Automation advances in PMSM-controlled packaging systems

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PMSM Packaging Evolution

The evolution of Permanent Magnet Synchronous Motor (PMSM) controlled packaging systems represents a significant advancement in automation technology. This progression has been driven by the increasing demand for more efficient, precise, and flexible packaging solutions across various industries.

In the early stages, packaging systems relied on simpler motor technologies, such as induction motors or stepper motors. These systems often lacked the precision and dynamic performance required for high-speed packaging operations. The introduction of PMSM technology marked a turning point in the packaging industry, offering superior control, higher efficiency, and improved power density.

The first generation of PMSM-controlled packaging systems focused on basic speed and position control. These systems provided better accuracy compared to their predecessors but were limited in terms of adaptability and integration with other packaging processes. As the technology matured, manufacturers began to incorporate more advanced control algorithms and sensor technologies, enabling real-time adjustments and improved synchronization between different components of the packaging line.

A significant milestone in PMSM packaging evolution was the integration of digital control systems and fieldbus communication protocols. This advancement allowed for seamless coordination between multiple motors and other packaging equipment, resulting in more complex and efficient packaging processes. The ability to precisely control multiple axes simultaneously opened up new possibilities for package design and production flexibility.

The next phase of evolution saw the incorporation of smart features and Industry 4.0 concepts. PMSM-controlled systems began to leverage data analytics, machine learning, and predictive maintenance capabilities. This shift towards intelligent packaging systems enabled real-time optimization of packaging processes, reduced downtime, and improved overall equipment effectiveness (OEE).

Recent developments in PMSM packaging technology have focused on sustainability and energy efficiency. Advanced motor designs and control strategies have led to significant reductions in energy consumption, aligning with global efforts to minimize environmental impact. Additionally, the integration of regenerative braking systems has further improved energy efficiency by recovering and reusing kinetic energy during deceleration phases.

The latest trends in PMSM-controlled packaging systems include the adoption of modular and scalable designs, allowing for greater flexibility and easier customization to meet specific packaging requirements. Furthermore, the integration of collaborative robots (cobots) with PMSM technology is opening up new possibilities for human-machine interaction in packaging operations, enhancing safety and efficiency.

As we look to the future, the evolution of PMSM-controlled packaging systems is expected to continue, with a focus on further integration of artificial intelligence, enhanced connectivity through Industrial Internet of Things (IIoT) platforms, and the development of more compact and powerful motor designs to meet the ever-increasing demands of the packaging industry.

In the early stages, packaging systems relied on simpler motor technologies, such as induction motors or stepper motors. These systems often lacked the precision and dynamic performance required for high-speed packaging operations. The introduction of PMSM technology marked a turning point in the packaging industry, offering superior control, higher efficiency, and improved power density.

The first generation of PMSM-controlled packaging systems focused on basic speed and position control. These systems provided better accuracy compared to their predecessors but were limited in terms of adaptability and integration with other packaging processes. As the technology matured, manufacturers began to incorporate more advanced control algorithms and sensor technologies, enabling real-time adjustments and improved synchronization between different components of the packaging line.

A significant milestone in PMSM packaging evolution was the integration of digital control systems and fieldbus communication protocols. This advancement allowed for seamless coordination between multiple motors and other packaging equipment, resulting in more complex and efficient packaging processes. The ability to precisely control multiple axes simultaneously opened up new possibilities for package design and production flexibility.

The next phase of evolution saw the incorporation of smart features and Industry 4.0 concepts. PMSM-controlled systems began to leverage data analytics, machine learning, and predictive maintenance capabilities. This shift towards intelligent packaging systems enabled real-time optimization of packaging processes, reduced downtime, and improved overall equipment effectiveness (OEE).

Recent developments in PMSM packaging technology have focused on sustainability and energy efficiency. Advanced motor designs and control strategies have led to significant reductions in energy consumption, aligning with global efforts to minimize environmental impact. Additionally, the integration of regenerative braking systems has further improved energy efficiency by recovering and reusing kinetic energy during deceleration phases.

The latest trends in PMSM-controlled packaging systems include the adoption of modular and scalable designs, allowing for greater flexibility and easier customization to meet specific packaging requirements. Furthermore, the integration of collaborative robots (cobots) with PMSM technology is opening up new possibilities for human-machine interaction in packaging operations, enhancing safety and efficiency.

As we look to the future, the evolution of PMSM-controlled packaging systems is expected to continue, with a focus on further integration of artificial intelligence, enhanced connectivity through Industrial Internet of Things (IIoT) platforms, and the development of more compact and powerful motor designs to meet the ever-increasing demands of the packaging industry.

Market Demand Analysis

The market demand for automation advances in PMSM-controlled packaging systems has been steadily increasing in recent years, driven by several key factors. The packaging industry, particularly in sectors such as food and beverage, pharmaceuticals, and consumer goods, is experiencing a growing need for more efficient, precise, and flexible packaging solutions. This demand is fueled by the increasing pressure to reduce operational costs, improve product quality, and meet stringent regulatory requirements.

PMSM (Permanent Magnet Synchronous Motor) technology has emerged as a crucial component in modern packaging systems due to its superior performance characteristics. These motors offer higher efficiency, better speed control, and improved torque-to-size ratio compared to traditional induction motors. As a result, packaging machinery equipped with PMSM-controlled systems can achieve higher speeds, greater accuracy, and enhanced energy efficiency, all of which are highly valued in the competitive packaging market.

The global packaging machinery market, which includes PMSM-controlled systems, is projected to experience significant growth. This expansion is attributed to the rising demand for packaged consumer goods, especially in emerging economies, and the increasing adoption of automation in manufacturing processes. Additionally, the trend towards sustainable packaging solutions is driving innovation in packaging machinery, with PMSM-controlled systems playing a vital role in developing more environmentally friendly packaging processes.

In the food and beverage sector, which represents a substantial portion of the packaging market, there is a growing demand for machines that can handle a wide variety of package sizes and types with minimal changeover time. PMSM-controlled packaging systems excel in this area, offering the flexibility and precision required to meet these diverse packaging needs. The pharmaceutical industry, another major driver of demand, requires packaging solutions that ensure product integrity and comply with strict regulatory standards. PMSM-controlled systems provide the necessary precision and reliability for these critical applications.

The e-commerce boom has also significantly impacted the packaging industry, creating a surge in demand for automated packaging solutions that can handle high-volume, varied-size orders efficiently. PMSM-controlled packaging systems are well-suited to meet these challenges, offering the speed and adaptability required in modern fulfillment centers.

As industries continue to embrace Industry 4.0 principles, there is an increasing focus on smart, connected packaging machinery. PMSM-controlled systems, with their advanced control capabilities, are well-positioned to integrate with IoT (Internet of Things) technologies, enabling real-time monitoring, predictive maintenance, and data-driven optimization of packaging processes. This trend is expected to further drive the demand for advanced PMSM-controlled packaging systems in the coming years.

PMSM (Permanent Magnet Synchronous Motor) technology has emerged as a crucial component in modern packaging systems due to its superior performance characteristics. These motors offer higher efficiency, better speed control, and improved torque-to-size ratio compared to traditional induction motors. As a result, packaging machinery equipped with PMSM-controlled systems can achieve higher speeds, greater accuracy, and enhanced energy efficiency, all of which are highly valued in the competitive packaging market.

The global packaging machinery market, which includes PMSM-controlled systems, is projected to experience significant growth. This expansion is attributed to the rising demand for packaged consumer goods, especially in emerging economies, and the increasing adoption of automation in manufacturing processes. Additionally, the trend towards sustainable packaging solutions is driving innovation in packaging machinery, with PMSM-controlled systems playing a vital role in developing more environmentally friendly packaging processes.

In the food and beverage sector, which represents a substantial portion of the packaging market, there is a growing demand for machines that can handle a wide variety of package sizes and types with minimal changeover time. PMSM-controlled packaging systems excel in this area, offering the flexibility and precision required to meet these diverse packaging needs. The pharmaceutical industry, another major driver of demand, requires packaging solutions that ensure product integrity and comply with strict regulatory standards. PMSM-controlled systems provide the necessary precision and reliability for these critical applications.

The e-commerce boom has also significantly impacted the packaging industry, creating a surge in demand for automated packaging solutions that can handle high-volume, varied-size orders efficiently. PMSM-controlled packaging systems are well-suited to meet these challenges, offering the speed and adaptability required in modern fulfillment centers.

As industries continue to embrace Industry 4.0 principles, there is an increasing focus on smart, connected packaging machinery. PMSM-controlled systems, with their advanced control capabilities, are well-positioned to integrate with IoT (Internet of Things) technologies, enabling real-time monitoring, predictive maintenance, and data-driven optimization of packaging processes. This trend is expected to further drive the demand for advanced PMSM-controlled packaging systems in the coming years.

Technical Challenges

The automation of Permanent Magnet Synchronous Motor (PMSM) controlled packaging systems faces several significant technical challenges. These challenges stem from the complex nature of integrating advanced motor control with sophisticated packaging processes, each requiring precise coordination and real-time adjustments.

One of the primary challenges is achieving high-precision control of PMSM in dynamic packaging environments. Packaging systems often involve rapid start-stop cycles, variable loads, and sudden changes in operating conditions. Maintaining optimal motor performance under these fluctuating conditions requires advanced control algorithms capable of real-time adaptation. The development of robust sensorless control techniques for PMSM in packaging applications is particularly challenging, as traditional sensor-based methods may be impractical or cost-prohibitive in certain packaging environments.

Another significant hurdle is the integration of PMSM control systems with existing packaging machinery and automation platforms. Many packaging facilities utilize legacy equipment or proprietary control systems, making seamless integration of new PMSM-based solutions complex. This challenge extends to ensuring compatibility with various communication protocols and industrial networks used in packaging automation, such as EtherCAT, PROFINET, or OPC UA.

Energy efficiency optimization presents another technical challenge in PMSM-controlled packaging systems. While PMSMs are inherently more efficient than some alternative motor types, maximizing their efficiency across diverse packaging operations requires sophisticated energy management strategies. This includes developing intelligent algorithms for optimal flux weakening, minimizing losses during partial load conditions, and implementing effective regenerative braking techniques.

The demand for increased flexibility in packaging lines adds another layer of complexity to PMSM control systems. Modern packaging facilities often require quick changeovers between different product formats or packaging styles. This necessitates the development of adaptive control systems capable of rapidly reconfiguring motor parameters and motion profiles without compromising performance or requiring extensive manual intervention.

Reliability and fault tolerance are critical concerns in packaging automation. Developing robust fault detection and diagnostic systems for PMSM-controlled packaging equipment is challenging, particularly in high-speed, continuous operation environments. This includes implementing advanced condition monitoring techniques, predictive maintenance algorithms, and fail-safe operational modes to minimize downtime and ensure product quality.

Lastly, the miniaturization of packaging machinery, driven by the need for space efficiency and compact production lines, poses challenges for PMSM integration. Designing compact, high-performance motor drives and control systems that can operate effectively in confined spaces, while managing heat dissipation and electromagnetic interference, requires innovative approaches in both hardware and software design.

One of the primary challenges is achieving high-precision control of PMSM in dynamic packaging environments. Packaging systems often involve rapid start-stop cycles, variable loads, and sudden changes in operating conditions. Maintaining optimal motor performance under these fluctuating conditions requires advanced control algorithms capable of real-time adaptation. The development of robust sensorless control techniques for PMSM in packaging applications is particularly challenging, as traditional sensor-based methods may be impractical or cost-prohibitive in certain packaging environments.

Another significant hurdle is the integration of PMSM control systems with existing packaging machinery and automation platforms. Many packaging facilities utilize legacy equipment or proprietary control systems, making seamless integration of new PMSM-based solutions complex. This challenge extends to ensuring compatibility with various communication protocols and industrial networks used in packaging automation, such as EtherCAT, PROFINET, or OPC UA.

Energy efficiency optimization presents another technical challenge in PMSM-controlled packaging systems. While PMSMs are inherently more efficient than some alternative motor types, maximizing their efficiency across diverse packaging operations requires sophisticated energy management strategies. This includes developing intelligent algorithms for optimal flux weakening, minimizing losses during partial load conditions, and implementing effective regenerative braking techniques.

The demand for increased flexibility in packaging lines adds another layer of complexity to PMSM control systems. Modern packaging facilities often require quick changeovers between different product formats or packaging styles. This necessitates the development of adaptive control systems capable of rapidly reconfiguring motor parameters and motion profiles without compromising performance or requiring extensive manual intervention.

Reliability and fault tolerance are critical concerns in packaging automation. Developing robust fault detection and diagnostic systems for PMSM-controlled packaging equipment is challenging, particularly in high-speed, continuous operation environments. This includes implementing advanced condition monitoring techniques, predictive maintenance algorithms, and fail-safe operational modes to minimize downtime and ensure product quality.

Lastly, the miniaturization of packaging machinery, driven by the need for space efficiency and compact production lines, poses challenges for PMSM integration. Designing compact, high-performance motor drives and control systems that can operate effectively in confined spaces, while managing heat dissipation and electromagnetic interference, requires innovative approaches in both hardware and software design.

Current PMSM Solutions

01 PMSM control systems for packaging automation

Permanent Magnet Synchronous Motor (PMSM) control systems are utilized in packaging automation to enhance precision, efficiency, and speed. These systems integrate advanced motor control algorithms with packaging machinery to optimize performance and reduce energy consumption in automated packaging processes.- PMSM control systems for packaging automation: Permanent Magnet Synchronous Motor (PMSM) control systems are utilized in packaging automation to enhance precision, efficiency, and speed. These systems integrate advanced motor control algorithms with packaging machinery to optimize performance and reduce energy consumption in automated packaging processes.

- Intelligent packaging systems with PMSM integration: Intelligent packaging systems incorporate PMSM technology to improve adaptability and responsiveness in automated packaging lines. These systems use sensors, data analytics, and machine learning algorithms to optimize motor performance, adjust to varying product specifications, and enhance overall packaging efficiency.

- Energy-efficient PMSM-driven packaging solutions: Energy-efficient packaging solutions leverage PMSM technology to reduce power consumption and improve sustainability in automated packaging processes. These systems optimize motor performance, utilize regenerative braking, and implement advanced control strategies to minimize energy waste while maintaining high productivity.

- High-speed PMSM control for packaging applications: High-speed PMSM control systems are developed for packaging applications requiring rapid and precise movements. These systems employ advanced control algorithms, real-time feedback mechanisms, and optimized motor designs to achieve high-speed operation while maintaining accuracy and reliability in packaging processes.

- Modular PMSM-based packaging automation systems: Modular PMSM-based packaging automation systems offer flexibility and scalability in packaging operations. These systems feature interchangeable components, standardized interfaces, and configurable control architectures, allowing for easy adaptation to different packaging requirements and facilitating system upgrades or modifications.

02 Intelligent packaging systems with PMSM integration

Intelligent packaging systems incorporate PMSM technology to achieve smart, adaptive, and flexible packaging solutions. These systems use sensor feedback, real-time monitoring, and advanced control algorithms to adjust packaging parameters dynamically, improving overall system responsiveness and product quality.Expand Specific Solutions03 Energy-efficient packaging automation using PMSM

PMSM-controlled packaging systems are designed to maximize energy efficiency in automated packaging processes. By utilizing precise motor control and optimized motion profiles, these systems reduce power consumption while maintaining high performance, contributing to sustainable manufacturing practices.Expand Specific Solutions04 High-speed packaging solutions with PMSM technology

PMSM technology enables the development of high-speed packaging solutions that can significantly increase production throughput. These systems leverage the superior dynamic response and torque characteristics of PMSMs to achieve rapid acceleration, deceleration, and precise positioning in packaging operations.Expand Specific Solutions05 Fault detection and diagnostics in PMSM-controlled packaging systems

Advanced fault detection and diagnostic features are integrated into PMSM-controlled packaging systems to enhance reliability and minimize downtime. These systems employ real-time monitoring, predictive maintenance algorithms, and intelligent error handling to identify and address potential issues before they impact production.Expand Specific Solutions

Key Industry Players

The automation advances in PMSM-controlled packaging systems are shaping a competitive landscape characterized by rapid technological evolution and market expansion. The industry is in a growth phase, with increasing demand for efficient and precise packaging solutions across various sectors. Market size is expanding as more industries adopt automated packaging systems to improve productivity and reduce costs. Technologically, companies like Sidel Participations SAS, MULTIVAC Sepp Haggenmüller SE & Co. KG, and ROVEMA GmbH are at the forefront, developing sophisticated PMSM-controlled systems that offer enhanced precision, energy efficiency, and flexibility in packaging operations. The technology's maturity is advancing, with continuous innovations in motor control, sensor integration, and machine learning applications driving performance improvements.

Sidel Participations SAS

Technical Solution: Sidel has developed a comprehensive PMSM-based automation solution for packaging systems, focusing on beverage and liquid food packaging. Their approach integrates PMSM technology with advanced robotics and vision systems, creating highly flexible packaging lines. Sidel's solution features a unique "digital twin" concept, where each physical packaging line has a virtual counterpart for simulation and optimization[5]. This allows for rapid line changeovers and real-time performance tuning. The company has also implemented an AI-driven predictive maintenance system that analyzes PMSM performance data to forecast potential issues, reportedly reducing unplanned downtime by up to 40%[6].

Strengths: Innovative digital twin technology, strong focus on flexibility and rapid changeovers, advanced predictive maintenance. Weaknesses: Primarily focused on liquid packaging, which may limit applicability in other sectors.

ROVEMA GmbH

Technical Solution: ROVEMA has made significant advances in PMSM-controlled packaging systems, particularly in the area of vertical form-fill-seal (VFFS) machines. Their solution incorporates a network of distributed PMSM drives, each optimized for specific packaging functions such as film transport, sealing, and cutting. ROVEMA's system utilizes a proprietary control algorithm that synchronizes multiple PMSM drives to achieve ultra-precise packaging operations, reportedly reducing film waste by up to 30%[7]. The company has also developed an energy recovery system that captures braking energy from PMSM motors and redistributes it within the packaging line, leading to overall energy savings of up to 20%[8].

Strengths: Highly specialized for VFFS applications, significant reductions in material waste and energy consumption. Weaknesses: May be less versatile for non-VFFS packaging applications.

Core PMSM Innovations

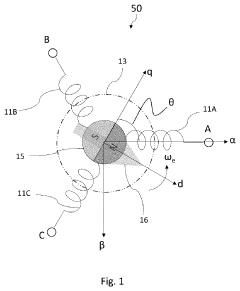

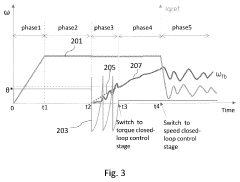

Permanent magnet synchronous motor (PMSM) and method for starting the PMSM

PatentActiveUS11942882B2

Innovation

- A multi-stage control method involving opening a control loop, aligning the rotor with a first direction, abruptly setting a second direction perpendicular to the first, and transitioning through asynchronous driving and closed-loop modes to ensure smooth startup and synchronization.

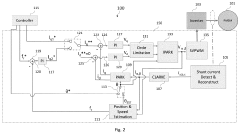

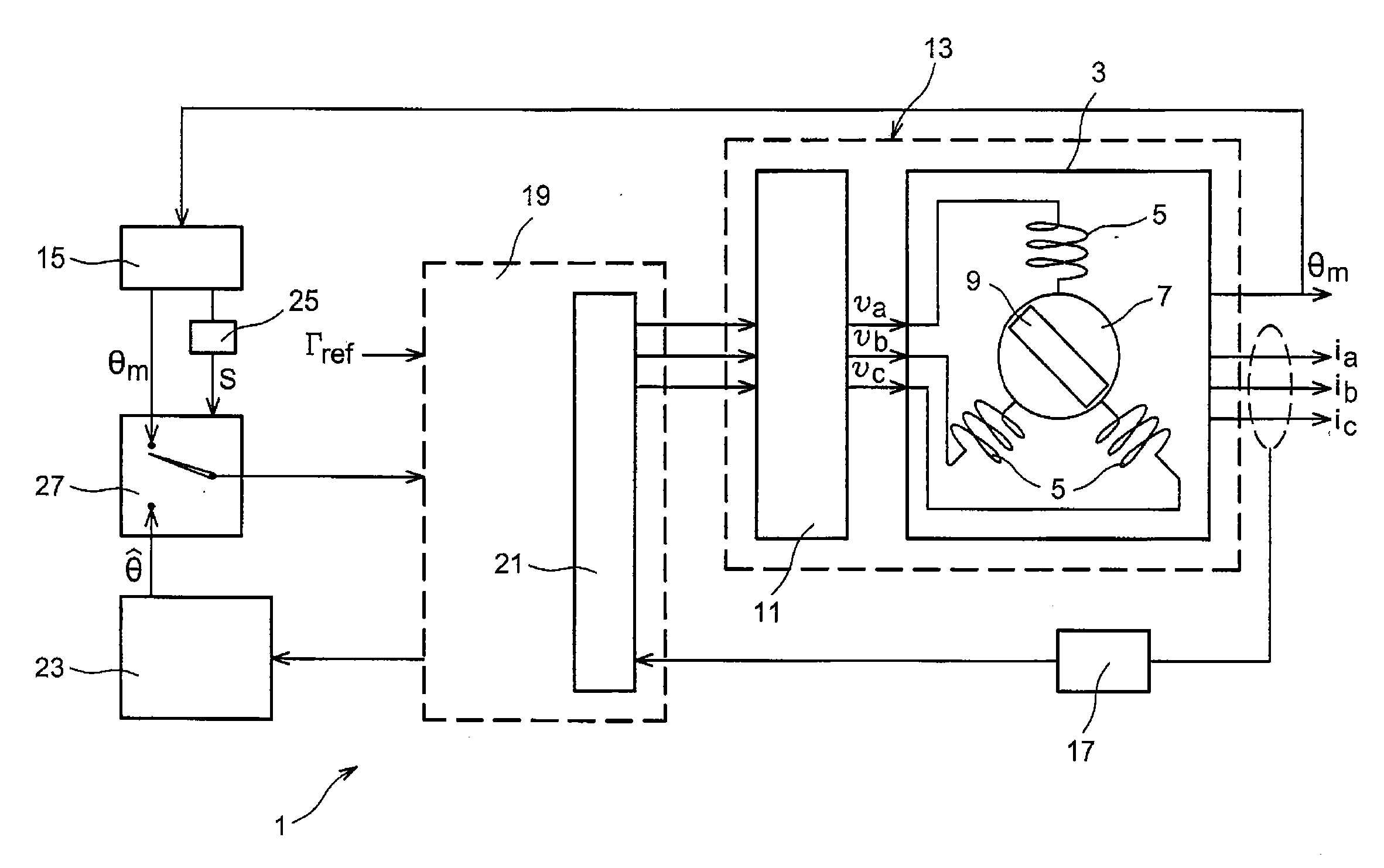

Device for control of a pmsm

PatentActiveUS20120280641A1

Innovation

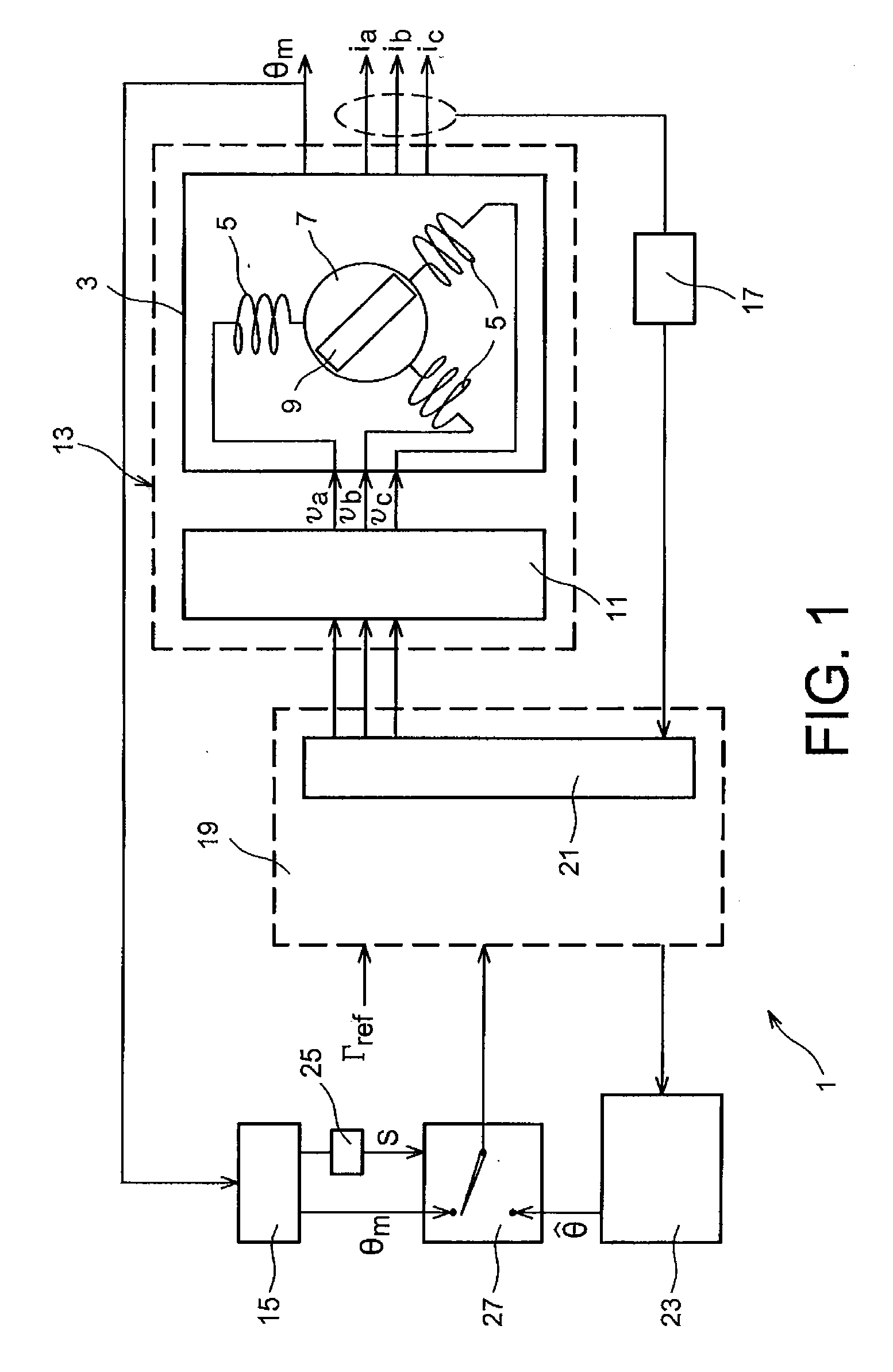

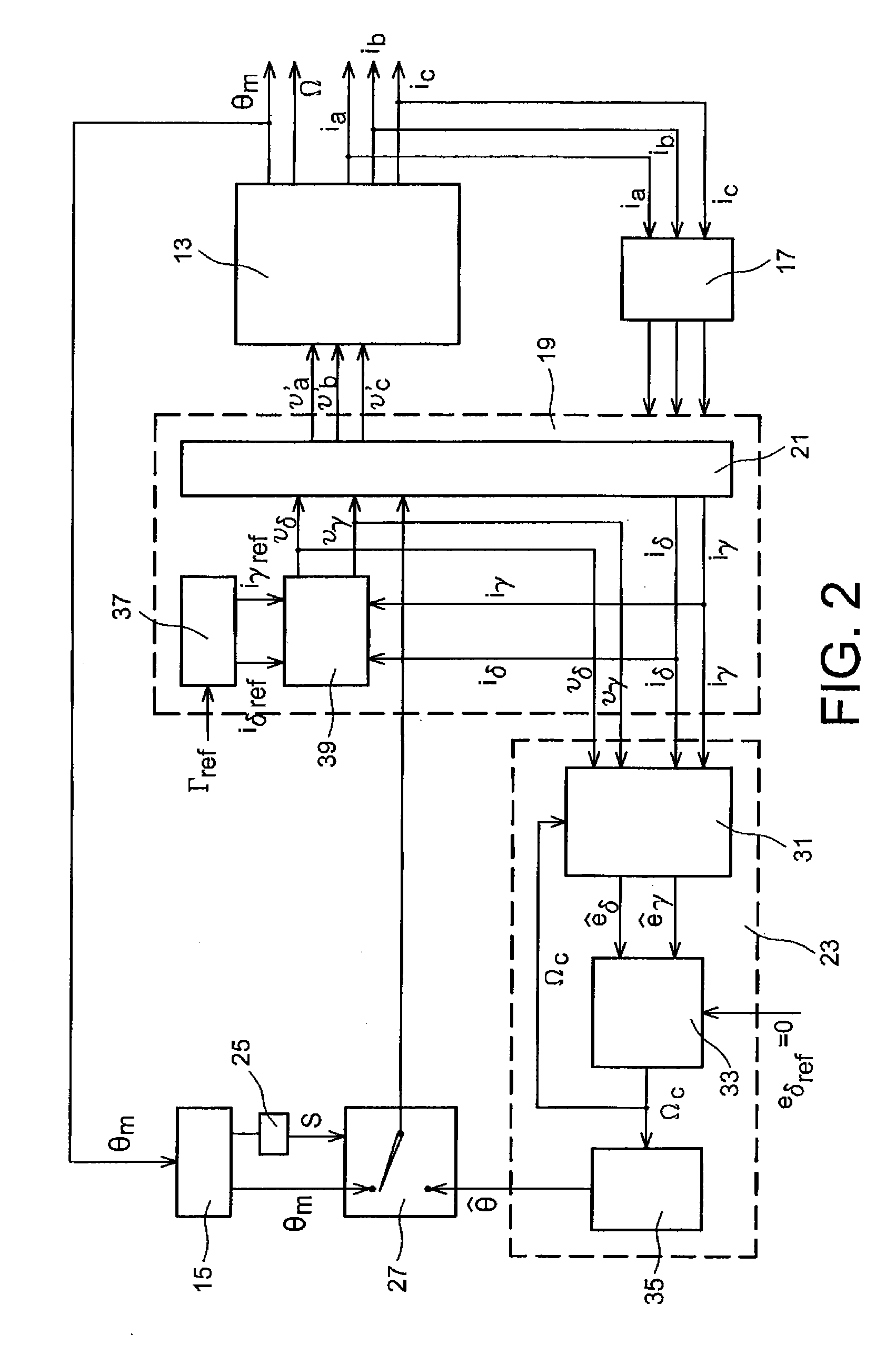

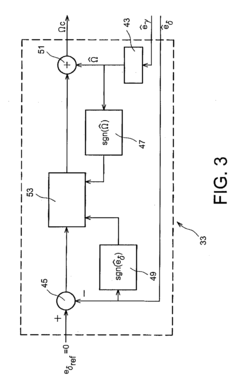

- A control device that includes a sensor for measuring rotor position, estimation means to determine an estimated rotor position, a malfunction detector, and a switch to transition from sensor-based to sensorless control when a malfunction is detected, using an electromotive force estimator and non-linear corrector to ensure global convergence to the desired operating point.

Energy Efficiency Impact

The integration of Permanent Magnet Synchronous Motors (PMSM) in packaging systems has significantly impacted energy efficiency in the automation industry. These motors, known for their high power density and excellent control characteristics, have become a cornerstone in the drive towards more sustainable packaging operations.

PMSM-controlled packaging systems have demonstrated substantial improvements in energy consumption compared to their predecessors. The precise control capabilities of PMSMs allow for optimized speed and torque adjustments, reducing energy waste during acceleration, deceleration, and steady-state operations. This fine-tuned control translates to energy savings of up to 30% in some applications, particularly in high-speed packaging lines where frequent start-stop cycles are common.

The energy efficiency gains are not limited to direct motor operations. PMSM systems often incorporate regenerative braking capabilities, which recover kinetic energy during deceleration phases and feed it back into the power supply. This feature is especially beneficial in packaging processes with frequent direction changes or load variations, further enhancing overall system efficiency.

Moreover, the compact design of PMSMs contributes to reduced heat generation and lower cooling requirements. This cascading effect leads to additional energy savings in ancillary systems, such as HVAC and cooling equipment, which are essential in maintaining optimal operating conditions for packaging machinery.

The implementation of advanced control algorithms in PMSM-driven packaging systems has opened new avenues for energy optimization. Adaptive control strategies that adjust motor parameters based on real-time load conditions ensure that energy consumption is always tailored to the immediate packaging task. This dynamic approach minimizes energy waste during partial load operations, a common scenario in flexible packaging lines.

Furthermore, the integration of PMSMs with smart sensors and IoT technologies has enabled comprehensive energy monitoring and management. Real-time data analytics allow for continuous optimization of energy usage patterns, identifying inefficiencies and suggesting improvements in the packaging process flow. This data-driven approach not only reduces energy consumption but also enhances overall equipment effectiveness (OEE) by minimizing downtime and maximizing productivity.

The energy efficiency impact of PMSM-controlled packaging systems extends beyond individual machines to entire production lines. By synchronizing multiple PMSM-driven components, packaging facilities can achieve a harmonized energy consumption profile, avoiding peak loads and optimizing power distribution across the production floor. This system-wide approach to energy management has led to significant reductions in overall energy costs and carbon footprint for many packaging operations.

PMSM-controlled packaging systems have demonstrated substantial improvements in energy consumption compared to their predecessors. The precise control capabilities of PMSMs allow for optimized speed and torque adjustments, reducing energy waste during acceleration, deceleration, and steady-state operations. This fine-tuned control translates to energy savings of up to 30% in some applications, particularly in high-speed packaging lines where frequent start-stop cycles are common.

The energy efficiency gains are not limited to direct motor operations. PMSM systems often incorporate regenerative braking capabilities, which recover kinetic energy during deceleration phases and feed it back into the power supply. This feature is especially beneficial in packaging processes with frequent direction changes or load variations, further enhancing overall system efficiency.

Moreover, the compact design of PMSMs contributes to reduced heat generation and lower cooling requirements. This cascading effect leads to additional energy savings in ancillary systems, such as HVAC and cooling equipment, which are essential in maintaining optimal operating conditions for packaging machinery.

The implementation of advanced control algorithms in PMSM-driven packaging systems has opened new avenues for energy optimization. Adaptive control strategies that adjust motor parameters based on real-time load conditions ensure that energy consumption is always tailored to the immediate packaging task. This dynamic approach minimizes energy waste during partial load operations, a common scenario in flexible packaging lines.

Furthermore, the integration of PMSMs with smart sensors and IoT technologies has enabled comprehensive energy monitoring and management. Real-time data analytics allow for continuous optimization of energy usage patterns, identifying inefficiencies and suggesting improvements in the packaging process flow. This data-driven approach not only reduces energy consumption but also enhances overall equipment effectiveness (OEE) by minimizing downtime and maximizing productivity.

The energy efficiency impact of PMSM-controlled packaging systems extends beyond individual machines to entire production lines. By synchronizing multiple PMSM-driven components, packaging facilities can achieve a harmonized energy consumption profile, avoiding peak loads and optimizing power distribution across the production floor. This system-wide approach to energy management has led to significant reductions in overall energy costs and carbon footprint for many packaging operations.

Regulatory Compliance

Regulatory compliance plays a crucial role in the development and implementation of automation advances in PMSM-controlled packaging systems. As these systems become more sophisticated and widespread, manufacturers and operators must navigate an increasingly complex landscape of regulations and standards to ensure safety, quality, and environmental responsibility.

In the packaging industry, regulatory bodies such as the Food and Drug Administration (FDA) in the United States and the European Food Safety Authority (EFSA) in the European Union have established stringent guidelines for packaging materials and processes that come into contact with food products. These regulations aim to prevent contamination and ensure the safety of packaged goods for consumers.

For PMSM-controlled packaging systems, compliance with electrical safety standards is paramount. Organizations like the International Electrotechnical Commission (IEC) and the National Electrical Manufacturers Association (NEMA) have developed specific standards for motor control systems, including those utilizing permanent magnet synchronous motors. These standards address issues such as electromagnetic compatibility, thermal management, and protection against electrical hazards.

Environmental regulations also impact the design and operation of packaging systems. Many countries have implemented energy efficiency standards that apply to industrial motors and drive systems. The European Union's Ecodesign Directive, for instance, sets minimum efficiency requirements for electric motors, including those used in packaging applications. Manufacturers must ensure that their PMSM-controlled systems meet or exceed these energy performance standards.

Workplace safety regulations, such as those enforced by the Occupational Safety and Health Administration (OSHA) in the United States, require packaging equipment to incorporate appropriate safeguards to protect operators from mechanical and electrical hazards. This includes features like emergency stop buttons, safety interlocks, and proper guarding of moving parts.

As automation advances, data protection and cybersecurity regulations are becoming increasingly relevant. With the integration of IoT and cloud technologies in packaging systems, manufacturers must comply with data privacy laws such as the General Data Protection Regulation (GDPR) in the European Union and similar regulations in other jurisdictions.

Compliance with these diverse regulatory requirements necessitates a comprehensive approach to system design, testing, and documentation. Manufacturers of PMSM-controlled packaging systems must implement robust quality management systems and maintain detailed records of compliance testing and certification. Regular audits and inspections may be required to ensure ongoing adherence to applicable standards and regulations.

In the packaging industry, regulatory bodies such as the Food and Drug Administration (FDA) in the United States and the European Food Safety Authority (EFSA) in the European Union have established stringent guidelines for packaging materials and processes that come into contact with food products. These regulations aim to prevent contamination and ensure the safety of packaged goods for consumers.

For PMSM-controlled packaging systems, compliance with electrical safety standards is paramount. Organizations like the International Electrotechnical Commission (IEC) and the National Electrical Manufacturers Association (NEMA) have developed specific standards for motor control systems, including those utilizing permanent magnet synchronous motors. These standards address issues such as electromagnetic compatibility, thermal management, and protection against electrical hazards.

Environmental regulations also impact the design and operation of packaging systems. Many countries have implemented energy efficiency standards that apply to industrial motors and drive systems. The European Union's Ecodesign Directive, for instance, sets minimum efficiency requirements for electric motors, including those used in packaging applications. Manufacturers must ensure that their PMSM-controlled systems meet or exceed these energy performance standards.

Workplace safety regulations, such as those enforced by the Occupational Safety and Health Administration (OSHA) in the United States, require packaging equipment to incorporate appropriate safeguards to protect operators from mechanical and electrical hazards. This includes features like emergency stop buttons, safety interlocks, and proper guarding of moving parts.

As automation advances, data protection and cybersecurity regulations are becoming increasingly relevant. With the integration of IoT and cloud technologies in packaging systems, manufacturers must comply with data privacy laws such as the General Data Protection Regulation (GDPR) in the European Union and similar regulations in other jurisdictions.

Compliance with these diverse regulatory requirements necessitates a comprehensive approach to system design, testing, and documentation. Manufacturers of PMSM-controlled packaging systems must implement robust quality management systems and maintain detailed records of compliance testing and certification. Regular audits and inspections may be required to ensure ongoing adherence to applicable standards and regulations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!