Smart sensor integration in PMSM diagnostics

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PMSM Diagnostics Evolution

The evolution of Permanent Magnet Synchronous Motor (PMSM) diagnostics has been marked by significant technological advancements over the past few decades. Initially, PMSM diagnostics relied heavily on manual inspections and basic electrical measurements. As technology progressed, more sophisticated methods were introduced, leading to the current era of smart sensor integration.

In the early stages, diagnostics primarily focused on detecting major faults through simple voltage and current measurements. This approach, while effective for identifying catastrophic failures, lacked the sensitivity to detect subtle performance degradations or incipient faults. The 1990s saw the introduction of more advanced signal processing techniques, such as Fast Fourier Transform (FFT) analysis, which allowed for better detection of electrical and mechanical anomalies.

The turn of the millennium brought about a significant shift with the integration of digital signal processors (DSPs) in PMSM control systems. This development enabled real-time monitoring and analysis of motor parameters, greatly enhancing the accuracy and speed of fault detection. Concurrently, the advent of artificial intelligence and machine learning algorithms began to influence PMSM diagnostics, allowing for more predictive and adaptive fault detection methodologies.

The mid-2000s marked the beginning of the smart sensor era in PMSM diagnostics. Miniaturized, high-precision sensors capable of measuring a wide range of parameters were integrated directly into motor assemblies. These smart sensors, combined with advanced data analytics, paved the way for comprehensive health monitoring systems that could detect and predict faults with unprecedented accuracy.

Recent years have seen a paradigm shift towards the Internet of Things (IoT) and Industry 4.0 concepts in PMSM diagnostics. This has led to the development of networked diagnostic systems that can aggregate data from multiple motors, enabling fleet-wide health monitoring and predictive maintenance strategies. The integration of cloud computing and big data analytics has further enhanced the capabilities of these systems, allowing for more sophisticated pattern recognition and fault prediction algorithms.

The latest frontier in PMSM diagnostics involves the use of digital twin technology. This approach creates a virtual replica of the physical motor, allowing for real-time simulation and comparison with actual performance data. By leveraging advanced physics-based models and machine learning algorithms, digital twins can provide highly accurate predictions of motor health and remaining useful life.

Looking ahead, the future of PMSM diagnostics is likely to be shaped by emerging technologies such as edge computing, 5G connectivity, and advanced AI algorithms. These developments promise to further enhance the speed, accuracy, and predictive capabilities of diagnostic systems, ultimately leading to more reliable and efficient PMSM operations across various industrial applications.

In the early stages, diagnostics primarily focused on detecting major faults through simple voltage and current measurements. This approach, while effective for identifying catastrophic failures, lacked the sensitivity to detect subtle performance degradations or incipient faults. The 1990s saw the introduction of more advanced signal processing techniques, such as Fast Fourier Transform (FFT) analysis, which allowed for better detection of electrical and mechanical anomalies.

The turn of the millennium brought about a significant shift with the integration of digital signal processors (DSPs) in PMSM control systems. This development enabled real-time monitoring and analysis of motor parameters, greatly enhancing the accuracy and speed of fault detection. Concurrently, the advent of artificial intelligence and machine learning algorithms began to influence PMSM diagnostics, allowing for more predictive and adaptive fault detection methodologies.

The mid-2000s marked the beginning of the smart sensor era in PMSM diagnostics. Miniaturized, high-precision sensors capable of measuring a wide range of parameters were integrated directly into motor assemblies. These smart sensors, combined with advanced data analytics, paved the way for comprehensive health monitoring systems that could detect and predict faults with unprecedented accuracy.

Recent years have seen a paradigm shift towards the Internet of Things (IoT) and Industry 4.0 concepts in PMSM diagnostics. This has led to the development of networked diagnostic systems that can aggregate data from multiple motors, enabling fleet-wide health monitoring and predictive maintenance strategies. The integration of cloud computing and big data analytics has further enhanced the capabilities of these systems, allowing for more sophisticated pattern recognition and fault prediction algorithms.

The latest frontier in PMSM diagnostics involves the use of digital twin technology. This approach creates a virtual replica of the physical motor, allowing for real-time simulation and comparison with actual performance data. By leveraging advanced physics-based models and machine learning algorithms, digital twins can provide highly accurate predictions of motor health and remaining useful life.

Looking ahead, the future of PMSM diagnostics is likely to be shaped by emerging technologies such as edge computing, 5G connectivity, and advanced AI algorithms. These developments promise to further enhance the speed, accuracy, and predictive capabilities of diagnostic systems, ultimately leading to more reliable and efficient PMSM operations across various industrial applications.

Market Demand Analysis

The integration of smart sensors in Permanent Magnet Synchronous Motor (PMSM) diagnostics has witnessed a significant surge in market demand over recent years. This trend is primarily driven by the increasing adoption of PMSMs across various industries, including automotive, industrial automation, and renewable energy sectors. The global PMSM market is expected to grow at a compound annual growth rate (CAGR) of 8.2% from 2021 to 2026, reaching a value of $30.12 billion by the end of the forecast period.

The automotive industry, in particular, has emerged as a key driver for smart sensor integration in PMSM diagnostics. With the rapid growth of electric vehicles (EVs) and hybrid electric vehicles (HEVs), there is a growing need for advanced motor control and diagnostic systems. Smart sensors play a crucial role in enhancing the efficiency, reliability, and performance of PMSMs in these applications. The global EV market is projected to expand at a CAGR of 21.7% from 2022 to 2030, further fueling the demand for smart sensor-integrated PMSM diagnostics.

In the industrial automation sector, the push towards Industry 4.0 and smart manufacturing has created a substantial market for intelligent motor diagnostics. Smart sensors enable real-time monitoring, predictive maintenance, and optimization of PMSM performance in industrial applications. This trend is expected to continue as manufacturers seek to improve operational efficiency and reduce downtime. The industrial automation market is forecasted to grow at a CAGR of 9.3% from 2021 to 2028, indicating a strong potential for smart sensor integration in PMSM diagnostics.

The renewable energy sector, particularly wind power generation, represents another significant market for smart sensor-integrated PMSM diagnostics. As wind turbines become larger and more sophisticated, the need for advanced motor control and monitoring systems increases. Smart sensors help in optimizing energy production, reducing maintenance costs, and extending the lifespan of wind turbines. The global wind power market is expected to grow at a CAGR of 10.4% from 2021 to 2026, presenting substantial opportunities for smart sensor integration in PMSM diagnostics.

The market demand for smart sensor integration in PMSM diagnostics is also driven by the increasing focus on energy efficiency and sustainability across industries. Smart sensors enable more precise control and monitoring of PMSMs, leading to improved energy efficiency and reduced carbon emissions. This aligns with global initiatives to combat climate change and promote sustainable industrial practices.

Furthermore, the growing adoption of Internet of Things (IoT) and artificial intelligence (AI) technologies is expected to boost the demand for smart sensor-integrated PMSM diagnostics. These technologies enable advanced data analytics, remote monitoring, and predictive maintenance capabilities, enhancing the overall value proposition of smart sensor integration in motor diagnostics.

The automotive industry, in particular, has emerged as a key driver for smart sensor integration in PMSM diagnostics. With the rapid growth of electric vehicles (EVs) and hybrid electric vehicles (HEVs), there is a growing need for advanced motor control and diagnostic systems. Smart sensors play a crucial role in enhancing the efficiency, reliability, and performance of PMSMs in these applications. The global EV market is projected to expand at a CAGR of 21.7% from 2022 to 2030, further fueling the demand for smart sensor-integrated PMSM diagnostics.

In the industrial automation sector, the push towards Industry 4.0 and smart manufacturing has created a substantial market for intelligent motor diagnostics. Smart sensors enable real-time monitoring, predictive maintenance, and optimization of PMSM performance in industrial applications. This trend is expected to continue as manufacturers seek to improve operational efficiency and reduce downtime. The industrial automation market is forecasted to grow at a CAGR of 9.3% from 2021 to 2028, indicating a strong potential for smart sensor integration in PMSM diagnostics.

The renewable energy sector, particularly wind power generation, represents another significant market for smart sensor-integrated PMSM diagnostics. As wind turbines become larger and more sophisticated, the need for advanced motor control and monitoring systems increases. Smart sensors help in optimizing energy production, reducing maintenance costs, and extending the lifespan of wind turbines. The global wind power market is expected to grow at a CAGR of 10.4% from 2021 to 2026, presenting substantial opportunities for smart sensor integration in PMSM diagnostics.

The market demand for smart sensor integration in PMSM diagnostics is also driven by the increasing focus on energy efficiency and sustainability across industries. Smart sensors enable more precise control and monitoring of PMSMs, leading to improved energy efficiency and reduced carbon emissions. This aligns with global initiatives to combat climate change and promote sustainable industrial practices.

Furthermore, the growing adoption of Internet of Things (IoT) and artificial intelligence (AI) technologies is expected to boost the demand for smart sensor-integrated PMSM diagnostics. These technologies enable advanced data analytics, remote monitoring, and predictive maintenance capabilities, enhancing the overall value proposition of smart sensor integration in motor diagnostics.

Current Sensor Tech

Current sensor technology in the field of Permanent Magnet Synchronous Motor (PMSM) diagnostics has seen significant advancements in recent years. The integration of smart sensors has revolutionized the way we monitor and diagnose these motors, offering enhanced precision, reliability, and real-time data acquisition capabilities.

One of the primary sensor technologies employed in PMSM diagnostics is the Hall effect sensor. These sensors are widely used for measuring current and detecting the rotor position. They offer high sensitivity and can operate in harsh environments, making them ideal for motor applications. Recent developments have led to the miniaturization of Hall effect sensors, allowing for more compact motor designs without compromising performance.

Another crucial sensor type is the magnetoresistive sensor, which provides excellent accuracy in detecting magnetic fields. These sensors are particularly useful in PMSM diagnostics for precise rotor position sensing and current measurement. The latest magnetoresistive sensors offer improved temperature stability and linearity, ensuring consistent performance across a wide range of operating conditions.

Optical encoders have also found their place in PMSM diagnostics, primarily for high-precision position and speed sensing. Modern optical encoders utilize advanced LED and photodetector technologies, resulting in improved resolution and reliability. Some cutting-edge designs incorporate built-in diagnostic features, enabling self-monitoring and early fault detection.

Current transformers (CTs) and Rogowski coils are widely used for current sensing in PMSM applications. Recent advancements in these technologies have led to the development of high-bandwidth CTs and flexible Rogowski coils, allowing for more accurate current measurements across a broader frequency range. These improvements are particularly beneficial for detecting high-frequency current components associated with certain motor faults.

The integration of microelectromechanical systems (MEMS) technology has brought about a new generation of smart sensors for PMSM diagnostics. MEMS-based accelerometers and gyroscopes are now commonly used for vibration analysis and rotor imbalance detection. These sensors offer high sensitivity, low power consumption, and compact size, making them ideal for embedding directly into motor assemblies.

Temperature sensing is another critical aspect of PMSM diagnostics. Modern temperature sensors, such as resistance temperature detectors (RTDs) and thermocouples, have been optimized for motor applications. Some advanced designs incorporate wireless communication capabilities, enabling remote temperature monitoring without the need for complex wiring.

The trend towards Industry 4.0 and the Industrial Internet of Things (IIoT) has driven the development of smart sensors with built-in processing capabilities and network connectivity. These sensors can perform local data analysis, reducing the burden on central processing systems and enabling faster response times to potential motor issues.

In conclusion, current sensor technology for PMSM diagnostics encompasses a wide range of solutions, from traditional electromagnetic sensors to cutting-edge MEMS devices. The ongoing focus on miniaturization, improved accuracy, and smart functionality continues to drive innovation in this field, paving the way for more efficient and reliable motor diagnostic systems.

One of the primary sensor technologies employed in PMSM diagnostics is the Hall effect sensor. These sensors are widely used for measuring current and detecting the rotor position. They offer high sensitivity and can operate in harsh environments, making them ideal for motor applications. Recent developments have led to the miniaturization of Hall effect sensors, allowing for more compact motor designs without compromising performance.

Another crucial sensor type is the magnetoresistive sensor, which provides excellent accuracy in detecting magnetic fields. These sensors are particularly useful in PMSM diagnostics for precise rotor position sensing and current measurement. The latest magnetoresistive sensors offer improved temperature stability and linearity, ensuring consistent performance across a wide range of operating conditions.

Optical encoders have also found their place in PMSM diagnostics, primarily for high-precision position and speed sensing. Modern optical encoders utilize advanced LED and photodetector technologies, resulting in improved resolution and reliability. Some cutting-edge designs incorporate built-in diagnostic features, enabling self-monitoring and early fault detection.

Current transformers (CTs) and Rogowski coils are widely used for current sensing in PMSM applications. Recent advancements in these technologies have led to the development of high-bandwidth CTs and flexible Rogowski coils, allowing for more accurate current measurements across a broader frequency range. These improvements are particularly beneficial for detecting high-frequency current components associated with certain motor faults.

The integration of microelectromechanical systems (MEMS) technology has brought about a new generation of smart sensors for PMSM diagnostics. MEMS-based accelerometers and gyroscopes are now commonly used for vibration analysis and rotor imbalance detection. These sensors offer high sensitivity, low power consumption, and compact size, making them ideal for embedding directly into motor assemblies.

Temperature sensing is another critical aspect of PMSM diagnostics. Modern temperature sensors, such as resistance temperature detectors (RTDs) and thermocouples, have been optimized for motor applications. Some advanced designs incorporate wireless communication capabilities, enabling remote temperature monitoring without the need for complex wiring.

The trend towards Industry 4.0 and the Industrial Internet of Things (IIoT) has driven the development of smart sensors with built-in processing capabilities and network connectivity. These sensors can perform local data analysis, reducing the burden on central processing systems and enabling faster response times to potential motor issues.

In conclusion, current sensor technology for PMSM diagnostics encompasses a wide range of solutions, from traditional electromagnetic sensors to cutting-edge MEMS devices. The ongoing focus on miniaturization, improved accuracy, and smart functionality continues to drive innovation in this field, paving the way for more efficient and reliable motor diagnostic systems.

Integration Solutions

01 Vehicle diagnostics using smart sensors

Smart sensors are integrated into vehicles for real-time diagnostics and monitoring. These sensors collect data on various vehicle systems and components, enabling early detection of issues, predictive maintenance, and improved overall vehicle performance. The system can analyze sensor data to provide insights on vehicle health and potential problems.- Vehicle diagnostics using smart sensors: Smart sensors are integrated into vehicles for real-time diagnostics and monitoring. These sensors collect data on various vehicle systems and components, enabling early detection of issues, predictive maintenance, and improved overall vehicle performance. The system can analyze sensor data to provide insights on vehicle health and potential problems.

- Medical diagnostics with smart sensors: Smart sensors are utilized in medical devices for advanced diagnostics and patient monitoring. These sensors can measure various physiological parameters, detect anomalies, and provide real-time health data. The integration of smart sensors in medical diagnostics improves accuracy, enables remote monitoring, and facilitates early detection of health issues.

- Industrial process monitoring and diagnostics: Smart sensors are employed in industrial settings for process monitoring and diagnostics. These sensors can detect equipment failures, monitor production quality, and optimize manufacturing processes. The use of smart sensors in industrial applications enhances efficiency, reduces downtime, and improves overall productivity.

- Environmental monitoring and diagnostics: Smart sensors are used for environmental monitoring and diagnostics, including air quality assessment, water quality monitoring, and pollution detection. These sensors can collect and analyze data on various environmental parameters, enabling early warning systems and informed decision-making for environmental protection.

- Smart sensor networks for diagnostics: Interconnected networks of smart sensors are deployed for comprehensive diagnostics across various applications. These networks enable data fusion, distributed processing, and collaborative diagnostics, enhancing the overall accuracy and reliability of diagnostic systems. Smart sensor networks can be applied in areas such as smart cities, agriculture, and infrastructure monitoring.

02 Medical diagnostics with smart sensors

Smart sensors are utilized in medical devices for advanced diagnostics and patient monitoring. These sensors can measure various physiological parameters, detect anomalies, and provide real-time health data. The integration of smart sensors in medical diagnostics enhances early disease detection, personalized treatment, and remote patient monitoring capabilities.Expand Specific Solutions03 Industrial process monitoring and diagnostics

Smart sensors are employed in industrial settings for process monitoring and diagnostics. These sensors can detect equipment failures, optimize production processes, and enhance overall efficiency. By continuously monitoring various parameters, the system can predict maintenance needs and prevent costly downtime.Expand Specific Solutions04 Environmental monitoring and diagnostics

Smart sensors are used for environmental monitoring and diagnostics, including air quality, water quality, and pollution levels. These sensors can collect and analyze data in real-time, providing valuable insights for environmental protection and management. The system can detect pollutants, monitor climate changes, and assist in implementing effective environmental policies.Expand Specific Solutions05 Smart building diagnostics and management

Smart sensors are integrated into building management systems for diagnostics and optimization. These sensors monitor various aspects of building performance, including energy consumption, occupancy, and environmental conditions. The system can automatically adjust settings, detect maintenance issues, and improve overall building efficiency and comfort.Expand Specific Solutions

Key Industry Players

The smart sensor integration in PMSM diagnostics market is in a growth phase, driven by increasing demand for efficient motor systems across industries. The market size is expanding rapidly, with a projected CAGR of over 8% in the coming years. Technologically, the field is advancing quickly, with major players like Shanghai Electric Group and Magna International leading innovation. Universities such as Zhejiang University and Harbin Institute of Technology are contributing significantly to research and development. The technology's maturity varies, with some applications well-established and others still emerging, indicating a dynamic and competitive landscape with ample room for further advancements and market penetration.

Shanghai Electric Group Co., Ltd.

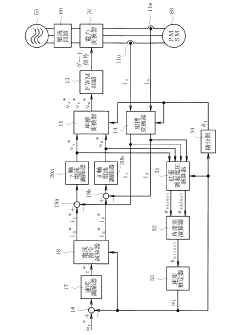

Technical Solution: Shanghai Electric has developed smart sensor integration solutions for PMSM diagnostics tailored to large-scale industrial applications. Their approach focuses on integrating multiple sensor types, including temperature, vibration, and electrical sensors, into a comprehensive monitoring system for high-power PMSMs used in power generation and industrial drives. The company's solution incorporates advanced signal processing techniques and AI-driven analytics to interpret complex sensor data. Shanghai Electric's system is designed to operate in harsh industrial environments, with robust sensors capable of withstanding high temperatures and electromagnetic interference. The solution provides real-time monitoring and predictive maintenance capabilities, significantly reducing unplanned downtime in critical industrial processes[9][10].

Strengths: Robust design for harsh industrial environments; specialized for high-power PMSM applications. Weaknesses: May be overly complex for smaller-scale applications; potentially higher cost due to industrial-grade components.

Infineon Technologies Americas Corp.

Technical Solution: Infineon has developed advanced smart sensor integration solutions for PMSM diagnostics. Their approach combines high-precision current and position sensors with integrated microcontrollers for real-time motor control and diagnostics. The system utilizes Hall effect sensors for rotor position detection and shunt resistors for current measurement, both integrated into a single chip solution. This integration allows for precise control and early fault detection in PMSMs. Infineon's solution also incorporates machine learning algorithms for predictive maintenance, analyzing sensor data to identify potential issues before they lead to motor failure[1][3].

Strengths: High level of integration reduces system complexity and cost; advanced algorithms improve diagnostic accuracy. Weaknesses: May require specialized knowledge for implementation; potential for increased heat generation in compact designs.

Core Sensor Innovations

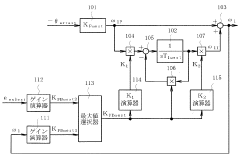

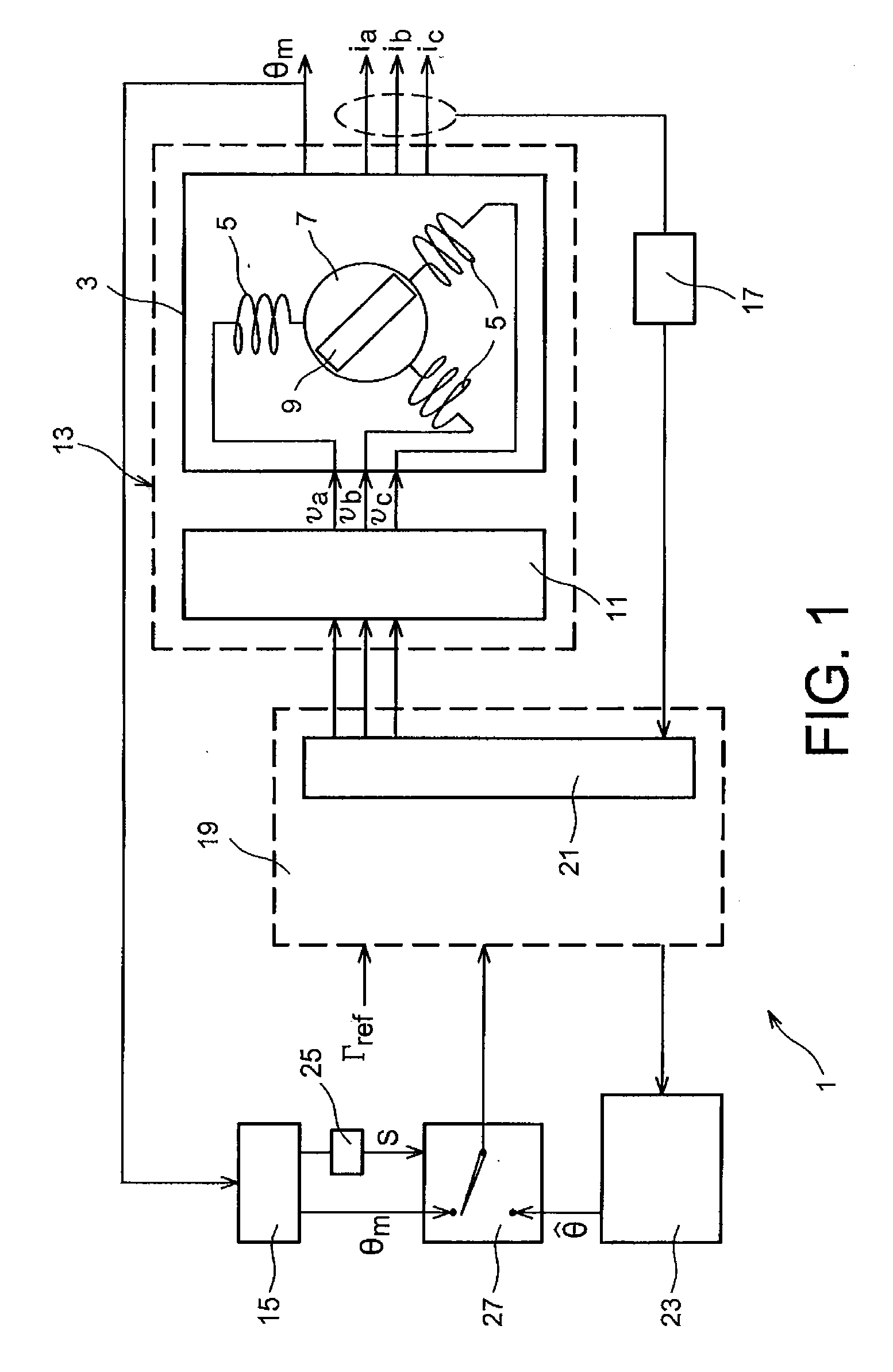

Control device for permanent magnet type synchronous motor

PatentActiveJP2017108477A

Innovation

- A control device for PMSMs that utilizes current and terminal voltage information to estimate speed and magnetic pole position, incorporating a position estimation error calculation, speed estimation, and integral term reduction mechanisms to enhance accuracy and stability, particularly during low-speed operations.

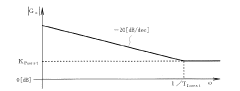

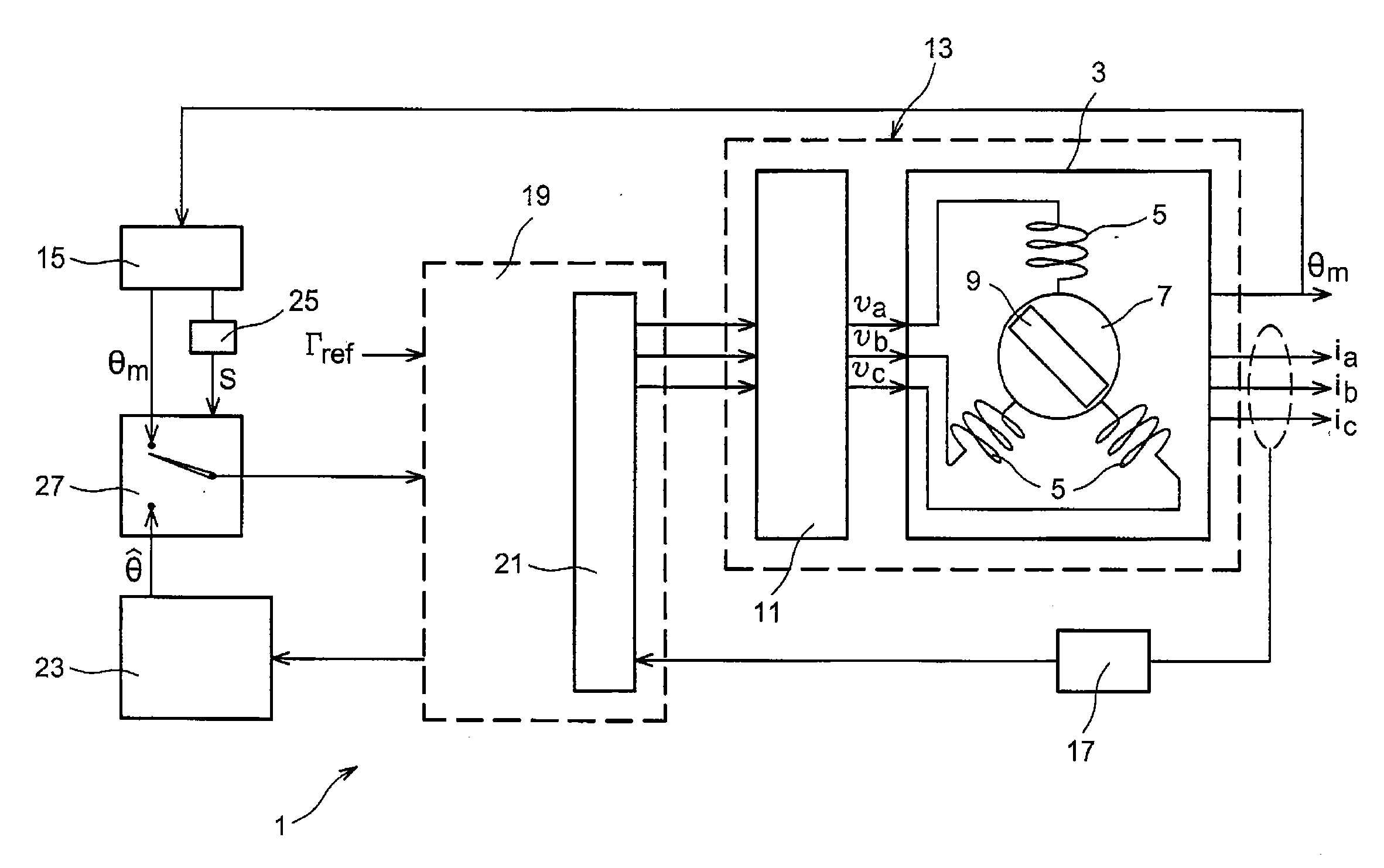

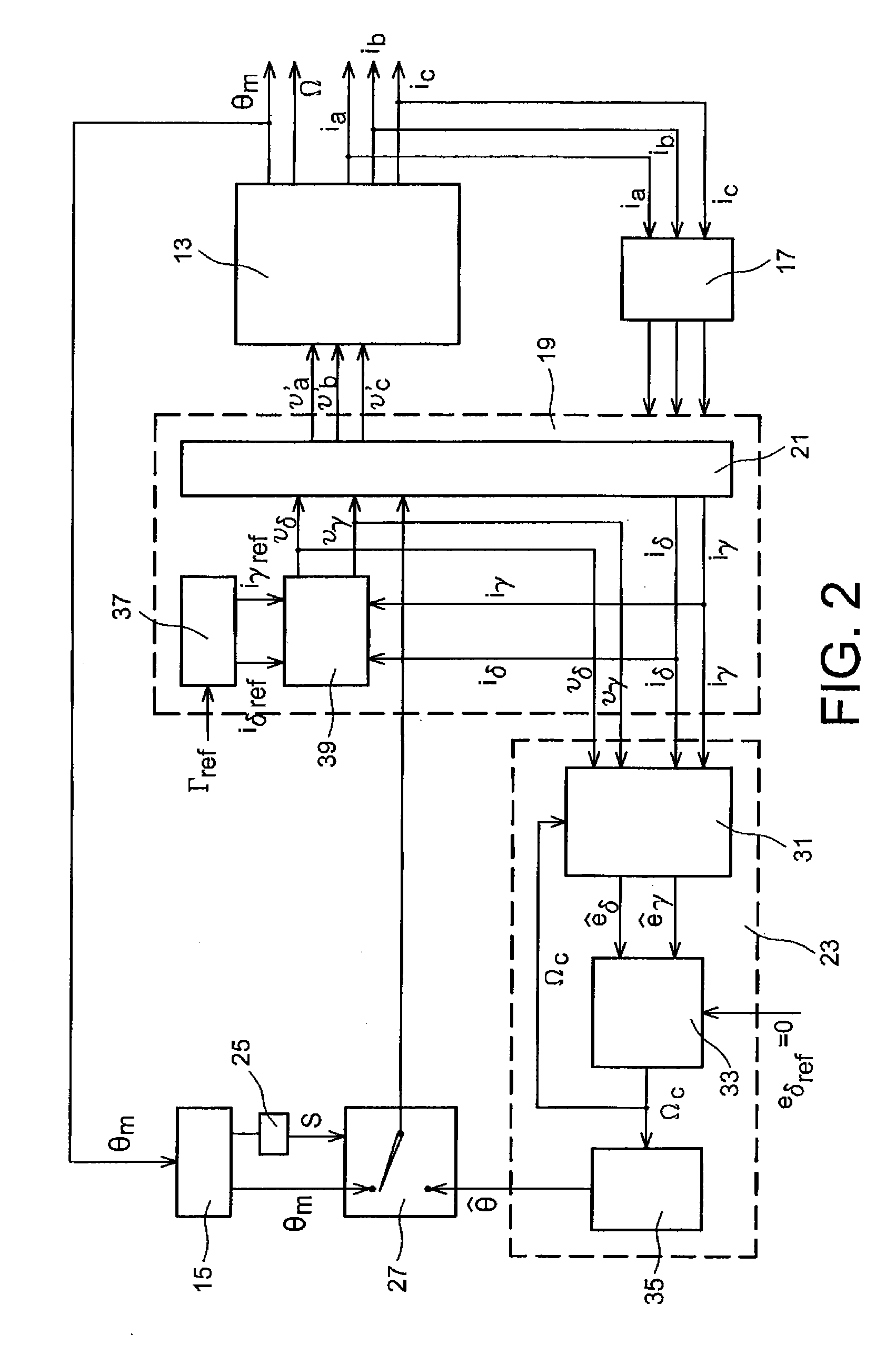

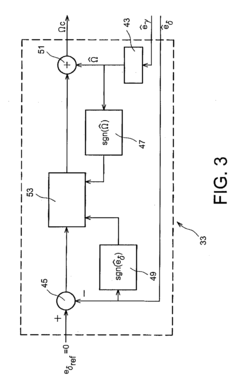

Device for control of a pmsm

PatentActiveUS20120280641A1

Innovation

- A control device that includes a sensor for measuring rotor position, estimation means to determine an estimated rotor position, a malfunction detector, and a switch to transition from sensor-based to sensorless control when a malfunction is detected, using an electromotive force estimator and non-linear corrector to ensure global convergence to the desired operating point.

Reliability Standards

Reliability standards play a crucial role in ensuring the effectiveness and longevity of smart sensor integration in Permanent Magnet Synchronous Motor (PMSM) diagnostics. These standards provide a framework for assessing and maintaining the reliability of sensor systems throughout their lifecycle, from design to implementation and operation.

The International Electrotechnical Commission (IEC) has established several standards relevant to smart sensor reliability in industrial applications. IEC 61508, for instance, focuses on functional safety and provides guidelines for the development and implementation of safety-related systems. This standard is particularly relevant for smart sensors used in PMSM diagnostics, as it ensures that the sensors can reliably detect and report critical motor conditions.

Another important standard is ISO/IEC/IEEE 15288, which addresses systems and software engineering lifecycle processes. This standard is applicable to smart sensor integration, as it provides a comprehensive approach to managing the entire lifecycle of sensor systems, including their integration into PMSM diagnostic systems.

For electromagnetic compatibility, which is crucial in motor environments, IEC 61000 series standards are essential. These standards ensure that smart sensors can operate reliably in the presence of electromagnetic interference commonly found in industrial settings where PMSMs are used.

Specific to motor systems, IEC 60034 series standards cover rotating electrical machines. While not directly addressing smart sensors, these standards provide important context for the operating conditions and requirements that sensors must meet when integrated into PMSM systems.

Reliability standards also encompass environmental testing, as smart sensors in PMSM applications often operate in harsh conditions. IEC 60068 series standards provide guidelines for environmental testing of electronic equipment, including temperature, humidity, and vibration tests, which are critical for ensuring sensor reliability in motor applications.

Data reliability and security are increasingly important aspects of smart sensor systems. Standards such as IEC 62443 for industrial communication networks security and ISO/IEC 27001 for information security management systems are becoming more relevant as sensor systems become more interconnected and data-driven.

Adherence to these reliability standards not only ensures the proper functioning of smart sensors in PMSM diagnostics but also contributes to the overall safety, efficiency, and performance of motor systems. As smart sensor technology continues to evolve, it is crucial for manufacturers and integrators to stay updated with the latest reliability standards and incorporate them into their development and implementation processes.

The International Electrotechnical Commission (IEC) has established several standards relevant to smart sensor reliability in industrial applications. IEC 61508, for instance, focuses on functional safety and provides guidelines for the development and implementation of safety-related systems. This standard is particularly relevant for smart sensors used in PMSM diagnostics, as it ensures that the sensors can reliably detect and report critical motor conditions.

Another important standard is ISO/IEC/IEEE 15288, which addresses systems and software engineering lifecycle processes. This standard is applicable to smart sensor integration, as it provides a comprehensive approach to managing the entire lifecycle of sensor systems, including their integration into PMSM diagnostic systems.

For electromagnetic compatibility, which is crucial in motor environments, IEC 61000 series standards are essential. These standards ensure that smart sensors can operate reliably in the presence of electromagnetic interference commonly found in industrial settings where PMSMs are used.

Specific to motor systems, IEC 60034 series standards cover rotating electrical machines. While not directly addressing smart sensors, these standards provide important context for the operating conditions and requirements that sensors must meet when integrated into PMSM systems.

Reliability standards also encompass environmental testing, as smart sensors in PMSM applications often operate in harsh conditions. IEC 60068 series standards provide guidelines for environmental testing of electronic equipment, including temperature, humidity, and vibration tests, which are critical for ensuring sensor reliability in motor applications.

Data reliability and security are increasingly important aspects of smart sensor systems. Standards such as IEC 62443 for industrial communication networks security and ISO/IEC 27001 for information security management systems are becoming more relevant as sensor systems become more interconnected and data-driven.

Adherence to these reliability standards not only ensures the proper functioning of smart sensors in PMSM diagnostics but also contributes to the overall safety, efficiency, and performance of motor systems. As smart sensor technology continues to evolve, it is crucial for manufacturers and integrators to stay updated with the latest reliability standards and incorporate them into their development and implementation processes.

Energy Efficiency Impact

The integration of smart sensors in Permanent Magnet Synchronous Motor (PMSM) diagnostics has a significant impact on energy efficiency. By providing real-time data on motor performance, these sensors enable more precise control and optimization of PMSM operation, leading to substantial energy savings.

Smart sensors can accurately measure various parameters such as temperature, vibration, current, and voltage. This comprehensive data collection allows for early detection of potential issues that may affect motor efficiency. For instance, detecting slight imbalances or misalignments in the rotor can prompt timely adjustments, preventing energy losses due to increased friction or magnetic field distortions.

Furthermore, these sensors facilitate the implementation of advanced control algorithms. With access to detailed performance data, motor control systems can dynamically adjust operating parameters to maintain optimal efficiency across different load conditions. This adaptive control strategy ensures that the PMSM operates at its highest efficiency point, regardless of varying external factors.

The energy efficiency impact extends beyond the motor itself. Smart sensor integration enables predictive maintenance strategies, reducing unplanned downtime and the associated energy waste. By identifying potential failures before they occur, maintenance can be scheduled during planned shutdowns, minimizing the energy-intensive process of frequent starts and stops.

In industrial applications, where PMSMs are often part of larger systems, the energy savings can be substantial. Smart sensors allow for system-wide optimization, ensuring that each component, including the PMSM, operates in harmony with others to maximize overall energy efficiency. This holistic approach can lead to significant reductions in energy consumption across entire production lines or facilities.

Moreover, the data collected by smart sensors contributes to long-term energy efficiency improvements. By analyzing historical performance data, engineers can identify trends and patterns that inform the design of more efficient motors and control systems. This continuous improvement cycle drives ongoing enhancements in PMSM energy efficiency, benefiting both manufacturers and end-users.

The integration of smart sensors also supports the transition towards more sustainable industrial practices. By enabling precise energy consumption monitoring, these systems facilitate compliance with energy efficiency regulations and support organizations in meeting their sustainability goals. The ability to quantify and report on energy savings provides tangible evidence of environmental stewardship, which is increasingly important in today's eco-conscious business landscape.

Smart sensors can accurately measure various parameters such as temperature, vibration, current, and voltage. This comprehensive data collection allows for early detection of potential issues that may affect motor efficiency. For instance, detecting slight imbalances or misalignments in the rotor can prompt timely adjustments, preventing energy losses due to increased friction or magnetic field distortions.

Furthermore, these sensors facilitate the implementation of advanced control algorithms. With access to detailed performance data, motor control systems can dynamically adjust operating parameters to maintain optimal efficiency across different load conditions. This adaptive control strategy ensures that the PMSM operates at its highest efficiency point, regardless of varying external factors.

The energy efficiency impact extends beyond the motor itself. Smart sensor integration enables predictive maintenance strategies, reducing unplanned downtime and the associated energy waste. By identifying potential failures before they occur, maintenance can be scheduled during planned shutdowns, minimizing the energy-intensive process of frequent starts and stops.

In industrial applications, where PMSMs are often part of larger systems, the energy savings can be substantial. Smart sensors allow for system-wide optimization, ensuring that each component, including the PMSM, operates in harmony with others to maximize overall energy efficiency. This holistic approach can lead to significant reductions in energy consumption across entire production lines or facilities.

Moreover, the data collected by smart sensors contributes to long-term energy efficiency improvements. By analyzing historical performance data, engineers can identify trends and patterns that inform the design of more efficient motors and control systems. This continuous improvement cycle drives ongoing enhancements in PMSM energy efficiency, benefiting both manufacturers and end-users.

The integration of smart sensors also supports the transition towards more sustainable industrial practices. By enabling precise energy consumption monitoring, these systems facilitate compliance with energy efficiency regulations and support organizations in meeting their sustainability goals. The ability to quantify and report on energy savings provides tangible evidence of environmental stewardship, which is increasingly important in today's eco-conscious business landscape.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!