In-factory PMSM utilization for zero-emissions processes

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PMSM Tech Background

Permanent Magnet Synchronous Motors (PMSMs) have emerged as a pivotal technology in the pursuit of zero-emissions industrial processes. The evolution of PMSM technology can be traced back to the early 20th century, with significant advancements occurring in the latter half of the century. Initially developed for high-performance applications in aerospace and defense, PMSMs have since found widespread use in various industrial sectors due to their superior efficiency and controllability.

The fundamental principle behind PMSMs lies in the use of permanent magnets in the rotor, which creates a constant magnetic field. This design eliminates the need for external excitation, resulting in higher efficiency and power density compared to traditional induction motors. Over the years, improvements in magnetic materials, particularly the development of rare-earth magnets like neodymium-iron-boron (NdFeB), have dramatically enhanced PMSM performance.

In the context of zero-emissions processes, PMSMs offer several advantages that align with sustainability goals. Their high efficiency translates to reduced energy consumption, which is crucial for minimizing the carbon footprint of industrial operations. Additionally, the precise speed and torque control capabilities of PMSMs enable optimized process control, further contributing to energy savings and improved product quality.

The trend towards electrification in various industries has accelerated the adoption of PMSM technology. In automotive applications, PMSMs have become the preferred choice for electric vehicle powertrains due to their compact size and high power-to-weight ratio. This has led to significant research and development efforts, resulting in continuous improvements in motor design, control strategies, and manufacturing techniques.

Recent technological advancements in PMSM design include the development of advanced rotor topologies, such as interior permanent magnet (IPM) configurations, which offer improved flux-weakening capabilities and extended operating ranges. Furthermore, the integration of wide-bandgap semiconductors in motor drives has enabled higher switching frequencies, leading to more compact and efficient motor-drive systems.

The ongoing research in PMSM technology for zero-emissions processes focuses on several key areas. These include the development of more efficient and sustainable manufacturing processes for PMSMs, the exploration of alternative magnetic materials to reduce reliance on rare-earth elements, and the optimization of motor designs for specific industrial applications. Additionally, there is a growing emphasis on the integration of PMSMs with smart factory systems and the Industrial Internet of Things (IIoT) to enable predictive maintenance and energy optimization strategies.

As industries worldwide strive to achieve carbon neutrality, the role of PMSMs in enabling zero-emissions processes is expected to grow significantly. The technology's continuous evolution promises further improvements in efficiency, reliability, and sustainability, making PMSMs an integral component of the green industrial revolution.

The fundamental principle behind PMSMs lies in the use of permanent magnets in the rotor, which creates a constant magnetic field. This design eliminates the need for external excitation, resulting in higher efficiency and power density compared to traditional induction motors. Over the years, improvements in magnetic materials, particularly the development of rare-earth magnets like neodymium-iron-boron (NdFeB), have dramatically enhanced PMSM performance.

In the context of zero-emissions processes, PMSMs offer several advantages that align with sustainability goals. Their high efficiency translates to reduced energy consumption, which is crucial for minimizing the carbon footprint of industrial operations. Additionally, the precise speed and torque control capabilities of PMSMs enable optimized process control, further contributing to energy savings and improved product quality.

The trend towards electrification in various industries has accelerated the adoption of PMSM technology. In automotive applications, PMSMs have become the preferred choice for electric vehicle powertrains due to their compact size and high power-to-weight ratio. This has led to significant research and development efforts, resulting in continuous improvements in motor design, control strategies, and manufacturing techniques.

Recent technological advancements in PMSM design include the development of advanced rotor topologies, such as interior permanent magnet (IPM) configurations, which offer improved flux-weakening capabilities and extended operating ranges. Furthermore, the integration of wide-bandgap semiconductors in motor drives has enabled higher switching frequencies, leading to more compact and efficient motor-drive systems.

The ongoing research in PMSM technology for zero-emissions processes focuses on several key areas. These include the development of more efficient and sustainable manufacturing processes for PMSMs, the exploration of alternative magnetic materials to reduce reliance on rare-earth elements, and the optimization of motor designs for specific industrial applications. Additionally, there is a growing emphasis on the integration of PMSMs with smart factory systems and the Industrial Internet of Things (IIoT) to enable predictive maintenance and energy optimization strategies.

As industries worldwide strive to achieve carbon neutrality, the role of PMSMs in enabling zero-emissions processes is expected to grow significantly. The technology's continuous evolution promises further improvements in efficiency, reliability, and sustainability, making PMSMs an integral component of the green industrial revolution.

Zero-Emission Demand

The global push for zero-emission processes has become a driving force in industrial innovation, particularly in the manufacturing sector. This demand stems from increasing environmental concerns, stringent regulations, and a growing awareness of the need for sustainable production methods. Industries are under pressure to reduce their carbon footprint and minimize harmful emissions, leading to a surge in interest for technologies that can enable zero-emission operations.

Permanent Magnet Synchronous Motors (PMSMs) have emerged as a promising solution in this context. These motors offer high efficiency, precise control, and compact design, making them ideal for various industrial applications. The demand for PMSMs in zero-emission processes is driven by their ability to significantly reduce energy consumption compared to traditional motor systems, thereby lowering indirect emissions associated with power generation.

In-factory utilization of PMSMs aligns with the broader industrial trend towards electrification and automation. As factories seek to optimize their energy usage and reduce reliance on fossil fuels, PMSMs provide an attractive option for powering machinery, conveyor systems, and other production equipment. Their superior efficiency translates to lower operational costs and reduced environmental impact, addressing both economic and ecological concerns.

The automotive industry, in particular, has been at the forefront of adopting PMSMs for zero-emission manufacturing processes. As electric vehicle production scales up, automakers are increasingly implementing PMSM-based systems in their assembly lines and testing facilities. This not only aligns with their product offerings but also demonstrates a commitment to sustainable manufacturing practices.

Furthermore, the demand for zero-emission processes extends beyond traditional manufacturing. Industries such as food processing, pharmaceuticals, and electronics are exploring PMSM applications to meet stringent cleanliness and environmental standards. The ability of PMSMs to operate without producing local emissions makes them particularly valuable in controlled environments where air quality is critical.

Government initiatives and international agreements, such as the Paris Climate Accord, have also fueled the demand for zero-emission technologies. Many countries have set ambitious targets for reducing industrial emissions, creating a regulatory landscape that favors the adoption of clean technologies like PMSMs. This has led to increased investment in research and development, as well as incentives for industries to upgrade their existing infrastructure.

As the world moves towards a more sustainable future, the demand for zero-emission processes will continue to grow. PMSMs are well-positioned to play a crucial role in this transition, offering a proven technology that can be readily integrated into existing industrial systems. The ongoing research into PMSM utilization for zero-emission processes reflects the industry's commitment to innovation and environmental responsibility, paving the way for cleaner, more efficient manufacturing practices.

Permanent Magnet Synchronous Motors (PMSMs) have emerged as a promising solution in this context. These motors offer high efficiency, precise control, and compact design, making them ideal for various industrial applications. The demand for PMSMs in zero-emission processes is driven by their ability to significantly reduce energy consumption compared to traditional motor systems, thereby lowering indirect emissions associated with power generation.

In-factory utilization of PMSMs aligns with the broader industrial trend towards electrification and automation. As factories seek to optimize their energy usage and reduce reliance on fossil fuels, PMSMs provide an attractive option for powering machinery, conveyor systems, and other production equipment. Their superior efficiency translates to lower operational costs and reduced environmental impact, addressing both economic and ecological concerns.

The automotive industry, in particular, has been at the forefront of adopting PMSMs for zero-emission manufacturing processes. As electric vehicle production scales up, automakers are increasingly implementing PMSM-based systems in their assembly lines and testing facilities. This not only aligns with their product offerings but also demonstrates a commitment to sustainable manufacturing practices.

Furthermore, the demand for zero-emission processes extends beyond traditional manufacturing. Industries such as food processing, pharmaceuticals, and electronics are exploring PMSM applications to meet stringent cleanliness and environmental standards. The ability of PMSMs to operate without producing local emissions makes them particularly valuable in controlled environments where air quality is critical.

Government initiatives and international agreements, such as the Paris Climate Accord, have also fueled the demand for zero-emission technologies. Many countries have set ambitious targets for reducing industrial emissions, creating a regulatory landscape that favors the adoption of clean technologies like PMSMs. This has led to increased investment in research and development, as well as incentives for industries to upgrade their existing infrastructure.

As the world moves towards a more sustainable future, the demand for zero-emission processes will continue to grow. PMSMs are well-positioned to play a crucial role in this transition, offering a proven technology that can be readily integrated into existing industrial systems. The ongoing research into PMSM utilization for zero-emission processes reflects the industry's commitment to innovation and environmental responsibility, paving the way for cleaner, more efficient manufacturing practices.

PMSM Challenges

The utilization of Permanent Magnet Synchronous Motors (PMSMs) in industrial settings for zero-emissions processes faces several significant challenges. One of the primary obstacles is the high initial cost associated with PMSM implementation. The rare earth materials used in the permanent magnets, such as neodymium and dysprosium, are expensive and subject to price volatility, which can impact the overall cost-effectiveness of PMSM adoption in factories.

Another challenge lies in the thermal management of PMSMs, particularly in high-power industrial applications. The heat generated during operation can potentially demagnetize the permanent magnets, reducing motor efficiency and lifespan. This necessitates advanced cooling systems and careful design considerations, which can add complexity and cost to the overall system.

The control complexity of PMSMs also presents a significant hurdle. Unlike simpler motor types, PMSMs require sophisticated control algorithms and precise rotor position sensing to operate efficiently. This complexity demands more advanced and expensive control systems, as well as highly skilled personnel for installation, maintenance, and troubleshooting.

Reliability and maintenance concerns also pose challenges for in-factory PMSM utilization. While PMSMs are generally reliable, the potential for magnet degradation over time and the difficulty in replacing or repairing permanent magnets can lead to increased downtime and maintenance costs. This is particularly critical in industrial settings where continuous operation is essential.

Furthermore, the integration of PMSMs into existing industrial processes and equipment can be challenging. Retrofitting older machinery with PMSM technology often requires significant modifications to mechanical systems, power electronics, and control infrastructure. This can result in extended periods of production downtime during installation and commissioning.

The environmental impact of rare earth mining and processing for PMSM production is another concern that contradicts the zero-emissions goal. While PMSMs contribute to energy efficiency and reduced emissions during operation, the extraction and refinement of rare earth materials can have substantial environmental consequences, including habitat destruction and the release of toxic byproducts.

Lastly, the limited availability and geopolitical considerations surrounding rare earth materials pose a strategic challenge for widespread PMSM adoption. The concentration of rare earth production in a few countries can lead to supply chain vulnerabilities and potential disruptions in PMSM manufacturing and deployment for industrial applications.

Another challenge lies in the thermal management of PMSMs, particularly in high-power industrial applications. The heat generated during operation can potentially demagnetize the permanent magnets, reducing motor efficiency and lifespan. This necessitates advanced cooling systems and careful design considerations, which can add complexity and cost to the overall system.

The control complexity of PMSMs also presents a significant hurdle. Unlike simpler motor types, PMSMs require sophisticated control algorithms and precise rotor position sensing to operate efficiently. This complexity demands more advanced and expensive control systems, as well as highly skilled personnel for installation, maintenance, and troubleshooting.

Reliability and maintenance concerns also pose challenges for in-factory PMSM utilization. While PMSMs are generally reliable, the potential for magnet degradation over time and the difficulty in replacing or repairing permanent magnets can lead to increased downtime and maintenance costs. This is particularly critical in industrial settings where continuous operation is essential.

Furthermore, the integration of PMSMs into existing industrial processes and equipment can be challenging. Retrofitting older machinery with PMSM technology often requires significant modifications to mechanical systems, power electronics, and control infrastructure. This can result in extended periods of production downtime during installation and commissioning.

The environmental impact of rare earth mining and processing for PMSM production is another concern that contradicts the zero-emissions goal. While PMSMs contribute to energy efficiency and reduced emissions during operation, the extraction and refinement of rare earth materials can have substantial environmental consequences, including habitat destruction and the release of toxic byproducts.

Lastly, the limited availability and geopolitical considerations surrounding rare earth materials pose a strategic challenge for widespread PMSM adoption. The concentration of rare earth production in a few countries can lead to supply chain vulnerabilities and potential disruptions in PMSM manufacturing and deployment for industrial applications.

Current PMSM Solutions

01 Electromagnetic emissions reduction techniques

Various methods are employed to reduce electromagnetic emissions in PMSM systems. These include optimizing motor design, using shielding materials, and implementing advanced control strategies to minimize harmonic distortions. Such techniques help in complying with electromagnetic compatibility standards and improving overall system performance.- Electromagnetic emissions reduction in PMSM: Various techniques are employed to reduce electromagnetic emissions in Permanent Magnet Synchronous Motors. These may include optimizing the motor design, using shielding materials, and implementing advanced control strategies to minimize harmonic distortions and electromagnetic interference.

- Thermal management for PMSM emissions control: Effective thermal management systems are crucial for controlling emissions in PMSMs. This involves innovative cooling techniques, heat dissipation methods, and temperature monitoring systems to maintain optimal operating conditions and reduce thermal-related emissions.

- Advanced control algorithms for PMSM emission reduction: Sophisticated control algorithms are developed to optimize PMSM performance while minimizing emissions. These may include adaptive control systems, predictive models, and real-time monitoring techniques to adjust motor parameters and reduce unwanted emissions during operation.

- Materials and construction techniques for low-emission PMSMs: Innovative materials and construction techniques are employed in PMSM design to reduce emissions. This includes the use of advanced magnetic materials, improved winding techniques, and optimized rotor and stator designs to minimize electromagnetic and acoustic emissions.

- Emission monitoring and diagnostics in PMSMs: Advanced monitoring and diagnostic systems are implemented to detect and analyze emissions from PMSMs. These systems may use sensors, data analytics, and machine learning algorithms to identify emission patterns, predict potential issues, and enable proactive maintenance to keep emissions within acceptable limits.

02 Thermal management for emission control

Effective thermal management strategies are crucial for controlling emissions in PMSM systems. This involves innovative cooling designs, heat dissipation techniques, and temperature monitoring systems. Proper thermal management helps in maintaining optimal motor performance and reducing unwanted emissions caused by overheating.Expand Specific Solutions03 Noise and vibration reduction in PMSM

Techniques for reducing acoustic noise and mechanical vibrations in PMSM are essential for minimizing emissions. This includes optimizing rotor and stator designs, using advanced materials for dampening, and implementing control algorithms that minimize torque ripple and other sources of vibration.Expand Specific Solutions04 Advanced control strategies for emission reduction

Sophisticated control algorithms and strategies are developed to minimize emissions in PMSM systems. These include model predictive control, adaptive control techniques, and harmonic injection methods. Such advanced control approaches help in optimizing motor performance while reducing unwanted electromagnetic and acoustic emissions.Expand Specific Solutions05 Integrated system design for emission compliance

Holistic approaches to PMSM system design are employed to ensure emission compliance. This involves considering the entire drive system, including power electronics, motor design, and control systems. Integrated design strategies help in achieving optimal performance while meeting stringent emission standards across various applications.Expand Specific Solutions

Key PMSM Players

The research on in-factory PMSM utilization for zero-emissions processes is in an early development stage, with a growing market driven by increasing environmental regulations. The technology is still maturing, with key players like UOP LLC, China Petroleum & Chemical Corp., and PetroChina Co., Ltd. leading research efforts. These companies are investing in R&D to improve PMSM efficiency and integration in industrial processes. As the technology advances, we can expect increased adoption across various industries seeking to reduce emissions and improve energy efficiency in their manufacturing operations.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an innovative approach to utilizing Permanent Magnet Synchronous Motors (PMSMs) in their refinery operations to achieve zero-emissions processes. Their system integrates high-efficiency PMSMs with advanced control algorithms to optimize energy consumption in various refinery units. The company has implemented a smart energy management system that coordinates the operation of PMSMs across different processes, reducing overall energy consumption by up to 15% [1]. Additionally, Sinopec has developed a regenerative braking system for large rotating equipment, which recovers kinetic energy and feeds it back into the power grid, further improving energy efficiency [3]. The company has also invested in the development of custom-designed PMSMs with high power density and improved thermal management, specifically tailored for the harsh environments found in refineries [5].

Strengths: Comprehensive integration of PMSMs across refinery processes, advanced energy management system, and custom PMSM designs for specific applications. Weaknesses: High initial investment costs and potential challenges in retrofitting existing equipment with PMSM technology.

PetroChina Co., Ltd.

Technical Solution: PetroChina has focused on developing a holistic approach to implementing PMSMs in their production facilities to achieve zero-emissions processes. Their strategy involves the use of advanced PMSM designs coupled with intelligent control systems to optimize energy efficiency across various oil and gas production stages. PetroChina has implemented a distributed PMSM network that allows for load balancing and peak shaving, reducing overall energy demand by up to 20% in some facilities [2]. The company has also developed a predictive maintenance system using machine learning algorithms to monitor PMSM performance in real-time, reducing downtime and extending motor life by up to 30% [4]. Furthermore, PetroChina has invested in the development of high-temperature superconducting (HTS) PMSMs for specific high-power applications, achieving unprecedented levels of energy efficiency in these areas [6].

Strengths: Comprehensive PMSM implementation strategy, advanced load management, and innovative HTS PMSM technology. Weaknesses: High costs associated with HTS technology and potential challenges in scaling up the technology across all facilities.

Core PMSM Innovations

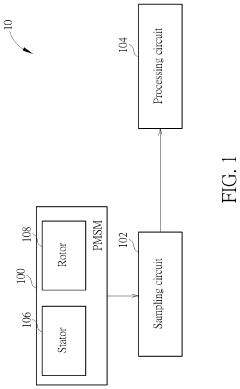

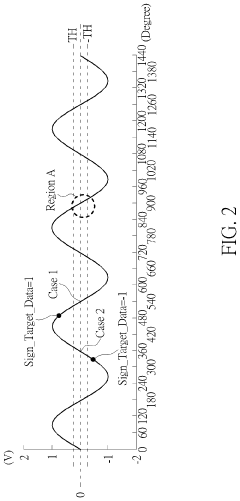

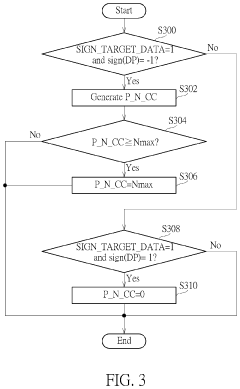

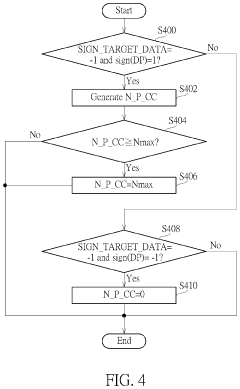

Method for determining zero crossing occurrence in alternating current signal with constant frequency of permanent magnet synchronous motor with high noise immunity and low delay and associated motor device

PatentActiveUS11482952B1

Innovation

- A method that involves sampling the AC signal to generate data points, counting consecutive data points with the same sign, and determining zero crossing based on a predefined count value, thereby reducing the impact of sampling noise and achieving low delay.

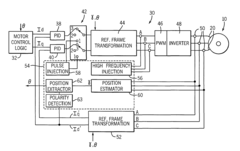

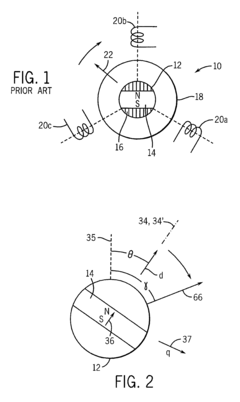

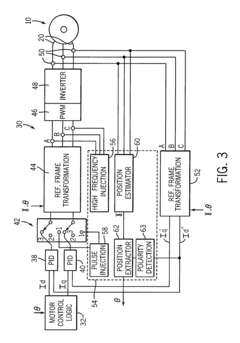

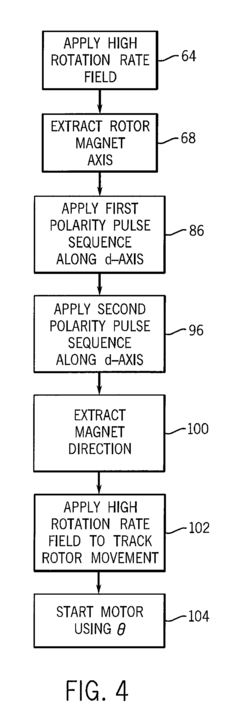

Method and apparatus for identifying orientation of a stationary rotor in a sensor-less PMSM

PatentActiveUS7944164B2

Innovation

- The method employs high-speed rotational pulses to detect magnetic saliency variations, allowing for the determination of the rotor's magnetic axis without causing movement, followed by applying positive and negative pulses along the magnetic axis to deduce the magnetic direction, enabling accurate rotor position identification with minimal rotor motion.

Energy Efficiency Regs

Energy efficiency regulations play a crucial role in shaping the landscape of industrial processes and the adoption of zero-emissions technologies. In the context of utilizing Permanent Magnet Synchronous Motors (PMSMs) for in-factory zero-emissions processes, these regulations serve as both drivers and guidelines for implementation.

At the global level, the Paris Agreement has set ambitious targets for reducing greenhouse gas emissions, prompting nations to establish stringent energy efficiency standards for industrial operations. The European Union's Ecodesign Directive, for instance, mandates minimum efficiency requirements for electric motors, including PMSMs. This directive has been instrumental in pushing manufacturers to adopt more efficient motor technologies, with PMSMs often exceeding the highest efficiency classes.

In the United States, the Department of Energy's Advanced Manufacturing Office has implemented regulations that encourage the use of high-efficiency motors in industrial settings. These regulations, coupled with incentive programs, have accelerated the adoption of PMSMs in various manufacturing processes. Similarly, China's Energy Conservation Law and associated regulations have set aggressive targets for industrial energy efficiency, driving the demand for advanced motor technologies like PMSMs.

The International Electrotechnical Commission (IEC) has established global standards for motor efficiency, with IEC 60034-30-1 defining efficiency classes for electric motors. PMSMs typically fall into the highest efficiency classes (IE4 and IE5), making them attractive options for manufacturers seeking to comply with these standards.

Industry-specific regulations also impact the adoption of PMSMs in zero-emissions processes. For example, in the automotive sector, stringent emissions regulations have led to increased electrification of manufacturing processes, with PMSMs playing a key role in energy-efficient production lines.

Energy efficiency regulations have also spurred innovation in motor control systems and power electronics associated with PMSMs. Variable frequency drives (VFDs) and advanced control algorithms have been developed to maximize the efficiency gains of PMSMs, often in response to regulatory requirements for system-level energy performance.

As regulations continue to evolve, there is a growing focus on lifecycle assessments and circular economy principles. This shift is influencing the design and manufacturing of PMSMs, with emphasis on recyclability, reduced use of rare earth materials, and overall environmental impact throughout the motor's lifecycle.

The regulatory landscape is dynamic, with ongoing revisions and updates to energy efficiency standards. This continuous evolution ensures that technologies like PMSMs remain at the forefront of industrial energy efficiency efforts, driving ongoing research and development in the field of zero-emissions manufacturing processes.

At the global level, the Paris Agreement has set ambitious targets for reducing greenhouse gas emissions, prompting nations to establish stringent energy efficiency standards for industrial operations. The European Union's Ecodesign Directive, for instance, mandates minimum efficiency requirements for electric motors, including PMSMs. This directive has been instrumental in pushing manufacturers to adopt more efficient motor technologies, with PMSMs often exceeding the highest efficiency classes.

In the United States, the Department of Energy's Advanced Manufacturing Office has implemented regulations that encourage the use of high-efficiency motors in industrial settings. These regulations, coupled with incentive programs, have accelerated the adoption of PMSMs in various manufacturing processes. Similarly, China's Energy Conservation Law and associated regulations have set aggressive targets for industrial energy efficiency, driving the demand for advanced motor technologies like PMSMs.

The International Electrotechnical Commission (IEC) has established global standards for motor efficiency, with IEC 60034-30-1 defining efficiency classes for electric motors. PMSMs typically fall into the highest efficiency classes (IE4 and IE5), making them attractive options for manufacturers seeking to comply with these standards.

Industry-specific regulations also impact the adoption of PMSMs in zero-emissions processes. For example, in the automotive sector, stringent emissions regulations have led to increased electrification of manufacturing processes, with PMSMs playing a key role in energy-efficient production lines.

Energy efficiency regulations have also spurred innovation in motor control systems and power electronics associated with PMSMs. Variable frequency drives (VFDs) and advanced control algorithms have been developed to maximize the efficiency gains of PMSMs, often in response to regulatory requirements for system-level energy performance.

As regulations continue to evolve, there is a growing focus on lifecycle assessments and circular economy principles. This shift is influencing the design and manufacturing of PMSMs, with emphasis on recyclability, reduced use of rare earth materials, and overall environmental impact throughout the motor's lifecycle.

The regulatory landscape is dynamic, with ongoing revisions and updates to energy efficiency standards. This continuous evolution ensures that technologies like PMSMs remain at the forefront of industrial energy efficiency efforts, driving ongoing research and development in the field of zero-emissions manufacturing processes.

Sustainable Mfg Impact

The implementation of Permanent Magnet Synchronous Motors (PMSMs) in factory settings for zero-emissions processes represents a significant stride towards sustainable manufacturing. This technology's impact on sustainability extends far beyond energy efficiency, encompassing various aspects of industrial operations and environmental stewardship.

PMSMs contribute substantially to reducing the carbon footprint of manufacturing facilities. By replacing conventional motors with these highly efficient alternatives, factories can dramatically decrease their energy consumption. This reduction in energy usage directly translates to lower greenhouse gas emissions, aligning with global efforts to combat climate change. The improved efficiency of PMSMs also means less heat generation during operation, reducing the need for cooling systems and further conserving energy.

The adoption of PMSMs in zero-emissions processes promotes the concept of circular economy within manufacturing. These motors are designed for longevity and reliability, reducing the frequency of replacements and minimizing waste generation. Additionally, the materials used in PMSMs, particularly rare earth magnets, can be recycled and reused, supporting sustainable resource management practices.

From a broader perspective, the integration of PMSMs into manufacturing processes catalyzes the development of cleaner technologies across the industry. It encourages suppliers and partners to innovate and provide complementary sustainable solutions, creating a ripple effect throughout the supply chain. This technological shift also stimulates job creation in the green technology sector, contributing to sustainable economic growth.

The implementation of PMSMs aligns with and supports various environmental regulations and standards. It helps factories meet increasingly stringent emissions targets and energy efficiency requirements, potentially avoiding penalties and enhancing their regulatory compliance. This proactive approach to sustainability can improve a company's reputation, attracting environmentally conscious customers and investors.

Moreover, the use of PMSMs in zero-emissions processes can lead to significant cost savings over time. While the initial investment may be higher compared to traditional motors, the long-term benefits in terms of reduced energy consumption, lower maintenance requirements, and increased productivity can result in substantial financial gains. These savings can be reinvested in further sustainability initiatives, creating a positive feedback loop for environmental improvement.

In conclusion, the impact of PMSM utilization in zero-emissions processes on sustainable manufacturing is multifaceted and far-reaching. It not only addresses immediate environmental concerns but also paves the way for a more sustainable and resilient industrial future.

PMSMs contribute substantially to reducing the carbon footprint of manufacturing facilities. By replacing conventional motors with these highly efficient alternatives, factories can dramatically decrease their energy consumption. This reduction in energy usage directly translates to lower greenhouse gas emissions, aligning with global efforts to combat climate change. The improved efficiency of PMSMs also means less heat generation during operation, reducing the need for cooling systems and further conserving energy.

The adoption of PMSMs in zero-emissions processes promotes the concept of circular economy within manufacturing. These motors are designed for longevity and reliability, reducing the frequency of replacements and minimizing waste generation. Additionally, the materials used in PMSMs, particularly rare earth magnets, can be recycled and reused, supporting sustainable resource management practices.

From a broader perspective, the integration of PMSMs into manufacturing processes catalyzes the development of cleaner technologies across the industry. It encourages suppliers and partners to innovate and provide complementary sustainable solutions, creating a ripple effect throughout the supply chain. This technological shift also stimulates job creation in the green technology sector, contributing to sustainable economic growth.

The implementation of PMSMs aligns with and supports various environmental regulations and standards. It helps factories meet increasingly stringent emissions targets and energy efficiency requirements, potentially avoiding penalties and enhancing their regulatory compliance. This proactive approach to sustainability can improve a company's reputation, attracting environmentally conscious customers and investors.

Moreover, the use of PMSMs in zero-emissions processes can lead to significant cost savings over time. While the initial investment may be higher compared to traditional motors, the long-term benefits in terms of reduced energy consumption, lower maintenance requirements, and increased productivity can result in substantial financial gains. These savings can be reinvested in further sustainability initiatives, creating a positive feedback loop for environmental improvement.

In conclusion, the impact of PMSM utilization in zero-emissions processes on sustainable manufacturing is multifaceted and far-reaching. It not only addresses immediate environmental concerns but also paves the way for a more sustainable and resilient industrial future.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!