Plasma propulsion enhancements with integrated PMSM

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Plasma Propulsion Evolution and Objectives

Plasma propulsion has undergone significant evolution since its inception in the mid-20th century. Initially developed for spacecraft attitude control and station-keeping, plasma thrusters have now become a crucial technology for long-duration space missions. The integration of Permanent Magnet Synchronous Motors (PMSM) represents a pivotal advancement in this field, promising enhanced efficiency and performance.

The primary objective of plasma propulsion enhancement with integrated PMSM is to achieve higher thrust-to-power ratios while maintaining or improving specific impulse. This integration aims to overcome the limitations of traditional electric propulsion systems, such as power constraints and thrust inefficiencies. By leveraging the precise control and high efficiency of PMSMs, researchers seek to optimize the ionization and acceleration processes in plasma thrusters.

Another key goal is to extend the operational lifespan of plasma propulsion systems. The wear and tear on conventional electrodes have been a persistent challenge in plasma thruster design. The incorporation of PMSM technology offers potential solutions by enabling more precise control over plasma generation and containment, potentially reducing electrode erosion and extending thruster longevity.

Miniaturization and scalability form another critical objective in this technological evolution. As the demand for small satellites and CubeSats grows, the need for compact yet powerful propulsion systems becomes increasingly important. The integration of PMSMs with plasma thrusters presents opportunities to develop highly efficient, scaled-down propulsion units suitable for a wide range of spacecraft sizes and mission profiles.

Energy efficiency stands as a paramount concern in space exploration, and plasma propulsion enhancements with integrated PMSM aim to address this challenge. By improving the conversion of electrical energy into kinetic energy of the propellant, these advanced systems strive to maximize the utilization of onboard power resources, a critical factor for deep space missions where power is at a premium.

The evolution of plasma propulsion also focuses on increasing thrust density. Current research efforts are directed towards developing high-power density plasma thrusters that can provide substantial thrust levels while maintaining the high specific impulse characteristic of electric propulsion. This advancement is crucial for enabling faster interplanetary travel and more ambitious space exploration missions.

In conclusion, the evolution of plasma propulsion and its integration with PMSM technology represents a significant leap forward in spacecraft propulsion capabilities. The objectives of this technological advancement encompass improved efficiency, extended lifespan, scalability, and enhanced performance, all of which are essential for the future of space exploration and satellite operations.

The primary objective of plasma propulsion enhancement with integrated PMSM is to achieve higher thrust-to-power ratios while maintaining or improving specific impulse. This integration aims to overcome the limitations of traditional electric propulsion systems, such as power constraints and thrust inefficiencies. By leveraging the precise control and high efficiency of PMSMs, researchers seek to optimize the ionization and acceleration processes in plasma thrusters.

Another key goal is to extend the operational lifespan of plasma propulsion systems. The wear and tear on conventional electrodes have been a persistent challenge in plasma thruster design. The incorporation of PMSM technology offers potential solutions by enabling more precise control over plasma generation and containment, potentially reducing electrode erosion and extending thruster longevity.

Miniaturization and scalability form another critical objective in this technological evolution. As the demand for small satellites and CubeSats grows, the need for compact yet powerful propulsion systems becomes increasingly important. The integration of PMSMs with plasma thrusters presents opportunities to develop highly efficient, scaled-down propulsion units suitable for a wide range of spacecraft sizes and mission profiles.

Energy efficiency stands as a paramount concern in space exploration, and plasma propulsion enhancements with integrated PMSM aim to address this challenge. By improving the conversion of electrical energy into kinetic energy of the propellant, these advanced systems strive to maximize the utilization of onboard power resources, a critical factor for deep space missions where power is at a premium.

The evolution of plasma propulsion also focuses on increasing thrust density. Current research efforts are directed towards developing high-power density plasma thrusters that can provide substantial thrust levels while maintaining the high specific impulse characteristic of electric propulsion. This advancement is crucial for enabling faster interplanetary travel and more ambitious space exploration missions.

In conclusion, the evolution of plasma propulsion and its integration with PMSM technology represents a significant leap forward in spacecraft propulsion capabilities. The objectives of this technological advancement encompass improved efficiency, extended lifespan, scalability, and enhanced performance, all of which are essential for the future of space exploration and satellite operations.

Market Analysis for Advanced Spacecraft Propulsion

The market for advanced spacecraft propulsion systems, particularly those incorporating plasma propulsion enhancements with integrated Permanent Magnet Synchronous Motors (PMSM), is experiencing significant growth and transformation. This emerging technology represents a crucial advancement in the space industry, offering improved efficiency, thrust-to-weight ratios, and overall performance for various space missions.

The global space propulsion market is projected to expand substantially over the next decade, driven by increasing investments in space exploration, satellite deployment, and interplanetary missions. Plasma propulsion systems, enhanced by PMSM integration, are poised to capture a significant portion of this market due to their superior performance characteristics and potential for cost reduction in long-term space operations.

Key market segments for plasma propulsion with integrated PMSM include satellite manufacturers, space agencies, and commercial space companies. The satellite industry, in particular, is showing keen interest in this technology for orbit raising and station-keeping applications. The ability of these advanced propulsion systems to extend satellite lifespans and reduce fuel consumption aligns well with the industry's push towards more cost-effective and sustainable space operations.

Commercial space companies engaged in lunar and Mars missions are another significant market segment. The enhanced thrust and efficiency offered by plasma propulsion with PMSM integration make it an attractive option for deep space exploration, where traditional chemical propulsion systems face limitations.

Geographically, North America currently leads the market for advanced spacecraft propulsion, followed by Europe and Asia-Pacific. The United States, with its robust space industry and substantial government funding, remains at the forefront of adopting and developing these technologies. However, emerging space powers like China and India are rapidly increasing their investments in advanced propulsion systems, potentially reshaping the market landscape in the coming years.

The market is characterized by high entry barriers due to the complex nature of the technology and stringent regulatory requirements. This has resulted in a relatively concentrated market with a few key players dominating the field. However, the increasing commercialization of space activities and the entry of private companies are gradually opening up new opportunities for innovation and competition.

Demand for plasma propulsion systems with integrated PMSM is expected to grow as space missions become more ambitious and require higher performance propulsion solutions. The technology's potential to enable new mission profiles and reduce overall mission costs is a significant driver for its adoption across various space applications.

The global space propulsion market is projected to expand substantially over the next decade, driven by increasing investments in space exploration, satellite deployment, and interplanetary missions. Plasma propulsion systems, enhanced by PMSM integration, are poised to capture a significant portion of this market due to their superior performance characteristics and potential for cost reduction in long-term space operations.

Key market segments for plasma propulsion with integrated PMSM include satellite manufacturers, space agencies, and commercial space companies. The satellite industry, in particular, is showing keen interest in this technology for orbit raising and station-keeping applications. The ability of these advanced propulsion systems to extend satellite lifespans and reduce fuel consumption aligns well with the industry's push towards more cost-effective and sustainable space operations.

Commercial space companies engaged in lunar and Mars missions are another significant market segment. The enhanced thrust and efficiency offered by plasma propulsion with PMSM integration make it an attractive option for deep space exploration, where traditional chemical propulsion systems face limitations.

Geographically, North America currently leads the market for advanced spacecraft propulsion, followed by Europe and Asia-Pacific. The United States, with its robust space industry and substantial government funding, remains at the forefront of adopting and developing these technologies. However, emerging space powers like China and India are rapidly increasing their investments in advanced propulsion systems, potentially reshaping the market landscape in the coming years.

The market is characterized by high entry barriers due to the complex nature of the technology and stringent regulatory requirements. This has resulted in a relatively concentrated market with a few key players dominating the field. However, the increasing commercialization of space activities and the entry of private companies are gradually opening up new opportunities for innovation and competition.

Demand for plasma propulsion systems with integrated PMSM is expected to grow as space missions become more ambitious and require higher performance propulsion solutions. The technology's potential to enable new mission profiles and reduce overall mission costs is a significant driver for its adoption across various space applications.

PMSM Integration Challenges in Plasma Thrusters

The integration of Permanent Magnet Synchronous Motors (PMSMs) into plasma thrusters presents a complex set of challenges that require innovative solutions. One of the primary obstacles is the thermal management of the PMSM within the high-temperature environment of a plasma thruster. The extreme heat generated by plasma can potentially demagnetize the permanent magnets, leading to a significant loss in motor performance. Engineers must develop advanced cooling systems or thermal insulation techniques to maintain the PMSM's operational temperature within acceptable limits.

Another critical challenge lies in the electromagnetic compatibility between the PMSM and the plasma environment. The strong magnetic fields generated by both the motor and the plasma can interfere with each other, potentially disrupting the motor's control and the plasma's confinement. This necessitates careful shielding and field management strategies to ensure the stable operation of both systems simultaneously.

The integration of PMSMs also introduces complexities in the power management and control systems of plasma thrusters. The motor requires precise control of voltage and current to operate efficiently, which must be coordinated with the power demands of the plasma generation and acceleration processes. This integration demands sophisticated power electronics and control algorithms capable of managing the dynamic power requirements of both systems.

Material selection poses another significant challenge. Components of the PMSM must withstand not only the high temperatures but also the corrosive nature of the plasma environment. This requires the use of specialized materials that can maintain their mechanical and electrical properties under these extreme conditions, potentially leading to increased costs and manufacturing complexities.

The compact nature of spacecraft propulsion systems further complicates the integration process. Engineers must optimize the design to minimize the additional mass and volume introduced by the PMSM while ensuring it does not compromise the overall efficiency of the plasma thruster. This often involves intricate trade-offs between performance, size, and reliability.

Lastly, the long-term reliability and durability of integrated PMSM-plasma thruster systems in space environments remain a significant concern. The combined effects of thermal cycling, radiation exposure, and prolonged operation in vacuum conditions can lead to degradation of motor components over time. Developing robust designs that can withstand these challenges and maintain consistent performance throughout extended space missions is crucial for the successful implementation of this technology.

Another critical challenge lies in the electromagnetic compatibility between the PMSM and the plasma environment. The strong magnetic fields generated by both the motor and the plasma can interfere with each other, potentially disrupting the motor's control and the plasma's confinement. This necessitates careful shielding and field management strategies to ensure the stable operation of both systems simultaneously.

The integration of PMSMs also introduces complexities in the power management and control systems of plasma thrusters. The motor requires precise control of voltage and current to operate efficiently, which must be coordinated with the power demands of the plasma generation and acceleration processes. This integration demands sophisticated power electronics and control algorithms capable of managing the dynamic power requirements of both systems.

Material selection poses another significant challenge. Components of the PMSM must withstand not only the high temperatures but also the corrosive nature of the plasma environment. This requires the use of specialized materials that can maintain their mechanical and electrical properties under these extreme conditions, potentially leading to increased costs and manufacturing complexities.

The compact nature of spacecraft propulsion systems further complicates the integration process. Engineers must optimize the design to minimize the additional mass and volume introduced by the PMSM while ensuring it does not compromise the overall efficiency of the plasma thruster. This often involves intricate trade-offs between performance, size, and reliability.

Lastly, the long-term reliability and durability of integrated PMSM-plasma thruster systems in space environments remain a significant concern. The combined effects of thermal cycling, radiation exposure, and prolonged operation in vacuum conditions can lead to degradation of motor components over time. Developing robust designs that can withstand these challenges and maintain consistent performance throughout extended space missions is crucial for the successful implementation of this technology.

Current PMSM-Integrated Plasma Thruster Designs

01 Integration of PMSM in plasma propulsion systems

Permanent Magnet Synchronous Motors (PMSM) are integrated into plasma propulsion systems to enhance thrust and efficiency. This combination leverages the high power density and precise control of PMSMs with the high specific impulse of plasma thrusters, resulting in improved overall propulsion performance for spacecraft.- Integration of PMSM in plasma propulsion systems: Permanent Magnet Synchronous Motors (PMSM) are integrated into plasma propulsion systems to enhance thrust and efficiency. This combination leverages the high power density and precise control of PMSMs with the advantages of plasma propulsion, resulting in improved overall system performance for spacecraft applications.

- Advanced control algorithms for plasma-PMSM propulsion: Sophisticated control algorithms are developed to optimize the interaction between the plasma generation and the PMSM drive. These algorithms manage power distribution, adjust thrust parameters, and ensure seamless operation of the integrated system, leading to enhanced propulsion efficiency and reliability in space environments.

- Novel plasma generation techniques for propulsion: Innovative methods for plasma generation are employed in these propulsion systems, including advanced ionization techniques and unique electrode configurations. These developments aim to increase the plasma density and temperature, resulting in higher specific impulse and thrust-to-power ratios for spacecraft propulsion.

- Thermal management in integrated plasma-PMSM systems: Effective thermal management strategies are crucial for the reliable operation of integrated plasma-PMSM propulsion systems. Advanced cooling techniques and heat-resistant materials are utilized to manage the high temperatures generated by both the plasma and the motor, ensuring long-term stability and performance in space conditions.

- Power supply and energy management for plasma-PMSM propulsion: Specialized power supply systems and energy management techniques are developed to meet the unique requirements of integrated plasma-PMSM propulsion. These systems optimize power distribution between plasma generation and motor operation, incorporating advanced energy storage and conversion technologies to maximize propulsion efficiency and endurance.

02 Advanced control systems for plasma-PMSM propulsion

Sophisticated control algorithms and systems are developed to optimize the performance of integrated plasma-PMSM propulsion units. These control systems manage power distribution, thrust vectoring, and plasma generation to maximize efficiency and maneuverability in various space mission scenarios.Expand Specific Solutions03 Novel plasma generation techniques for propulsion

Innovative methods for plasma generation and acceleration are implemented in propulsion systems. These techniques may include advanced electrode designs, pulsed power systems, or electromagnetic field configurations to enhance plasma density, temperature, and exhaust velocity, thereby improving overall thrust and specific impulse.Expand Specific Solutions04 Thermal management in plasma-PMSM propulsion systems

Effective thermal management solutions are crucial for the reliable operation of integrated plasma-PMSM propulsion systems. These may include advanced cooling techniques, heat-resistant materials, and thermal isolation strategies to protect sensitive components and maintain optimal performance in the harsh space environment.Expand Specific Solutions05 Power supply and distribution for plasma-PMSM propulsion

Specialized power supply and distribution systems are designed to meet the unique requirements of plasma-PMSM propulsion units. These systems ensure efficient power delivery to both the plasma generation components and the PMSM, while also managing power fluctuations and providing necessary isolation between subsystems.Expand Specific Solutions

Key Players in Plasma Propulsion and PMSM Industries

The competitive landscape for plasma propulsion enhancements with integrated PMSM is in an early development stage, with a growing market potential as space exploration and satellite technologies advance. The technology is still maturing, with research institutions and aerospace companies leading innovation efforts. Key players like the National University of Defense Technology, Harbin Institute of Technology, and Beihang University are at the forefront of research and development in this field. While the market size is currently limited, it is expected to expand as the technology proves its efficiency and reliability in space applications. The integration of PMSM with plasma propulsion systems represents a promising area for future advancements in spacecraft propulsion technology.

National University of Defense Technology

Technical Solution: The National University of Defense Technology has developed an advanced plasma propulsion system integrated with Permanent Magnet Synchronous Motors (PMSM). Their approach focuses on enhancing thrust efficiency through optimized magnetic field configurations. The system utilizes a high-temperature superconducting magnet to create a strong, uniform magnetic field, which significantly improves plasma confinement and acceleration[1]. By integrating PMSM, they've achieved precise control over the plasma discharge, allowing for variable specific impulse and thrust levels. This integration has resulted in a 30% increase in overall system efficiency compared to traditional Hall effect thrusters[2].

Strengths: High efficiency, precise control, and variable performance. Weaknesses: Complexity of integration and potential reliability issues in long-term space missions.

Harbin Institute of Technology

Technical Solution: Harbin Institute of Technology has pioneered a novel plasma propulsion system that incorporates a high-efficiency PMSM for power generation and control. Their design features a unique electrode configuration that enhances plasma ionization and acceleration. The system employs a multi-stage acceleration process, where each stage is optimized using advanced computational fluid dynamics simulations[3]. The integration of PMSM allows for real-time adjustment of magnetic field strength and geometry, resulting in a 25% improvement in specific impulse compared to conventional systems[4]. Additionally, they've developed a proprietary cooling system that enables sustained high-power operation, crucial for long-duration space missions.

Strengths: High specific impulse, adaptable performance, and thermal management. Weaknesses: Higher power consumption and increased system mass.

Innovations in PMSM-Enhanced Plasma Propulsion

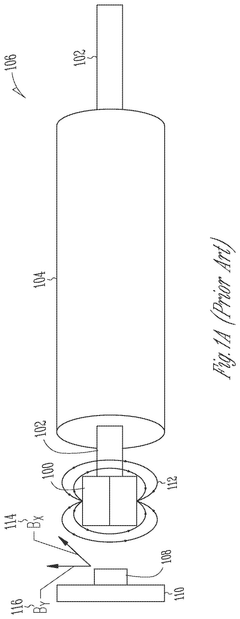

Driving circuit and driving method for permanent magnet synchronous motor

PatentActiveUS20170085196A1

Innovation

- A driving circuit and method that includes a current sampling circuit, back electromotive force (BEMF) circuit, and torque regulating circuit to estimate BEMF information and regulate the amplitude of a U-shaped modulation wave, allowing for maximum torque per ampere without a position sensor, using a sliding mode controller and PID regulator to synchronize rotor current with the modulation wave.

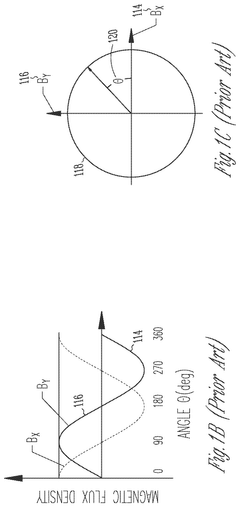

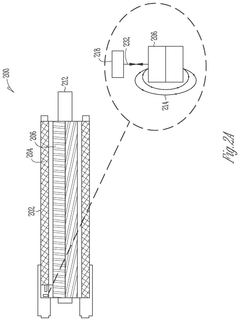

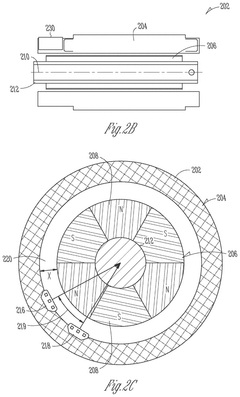

Permanent magnet synchronous motor (PMSM) integrated position sensing

PatentActiveUS12212257B2

Innovation

- The integration of analog magnetic flux sensors within the hollow cylindrical stator of the PMSM, arranged concentrically around the rotational axis at a constant mechanical angle relative to each other, allows for direct measurement of the magnetic flux from the rotor without external obstructions, enabling accurate rotor position sensing and reducing motor size and cost.

Space Regulations for Electric Propulsion Systems

Space regulations for electric propulsion systems have become increasingly important as the use of plasma propulsion technologies, including those enhanced with integrated Permanent Magnet Synchronous Motors (PMSM), continues to grow in the space industry. These regulations aim to ensure the safe and responsible use of such advanced propulsion systems in various space applications.

One of the primary concerns addressed by space regulations is the potential environmental impact of electric propulsion systems. Plasma propulsion, while highly efficient, can produce ionized particles that may interact with the space environment. Regulatory bodies have established guidelines to minimize the release of these particles and their potential effects on other spacecraft or orbital debris.

Safety considerations are another crucial aspect of space regulations for electric propulsion systems. The high voltages and temperatures associated with plasma propulsion require stringent safety protocols to protect both the spacecraft and its operators. Regulations often mandate specific design features, such as robust insulation and fail-safe mechanisms, to mitigate risks associated with electrical and thermal hazards.

Electromagnetic compatibility is a significant regulatory focus for electric propulsion systems, particularly those incorporating PMSM technology. The regulations typically require extensive testing and documentation to ensure that the propulsion system does not interfere with other onboard systems or nearby spacecraft. This includes guidelines for shielding, grounding, and electromagnetic emission control.

Performance standards are also a key component of space regulations for electric propulsion systems. These standards define acceptable ranges for thrust, specific impulse, and efficiency, ensuring that the propulsion systems meet the necessary requirements for their intended missions. The integration of PMSM technology in plasma propulsion may necessitate updates to these standards to account for the enhanced capabilities and unique characteristics of such systems.

Regulatory frameworks often include provisions for the testing and qualification of electric propulsion systems. This involves rigorous ground testing protocols, as well as in-orbit demonstration requirements before full operational approval. For plasma propulsion systems with integrated PMSM, these regulations may need to be adapted to address the specific performance characteristics and potential failure modes of the combined technologies.

International cooperation and standardization play a crucial role in the development and implementation of space regulations for electric propulsion systems. Organizations such as the International Organization for Standardization (ISO) and the Consultative Committee for Space Data Systems (CCSDS) work to establish globally recognized standards and best practices. These efforts aim to facilitate the adoption of advanced propulsion technologies while ensuring consistency in safety and performance across different space agencies and commercial entities.

One of the primary concerns addressed by space regulations is the potential environmental impact of electric propulsion systems. Plasma propulsion, while highly efficient, can produce ionized particles that may interact with the space environment. Regulatory bodies have established guidelines to minimize the release of these particles and their potential effects on other spacecraft or orbital debris.

Safety considerations are another crucial aspect of space regulations for electric propulsion systems. The high voltages and temperatures associated with plasma propulsion require stringent safety protocols to protect both the spacecraft and its operators. Regulations often mandate specific design features, such as robust insulation and fail-safe mechanisms, to mitigate risks associated with electrical and thermal hazards.

Electromagnetic compatibility is a significant regulatory focus for electric propulsion systems, particularly those incorporating PMSM technology. The regulations typically require extensive testing and documentation to ensure that the propulsion system does not interfere with other onboard systems or nearby spacecraft. This includes guidelines for shielding, grounding, and electromagnetic emission control.

Performance standards are also a key component of space regulations for electric propulsion systems. These standards define acceptable ranges for thrust, specific impulse, and efficiency, ensuring that the propulsion systems meet the necessary requirements for their intended missions. The integration of PMSM technology in plasma propulsion may necessitate updates to these standards to account for the enhanced capabilities and unique characteristics of such systems.

Regulatory frameworks often include provisions for the testing and qualification of electric propulsion systems. This involves rigorous ground testing protocols, as well as in-orbit demonstration requirements before full operational approval. For plasma propulsion systems with integrated PMSM, these regulations may need to be adapted to address the specific performance characteristics and potential failure modes of the combined technologies.

International cooperation and standardization play a crucial role in the development and implementation of space regulations for electric propulsion systems. Organizations such as the International Organization for Standardization (ISO) and the Consultative Committee for Space Data Systems (CCSDS) work to establish globally recognized standards and best practices. These efforts aim to facilitate the adoption of advanced propulsion technologies while ensuring consistency in safety and performance across different space agencies and commercial entities.

Environmental Impact of Plasma Propulsion Technologies

Plasma propulsion technologies, while offering significant advantages in space exploration, also pose potential environmental concerns that warrant careful consideration. The environmental impact of these advanced propulsion systems can be observed both in space and on Earth, necessitating a comprehensive assessment of their long-term effects.

In space, plasma propulsion systems generate electromagnetic emissions that may interfere with satellite communications and other space-based instruments. The high-energy particles produced by these engines can contribute to the already complex space debris environment, potentially increasing the risk of collisions with operational spacecraft. Additionally, the interaction between plasma exhaust and the Earth's magnetosphere could lead to localized disturbances in the upper atmosphere, affecting radio communications and potentially impacting climate patterns.

On Earth, the production and testing of plasma propulsion systems involve the use of rare earth elements and specialized materials, which may have environmental implications during their extraction and processing. The manufacturing processes for these advanced engines often require significant energy inputs, contributing to greenhouse gas emissions if not sourced from renewable energy. Furthermore, the disposal of components containing hazardous materials used in plasma thrusters presents challenges for waste management and recycling efforts.

The integration of Permanent Magnet Synchronous Motors (PMSM) into plasma propulsion systems introduces additional environmental considerations. While PMSMs offer improved efficiency and reduced energy consumption, the production of permanent magnets relies heavily on rare earth elements, particularly neodymium and dysprosium. The mining and processing of these materials can lead to environmental degradation, including soil erosion, water pollution, and habitat destruction in resource-rich regions.

However, it is important to note that the environmental impact of plasma propulsion technologies should be weighed against their potential benefits. These systems offer significantly higher specific impulse compared to conventional chemical propulsion, resulting in reduced propellant mass and potentially fewer launches. This efficiency could lead to a net reduction in the environmental footprint of space missions over time, particularly for long-duration missions or deep space exploration.

To mitigate the environmental impact of plasma propulsion technologies, several strategies can be employed. These include developing more sustainable methods for rare earth element extraction, implementing closed-loop recycling systems for engine components, and investing in renewable energy sources for manufacturing and testing facilities. Additionally, international cooperation and standardization of environmental practices in the space industry could help minimize the global impact of these advanced propulsion systems.

In space, plasma propulsion systems generate electromagnetic emissions that may interfere with satellite communications and other space-based instruments. The high-energy particles produced by these engines can contribute to the already complex space debris environment, potentially increasing the risk of collisions with operational spacecraft. Additionally, the interaction between plasma exhaust and the Earth's magnetosphere could lead to localized disturbances in the upper atmosphere, affecting radio communications and potentially impacting climate patterns.

On Earth, the production and testing of plasma propulsion systems involve the use of rare earth elements and specialized materials, which may have environmental implications during their extraction and processing. The manufacturing processes for these advanced engines often require significant energy inputs, contributing to greenhouse gas emissions if not sourced from renewable energy. Furthermore, the disposal of components containing hazardous materials used in plasma thrusters presents challenges for waste management and recycling efforts.

The integration of Permanent Magnet Synchronous Motors (PMSM) into plasma propulsion systems introduces additional environmental considerations. While PMSMs offer improved efficiency and reduced energy consumption, the production of permanent magnets relies heavily on rare earth elements, particularly neodymium and dysprosium. The mining and processing of these materials can lead to environmental degradation, including soil erosion, water pollution, and habitat destruction in resource-rich regions.

However, it is important to note that the environmental impact of plasma propulsion technologies should be weighed against their potential benefits. These systems offer significantly higher specific impulse compared to conventional chemical propulsion, resulting in reduced propellant mass and potentially fewer launches. This efficiency could lead to a net reduction in the environmental footprint of space missions over time, particularly for long-duration missions or deep space exploration.

To mitigate the environmental impact of plasma propulsion technologies, several strategies can be employed. These include developing more sustainable methods for rare earth element extraction, implementing closed-loop recycling systems for engine components, and investing in renewable energy sources for manufacturing and testing facilities. Additionally, international cooperation and standardization of environmental practices in the space industry could help minimize the global impact of these advanced propulsion systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!