnets in the 1980s, marked a crucial turning point. These magnets offered superior magnetic properties, allowing for more compact and powerful motors.

The next phase saw advancements in power electronics and control systems. The development of high-speed switching devices, such as IGBTs and MOSFETs, enabled more precise and efficient motor control. This led to the implementation of sophisticated control algorithms, including field-oriented control (FOC) and direct torque control (DTC), which significantly enhanced the dynamic performance of PMSM drives.

As digital technology progressed, the integration of microcontrollers and digital signal processors (DSPs) into drive systems became a game-changer. This allowed for more complex control strategies and real-time optimization of motor performance. The advent of sensorless control techniques further simplified the drive system, reducing costs and improving reliability.

Recent years have witnessed a shift towards more intelligent and connected drive systems. The incorporation of advanced sensors, coupled with machine learning algorithms, has enabled predictive maintenance and adaptive control strategies. This has resulted in drive systems that can self-optimize for different operating conditions and anticipate potential issues before they occur.

The latest trend in PMSM drive evolution is the integration of wide bandgap (WBG) semiconductors, such as silicon carbide (SiC) and gallium nitride (GaN). These materials offer higher switching frequencies, lower losses, and better thermal performance compared to traditional silicon-based devices. This has led to more compact, efficient, and reliable drive systems.

Looking forward, the evolution of PMSM drives is likely to continue in the direction of increased integration and intelligence. The concept of "smart drives" that can communicate with other systems, self-diagnose, and adapt to changing environments is becoming a reality. Additionally, ongoing research in areas such as advanced materials for magnets and innovative motor topologies promises to push the boundaries of PMSM performance even further.

In the early stages of PMSM development, the focus was primarily on improving the basic motor design and materials. The introduction of rare-earth permanent magnets, particularly neodymium-iron-boron (NdFeB) magnets in the 1980s, marked a crucial turning point. These magnets offered superior magnetic properties, allowing for more compact and powerful motors.

The next phase saw advancements in power electronics and control systems. The development of high-speed switching devices, such as IGBTs and MOSFETs, enabled more precise and efficient motor control. This led to the implementation of sophisticated control algorithms, including field-oriented control (FOC) and direct torque control (DTC), which significantly enhanced the dynamic performance of PMSM drives.

As digital technology progressed, the integration of microcontrollers and digital signal processors (DSPs) into drive systems became a game-changer. This allowed for more complex control strategies and real-time optimization of motor performance. The advent of sensorless control techniques further simplified the drive system, reducing costs and improving reliability.

Recent years have witnessed a shift towards more intelligent and connected drive systems. The incorporation of advanced sensors, coupled with machine learning algorithms, has enabled predictive maintenance and adaptive control strategies. This has resulted in drive systems that can self-optimize for different operating conditions and anticipate potential issues before they occur.

The latest trend in PMSM drive evolution is the integration of wide bandgap (WBG) semiconductors, such as silicon carbide (SiC) and gallium nitride (GaN). These materials offer higher switching frequencies, lower losses, and better thermal performance compared to traditional silicon-based devices. This has led to more compact, efficient, and reliable drive systems.

Looking forward, the evolution of PMSM drives is likely to continue in the direction of increased integration and intelligence. The concept of "smart drives" that can communicate with other systems, self-diagnose, and adapt to changing environments is becoming a reality. Additionally, ongoing research in areas such as advanced materials for magnets and innovative motor topologies promises to push the boundaries of PMSM performance even further.

Market Demand Analysis

The market demand for electronically commutated drive systems with Permanent Magnet Synchronous Motor (PMSM) integration has been experiencing significant growth in recent years. This surge is primarily driven by the increasing need for energy-efficient and high-performance motor systems across various industries.

In the automotive sector, the shift towards electric vehicles (EVs) has created a substantial demand for PMSM-based drive systems. These motors offer higher efficiency, better power density, and improved control compared to traditional induction motors. As governments worldwide implement stricter emissions regulations and promote EV adoption, the market for PMSM drive systems is expected to expand rapidly.

The industrial automation sector is another key driver of market demand. Manufacturing facilities are increasingly adopting electronically commutated drive systems with PMSM integration to enhance productivity, reduce energy consumption, and improve overall equipment effectiveness. These systems provide precise speed control, high torque at low speeds, and excellent dynamic response, making them ideal for applications such as robotics, CNC machines, and conveyor systems.

In the HVAC industry, there is a growing trend towards energy-efficient solutions. Electronically commutated motors with PMSM technology are being widely adopted in air handling units, fans, and compressors. These systems offer significant energy savings, reduced noise levels, and improved temperature control, aligning with the industry's focus on sustainability and reduced operating costs.

The renewable energy sector, particularly wind power generation, has also contributed to the increasing demand for PMSM-based drive systems. Wind turbines equipped with these motors can operate at variable speeds, maximizing energy capture and improving overall system efficiency. As countries invest in expanding their renewable energy capacity, the demand for advanced motor technologies is expected to rise.

Furthermore, the aerospace industry is showing interest in electronically commutated drive systems with PMSM integration for applications such as electric propulsion systems and more electric aircraft initiatives. These systems offer weight reduction, improved reliability, and enhanced performance, which are crucial factors in aerospace applications.

The market demand is also influenced by the ongoing trend of miniaturization and the need for compact, high-performance motor solutions in consumer electronics and medical devices. PMSM-based systems are well-suited for these applications due to their small form factor and precise control capabilities.

As industries continue to prioritize energy efficiency, performance, and sustainability, the market for electronically commutated drive systems with PMSM integration is poised for sustained growth. Manufacturers and researchers are focusing on further improving motor designs, control algorithms, and power electronics to meet the evolving demands of various sectors and capitalize on the expanding market opportunities.

In the automotive sector, the shift towards electric vehicles (EVs) has created a substantial demand for PMSM-based drive systems. These motors offer higher efficiency, better power density, and improved control compared to traditional induction motors. As governments worldwide implement stricter emissions regulations and promote EV adoption, the market for PMSM drive systems is expected to expand rapidly.

The industrial automation sector is another key driver of market demand. Manufacturing facilities are increasingly adopting electronically commutated drive systems with PMSM integration to enhance productivity, reduce energy consumption, and improve overall equipment effectiveness. These systems provide precise speed control, high torque at low speeds, and excellent dynamic response, making them ideal for applications such as robotics, CNC machines, and conveyor systems.

In the HVAC industry, there is a growing trend towards energy-efficient solutions. Electronically commutated motors with PMSM technology are being widely adopted in air handling units, fans, and compressors. These systems offer significant energy savings, reduced noise levels, and improved temperature control, aligning with the industry's focus on sustainability and reduced operating costs.

The renewable energy sector, particularly wind power generation, has also contributed to the increasing demand for PMSM-based drive systems. Wind turbines equipped with these motors can operate at variable speeds, maximizing energy capture and improving overall system efficiency. As countries invest in expanding their renewable energy capacity, the demand for advanced motor technologies is expected to rise.

Furthermore, the aerospace industry is showing interest in electronically commutated drive systems with PMSM integration for applications such as electric propulsion systems and more electric aircraft initiatives. These systems offer weight reduction, improved reliability, and enhanced performance, which are crucial factors in aerospace applications.

The market demand is also influenced by the ongoing trend of miniaturization and the need for compact, high-performance motor solutions in consumer electronics and medical devices. PMSM-based systems are well-suited for these applications due to their small form factor and precise control capabilities.

As industries continue to prioritize energy efficiency, performance, and sustainability, the market for electronically commutated drive systems with PMSM integration is poised for sustained growth. Manufacturers and researchers are focusing on further improving motor designs, control algorithms, and power electronics to meet the evolving demands of various sectors and capitalize on the expanding market opportunities.

Technical Challenges

The integration of Permanent Magnet Synchronous Motors (PMSM) into electronically commutated drive systems presents several significant technical challenges. These challenges stem from the complex interplay between the motor's electromagnetic characteristics, power electronics, and control algorithms.

One of the primary obstacles is the precise control of rotor position and speed. PMSM requires accurate rotor position information for optimal commutation, which is critical for achieving high efficiency and performance. Traditional sensor-based methods, while effective, add cost and complexity to the system. Sensorless control techniques have emerged as a potential solution, but they face difficulties in low-speed operations and during startup conditions.

The thermal management of PMSM-integrated drive systems poses another substantial challenge. The compact design of these systems often leads to high power density, resulting in increased heat generation. Efficient heat dissipation is crucial to prevent performance degradation and ensure the longevity of both the motor and the electronic components. Innovative cooling solutions and thermal modeling techniques are necessary to address this issue effectively.

Power electronics integration presents its own set of challenges. The drive system must handle high switching frequencies to achieve precise motor control while minimizing losses. This requirement puts stress on semiconductor devices and increases electromagnetic interference (EMI). Balancing performance with EMI mitigation and thermal management in a compact package remains a significant engineering challenge.

The control algorithms for PMSM-integrated drive systems are inherently complex. They must account for motor parameters that can vary with temperature and magnetic saturation. Implementing robust control strategies that maintain stability and performance across a wide operating range, including field weakening operations, is a demanding task. Advanced control techniques such as model predictive control and adaptive control systems are being explored to address these challenges.

Energy efficiency optimization across the entire operating range of the drive system is another critical challenge. While PMSMs are inherently efficient, the overall system efficiency depends on the interplay between the motor, power electronics, and control strategy. Developing algorithms that can dynamically adjust system parameters to maximize efficiency under varying load conditions and speeds is an ongoing area of research.

Lastly, the cost-effectiveness of PMSM-integrated drive systems remains a challenge, particularly for mass-market applications. The use of rare-earth magnets in PMSMs contributes significantly to the overall cost. Research into alternative magnet materials and motor designs that can deliver comparable performance at lower costs is crucial for wider adoption of this technology.

One of the primary obstacles is the precise control of rotor position and speed. PMSM requires accurate rotor position information for optimal commutation, which is critical for achieving high efficiency and performance. Traditional sensor-based methods, while effective, add cost and complexity to the system. Sensorless control techniques have emerged as a potential solution, but they face difficulties in low-speed operations and during startup conditions.

The thermal management of PMSM-integrated drive systems poses another substantial challenge. The compact design of these systems often leads to high power density, resulting in increased heat generation. Efficient heat dissipation is crucial to prevent performance degradation and ensure the longevity of both the motor and the electronic components. Innovative cooling solutions and thermal modeling techniques are necessary to address this issue effectively.

Power electronics integration presents its own set of challenges. The drive system must handle high switching frequencies to achieve precise motor control while minimizing losses. This requirement puts stress on semiconductor devices and increases electromagnetic interference (EMI). Balancing performance with EMI mitigation and thermal management in a compact package remains a significant engineering challenge.

The control algorithms for PMSM-integrated drive systems are inherently complex. They must account for motor parameters that can vary with temperature and magnetic saturation. Implementing robust control strategies that maintain stability and performance across a wide operating range, including field weakening operations, is a demanding task. Advanced control techniques such as model predictive control and adaptive control systems are being explored to address these challenges.

Energy efficiency optimization across the entire operating range of the drive system is another critical challenge. While PMSMs are inherently efficient, the overall system efficiency depends on the interplay between the motor, power electronics, and control strategy. Developing algorithms that can dynamically adjust system parameters to maximize efficiency under varying load conditions and speeds is an ongoing area of research.

Lastly, the cost-effectiveness of PMSM-integrated drive systems remains a challenge, particularly for mass-market applications. The use of rare-earth magnets in PMSMs contributes significantly to the overall cost. Research into alternative magnet materials and motor designs that can deliver comparable performance at lower costs is crucial for wider adoption of this technology.

Current EC Solutions

01 Integration of PMSM in electronically commutated drive systems

Electronically commutated drive systems incorporate Permanent Magnet Synchronous Motors (PMSM) to enhance efficiency and performance. These systems utilize electronic commutation to control the motor's operation, replacing traditional mechanical commutators. The integration of PMSM allows for precise speed and torque control, improved power density, and reduced maintenance requirements.- Integration of PMSM in electronically commutated drive systems: Electronically commutated drive systems incorporate Permanent Magnet Synchronous Motors (PMSM) to enhance efficiency and performance. This integration combines the benefits of electronic commutation with the high power density and efficiency of PMSMs, resulting in improved overall system performance.

- Control strategies for PMSM in electronically commutated systems: Advanced control strategies are implemented to optimize the performance of PMSMs in electronically commutated drive systems. These strategies may include sensorless control techniques, adaptive control algorithms, and advanced modulation schemes to improve efficiency, reduce torque ripple, and enhance dynamic response.

- Power electronics and driver circuits for PMSM commutation: Specialized power electronics and driver circuits are designed to facilitate the electronic commutation of PMSMs. These circuits may include advanced inverter topologies, gate drivers, and protection mechanisms to ensure efficient and reliable operation of the motor in various applications.

- Sensorless position detection in PMSM drive systems: Sensorless position detection techniques are developed for PMSM-based electronically commutated drive systems. These methods eliminate the need for physical position sensors, reducing system complexity and cost while maintaining accurate rotor position information for proper commutation.

- Efficiency optimization in PMSM-integrated drive systems: Various techniques are employed to optimize the efficiency of PMSM-integrated electronically commutated drive systems. These may include flux weakening control, loss minimization algorithms, and adaptive parameter tuning to maximize system efficiency across different operating conditions.

02 Control strategies for PMSM in electronically commutated systems

Advanced control strategies are implemented in electronically commutated drive systems with PMSM integration. These strategies may include field-oriented control, direct torque control, or sensorless control techniques. The control algorithms optimize motor performance, reduce energy consumption, and enhance system reliability across various operating conditions.Expand Specific Solutions03 Power electronics and driver circuits for PMSM commutation

Specialized power electronics and driver circuits are designed for electronically commutated PMSM systems. These circuits manage the switching of power semiconductors to control current flow through motor windings. Advanced driver designs may incorporate features such as overcurrent protection, thermal management, and fault detection to ensure reliable operation of the drive system.Expand Specific Solutions04 Sensorless control techniques for PMSM in commutated drives

Sensorless control methods are developed for electronically commutated PMSM systems to eliminate the need for position sensors. These techniques estimate rotor position and speed using motor current and voltage measurements, reducing system complexity and cost. Various algorithms, such as back-EMF estimation or model-based observers, are employed to achieve accurate sensorless control across a wide speed range.Expand Specific Solutions05 Efficiency optimization in PMSM-integrated commutated drives

Efficiency optimization techniques are implemented in electronically commutated drive systems with PMSM integration. These methods may include adaptive control algorithms, loss minimization strategies, or optimal flux weakening control. By dynamically adjusting motor parameters and control variables, the system maximizes energy efficiency across different operating points and load conditions.Expand Specific Solutions

Key Industry Players

The research on electronically commutated drive systems with PMSM integration is in a mature development stage, with significant market potential and technological advancements. The global market for these systems is expanding rapidly, driven by increasing demand for energy-efficient solutions in various industries. Key players in this field include both academic institutions and major corporations. Universities such as Jiangsu University, Harbin Institute of Technology, and Shanghai University are contributing to research and development. Meanwhile, companies like Infineon Technologies, ZF Friedrichshafen AG, and Robert Bosch GmbH are leading the commercial applications. The technology's maturity is evident in its widespread adoption across automotive, industrial, and consumer electronics sectors, with ongoing innovations focusing on improved efficiency and control algorithms.

Infineon Technologies Americas Corp.

Technical Solution: Infineon has made significant strides in electronically commutated drive systems with PMSM integration. Their approach combines high-performance microcontrollers with advanced power semiconductors. Infineon's solution utilizes their AURIX™ microcontroller family for motor control, featuring multi-core architecture for enhanced processing capabilities[5]. They have developed intelligent power modules (IPMs) specifically designed for PMSM drives, integrating gate drivers, protection circuits, and power switches in a single package[6]. Infineon's systems employ advanced current sensing techniques and adaptive control algorithms to optimize motor performance across various operating conditions[7].

Strengths: Highly integrated solutions, advanced power electronics, robust control systems. Weaknesses: Dependency on proprietary components, potential for higher initial system cost.

ZF Friedrichshafen AG

Technical Solution: ZF Friedrichshafen AG has developed innovative electronically commutated drive systems with PMSM integration, focusing on automotive and industrial applications. Their technology incorporates advanced vector control algorithms for precise torque and speed regulation[8]. ZF's systems feature high-speed switching GaN (Gallium Nitride) power devices, enabling higher efficiency and power density[9]. They have implemented advanced thermal management techniques, including direct oil cooling for both motor and inverter, allowing for sustained high-performance operation[10]. ZF's drive systems also incorporate predictive maintenance capabilities through integrated sensors and real-time data analysis[11].

Strengths: High-performance automotive-grade systems, advanced thermal management, predictive maintenance capabilities. Weaknesses: Potentially higher cost due to specialized components, may require specific expertise for integration and maintenance.

PMSM Integration Tech

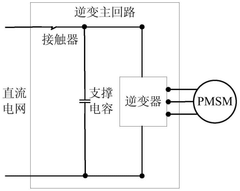

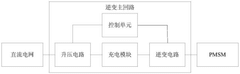

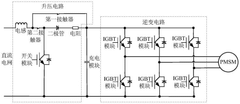

Inverter main circuit and permanent magnet synchronous motor drive system

PatentActiveCN110149083B

Innovation

- An inverter main circuit is designed, including a boost circuit, a charging module and a control unit. The control unit sends a boost signal to make the output voltage of the charging module greater than the DC bus voltage to ensure that the inverter circuit will not appear during re-starting. Brake and avoid overcurrent and overvoltage faults.

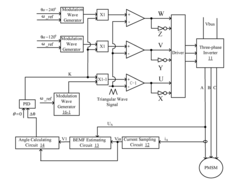

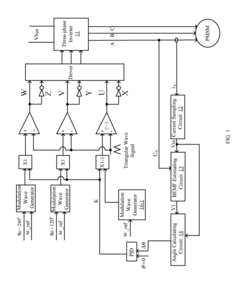

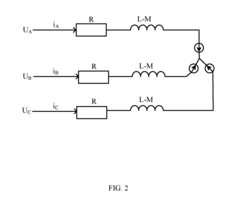

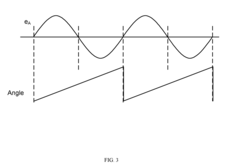

Driving circuit and driving method for permanent magnet synchronous motor

PatentActiveUS20170085196A1

Innovation

- A driving circuit and method that includes a current sampling circuit, back electromotive force (BEMF) circuit, and torque regulating circuit to estimate BEMF information and regulate the amplitude of a U-shaped modulation wave, allowing for maximum torque per ampere without a position sensor, using a sliding mode controller and PID regulator to synchronize rotor current with the modulation wave.

Energy Efficiency

Energy efficiency is a critical aspect of electronically commutated drive systems with Permanent Magnet Synchronous Motor (PMSM) integration. These systems have gained significant attention due to their potential to reduce energy consumption and improve overall system performance. The integration of PMSM technology in electronically commutated drive systems offers several advantages in terms of energy efficiency.

One of the primary benefits of PMSM integration is the elimination of rotor copper losses, which are present in traditional induction motors. This reduction in losses directly translates to improved energy efficiency, as less energy is wasted as heat during operation. Additionally, PMSMs exhibit higher power density compared to other motor types, allowing for more compact and lightweight designs without compromising performance.

The use of electronic commutation in these drive systems further enhances energy efficiency by enabling precise control of motor speed and torque. This level of control allows for optimized operation across a wide range of operating conditions, ensuring that the motor operates at its most efficient point for any given load. The ability to adjust motor parameters in real-time also contributes to reduced energy consumption during partial load conditions, which are common in many applications.

Another factor contributing to the energy efficiency of these systems is the high-quality magnetic materials used in PMSMs. These materials, such as rare earth magnets, provide strong magnetic fields with minimal losses, resulting in improved motor efficiency. The use of advanced control algorithms, such as field-oriented control (FOC), further optimizes the motor's performance by maintaining optimal magnetic flux levels and minimizing losses.

The integration of power electronics in electronically commutated drive systems also plays a crucial role in energy efficiency. Modern power electronic devices, such as high-frequency switching IGBTs or SiC MOSFETs, offer reduced switching losses and improved thermal management. This results in higher overall system efficiency and allows for more compact designs with better heat dissipation characteristics.

Furthermore, the regenerative braking capability of PMSM-based drive systems contributes to energy savings in applications with frequent start-stop cycles or descending loads. By recovering kinetic energy during deceleration and converting it back into electrical energy, these systems can significantly reduce overall energy consumption in certain applications, such as electric vehicles or industrial machinery.

In conclusion, the integration of PMSMs in electronically commutated drive systems offers substantial improvements in energy efficiency through various mechanisms, including reduced losses, optimized control, and energy recovery. These advancements contribute to the growing adoption of such systems across various industries, driving innovation and sustainability in electric motor applications.

One of the primary benefits of PMSM integration is the elimination of rotor copper losses, which are present in traditional induction motors. This reduction in losses directly translates to improved energy efficiency, as less energy is wasted as heat during operation. Additionally, PMSMs exhibit higher power density compared to other motor types, allowing for more compact and lightweight designs without compromising performance.

The use of electronic commutation in these drive systems further enhances energy efficiency by enabling precise control of motor speed and torque. This level of control allows for optimized operation across a wide range of operating conditions, ensuring that the motor operates at its most efficient point for any given load. The ability to adjust motor parameters in real-time also contributes to reduced energy consumption during partial load conditions, which are common in many applications.

Another factor contributing to the energy efficiency of these systems is the high-quality magnetic materials used in PMSMs. These materials, such as rare earth magnets, provide strong magnetic fields with minimal losses, resulting in improved motor efficiency. The use of advanced control algorithms, such as field-oriented control (FOC), further optimizes the motor's performance by maintaining optimal magnetic flux levels and minimizing losses.

The integration of power electronics in electronically commutated drive systems also plays a crucial role in energy efficiency. Modern power electronic devices, such as high-frequency switching IGBTs or SiC MOSFETs, offer reduced switching losses and improved thermal management. This results in higher overall system efficiency and allows for more compact designs with better heat dissipation characteristics.

Furthermore, the regenerative braking capability of PMSM-based drive systems contributes to energy savings in applications with frequent start-stop cycles or descending loads. By recovering kinetic energy during deceleration and converting it back into electrical energy, these systems can significantly reduce overall energy consumption in certain applications, such as electric vehicles or industrial machinery.

In conclusion, the integration of PMSMs in electronically commutated drive systems offers substantial improvements in energy efficiency through various mechanisms, including reduced losses, optimized control, and energy recovery. These advancements contribute to the growing adoption of such systems across various industries, driving innovation and sustainability in electric motor applications.

Control Algorithms

Control algorithms play a crucial role in the performance and efficiency of electronically commutated drive systems with Permanent Magnet Synchronous Motor (PMSM) integration. These algorithms are responsible for managing the motor's speed, torque, and position with high precision and reliability.

Field-Oriented Control (FOC) is the most widely adopted control strategy for PMSM drives. It enables independent control of torque and flux, resulting in improved dynamic performance and energy efficiency. FOC utilizes Park and Clarke transformations to convert three-phase currents into a two-axis rotating reference frame, simplifying the control process.

Direct Torque Control (DTC) is another prominent algorithm that offers faster torque response compared to FOC. DTC directly controls the motor's torque and stator flux by selecting appropriate voltage vectors. This method eliminates the need for coordinate transformations and reduces the complexity of the control system.

Model Predictive Control (MPC) has gained significant attention in recent years due to its ability to handle multi-variable systems and constraints. MPC predicts the future behavior of the motor based on a mathematical model and optimizes the control actions accordingly. This approach can lead to improved performance, especially in applications with varying operating conditions.

Sensorless control techniques have become increasingly important in PMSM drives to reduce costs and improve reliability. These methods estimate the rotor position and speed without using physical sensors. Common sensorless techniques include back-EMF estimation, high-frequency signal injection, and observer-based methods.

Adaptive control algorithms have been developed to address the challenges posed by parameter variations and external disturbances. These algorithms can adjust their parameters in real-time to maintain optimal performance under changing conditions. Examples include Model Reference Adaptive Control (MRAC) and Self-Tuning Regulators (STR).

Advanced control techniques such as sliding mode control and fuzzy logic control have also been applied to PMSM drives. These methods offer improved robustness and can handle nonlinearities more effectively than traditional linear control approaches.

The integration of artificial intelligence and machine learning algorithms in PMSM control systems is an emerging trend. These techniques can optimize control parameters, predict system behavior, and adapt to changing operating conditions, potentially leading to significant improvements in drive system performance and efficiency.

Field-Oriented Control (FOC) is the most widely adopted control strategy for PMSM drives. It enables independent control of torque and flux, resulting in improved dynamic performance and energy efficiency. FOC utilizes Park and Clarke transformations to convert three-phase currents into a two-axis rotating reference frame, simplifying the control process.

Direct Torque Control (DTC) is another prominent algorithm that offers faster torque response compared to FOC. DTC directly controls the motor's torque and stator flux by selecting appropriate voltage vectors. This method eliminates the need for coordinate transformations and reduces the complexity of the control system.

Model Predictive Control (MPC) has gained significant attention in recent years due to its ability to handle multi-variable systems and constraints. MPC predicts the future behavior of the motor based on a mathematical model and optimizes the control actions accordingly. This approach can lead to improved performance, especially in applications with varying operating conditions.

Sensorless control techniques have become increasingly important in PMSM drives to reduce costs and improve reliability. These methods estimate the rotor position and speed without using physical sensors. Common sensorless techniques include back-EMF estimation, high-frequency signal injection, and observer-based methods.

Adaptive control algorithms have been developed to address the challenges posed by parameter variations and external disturbances. These algorithms can adjust their parameters in real-time to maintain optimal performance under changing conditions. Examples include Model Reference Adaptive Control (MRAC) and Self-Tuning Regulators (STR).

Advanced control techniques such as sliding mode control and fuzzy logic control have also been applied to PMSM drives. These methods offer improved robustness and can handle nonlinearities more effectively than traditional linear control approaches.

The integration of artificial intelligence and machine learning algorithms in PMSM control systems is an emerging trend. These techniques can optimize control parameters, predict system behavior, and adapt to changing operating conditions, potentially leading to significant improvements in drive system performance and efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!