Decarbonizing industrial motors with optimized PMSM

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PMSM Decarbonization Background and Objectives

Permanent Magnet Synchronous Motors (PMSMs) have emerged as a pivotal technology in the global effort to decarbonize industrial processes. The evolution of PMSM technology has been driven by the increasing demand for energy-efficient and environmentally friendly solutions in various industrial applications. As climate change concerns intensify, the focus on reducing carbon emissions from industrial operations has become paramount, positioning PMSMs at the forefront of sustainable motor technologies.

The development of PMSMs can be traced back to the mid-20th century, with significant advancements occurring in recent decades. These motors have gained traction due to their superior efficiency, compact size, and excellent control characteristics compared to traditional induction motors. The integration of rare-earth permanent magnets has been a key factor in enhancing PMSM performance, enabling higher power density and improved dynamic response.

In the context of industrial decarbonization, PMSMs offer substantial benefits. They can operate at higher efficiencies across a wide range of speeds and loads, resulting in reduced energy consumption and, consequently, lower carbon emissions. This aligns with global initiatives to mitigate climate change and meet stringent environmental regulations.

The primary objective of optimizing PMSMs for decarbonization is to further enhance their energy efficiency while maintaining or improving their performance characteristics. This involves addressing several key areas, including advanced motor design, improved materials, and sophisticated control strategies. By optimizing these aspects, researchers and engineers aim to push the boundaries of PMSM technology, making them even more effective tools for reducing industrial carbon footprints.

Another critical goal is to expand the application range of PMSMs in industrial settings. While they have already made significant inroads in sectors such as manufacturing, HVAC systems, and electric vehicles, there is potential for broader adoption across diverse industrial processes. This expansion would contribute to a more comprehensive decarbonization strategy for the industrial sector as a whole.

Furthermore, the optimization of PMSMs for decarbonization aims to address challenges related to the sourcing and use of rare-earth materials. As these materials are crucial for high-performance PMSMs, developing alternatives or more efficient use of existing resources is a key objective. This not only has environmental implications but also addresses concerns about the long-term sustainability and geopolitical aspects of rare-earth supply chains.

In conclusion, the background and objectives of PMSM decarbonization reflect a convergence of technological advancement, environmental imperatives, and industrial efficiency needs. The ongoing efforts to optimize PMSMs represent a critical pathway towards achieving significant reductions in industrial carbon emissions, aligning with global sustainability goals and shaping the future of industrial motor technology.

The development of PMSMs can be traced back to the mid-20th century, with significant advancements occurring in recent decades. These motors have gained traction due to their superior efficiency, compact size, and excellent control characteristics compared to traditional induction motors. The integration of rare-earth permanent magnets has been a key factor in enhancing PMSM performance, enabling higher power density and improved dynamic response.

In the context of industrial decarbonization, PMSMs offer substantial benefits. They can operate at higher efficiencies across a wide range of speeds and loads, resulting in reduced energy consumption and, consequently, lower carbon emissions. This aligns with global initiatives to mitigate climate change and meet stringent environmental regulations.

The primary objective of optimizing PMSMs for decarbonization is to further enhance their energy efficiency while maintaining or improving their performance characteristics. This involves addressing several key areas, including advanced motor design, improved materials, and sophisticated control strategies. By optimizing these aspects, researchers and engineers aim to push the boundaries of PMSM technology, making them even more effective tools for reducing industrial carbon footprints.

Another critical goal is to expand the application range of PMSMs in industrial settings. While they have already made significant inroads in sectors such as manufacturing, HVAC systems, and electric vehicles, there is potential for broader adoption across diverse industrial processes. This expansion would contribute to a more comprehensive decarbonization strategy for the industrial sector as a whole.

Furthermore, the optimization of PMSMs for decarbonization aims to address challenges related to the sourcing and use of rare-earth materials. As these materials are crucial for high-performance PMSMs, developing alternatives or more efficient use of existing resources is a key objective. This not only has environmental implications but also addresses concerns about the long-term sustainability and geopolitical aspects of rare-earth supply chains.

In conclusion, the background and objectives of PMSM decarbonization reflect a convergence of technological advancement, environmental imperatives, and industrial efficiency needs. The ongoing efforts to optimize PMSMs represent a critical pathway towards achieving significant reductions in industrial carbon emissions, aligning with global sustainability goals and shaping the future of industrial motor technology.

Industrial Motor Market Demand Analysis

The industrial motor market is experiencing a significant shift towards decarbonization, driven by increasing environmental concerns and stringent regulations. This trend has created a substantial demand for more efficient and sustainable motor technologies, particularly Permanent Magnet Synchronous Motors (PMSMs). The global industrial motor market, valued at approximately $25 billion in 2020, is projected to grow at a CAGR of 6.2% from 2021 to 2028, with a significant portion of this growth attributed to the adoption of energy-efficient motors.

The demand for PMSMs in industrial applications is rapidly increasing due to their superior efficiency, compact size, and excellent control characteristics. Industries such as manufacturing, automotive, and renewable energy are the primary drivers of this demand. In the manufacturing sector, the push for Industry 4.0 and smart factories has led to a greater need for precise motor control and energy efficiency, which PMSMs can provide.

The automotive industry, particularly the electric vehicle (EV) segment, is another major contributor to the growing demand for PMSMs. As EV production scales up, the need for high-performance, energy-efficient motors becomes critical. This demand is expected to have a spillover effect on other industrial applications, driving innovation and cost reduction in PMSM technology.

In the renewable energy sector, PMSMs are gaining traction in wind turbine applications due to their ability to operate efficiently at variable speeds. This aligns with the global push for clean energy and contributes to the overall demand for decarbonization solutions in industrial motors.

The market demand for optimized PMSMs is also influenced by regulatory pressures. Governments worldwide are implementing stricter energy efficiency standards for industrial equipment. For instance, the EU's Ecodesign Directive and the US Department of Energy's efficiency regulations are pushing industries to adopt more energy-efficient motor technologies, further boosting the demand for PMSMs.

Cost considerations remain a significant factor in the adoption of PMSMs. While the initial cost of PMSMs is higher compared to traditional induction motors, the long-term energy savings and performance benefits are driving their adoption. As production scales up and technology advances, the cost gap is expected to narrow, further accelerating market demand.

The Asia-Pacific region, led by China and India, is expected to witness the highest growth in demand for industrial PMSMs. This is due to rapid industrialization, government initiatives promoting energy efficiency, and the region's dominant position in manufacturing and electric vehicle production.

The demand for PMSMs in industrial applications is rapidly increasing due to their superior efficiency, compact size, and excellent control characteristics. Industries such as manufacturing, automotive, and renewable energy are the primary drivers of this demand. In the manufacturing sector, the push for Industry 4.0 and smart factories has led to a greater need for precise motor control and energy efficiency, which PMSMs can provide.

The automotive industry, particularly the electric vehicle (EV) segment, is another major contributor to the growing demand for PMSMs. As EV production scales up, the need for high-performance, energy-efficient motors becomes critical. This demand is expected to have a spillover effect on other industrial applications, driving innovation and cost reduction in PMSM technology.

In the renewable energy sector, PMSMs are gaining traction in wind turbine applications due to their ability to operate efficiently at variable speeds. This aligns with the global push for clean energy and contributes to the overall demand for decarbonization solutions in industrial motors.

The market demand for optimized PMSMs is also influenced by regulatory pressures. Governments worldwide are implementing stricter energy efficiency standards for industrial equipment. For instance, the EU's Ecodesign Directive and the US Department of Energy's efficiency regulations are pushing industries to adopt more energy-efficient motor technologies, further boosting the demand for PMSMs.

Cost considerations remain a significant factor in the adoption of PMSMs. While the initial cost of PMSMs is higher compared to traditional induction motors, the long-term energy savings and performance benefits are driving their adoption. As production scales up and technology advances, the cost gap is expected to narrow, further accelerating market demand.

The Asia-Pacific region, led by China and India, is expected to witness the highest growth in demand for industrial PMSMs. This is due to rapid industrialization, government initiatives promoting energy efficiency, and the region's dominant position in manufacturing and electric vehicle production.

PMSM Technology Status and Challenges

Permanent Magnet Synchronous Motors (PMSMs) have emerged as a promising technology for industrial decarbonization, offering high efficiency and power density. However, the current state of PMSM technology faces several challenges that need to be addressed for widespread adoption in industrial applications.

One of the primary challenges is the reliance on rare earth materials for permanent magnets. The limited availability and volatile pricing of these materials pose significant risks to the supply chain and cost-effectiveness of PMSMs. Researchers are actively exploring alternative magnet materials and designs to reduce or eliminate the dependence on rare earth elements while maintaining performance.

Thermal management remains a critical issue in PMSM technology. As industrial motors often operate in harsh environments and under high loads, effective heat dissipation is crucial for maintaining efficiency and prolonging motor lifespan. Current cooling solutions may not be sufficient for all industrial applications, necessitating innovative thermal management techniques.

Control systems for PMSMs present another technological hurdle. While advanced control algorithms have improved motor performance, there is still a need for more robust and adaptive control strategies to handle varying load conditions and optimize energy efficiency across different operating scenarios.

The manufacturing process for PMSMs, particularly for large industrial motors, poses challenges in terms of cost and scalability. Precision assembly of components and magnetization of permanent magnets require specialized equipment and expertise, which can limit production capacity and increase costs.

Reliability and maintenance considerations are also at the forefront of PMSM technology development. Industrial motors must operate continuously for extended periods, and any downtime can result in significant production losses. Improving the durability of components and developing predictive maintenance techniques are crucial for enhancing the overall reliability of PMSM systems.

Integration of PMSMs into existing industrial infrastructure presents both technical and economic challenges. Retrofitting older systems with new PMSM technology often requires significant modifications to control systems, power electronics, and mechanical interfaces. This can be a barrier to adoption for many industrial facilities.

Lastly, the optimization of PMSM designs for specific industrial applications remains an ongoing challenge. Different industries have varying requirements in terms of torque, speed, and operating conditions. Developing customized PMSM solutions that meet these diverse needs while maintaining high efficiency and cost-effectiveness is a complex task that requires continuous research and development efforts.

One of the primary challenges is the reliance on rare earth materials for permanent magnets. The limited availability and volatile pricing of these materials pose significant risks to the supply chain and cost-effectiveness of PMSMs. Researchers are actively exploring alternative magnet materials and designs to reduce or eliminate the dependence on rare earth elements while maintaining performance.

Thermal management remains a critical issue in PMSM technology. As industrial motors often operate in harsh environments and under high loads, effective heat dissipation is crucial for maintaining efficiency and prolonging motor lifespan. Current cooling solutions may not be sufficient for all industrial applications, necessitating innovative thermal management techniques.

Control systems for PMSMs present another technological hurdle. While advanced control algorithms have improved motor performance, there is still a need for more robust and adaptive control strategies to handle varying load conditions and optimize energy efficiency across different operating scenarios.

The manufacturing process for PMSMs, particularly for large industrial motors, poses challenges in terms of cost and scalability. Precision assembly of components and magnetization of permanent magnets require specialized equipment and expertise, which can limit production capacity and increase costs.

Reliability and maintenance considerations are also at the forefront of PMSM technology development. Industrial motors must operate continuously for extended periods, and any downtime can result in significant production losses. Improving the durability of components and developing predictive maintenance techniques are crucial for enhancing the overall reliability of PMSM systems.

Integration of PMSMs into existing industrial infrastructure presents both technical and economic challenges. Retrofitting older systems with new PMSM technology often requires significant modifications to control systems, power electronics, and mechanical interfaces. This can be a barrier to adoption for many industrial facilities.

Lastly, the optimization of PMSM designs for specific industrial applications remains an ongoing challenge. Different industries have varying requirements in terms of torque, speed, and operating conditions. Developing customized PMSM solutions that meet these diverse needs while maintaining high efficiency and cost-effectiveness is a complex task that requires continuous research and development efforts.

Current PMSM Optimization Techniques

01 Improved motor efficiency for reduced carbon emissions

Enhancing the efficiency of permanent magnet synchronous motors (PMSMs) through advanced design techniques and materials can significantly reduce energy consumption and carbon emissions. This includes optimizing magnetic circuits, minimizing losses, and improving thermal management to achieve higher power density and overall performance.- Improved motor efficiency for reduced carbon emissions: Enhancing the efficiency of permanent magnet synchronous motors (PMSMs) through advanced design techniques and materials can significantly reduce energy consumption and carbon emissions. This includes optimizing magnetic circuits, minimizing losses, and improving thermal management to achieve higher power density and overall performance.

- Use of sustainable materials in PMSM manufacturing: Incorporating eco-friendly and recyclable materials in the production of PMSMs can contribute to decarbonization efforts. This involves using sustainable alternatives for magnets, windings, and other components, as well as implementing manufacturing processes that reduce waste and energy consumption.

- Integration of PMSMs with renewable energy systems: Combining PMSMs with renewable energy sources such as solar and wind power can create more sustainable and carbon-neutral drive systems. This integration can optimize energy utilization and reduce reliance on fossil fuels, particularly in applications like electric vehicles and industrial machinery.

- Advanced control strategies for PMSM energy optimization: Implementing sophisticated control algorithms and power electronics can enhance the energy efficiency of PMSMs. These strategies may include adaptive control, sensorless operation, and intelligent power management to minimize losses and optimize performance across various operating conditions.

- Life cycle assessment and circular economy approaches: Adopting a holistic approach to PMSM decarbonization by considering the entire life cycle of the motor, from raw material extraction to end-of-life recycling. This includes designing for recyclability, implementing take-back programs, and optimizing the reuse of components to minimize the overall carbon footprint of PMSMs.

02 Use of eco-friendly materials in PMSM manufacturing

Incorporating sustainable and recyclable materials in the production of PMSMs can contribute to decarbonization efforts. This involves using environmentally friendly magnets, reducing rare earth element usage, and exploring alternative materials for motor components to minimize the carbon footprint of manufacturing processes.Expand Specific Solutions03 Integration of PMSMs with renewable energy systems

Combining PMSMs with renewable energy sources such as solar and wind power can create more sustainable and carbon-neutral drive systems. This integration can optimize energy utilization, reduce reliance on fossil fuels, and contribute to overall decarbonization goals in various applications.Expand Specific Solutions04 Advanced control strategies for PMSM energy optimization

Implementing sophisticated control algorithms and strategies can enhance the energy efficiency of PMSMs. These may include adaptive control systems, predictive maintenance techniques, and intelligent power management to minimize energy waste and optimize motor performance across various operating conditions.Expand Specific Solutions05 Lifecycle assessment and circular economy approaches for PMSMs

Adopting lifecycle assessment methodologies and circular economy principles in the design, manufacturing, and end-of-life management of PMSMs can significantly reduce their environmental impact. This includes designing for recyclability, implementing take-back programs, and optimizing resource utilization throughout the motor's lifecycle.Expand Specific Solutions

Key Players in PMSM Manufacturing

The decarbonization of industrial motors using optimized Permanent Magnet Synchronous Motors (PMSM) is in a growth phase, with increasing market size driven by sustainability goals. The technology is maturing rapidly, with key players like Rolls-Royce, Isuzu Motors, and GM Global Technology Operations leading innovation. Academic institutions such as Harbin Institute of Technology and Nanjing University of Aeronautics & Astronautics are contributing to research advancements. Companies like ebm-papst and Carrier Corp. are focusing on practical applications, while automotive giants like Hyundai and Kia are integrating this technology into electric vehicles, indicating a broad industry adoption trend.

GM Global Technology Operations LLC

Technical Solution: GM has developed PMSM technology primarily for automotive applications, but their innovations are applicable to industrial motors. Their focus is on reducing rare earth material usage while maintaining high efficiency. GM's PMSMs utilize advanced magnetic designs and optimized geometries to maximize torque density. The company has implemented innovative manufacturing techniques to reduce production costs and improve scalability. GM's motor designs also incorporate advanced thermal management systems and high-efficiency power electronics. Their PMSMs feature adaptive control algorithms that optimize performance based on operating conditions[4][6].

Strengths: Reduced rare earth material usage, advanced manufacturing techniques, and adaptive control systems. Weaknesses: Primary focus on automotive applications may limit industrial-specific optimizations.

Infineon Technologies Americas Corp.

Technical Solution: Infineon has developed comprehensive solutions for PMSM control and power electronics, which are crucial for optimizing industrial motor efficiency. Their approach focuses on integrating advanced semiconductor technologies with intelligent control algorithms. Infineon's solutions include high-performance microcontrollers and power modules specifically designed for PMSM applications. The company has implemented advanced sensorless control techniques that reduce system complexity and cost. Infineon's power electronics feature high switching frequencies and low losses, contributing to overall system efficiency. Their solutions also incorporate advanced protection features and diagnostics capabilities[7][8].

Strengths: Integrated semiconductor and control solutions, advanced sensorless control techniques. Weaknesses: Reliance on third-party motor manufacturers for complete systems.

Core Innovations in PMSM Efficiency

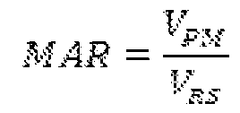

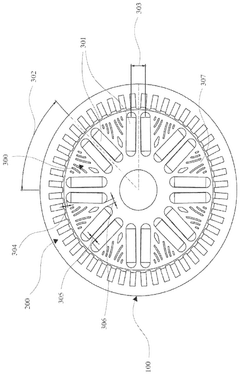

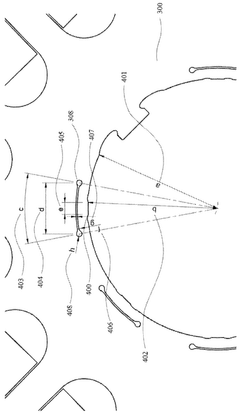

Permanent magnet synchronous machine rotor geometries with a maximized torque-speed density

PatentWO2025104500A1

Innovation

- The development of a radial-field electric motor geometry with a multi-pole rotor, optimized parameters such as magnet thickness, rotor bridge, flux return path, and magnet post, and inclusion of slots to reduce weight and maintain structural integrity, achieving a magnet aspect ratio of 45-70%.

Environmental Impact Assessment

The environmental impact assessment of decarbonizing industrial motors with optimized Permanent Magnet Synchronous Motors (PMSMs) reveals significant potential for reducing greenhouse gas emissions and improving energy efficiency in the industrial sector. PMSMs, when optimized for industrial applications, can substantially decrease electricity consumption compared to conventional induction motors, leading to a notable reduction in carbon footprint.

The primary environmental benefit of implementing optimized PMSMs lies in their superior energy efficiency. These motors can achieve efficiency levels of up to 98%, compared to the 85-90% efficiency of traditional induction motors. This improvement translates to a substantial decrease in energy consumption, directly contributing to reduced CO2 emissions from power generation. In large-scale industrial operations, the cumulative effect of this efficiency gain can lead to significant reductions in overall carbon emissions.

Furthermore, the use of optimized PMSMs can indirectly contribute to environmental conservation through the reduced demand for raw materials in power generation infrastructure. As these motors require less energy to operate, there is a corresponding decrease in the need for new power plants and transmission lines, potentially mitigating habitat destruction and resource depletion associated with energy infrastructure expansion.

However, the environmental assessment must also consider the lifecycle impact of PMSMs, including the production and disposal phases. The manufacturing of permanent magnets used in these motors often involves rare earth elements, which can have significant environmental implications during extraction and processing. Responsible sourcing and improved recycling techniques for these materials are crucial to mitigate potential negative impacts.

The longevity and reliability of optimized PMSMs also play a role in their environmental impact. These motors typically have a longer operational lifespan and require less maintenance than conventional motors, reducing the frequency of replacements and associated waste generation. This aspect contributes to a more sustainable industrial ecosystem by minimizing the environmental burden of motor production and disposal over time.

In terms of noise pollution, PMSMs generally operate more quietly than their induction counterparts, potentially improving the working environment in industrial settings. This reduction in noise can have positive effects on both human health and local ecosystems, particularly in areas where industrial facilities are in close proximity to residential or ecologically sensitive zones.

The adoption of optimized PMSMs also aligns with broader environmental policies and initiatives aimed at industrial decarbonization. By facilitating compliance with increasingly stringent energy efficiency standards and emissions regulations, these motors can help industries meet environmental targets while maintaining or improving productivity. This alignment can accelerate the transition towards more sustainable industrial practices on a global scale.

The primary environmental benefit of implementing optimized PMSMs lies in their superior energy efficiency. These motors can achieve efficiency levels of up to 98%, compared to the 85-90% efficiency of traditional induction motors. This improvement translates to a substantial decrease in energy consumption, directly contributing to reduced CO2 emissions from power generation. In large-scale industrial operations, the cumulative effect of this efficiency gain can lead to significant reductions in overall carbon emissions.

Furthermore, the use of optimized PMSMs can indirectly contribute to environmental conservation through the reduced demand for raw materials in power generation infrastructure. As these motors require less energy to operate, there is a corresponding decrease in the need for new power plants and transmission lines, potentially mitigating habitat destruction and resource depletion associated with energy infrastructure expansion.

However, the environmental assessment must also consider the lifecycle impact of PMSMs, including the production and disposal phases. The manufacturing of permanent magnets used in these motors often involves rare earth elements, which can have significant environmental implications during extraction and processing. Responsible sourcing and improved recycling techniques for these materials are crucial to mitigate potential negative impacts.

The longevity and reliability of optimized PMSMs also play a role in their environmental impact. These motors typically have a longer operational lifespan and require less maintenance than conventional motors, reducing the frequency of replacements and associated waste generation. This aspect contributes to a more sustainable industrial ecosystem by minimizing the environmental burden of motor production and disposal over time.

In terms of noise pollution, PMSMs generally operate more quietly than their induction counterparts, potentially improving the working environment in industrial settings. This reduction in noise can have positive effects on both human health and local ecosystems, particularly in areas where industrial facilities are in close proximity to residential or ecologically sensitive zones.

The adoption of optimized PMSMs also aligns with broader environmental policies and initiatives aimed at industrial decarbonization. By facilitating compliance with increasingly stringent energy efficiency standards and emissions regulations, these motors can help industries meet environmental targets while maintaining or improving productivity. This alignment can accelerate the transition towards more sustainable industrial practices on a global scale.

Policy Landscape for Industrial Decarbonization

The policy landscape for industrial decarbonization is rapidly evolving as governments worldwide recognize the urgent need to address climate change and reduce greenhouse gas emissions. In the context of decarbonizing industrial motors with optimized Permanent Magnet Synchronous Motors (PMSM), several key policy initiatives and frameworks are shaping the industry's trajectory.

At the international level, the Paris Agreement serves as a cornerstone for global climate action, setting ambitious targets for reducing carbon emissions. This has prompted many countries to develop national strategies and policies specifically targeting industrial decarbonization. The European Union's Green Deal, for instance, outlines a comprehensive approach to achieving carbon neutrality by 2050, with a strong focus on industrial sectors.

In the United States, the Biden administration has introduced the American Jobs Plan, which includes significant investments in clean energy and industrial decarbonization. This plan emphasizes the importance of upgrading industrial equipment, including motors, to more energy-efficient alternatives like optimized PMSMs.

China, as the world's largest manufacturer, has also implemented policies to promote industrial energy efficiency and decarbonization. The country's 14th Five-Year Plan (2021-2025) sets targets for reducing energy intensity and carbon emissions in key industrial sectors, including motor-driven systems.

Many countries have introduced specific regulations and standards for industrial motor efficiency. For example, the International Electrotechnical Commission (IEC) has established global standards for motor efficiency classes, with IE4 and IE5 representing the highest efficiency levels. These standards are increasingly being adopted and enforced by national governments, driving the adoption of high-efficiency motors like PMSMs.

Financial incentives play a crucial role in the policy landscape. Governments are offering tax credits, grants, and subsidies to industries that invest in energy-efficient technologies, including advanced motor systems. For instance, the EU's Innovation Fund provides support for innovative low-carbon technologies in energy-intensive industries.

Carbon pricing mechanisms, such as emissions trading systems and carbon taxes, are becoming more prevalent globally. These policies create economic incentives for industries to reduce their carbon footprint, making investments in technologies like optimized PMSMs more attractive.

Research and development support is another key aspect of the policy landscape. Many governments are allocating funds for R&D in clean energy technologies, including advanced motor systems. This support is crucial for driving innovation in PMSM technology and accelerating its adoption in industrial applications.

As the urgency of climate action intensifies, it is likely that the policy landscape will continue to evolve, with more stringent regulations and stronger incentives for industrial decarbonization. This dynamic environment underscores the importance of staying informed about policy developments and their potential impacts on the adoption of technologies like optimized PMSMs in industrial motors.

At the international level, the Paris Agreement serves as a cornerstone for global climate action, setting ambitious targets for reducing carbon emissions. This has prompted many countries to develop national strategies and policies specifically targeting industrial decarbonization. The European Union's Green Deal, for instance, outlines a comprehensive approach to achieving carbon neutrality by 2050, with a strong focus on industrial sectors.

In the United States, the Biden administration has introduced the American Jobs Plan, which includes significant investments in clean energy and industrial decarbonization. This plan emphasizes the importance of upgrading industrial equipment, including motors, to more energy-efficient alternatives like optimized PMSMs.

China, as the world's largest manufacturer, has also implemented policies to promote industrial energy efficiency and decarbonization. The country's 14th Five-Year Plan (2021-2025) sets targets for reducing energy intensity and carbon emissions in key industrial sectors, including motor-driven systems.

Many countries have introduced specific regulations and standards for industrial motor efficiency. For example, the International Electrotechnical Commission (IEC) has established global standards for motor efficiency classes, with IE4 and IE5 representing the highest efficiency levels. These standards are increasingly being adopted and enforced by national governments, driving the adoption of high-efficiency motors like PMSMs.

Financial incentives play a crucial role in the policy landscape. Governments are offering tax credits, grants, and subsidies to industries that invest in energy-efficient technologies, including advanced motor systems. For instance, the EU's Innovation Fund provides support for innovative low-carbon technologies in energy-intensive industries.

Carbon pricing mechanisms, such as emissions trading systems and carbon taxes, are becoming more prevalent globally. These policies create economic incentives for industries to reduce their carbon footprint, making investments in technologies like optimized PMSMs more attractive.

Research and development support is another key aspect of the policy landscape. Many governments are allocating funds for R&D in clean energy technologies, including advanced motor systems. This support is crucial for driving innovation in PMSM technology and accelerating its adoption in industrial applications.

As the urgency of climate action intensifies, it is likely that the policy landscape will continue to evolve, with more stringent regulations and stronger incentives for industrial decarbonization. This dynamic environment underscores the importance of staying informed about policy developments and their potential impacts on the adoption of technologies like optimized PMSMs in industrial motors.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!