Enhancing PMSM in hot climate operational conditions

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PMSM Hot Climate Challenges and Objectives

Permanent Magnet Synchronous Motors (PMSMs) have gained significant traction in various applications due to their high efficiency and power density. However, their performance in hot climates presents unique challenges that demand innovative solutions. The primary objective of enhancing PMSM operation in hot climate conditions is to maintain optimal performance while mitigating the adverse effects of elevated temperatures on motor components and overall system efficiency.

The evolution of PMSM technology has been marked by continuous improvements in materials, design, and control strategies. Recent trends indicate a growing focus on thermal management and temperature-resistant components to address the specific needs of hot climate operations. As global temperatures rise and the demand for efficient motor systems in challenging environments increases, the development of heat-resistant PMSMs has become a critical area of research and development.

One of the key technical goals in this domain is to enhance the thermal stability of permanent magnets, particularly at high operating temperatures. This involves exploring advanced magnetic materials with higher Curie temperatures and improved resistance to demagnetization. Additionally, there is a pressing need to develop more effective cooling systems that can efficiently dissipate heat from the motor's core components, ensuring sustained performance in hot environments.

Another crucial objective is to optimize the motor's electrical and mechanical design to minimize heat generation and improve heat distribution. This encompasses advancements in winding technologies, innovative rotor and stator designs, and the integration of thermally conductive materials throughout the motor structure. The aim is to create a more thermally resilient PMSM that can maintain its efficiency and power output even under prolonged exposure to high ambient temperatures.

Furthermore, the development of advanced control algorithms and sensing technologies is essential for real-time temperature monitoring and adaptive performance optimization. These systems must be capable of adjusting motor parameters dynamically to prevent thermal overload while maximizing efficiency across a wide range of operating conditions. The integration of predictive thermal modeling and artificial intelligence-driven control strategies represents a promising frontier in this field.

Addressing these challenges requires a multidisciplinary approach, combining expertise in materials science, thermal engineering, power electronics, and control systems. The ultimate goal is to create a new generation of PMSMs that not only survive but thrive in hot climate conditions, expanding their applicability in sectors such as automotive, renewable energy, and industrial automation in regions with harsh thermal environments.

The evolution of PMSM technology has been marked by continuous improvements in materials, design, and control strategies. Recent trends indicate a growing focus on thermal management and temperature-resistant components to address the specific needs of hot climate operations. As global temperatures rise and the demand for efficient motor systems in challenging environments increases, the development of heat-resistant PMSMs has become a critical area of research and development.

One of the key technical goals in this domain is to enhance the thermal stability of permanent magnets, particularly at high operating temperatures. This involves exploring advanced magnetic materials with higher Curie temperatures and improved resistance to demagnetization. Additionally, there is a pressing need to develop more effective cooling systems that can efficiently dissipate heat from the motor's core components, ensuring sustained performance in hot environments.

Another crucial objective is to optimize the motor's electrical and mechanical design to minimize heat generation and improve heat distribution. This encompasses advancements in winding technologies, innovative rotor and stator designs, and the integration of thermally conductive materials throughout the motor structure. The aim is to create a more thermally resilient PMSM that can maintain its efficiency and power output even under prolonged exposure to high ambient temperatures.

Furthermore, the development of advanced control algorithms and sensing technologies is essential for real-time temperature monitoring and adaptive performance optimization. These systems must be capable of adjusting motor parameters dynamically to prevent thermal overload while maximizing efficiency across a wide range of operating conditions. The integration of predictive thermal modeling and artificial intelligence-driven control strategies represents a promising frontier in this field.

Addressing these challenges requires a multidisciplinary approach, combining expertise in materials science, thermal engineering, power electronics, and control systems. The ultimate goal is to create a new generation of PMSMs that not only survive but thrive in hot climate conditions, expanding their applicability in sectors such as automotive, renewable energy, and industrial automation in regions with harsh thermal environments.

Market Demand for Heat-Resistant PMSM

The market demand for heat-resistant Permanent Magnet Synchronous Motors (PMSMs) has been steadily increasing, driven by the growing need for efficient and reliable electric motors in hot climate regions. As global temperatures continue to rise and extreme weather events become more frequent, industries across various sectors are seeking robust motor solutions that can maintain optimal performance under challenging thermal conditions.

In the automotive industry, the shift towards electric vehicles (EVs) has created a significant demand for heat-resistant PMSMs. Electric vehicles operating in hot climates require motors that can withstand high temperatures without compromising efficiency or longevity. This demand is particularly strong in regions such as the Middle East, North Africa, and parts of Asia and Australia, where ambient temperatures can regularly exceed 40°C.

The renewable energy sector, especially solar power generation, has also emerged as a key driver for heat-resistant PMSMs. Solar farms in desert regions require motors that can operate reliably in extreme heat for applications such as solar tracking systems and cooling equipment. As the global push for renewable energy intensifies, the demand for these specialized motors is expected to grow substantially.

Industrial applications in hot climates represent another significant market for heat-resistant PMSMs. Oil and gas operations, mining activities, and manufacturing plants in tropical and arid regions all require motors that can maintain performance and reliability under high-temperature conditions. The need for energy-efficient solutions in these industries further amplifies the demand for advanced PMSMs.

The HVAC industry is experiencing increased demand for heat-resistant PMSMs, particularly in regions with hot climates. As urbanization continues and energy efficiency standards become more stringent, there is a growing need for high-performance, heat-tolerant motors in air conditioning and ventilation systems for both residential and commercial buildings.

Market analysis indicates that the Asia-Pacific region is expected to lead in terms of demand growth for heat-resistant PMSMs, followed by the Middle East and Africa. This trend is attributed to rapid industrialization, infrastructure development, and the increasing adoption of electric vehicles in these regions.

The market size for heat-resistant PMSMs is projected to expand significantly over the next decade. Factors contributing to this growth include the increasing electrification of various industries, the push for energy efficiency, and the need for reliable operation in challenging environmental conditions. Additionally, government regulations promoting energy-efficient technologies and the reduction of carbon emissions are expected to further boost the demand for advanced PMSMs.

In the automotive industry, the shift towards electric vehicles (EVs) has created a significant demand for heat-resistant PMSMs. Electric vehicles operating in hot climates require motors that can withstand high temperatures without compromising efficiency or longevity. This demand is particularly strong in regions such as the Middle East, North Africa, and parts of Asia and Australia, where ambient temperatures can regularly exceed 40°C.

The renewable energy sector, especially solar power generation, has also emerged as a key driver for heat-resistant PMSMs. Solar farms in desert regions require motors that can operate reliably in extreme heat for applications such as solar tracking systems and cooling equipment. As the global push for renewable energy intensifies, the demand for these specialized motors is expected to grow substantially.

Industrial applications in hot climates represent another significant market for heat-resistant PMSMs. Oil and gas operations, mining activities, and manufacturing plants in tropical and arid regions all require motors that can maintain performance and reliability under high-temperature conditions. The need for energy-efficient solutions in these industries further amplifies the demand for advanced PMSMs.

The HVAC industry is experiencing increased demand for heat-resistant PMSMs, particularly in regions with hot climates. As urbanization continues and energy efficiency standards become more stringent, there is a growing need for high-performance, heat-tolerant motors in air conditioning and ventilation systems for both residential and commercial buildings.

Market analysis indicates that the Asia-Pacific region is expected to lead in terms of demand growth for heat-resistant PMSMs, followed by the Middle East and Africa. This trend is attributed to rapid industrialization, infrastructure development, and the increasing adoption of electric vehicles in these regions.

The market size for heat-resistant PMSMs is projected to expand significantly over the next decade. Factors contributing to this growth include the increasing electrification of various industries, the push for energy efficiency, and the need for reliable operation in challenging environmental conditions. Additionally, government regulations promoting energy-efficient technologies and the reduction of carbon emissions are expected to further boost the demand for advanced PMSMs.

Current PMSM Thermal Management Limitations

Permanent Magnet Synchronous Motors (PMSMs) face significant thermal management challenges in hot climate conditions, which can severely impact their performance and longevity. The current limitations in PMSM thermal management primarily stem from the inherent heat generation during operation and the difficulty in efficiently dissipating this heat in elevated ambient temperatures.

One of the primary thermal management limitations is the inadequate cooling capacity of traditional cooling systems when operating in hot climates. Conventional air-cooling methods become less effective as the ambient temperature rises, leading to reduced heat dissipation and potential thermal runaway. This issue is particularly pronounced in regions where temperatures frequently exceed 40°C, pushing cooling systems to their limits.

The thermal conductivity of materials used in PMSM construction also poses a significant limitation. While efforts have been made to improve the thermal properties of stator windings and rotor magnets, the overall heat transfer from the motor's core to its exterior remains a bottleneck. This results in localized hot spots within the motor, which can lead to accelerated degradation of insulation materials and permanent magnets.

Another critical limitation is the lack of precise thermal modeling and real-time temperature monitoring systems in many PMSM applications. Without accurate thermal data and predictive capabilities, it becomes challenging to implement adaptive cooling strategies or preemptive measures to prevent overheating. This gap in thermal management intelligence often leads to conservative operational parameters, limiting the motor's full performance potential in hot climates.

The current design of PMSMs also presents limitations in terms of heat distribution and evacuation. The compact nature of these motors, while beneficial for power density, creates challenges in incorporating effective cooling channels or heat sinks without compromising the motor's size and weight advantages. This trade-off between compactness and thermal management efficiency remains a significant hurdle in hot climate applications.

Furthermore, the thermal sensitivity of permanent magnets used in PMSMs presents a unique challenge. As temperatures rise, these magnets can experience partial demagnetization, leading to reduced motor efficiency and potential performance degradation. The current limitations in magnet materials and their thermal stability restrict the operational temperature range of PMSMs, particularly in hot climates where ambient temperatures are already high.

The integration of power electronics and control systems within or near the motor housing, while beneficial for compact designs, introduces additional heat sources that exacerbate thermal management challenges. The proximity of these heat-generating components to the motor core complicates cooling strategies and can lead to thermal coupling effects that are difficult to mitigate with current technologies.

One of the primary thermal management limitations is the inadequate cooling capacity of traditional cooling systems when operating in hot climates. Conventional air-cooling methods become less effective as the ambient temperature rises, leading to reduced heat dissipation and potential thermal runaway. This issue is particularly pronounced in regions where temperatures frequently exceed 40°C, pushing cooling systems to their limits.

The thermal conductivity of materials used in PMSM construction also poses a significant limitation. While efforts have been made to improve the thermal properties of stator windings and rotor magnets, the overall heat transfer from the motor's core to its exterior remains a bottleneck. This results in localized hot spots within the motor, which can lead to accelerated degradation of insulation materials and permanent magnets.

Another critical limitation is the lack of precise thermal modeling and real-time temperature monitoring systems in many PMSM applications. Without accurate thermal data and predictive capabilities, it becomes challenging to implement adaptive cooling strategies or preemptive measures to prevent overheating. This gap in thermal management intelligence often leads to conservative operational parameters, limiting the motor's full performance potential in hot climates.

The current design of PMSMs also presents limitations in terms of heat distribution and evacuation. The compact nature of these motors, while beneficial for power density, creates challenges in incorporating effective cooling channels or heat sinks without compromising the motor's size and weight advantages. This trade-off between compactness and thermal management efficiency remains a significant hurdle in hot climate applications.

Furthermore, the thermal sensitivity of permanent magnets used in PMSMs presents a unique challenge. As temperatures rise, these magnets can experience partial demagnetization, leading to reduced motor efficiency and potential performance degradation. The current limitations in magnet materials and their thermal stability restrict the operational temperature range of PMSMs, particularly in hot climates where ambient temperatures are already high.

The integration of power electronics and control systems within or near the motor housing, while beneficial for compact designs, introduces additional heat sources that exacerbate thermal management challenges. The proximity of these heat-generating components to the motor core complicates cooling strategies and can lead to thermal coupling effects that are difficult to mitigate with current technologies.

Existing Hot Climate PMSM Solutions

01 Improved motor control strategies

Advanced control algorithms and techniques are developed to enhance PMSM performance. These strategies focus on optimizing torque control, speed regulation, and efficiency across various operating conditions. Implementations may include adaptive control, sensorless control, and advanced vector control methods to improve dynamic response and stability.- Improved motor control strategies: Advanced control algorithms and techniques are developed to enhance PMSM performance. These strategies focus on optimizing torque production, reducing torque ripple, and improving overall efficiency. They may include sensorless control methods, adaptive control systems, and advanced vector control techniques to achieve better dynamic response and stability across various operating conditions.

- Rotor design optimization: Innovations in rotor design aim to improve PMSM performance. This includes optimizing magnet arrangements, using novel magnet materials, and implementing advanced rotor structures. These design enhancements can lead to increased power density, improved efficiency, and better thermal management, ultimately resulting in superior motor performance.

- Thermal management and cooling systems: Effective thermal management is crucial for maintaining PMSM performance. Advanced cooling systems and thermal design techniques are developed to dissipate heat more efficiently, allowing for higher power output and improved reliability. This may include innovative cooling channel designs, advanced materials with better thermal properties, and integrated cooling solutions.

- Fault detection and diagnosis: Implementing robust fault detection and diagnosis systems enhances PMSM reliability and performance. These systems use advanced sensors, signal processing techniques, and machine learning algorithms to detect and identify potential faults early. This allows for predictive maintenance and helps prevent unexpected downtime, ensuring consistent motor performance.

- Integration of power electronics: Advancements in power electronics integration aim to improve overall PMSM system performance. This includes developing compact, efficient inverters and drive systems specifically designed for PMSMs. Integrated solutions can lead to better control, reduced losses, and improved power density of the entire motor system, resulting in enhanced overall performance.

02 Rotor and magnet design optimization

Innovations in rotor structure and permanent magnet configurations aim to improve PMSM performance. This includes optimizing magnet shapes, arrangements, and materials to enhance flux distribution, reduce cogging torque, and increase power density. Advanced rotor designs may incorporate features to minimize losses and improve thermal management.Expand Specific Solutions03 Stator winding and core enhancements

Advancements in stator design focus on improving winding configurations and core materials to enhance PMSM performance. This may include novel winding patterns, use of advanced core materials, and optimized slot designs to reduce losses, improve heat dissipation, and increase power output.Expand Specific Solutions04 Thermal management and cooling systems

Innovative cooling techniques and thermal management solutions are developed to improve PMSM performance and reliability. These may include advanced cooling channel designs, integration of heat pipes, use of novel cooling fluids, and improved insulation materials to maintain optimal operating temperatures and extend motor life.Expand Specific Solutions05 Integration of sensors and diagnostics

Incorporation of advanced sensing technologies and diagnostic systems to monitor and optimize PMSM performance in real-time. This includes the integration of temperature, position, and current sensors, as well as the development of fault detection and predictive maintenance algorithms to ensure reliable operation and extend motor lifespan.Expand Specific Solutions

Key PMSM Manufacturers and Suppliers

The competition landscape for enhancing Permanent Magnet Synchronous Motors (PMSM) in hot climate operational conditions is in a growth phase, with increasing market size and technological advancements. The global PMSM market is expanding due to rising demand for energy-efficient motors in various industries. Companies like Gree Electric Appliances, General Electric, and Hitachi are leading players, leveraging their extensive R&D capabilities to improve PMSM performance in challenging environments. Academic institutions such as Beihang University and IIT Delhi are contributing to technological progress through research collaborations. The technology is maturing, with focus shifting towards optimizing thermal management and efficiency in extreme temperatures, indicating a competitive and innovation-driven market.

GM Global Technology Operations LLC

Technical Solution: GM has developed an advanced thermal management system for PMSMs operating in hot climates. Their solution incorporates a dual-circuit cooling system that separately cools the stator and rotor. The stator cooling uses a water-glycol mixture circulated through jacket channels, while the rotor employs an oil spray cooling method. This approach allows for more efficient heat dissipation, particularly in high-temperature environments. GM has also implemented advanced insulation materials with higher thermal conductivity to improve heat transfer from windings to the cooling system. Additionally, they've optimized the motor design to reduce internal heat generation, including the use of low-loss electrical steel and segmented stator designs[1][3].

Strengths: Effective dual-circuit cooling, improved insulation materials, and optimized motor design for reduced heat generation. Weaknesses: Potentially higher complexity and cost due to the dual cooling system.

Zhejiang Leapmotor Technology Co., Ltd.

Technical Solution: Leapmotor has focused on enhancing PMSM performance in hot climates through innovative material selection and cooling strategies. They've developed a high-temperature resistant magnet material that maintains its magnetic properties at elevated temperatures, reducing the risk of demagnetization in hot environments. Their cooling system utilizes a combination of liquid cooling for the stator and a novel phase-change material (PCM) for the rotor. The PCM absorbs excess heat during peak operation and releases it during cooler periods, helping to stabilize motor temperature. Leapmotor has also implemented advanced thermal modeling techniques to optimize the motor design for hot climate operation, including strategic placement of cooling channels and heat sinks[2][4].

Strengths: Innovative use of high-temperature magnets and phase-change materials for cooling. Weaknesses: Potential complexity in manufacturing and maintaining the PCM-based cooling system.

Thermal Management Innovations for PMSM

Permanent magnet FLUX linkage determination for permanent magnet synchronous motors

PatentWO2021188958A1

Innovation

- A method and system that applies phase voltages to PMSM leads at standstill conditions to measure current, determining flux linkage, PM strength, and state of health, using an inverter, current sensors, and a controller to diagnose demagnetization by analyzing RMS values of phase currents.

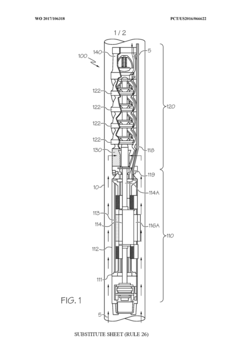

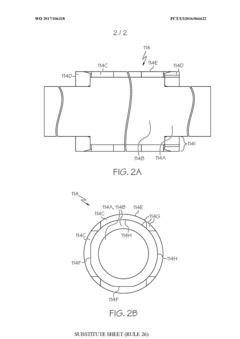

Permanent magnet submersible motor with a one-piece rotor/yoke configuration and resin embedded magnets

PatentWO2017106318A1

Innovation

- A one-piece rotor/yoke configuration with resin-embedded magnets, secured by a cladding tube and stepped collar, provides enhanced protection and durability by increasing bending stiffness, sealing the magnets from the environment, and simplifying assembly processes.

Environmental Impact of PMSM Cooling Systems

The environmental impact of cooling systems for Permanent Magnet Synchronous Motors (PMSMs) in hot climates is a critical consideration as the demand for these motors increases in various applications. Traditional cooling methods often rely on refrigerants and energy-intensive processes, which can contribute to greenhouse gas emissions and increased energy consumption.

Air-cooled systems, while simpler and more environmentally friendly, may struggle to maintain optimal performance in extreme heat conditions. This limitation has led to the development of more advanced cooling technologies that aim to balance efficiency with environmental responsibility. Liquid cooling systems, for instance, offer improved heat dissipation but require careful consideration of the coolant's environmental impact throughout its lifecycle.

The use of phase-change materials (PCMs) in PMSM cooling systems presents a promising avenue for reducing environmental impact. PCMs can absorb and release large amounts of thermal energy during phase transitions, potentially reducing the need for energy-intensive active cooling. However, the production and disposal of PCMs must be carefully managed to ensure their overall environmental benefit.

Another emerging approach is the integration of thermoelectric cooling devices, which can provide localized cooling without the use of refrigerants. While these devices offer the advantage of precise temperature control, their production often involves rare earth elements, raising concerns about resource depletion and mining impacts.

The environmental footprint of PMSM cooling systems extends beyond their operational phase. The manufacturing processes for advanced cooling components, such as heat pipes or specialized heat sinks, may involve energy-intensive production methods and the use of materials with significant environmental impacts. Lifecycle assessments are crucial to understanding the full environmental implications of these cooling technologies.

Recycling and proper disposal of cooling system components at the end of their life cycle are essential considerations. Many cooling systems contain materials that can be recycled, but the process may be complex and energy-intensive. Developing efficient recycling methods and designing cooling systems with end-of-life considerations in mind can significantly reduce their overall environmental impact.

As research continues, there is a growing focus on bio-inspired cooling solutions that mimic natural heat dissipation mechanisms. These innovative approaches, such as vascular cooling networks inspired by plant leaves, hold the potential for highly efficient and environmentally friendly cooling systems for PMSMs in hot climates.

Air-cooled systems, while simpler and more environmentally friendly, may struggle to maintain optimal performance in extreme heat conditions. This limitation has led to the development of more advanced cooling technologies that aim to balance efficiency with environmental responsibility. Liquid cooling systems, for instance, offer improved heat dissipation but require careful consideration of the coolant's environmental impact throughout its lifecycle.

The use of phase-change materials (PCMs) in PMSM cooling systems presents a promising avenue for reducing environmental impact. PCMs can absorb and release large amounts of thermal energy during phase transitions, potentially reducing the need for energy-intensive active cooling. However, the production and disposal of PCMs must be carefully managed to ensure their overall environmental benefit.

Another emerging approach is the integration of thermoelectric cooling devices, which can provide localized cooling without the use of refrigerants. While these devices offer the advantage of precise temperature control, their production often involves rare earth elements, raising concerns about resource depletion and mining impacts.

The environmental footprint of PMSM cooling systems extends beyond their operational phase. The manufacturing processes for advanced cooling components, such as heat pipes or specialized heat sinks, may involve energy-intensive production methods and the use of materials with significant environmental impacts. Lifecycle assessments are crucial to understanding the full environmental implications of these cooling technologies.

Recycling and proper disposal of cooling system components at the end of their life cycle are essential considerations. Many cooling systems contain materials that can be recycled, but the process may be complex and energy-intensive. Developing efficient recycling methods and designing cooling systems with end-of-life considerations in mind can significantly reduce their overall environmental impact.

As research continues, there is a growing focus on bio-inspired cooling solutions that mimic natural heat dissipation mechanisms. These innovative approaches, such as vascular cooling networks inspired by plant leaves, hold the potential for highly efficient and environmentally friendly cooling systems for PMSMs in hot climates.

PMSM Efficiency Standards in Hot Climates

Efficiency standards for Permanent Magnet Synchronous Motors (PMSMs) in hot climates have become increasingly important as global temperatures rise and energy conservation efforts intensify. These standards aim to ensure optimal performance and energy efficiency of PMSMs under challenging thermal conditions. In hot climates, PMSMs face unique challenges that can significantly impact their efficiency and overall performance.

The International Electrotechnical Commission (IEC) has established specific guidelines for PMSM efficiency in hot climates, outlined in IEC 60034-30-1. This standard defines efficiency classes for electric motors, including those operating in high-temperature environments. The classes range from IE1 (standard efficiency) to IE4 (super premium efficiency), with higher classes indicating better performance in hot conditions.

NEMA (National Electrical Manufacturers Association) has also developed standards for motor efficiency in hot climates, particularly relevant for North American markets. These standards, such as NEMA MG 1, provide guidelines for motor design and performance under various environmental conditions, including high ambient temperatures.

The European Union's Ecodesign Directive (2009/125/EC) sets minimum efficiency requirements for electric motors, including those used in hot climates. This directive has been instrumental in driving improvements in motor efficiency across Europe and has influenced global standards.

Key factors considered in these standards include temperature rise limits, insulation class requirements, and cooling system effectiveness. For instance, motors operating in hot climates often require higher insulation classes (e.g., Class H or C) to withstand elevated temperatures without degradation.

Efficiency testing procedures for PMSMs in hot climates typically involve simulating high ambient temperatures and measuring performance under these conditions. Standards often specify test conditions, such as ambient temperature ranges and load profiles, to ensure consistent and comparable results across different motor designs and manufacturers.

As climate change continues to affect global temperatures, these standards are likely to evolve. Future iterations may include more stringent efficiency requirements, advanced thermal management techniques, and potentially new efficiency classes specifically tailored for extreme temperature operations. This ongoing development of standards will play a crucial role in driving innovation and improving the performance of PMSMs in hot climate applications.

The International Electrotechnical Commission (IEC) has established specific guidelines for PMSM efficiency in hot climates, outlined in IEC 60034-30-1. This standard defines efficiency classes for electric motors, including those operating in high-temperature environments. The classes range from IE1 (standard efficiency) to IE4 (super premium efficiency), with higher classes indicating better performance in hot conditions.

NEMA (National Electrical Manufacturers Association) has also developed standards for motor efficiency in hot climates, particularly relevant for North American markets. These standards, such as NEMA MG 1, provide guidelines for motor design and performance under various environmental conditions, including high ambient temperatures.

The European Union's Ecodesign Directive (2009/125/EC) sets minimum efficiency requirements for electric motors, including those used in hot climates. This directive has been instrumental in driving improvements in motor efficiency across Europe and has influenced global standards.

Key factors considered in these standards include temperature rise limits, insulation class requirements, and cooling system effectiveness. For instance, motors operating in hot climates often require higher insulation classes (e.g., Class H or C) to withstand elevated temperatures without degradation.

Efficiency testing procedures for PMSMs in hot climates typically involve simulating high ambient temperatures and measuring performance under these conditions. Standards often specify test conditions, such as ambient temperature ranges and load profiles, to ensure consistent and comparable results across different motor designs and manufacturers.

As climate change continues to affect global temperatures, these standards are likely to evolve. Future iterations may include more stringent efficiency requirements, advanced thermal management techniques, and potentially new efficiency classes specifically tailored for extreme temperature operations. This ongoing development of standards will play a crucial role in driving innovation and improving the performance of PMSMs in hot climate applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!