Comparative study of PMSM and BLDC Motors

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PMSM and BLDC Overview

Permanent Magnet Synchronous Motors (PMSM) and Brushless DC Motors (BLDC) are two prominent types of electric motors widely used in various industrial and consumer applications. Both motors utilize permanent magnets in their design, offering high efficiency and power density compared to traditional induction motors.

PMSM motors feature a rotor with permanent magnets and a stator with distributed windings. They operate on sinusoidal current waveforms, resulting in smooth torque output and precise speed control. PMSMs excel in applications requiring high dynamic performance and energy efficiency, such as electric vehicles, industrial automation, and high-end appliances.

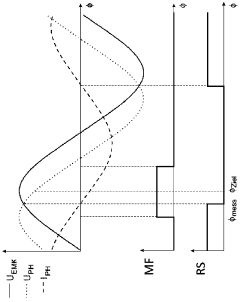

BLDC motors, on the other hand, have a simpler construction with permanent magnets on the rotor and concentrated windings on the stator. They operate using trapezoidal current waveforms, which leads to slightly higher torque ripple compared to PMSMs. BLDC motors are known for their reliability, cost-effectiveness, and ease of control, making them popular in applications like computer cooling fans, power tools, and robotics.

Both motor types offer significant advantages over traditional brushed DC motors, including higher efficiency, longer lifespan, and reduced maintenance requirements due to the absence of mechanical commutation. The choice between PMSM and BLDC motors depends on specific application requirements, such as torque smoothness, control precision, and cost considerations.

In terms of control strategies, PMSMs typically employ vector control techniques, allowing for precise manipulation of magnetic flux and torque. This enables excellent dynamic response and efficiency across a wide speed range. BLDC motors, conversely, often use simpler six-step commutation or sensor-based control methods, which are adequate for many applications but may limit performance in high-precision scenarios.

Recent advancements in power electronics and control algorithms have further enhanced the capabilities of both motor types. For PMSMs, developments in sensorless control techniques have improved reliability and reduced system complexity. In BLDC motors, advanced commutation strategies and improved magnet materials have led to increased efficiency and power density.

As the demand for energy-efficient and high-performance electric motors continues to grow, both PMSM and BLDC technologies are expected to evolve further. Research efforts are focused on optimizing motor designs, improving control algorithms, and developing more cost-effective manufacturing processes to meet the diverse needs of various industries and applications.

PMSM motors feature a rotor with permanent magnets and a stator with distributed windings. They operate on sinusoidal current waveforms, resulting in smooth torque output and precise speed control. PMSMs excel in applications requiring high dynamic performance and energy efficiency, such as electric vehicles, industrial automation, and high-end appliances.

BLDC motors, on the other hand, have a simpler construction with permanent magnets on the rotor and concentrated windings on the stator. They operate using trapezoidal current waveforms, which leads to slightly higher torque ripple compared to PMSMs. BLDC motors are known for their reliability, cost-effectiveness, and ease of control, making them popular in applications like computer cooling fans, power tools, and robotics.

Both motor types offer significant advantages over traditional brushed DC motors, including higher efficiency, longer lifespan, and reduced maintenance requirements due to the absence of mechanical commutation. The choice between PMSM and BLDC motors depends on specific application requirements, such as torque smoothness, control precision, and cost considerations.

In terms of control strategies, PMSMs typically employ vector control techniques, allowing for precise manipulation of magnetic flux and torque. This enables excellent dynamic response and efficiency across a wide speed range. BLDC motors, conversely, often use simpler six-step commutation or sensor-based control methods, which are adequate for many applications but may limit performance in high-precision scenarios.

Recent advancements in power electronics and control algorithms have further enhanced the capabilities of both motor types. For PMSMs, developments in sensorless control techniques have improved reliability and reduced system complexity. In BLDC motors, advanced commutation strategies and improved magnet materials have led to increased efficiency and power density.

As the demand for energy-efficient and high-performance electric motors continues to grow, both PMSM and BLDC technologies are expected to evolve further. Research efforts are focused on optimizing motor designs, improving control algorithms, and developing more cost-effective manufacturing processes to meet the diverse needs of various industries and applications.

Market Trends Analysis

The market for electric motors, particularly Permanent Magnet Synchronous Motors (PMSM) and Brushless DC Motors (BLDC), has been experiencing significant growth and transformation in recent years. This trend is driven by the increasing demand for energy-efficient and high-performance motor solutions across various industries, including automotive, industrial automation, and consumer electronics.

In the automotive sector, the shift towards electric vehicles (EVs) has been a major catalyst for the adoption of both PMSM and BLDC motors. These motors offer superior efficiency, power density, and control capabilities compared to traditional induction motors, making them ideal for EV powertrains. The global EV market is projected to grow at a compound annual growth rate (CAGR) of over 20% in the coming years, directly impacting the demand for these advanced motor technologies.

The industrial automation sector is another key driver of market growth for PMSM and BLDC motors. As manufacturers increasingly focus on improving energy efficiency and precision control in their production processes, these motors are becoming the preferred choice for applications such as robotics, CNC machines, and conveyor systems. The industrial robotics market, in particular, is expected to see substantial growth, further boosting the demand for high-performance motors.

In the consumer electronics segment, BLDC motors have gained significant traction due to their compact size, low noise, and high efficiency. They are widely used in applications such as computer cooling fans, hard disk drives, and small household appliances. The growing consumer electronics market, especially in emerging economies, is contributing to the increased adoption of BLDC motors.

A notable market trend is the increasing focus on motor miniaturization and power density improvement. Both PMSM and BLDC motors are being developed with smaller form factors and higher power outputs to meet the demands of space-constrained applications in various industries. This trend is particularly evident in the aerospace and medical device sectors, where size and weight constraints are critical.

The market is also witnessing a shift towards more integrated motor solutions. Manufacturers are developing smart motors with built-in controllers, sensors, and communication capabilities, enabling easier integration into IoT and Industry 4.0 ecosystems. This trend is driving the convergence of motor technology with advanced electronics and software, creating new opportunities for innovation and market growth.

Geographically, Asia-Pacific is emerging as a key market for both PMSM and BLDC motors, driven by rapid industrialization, automotive sector growth, and increasing adoption of energy-efficient technologies in countries like China, Japan, and South Korea. North America and Europe continue to be significant markets, particularly in high-end applications and research and development activities.

In the automotive sector, the shift towards electric vehicles (EVs) has been a major catalyst for the adoption of both PMSM and BLDC motors. These motors offer superior efficiency, power density, and control capabilities compared to traditional induction motors, making them ideal for EV powertrains. The global EV market is projected to grow at a compound annual growth rate (CAGR) of over 20% in the coming years, directly impacting the demand for these advanced motor technologies.

The industrial automation sector is another key driver of market growth for PMSM and BLDC motors. As manufacturers increasingly focus on improving energy efficiency and precision control in their production processes, these motors are becoming the preferred choice for applications such as robotics, CNC machines, and conveyor systems. The industrial robotics market, in particular, is expected to see substantial growth, further boosting the demand for high-performance motors.

In the consumer electronics segment, BLDC motors have gained significant traction due to their compact size, low noise, and high efficiency. They are widely used in applications such as computer cooling fans, hard disk drives, and small household appliances. The growing consumer electronics market, especially in emerging economies, is contributing to the increased adoption of BLDC motors.

A notable market trend is the increasing focus on motor miniaturization and power density improvement. Both PMSM and BLDC motors are being developed with smaller form factors and higher power outputs to meet the demands of space-constrained applications in various industries. This trend is particularly evident in the aerospace and medical device sectors, where size and weight constraints are critical.

The market is also witnessing a shift towards more integrated motor solutions. Manufacturers are developing smart motors with built-in controllers, sensors, and communication capabilities, enabling easier integration into IoT and Industry 4.0 ecosystems. This trend is driving the convergence of motor technology with advanced electronics and software, creating new opportunities for innovation and market growth.

Geographically, Asia-Pacific is emerging as a key market for both PMSM and BLDC motors, driven by rapid industrialization, automotive sector growth, and increasing adoption of energy-efficient technologies in countries like China, Japan, and South Korea. North America and Europe continue to be significant markets, particularly in high-end applications and research and development activities.

Technical Challenges

The comparative study of Permanent Magnet Synchronous Motors (PMSM) and Brushless DC Motors (BLDC) reveals several technical challenges that researchers and engineers must address. One of the primary challenges lies in the control strategies for these motors. PMSM requires more complex control algorithms, such as field-oriented control (FOC), which demands precise rotor position feedback and sophisticated mathematical models. In contrast, BLDC motors typically use simpler trapezoidal control methods, but achieving smooth torque output and minimizing torque ripple remains a challenge, especially at low speeds.

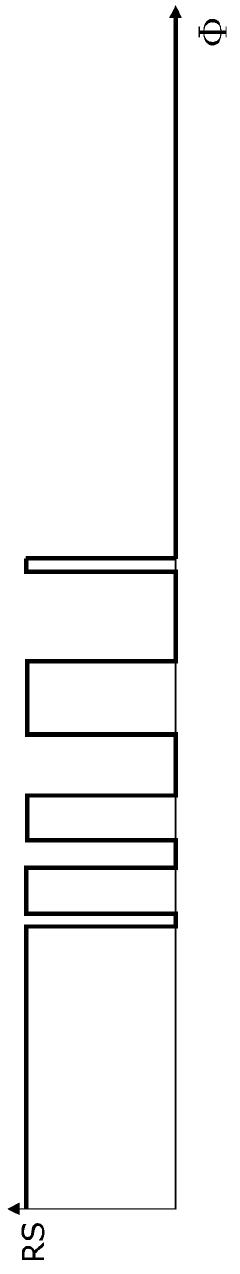

Power electronics and switching techniques present another significant challenge. Both motor types rely on inverters for operation, but the switching strategies differ. PMSM often requires high-frequency pulse width modulation (PWM) techniques to achieve sinusoidal current waveforms, while BLDC motors use six-step commutation. Optimizing these switching strategies to reduce losses, electromagnetic interference (EMI), and acoustic noise is an ongoing area of research.

Thermal management is a critical issue for both motor types. The permanent magnets in PMSM and BLDC motors are sensitive to temperature, with the risk of demagnetization at high temperatures. Developing effective cooling systems and thermal modeling techniques to predict and manage heat distribution within the motor structure is essential for maintaining performance and longevity.

Cogging torque reduction is another technical challenge, particularly for PMSM. This unwanted torque ripple, caused by the interaction between the rotor magnets and stator teeth, can lead to vibrations and noise. Various design techniques, such as magnet shaping, skewing, and optimized slot-pole combinations, are being explored to mitigate this issue.

Material selection and optimization pose ongoing challenges. The development of high-performance magnetic materials for rotors and advanced lamination steels for stators is crucial for improving motor efficiency and power density. Additionally, the search for alternatives to rare-earth magnets, which are often used in high-performance motors, is driven by concerns over supply chain stability and environmental impact.

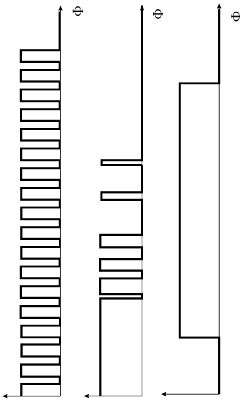

Sensorless control techniques represent an area of significant research interest. While both PMSM and BLDC motors traditionally rely on position sensors for commutation and control, eliminating these sensors can reduce costs and improve reliability. However, developing robust sensorless algorithms that perform well across all operating conditions, especially at low speeds and standstill, remains challenging.

Finally, the integration of these motors into various applications, such as electric vehicles and industrial automation, presents system-level challenges. This includes optimizing the motor design for specific application requirements, addressing electromagnetic compatibility issues, and developing fault-tolerant control strategies to ensure safe and reliable operation under diverse conditions.

Power electronics and switching techniques present another significant challenge. Both motor types rely on inverters for operation, but the switching strategies differ. PMSM often requires high-frequency pulse width modulation (PWM) techniques to achieve sinusoidal current waveforms, while BLDC motors use six-step commutation. Optimizing these switching strategies to reduce losses, electromagnetic interference (EMI), and acoustic noise is an ongoing area of research.

Thermal management is a critical issue for both motor types. The permanent magnets in PMSM and BLDC motors are sensitive to temperature, with the risk of demagnetization at high temperatures. Developing effective cooling systems and thermal modeling techniques to predict and manage heat distribution within the motor structure is essential for maintaining performance and longevity.

Cogging torque reduction is another technical challenge, particularly for PMSM. This unwanted torque ripple, caused by the interaction between the rotor magnets and stator teeth, can lead to vibrations and noise. Various design techniques, such as magnet shaping, skewing, and optimized slot-pole combinations, are being explored to mitigate this issue.

Material selection and optimization pose ongoing challenges. The development of high-performance magnetic materials for rotors and advanced lamination steels for stators is crucial for improving motor efficiency and power density. Additionally, the search for alternatives to rare-earth magnets, which are often used in high-performance motors, is driven by concerns over supply chain stability and environmental impact.

Sensorless control techniques represent an area of significant research interest. While both PMSM and BLDC motors traditionally rely on position sensors for commutation and control, eliminating these sensors can reduce costs and improve reliability. However, developing robust sensorless algorithms that perform well across all operating conditions, especially at low speeds and standstill, remains challenging.

Finally, the integration of these motors into various applications, such as electric vehicles and industrial automation, presents system-level challenges. This includes optimizing the motor design for specific application requirements, addressing electromagnetic compatibility issues, and developing fault-tolerant control strategies to ensure safe and reliable operation under diverse conditions.

Current Design Solutions

01 Motor control techniques for PMSM and BLDC motors

Advanced control techniques are employed for Permanent Magnet Synchronous Motors (PMSM) and Brushless DC (BLDC) motors to improve performance and efficiency. These methods may include sensorless control, vector control, and adaptive control algorithms to optimize motor operation under various conditions.- Motor control techniques for PMSM and BLDC motors: Advanced control techniques are employed for Permanent Magnet Synchronous Motors (PMSM) and Brushless DC (BLDC) motors to improve performance and efficiency. These methods may include sensorless control, vector control, and adaptive control algorithms to optimize motor operation under various conditions.

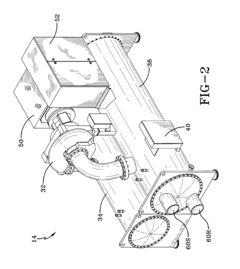

- Design and optimization of PMSM and BLDC motor structures: Innovations in motor design focus on optimizing the structure of PMSM and BLDC motors. This includes improvements in rotor and stator configurations, magnet arrangements, and winding designs to enhance power density, torque output, and overall efficiency.

- Thermal management and cooling systems: Effective thermal management is crucial for PMSM and BLDC motors to maintain performance and longevity. Advanced cooling systems and heat dissipation techniques are developed to address thermal challenges in high-performance motor applications.

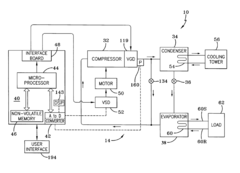

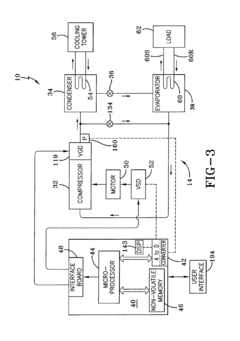

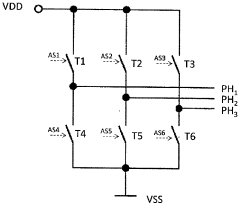

- Integration of power electronics and motor drives: Advancements in power electronics and motor drive systems are integrated with PMSM and BLDC motors to improve overall system performance. This includes the development of compact, efficient inverters and controllers specifically designed for these motor types.

- Application-specific motor designs and optimizations: PMSM and BLDC motors are tailored for specific applications such as electric vehicles, industrial automation, and renewable energy systems. These designs focus on meeting unique requirements like high torque density, wide speed range, or operation in harsh environments.

02 Design and optimization of PMSM and BLDC motor structures

Innovations in motor design focus on optimizing the structure of PMSM and BLDC motors. This includes improvements in rotor and stator configurations, magnet arrangements, and winding designs to enhance power density, torque output, and overall efficiency.Expand Specific Solutions03 Thermal management and cooling systems

Effective thermal management is crucial for PMSM and BLDC motors to maintain performance and longevity. Advanced cooling systems and heat dissipation techniques are developed to address thermal challenges in high-performance motor applications.Expand Specific Solutions04 Integration of power electronics and motor drives

Advancements in power electronics and motor drive integration aim to improve the overall system efficiency and compactness of PMSM and BLDC motor setups. This includes the development of integrated motor controllers and smart drive systems.Expand Specific Solutions05 Fault diagnosis and condition monitoring

Innovative techniques for fault diagnosis and condition monitoring are developed for PMSM and BLDC motors. These methods aim to enhance motor reliability, predict potential failures, and optimize maintenance schedules in various applications.Expand Specific Solutions

Key Manufacturers

The comparative study of PMSM and BLDC motors is currently in a mature development stage, with a growing market driven by increasing demand for efficient electric motors in various industries. The global market size for these motors is expected to reach significant figures in the coming years. Technologically, both motor types are well-established, with ongoing research focused on improving efficiency and performance. Companies like Microchip Technology, Infineon Technologies, and STMicroelectronics are at the forefront of developing advanced control solutions for these motors. Academic institutions such as Nanjing University of Aeronautics & Astronautics and Harbin Institute of Technology are contributing to research and innovation in this field, further enhancing the technological landscape.

Microchip Technology, Inc.

Technical Solution: Microchip Technology has developed advanced motor control solutions for both PMSM and BLDC motors. Their approach involves using high-performance dsPIC® Digital Signal Controllers (DSCs) and PIC® microcontrollers (MCUs) to implement Field-Oriented Control (FOC) for PMSMs and Six-Step Commutation for BLDCs[1]. They have implemented sensorless control techniques, such as sliding mode observer and high-frequency injection methods, to eliminate the need for position sensors[2]. Microchip's solutions also incorporate advanced features like power factor correction, active harmonic filtering, and torque ripple minimization to enhance overall system efficiency and performance[3].

Strengths: Versatile solutions for both motor types, advanced control algorithms, and sensorless operation. Weaknesses: May require specialized knowledge to implement, potentially higher initial cost compared to simpler control methods.

Infineon Technologies Americas Corp.

Technical Solution: Infineon has developed a comprehensive motor control portfolio for both PMSM and BLDC motors. Their solution includes the iMOTION™ platform, which integrates MCUs, gate drivers, and power devices optimized for motor control applications[4]. For PMSMs, Infineon employs advanced FOC techniques with space vector modulation, while for BLDCs, they offer both trapezoidal and sinusoidal control methods[5]. Infineon's approach also includes sensorless control algorithms, such as flux observer and back-EMF detection, to eliminate the need for position sensors. Additionally, they have implemented advanced features like predictive current control and online parameter estimation to improve dynamic performance and efficiency[6].

Strengths: Integrated hardware and software solutions, wide range of control options, and high-performance power devices. Weaknesses: Potential vendor lock-in, may be overkill for simpler applications.

Core Technologies

Motor control system and method with adaptive flux linkage estimation

PatentActiveUS20160218653A1

Innovation

- A method that estimates rotor position by applying a voltage and current to a transfer function with an S-domain integration operation and error correction variable, generating an estimated rotor flux linkage, and using this to control the motor position or speed without the need for speed/position sensors.

Procedure for determining the position of the rotor of a brushless motor using current direction detection

PatentPendingDE102016114185A1

Innovation

- A method that generates a clocked rotor position angle change signal synchronously with the rotating magnetic field, defines a measurement window for zero crossing of motor phase currents, and counts pulses within this window to accurately determine the rotor position, independent of motor speed, by filtering out noise in the phase current direction signal.

Performance Comparison

The performance comparison between Permanent Magnet Synchronous Motors (PMSM) and Brushless DC Motors (BLDC) reveals significant differences in their operational characteristics and efficiency. PMSM motors generally exhibit superior performance in terms of torque density, efficiency, and control precision. They offer smoother torque output due to their sinusoidal back-EMF waveform, resulting in reduced torque ripple and noise compared to BLDC motors.

In terms of efficiency, PMSMs typically achieve higher levels, especially at higher speeds and partial load conditions. This is attributed to their ability to maintain a constant power factor over a wide speed range. PMSMs also demonstrate better performance in field weakening operations, allowing for a broader constant power speed range.

BLDC motors, on the other hand, excel in simplicity and cost-effectiveness. They offer easier control algorithms and require less complex drive electronics. BLDC motors generally provide higher starting torque and are more suitable for applications requiring rapid acceleration and deceleration.

When comparing power density, PMSMs often have a slight edge due to their more efficient use of magnetic flux. This results in a more compact design for a given power output. However, BLDC motors can achieve comparable power densities in certain configurations, particularly in applications where high torque at low speeds is required.

In terms of speed range, PMSMs typically offer a wider operational range with consistent performance. They maintain higher efficiency across a broader speed spectrum, making them ideal for variable speed applications. BLDC motors, while capable of high-speed operation, may experience a more pronounced efficiency drop at extreme speeds.

Thermal management is another crucial aspect of performance comparison. PMSMs generally have better heat dissipation characteristics due to their distributed winding structure, allowing for more efficient cooling. This translates to improved continuous operation capabilities and potentially longer lifespan.

Considering control complexity, BLDC motors have an advantage in simpler applications. Their trapezoidal back-EMF allows for straightforward six-step commutation control. PMSMs, requiring more sophisticated vector control algorithms, offer superior dynamic response and position control accuracy, making them preferable in high-precision applications.

In conclusion, while both motor types have their strengths, PMSMs generally outperform BLDC motors in efficiency, torque smoothness, and control precision. However, BLDC motors remain competitive in applications prioritizing simplicity and cost-effectiveness. The choice between the two ultimately depends on the specific requirements of the application, balancing factors such as performance needs, cost constraints, and control complexity.

In terms of efficiency, PMSMs typically achieve higher levels, especially at higher speeds and partial load conditions. This is attributed to their ability to maintain a constant power factor over a wide speed range. PMSMs also demonstrate better performance in field weakening operations, allowing for a broader constant power speed range.

BLDC motors, on the other hand, excel in simplicity and cost-effectiveness. They offer easier control algorithms and require less complex drive electronics. BLDC motors generally provide higher starting torque and are more suitable for applications requiring rapid acceleration and deceleration.

When comparing power density, PMSMs often have a slight edge due to their more efficient use of magnetic flux. This results in a more compact design for a given power output. However, BLDC motors can achieve comparable power densities in certain configurations, particularly in applications where high torque at low speeds is required.

In terms of speed range, PMSMs typically offer a wider operational range with consistent performance. They maintain higher efficiency across a broader speed spectrum, making them ideal for variable speed applications. BLDC motors, while capable of high-speed operation, may experience a more pronounced efficiency drop at extreme speeds.

Thermal management is another crucial aspect of performance comparison. PMSMs generally have better heat dissipation characteristics due to their distributed winding structure, allowing for more efficient cooling. This translates to improved continuous operation capabilities and potentially longer lifespan.

Considering control complexity, BLDC motors have an advantage in simpler applications. Their trapezoidal back-EMF allows for straightforward six-step commutation control. PMSMs, requiring more sophisticated vector control algorithms, offer superior dynamic response and position control accuracy, making them preferable in high-precision applications.

In conclusion, while both motor types have their strengths, PMSMs generally outperform BLDC motors in efficiency, torque smoothness, and control precision. However, BLDC motors remain competitive in applications prioritizing simplicity and cost-effectiveness. The choice between the two ultimately depends on the specific requirements of the application, balancing factors such as performance needs, cost constraints, and control complexity.

Application Scenarios

Permanent Magnet Synchronous Motors (PMSM) and Brushless DC Motors (BLDC) find extensive applications across various industries due to their high efficiency, compact size, and excellent performance characteristics. In the automotive sector, both motor types are widely used in electric vehicles (EVs) and hybrid electric vehicles (HEVs). PMSMs are often preferred for their smooth torque output and high power density, making them ideal for main traction motors in EVs. BLDCs, on the other hand, are commonly employed in auxiliary systems such as power steering, cooling fans, and windshield wipers due to their simpler control requirements and lower cost.

In industrial automation, PMSMs are frequently utilized in high-precision motion control applications, such as CNC machines, robotics, and servo systems. Their ability to maintain accurate speed and position control makes them suitable for tasks requiring precise movements. BLDCs are often found in applications where cost-effectiveness and reliability are paramount, such as conveyor systems, pumps, and compressors.

The aerospace industry leverages both motor types for different purposes. PMSMs are used in flight control surfaces and landing gear actuators, where high torque density and precise control are crucial. BLDCs are commonly employed in fuel pumps, environmental control systems, and small unmanned aerial vehicles (UAVs) due to their reliability and efficiency at high speeds.

In the renewable energy sector, PMSMs are increasingly used in wind turbine generators, especially for direct-drive configurations, due to their high efficiency and ability to operate at variable speeds. BLDCs find applications in solar tracking systems and small-scale wind turbines, where their simplicity and robustness are advantageous.

The healthcare industry utilizes both motor types in various medical equipment. PMSMs are often found in high-end imaging devices like MRI machines and CT scanners, where precise control and low noise operation are essential. BLDCs are commonly used in medical pumps, ventilators, and surgical tools, benefiting from their compact size and reliability.

In consumer electronics, BLDCs are widely used in hard disk drives, cooling fans for computers, and small household appliances due to their cost-effectiveness and compact size. PMSMs, while less common in this sector, are sometimes employed in high-end audio equipment and precision turntables where superior performance justifies the higher cost.

In industrial automation, PMSMs are frequently utilized in high-precision motion control applications, such as CNC machines, robotics, and servo systems. Their ability to maintain accurate speed and position control makes them suitable for tasks requiring precise movements. BLDCs are often found in applications where cost-effectiveness and reliability are paramount, such as conveyor systems, pumps, and compressors.

The aerospace industry leverages both motor types for different purposes. PMSMs are used in flight control surfaces and landing gear actuators, where high torque density and precise control are crucial. BLDCs are commonly employed in fuel pumps, environmental control systems, and small unmanned aerial vehicles (UAVs) due to their reliability and efficiency at high speeds.

In the renewable energy sector, PMSMs are increasingly used in wind turbine generators, especially for direct-drive configurations, due to their high efficiency and ability to operate at variable speeds. BLDCs find applications in solar tracking systems and small-scale wind turbines, where their simplicity and robustness are advantageous.

The healthcare industry utilizes both motor types in various medical equipment. PMSMs are often found in high-end imaging devices like MRI machines and CT scanners, where precise control and low noise operation are essential. BLDCs are commonly used in medical pumps, ventilators, and surgical tools, benefiting from their compact size and reliability.

In consumer electronics, BLDCs are widely used in hard disk drives, cooling fans for computers, and small household appliances due to their cost-effectiveness and compact size. PMSMs, while less common in this sector, are sometimes employed in high-end audio equipment and precision turntables where superior performance justifies the higher cost.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!