Reactive power compensation in PMSM-driven systems

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PMSM Reactive Power Background and Objectives

Reactive power compensation in Permanent Magnet Synchronous Motor (PMSM) driven systems has emerged as a critical area of focus in modern electrical engineering. The evolution of this technology can be traced back to the early development of synchronous motors in the late 19th century. However, it was not until the advent of high-performance permanent magnets and advanced power electronics that PMSM systems gained widespread adoption in various industrial applications.

The primary objective of reactive power compensation in PMSM-driven systems is to optimize power factor, enhance system efficiency, and improve overall performance. This technology aims to address the inherent challenges associated with reactive power consumption in electric motor operations, which can lead to increased energy losses, reduced system capacity, and potential instability in power networks.

Over the past few decades, the field has witnessed significant advancements, driven by the growing demand for energy-efficient and high-performance motor systems across industries such as automotive, renewable energy, and industrial automation. The integration of sophisticated control algorithms and power electronic converters has played a crucial role in enhancing the reactive power compensation capabilities of PMSM systems.

One of the key trends in this domain is the development of more accurate and responsive control strategies that can dynamically adjust the reactive power flow in real-time. This trend is closely aligned with the broader movement towards smart grid technologies and the need for more flexible and resilient power systems.

Another important aspect of the technology's evolution is the increasing focus on harmonizing PMSM systems with renewable energy sources. As the world transitions towards cleaner energy alternatives, the ability to efficiently manage reactive power becomes even more critical in maintaining grid stability and power quality.

The future trajectory of reactive power compensation in PMSM-driven systems is likely to be shaped by advancements in materials science, particularly in the development of more efficient permanent magnets and power semiconductor devices. Additionally, the integration of artificial intelligence and machine learning algorithms is expected to further enhance the predictive and adaptive capabilities of these systems.

In conclusion, the background and objectives of reactive power compensation in PMSM-driven systems reflect a dynamic and rapidly evolving field. The technology continues to push the boundaries of motor efficiency and power system stability, with far-reaching implications for energy conservation and sustainable industrial practices.

The primary objective of reactive power compensation in PMSM-driven systems is to optimize power factor, enhance system efficiency, and improve overall performance. This technology aims to address the inherent challenges associated with reactive power consumption in electric motor operations, which can lead to increased energy losses, reduced system capacity, and potential instability in power networks.

Over the past few decades, the field has witnessed significant advancements, driven by the growing demand for energy-efficient and high-performance motor systems across industries such as automotive, renewable energy, and industrial automation. The integration of sophisticated control algorithms and power electronic converters has played a crucial role in enhancing the reactive power compensation capabilities of PMSM systems.

One of the key trends in this domain is the development of more accurate and responsive control strategies that can dynamically adjust the reactive power flow in real-time. This trend is closely aligned with the broader movement towards smart grid technologies and the need for more flexible and resilient power systems.

Another important aspect of the technology's evolution is the increasing focus on harmonizing PMSM systems with renewable energy sources. As the world transitions towards cleaner energy alternatives, the ability to efficiently manage reactive power becomes even more critical in maintaining grid stability and power quality.

The future trajectory of reactive power compensation in PMSM-driven systems is likely to be shaped by advancements in materials science, particularly in the development of more efficient permanent magnets and power semiconductor devices. Additionally, the integration of artificial intelligence and machine learning algorithms is expected to further enhance the predictive and adaptive capabilities of these systems.

In conclusion, the background and objectives of reactive power compensation in PMSM-driven systems reflect a dynamic and rapidly evolving field. The technology continues to push the boundaries of motor efficiency and power system stability, with far-reaching implications for energy conservation and sustainable industrial practices.

Market Demand Analysis for PMSM Systems

The market demand for Permanent Magnet Synchronous Motor (PMSM) systems has been experiencing significant growth, driven by the increasing need for energy-efficient and high-performance electric motor solutions across various industries. The global PMSM market is expected to expand at a compound annual growth rate (CAGR) of over 8% from 2021 to 2026, reflecting the strong demand for these systems.

One of the key factors contributing to the rising demand for PMSM systems is the growing emphasis on energy efficiency and sustainability. As governments worldwide implement stricter energy regulations and environmental policies, industries are increasingly adopting PMSM technology to reduce energy consumption and carbon emissions. This trend is particularly evident in sectors such as automotive, industrial automation, and renewable energy.

In the automotive industry, the shift towards electric vehicles (EVs) has created a substantial market for PMSM systems. PMSMs offer higher efficiency, better power density, and improved performance compared to traditional induction motors, making them ideal for EV powertrains. The global EV market is projected to grow at a CAGR of over 20% in the coming years, directly impacting the demand for PMSM systems.

The industrial automation sector is another major driver of PMSM market growth. As manufacturers strive to improve productivity and reduce operational costs, the adoption of PMSM-driven systems in robotics, CNC machines, and other automated equipment is increasing. The precision control and energy efficiency offered by PMSMs align well with the requirements of Industry 4.0 and smart manufacturing initiatives.

Renewable energy applications, particularly wind power generation, represent a significant market opportunity for PMSM systems. Direct-drive wind turbines using PMSMs are gaining popularity due to their higher reliability and lower maintenance requirements compared to geared systems. The global wind energy market is expected to grow steadily, further boosting the demand for PMSM technology.

However, the market for PMSM systems also faces challenges, primarily related to the cost and availability of rare earth materials used in permanent magnets. Fluctuations in the supply and pricing of these materials can impact the overall cost-effectiveness of PMSM solutions. This has led to increased research and development efforts focused on alternative magnet materials and designs to mitigate supply chain risks.

The demand for reactive power compensation in PMSM-driven systems is closely tied to the overall market growth of PMSM technology. As the deployment of PMSM systems increases across various applications, the need for effective reactive power management becomes more critical. This is particularly important in grid-connected systems, where power factor correction and voltage stability are essential for compliance with grid codes and optimal system performance.

One of the key factors contributing to the rising demand for PMSM systems is the growing emphasis on energy efficiency and sustainability. As governments worldwide implement stricter energy regulations and environmental policies, industries are increasingly adopting PMSM technology to reduce energy consumption and carbon emissions. This trend is particularly evident in sectors such as automotive, industrial automation, and renewable energy.

In the automotive industry, the shift towards electric vehicles (EVs) has created a substantial market for PMSM systems. PMSMs offer higher efficiency, better power density, and improved performance compared to traditional induction motors, making them ideal for EV powertrains. The global EV market is projected to grow at a CAGR of over 20% in the coming years, directly impacting the demand for PMSM systems.

The industrial automation sector is another major driver of PMSM market growth. As manufacturers strive to improve productivity and reduce operational costs, the adoption of PMSM-driven systems in robotics, CNC machines, and other automated equipment is increasing. The precision control and energy efficiency offered by PMSMs align well with the requirements of Industry 4.0 and smart manufacturing initiatives.

Renewable energy applications, particularly wind power generation, represent a significant market opportunity for PMSM systems. Direct-drive wind turbines using PMSMs are gaining popularity due to their higher reliability and lower maintenance requirements compared to geared systems. The global wind energy market is expected to grow steadily, further boosting the demand for PMSM technology.

However, the market for PMSM systems also faces challenges, primarily related to the cost and availability of rare earth materials used in permanent magnets. Fluctuations in the supply and pricing of these materials can impact the overall cost-effectiveness of PMSM solutions. This has led to increased research and development efforts focused on alternative magnet materials and designs to mitigate supply chain risks.

The demand for reactive power compensation in PMSM-driven systems is closely tied to the overall market growth of PMSM technology. As the deployment of PMSM systems increases across various applications, the need for effective reactive power management becomes more critical. This is particularly important in grid-connected systems, where power factor correction and voltage stability are essential for compliance with grid codes and optimal system performance.

Current Challenges in Reactive Power Compensation

Reactive power compensation in Permanent Magnet Synchronous Motor (PMSM) driven systems faces several significant challenges in the current technological landscape. One of the primary issues is the dynamic nature of reactive power demands in these systems. PMSM-driven applications often experience rapid and frequent changes in load conditions, making it difficult to maintain optimal reactive power balance consistently.

The integration of power electronic converters, while essential for PMSM control, introduces harmonic distortions into the system. These harmonics not only affect power quality but also complicate the reactive power compensation process. Traditional compensation methods struggle to address both fundamental and harmonic reactive power components simultaneously, leading to suboptimal system performance.

Another challenge lies in the accurate measurement and estimation of reactive power in real-time. The high-speed operation of PMSMs, coupled with the complex interactions between the motor, drive, and grid, makes it challenging to obtain precise reactive power data. This uncertainty can lead to overcompensation or undercompensation, both of which negatively impact system efficiency and stability.

The size and cost constraints of compensation devices present another hurdle. As PMSM-driven systems are often employed in applications where space and weight are critical factors, such as electric vehicles or industrial robotics, the integration of bulky compensation equipment becomes problematic. Engineers must balance the need for effective compensation with the practical limitations of system design and cost considerations.

Energy storage integration for reactive power support is an emerging area that presents its own set of challenges. While energy storage systems can potentially provide rapid and flexible reactive power compensation, issues related to battery life, charging/discharging efficiency, and control complexity need to be addressed.

The varying operating conditions of PMSM-driven systems also pose challenges for reactive power compensation strategies. Factors such as temperature fluctuations, motor aging, and changes in system parameters can affect the reactive power requirements, necessitating adaptive compensation techniques that can adjust in real-time to maintain optimal performance.

Lastly, the regulatory landscape and grid code requirements for reactive power management are becoming increasingly stringent. PMSM-driven systems, especially in grid-connected applications, must comply with these regulations while maintaining high efficiency and reliability. This necessitates more sophisticated control algorithms and compensation strategies that can meet both operational and regulatory demands.

The integration of power electronic converters, while essential for PMSM control, introduces harmonic distortions into the system. These harmonics not only affect power quality but also complicate the reactive power compensation process. Traditional compensation methods struggle to address both fundamental and harmonic reactive power components simultaneously, leading to suboptimal system performance.

Another challenge lies in the accurate measurement and estimation of reactive power in real-time. The high-speed operation of PMSMs, coupled with the complex interactions between the motor, drive, and grid, makes it challenging to obtain precise reactive power data. This uncertainty can lead to overcompensation or undercompensation, both of which negatively impact system efficiency and stability.

The size and cost constraints of compensation devices present another hurdle. As PMSM-driven systems are often employed in applications where space and weight are critical factors, such as electric vehicles or industrial robotics, the integration of bulky compensation equipment becomes problematic. Engineers must balance the need for effective compensation with the practical limitations of system design and cost considerations.

Energy storage integration for reactive power support is an emerging area that presents its own set of challenges. While energy storage systems can potentially provide rapid and flexible reactive power compensation, issues related to battery life, charging/discharging efficiency, and control complexity need to be addressed.

The varying operating conditions of PMSM-driven systems also pose challenges for reactive power compensation strategies. Factors such as temperature fluctuations, motor aging, and changes in system parameters can affect the reactive power requirements, necessitating adaptive compensation techniques that can adjust in real-time to maintain optimal performance.

Lastly, the regulatory landscape and grid code requirements for reactive power management are becoming increasingly stringent. PMSM-driven systems, especially in grid-connected applications, must comply with these regulations while maintaining high efficiency and reliability. This necessitates more sophisticated control algorithms and compensation strategies that can meet both operational and regulatory demands.

Existing Reactive Power Compensation Solutions

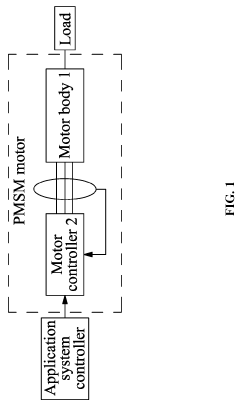

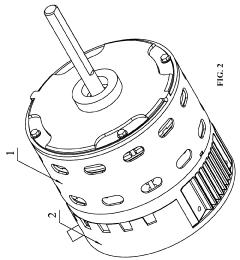

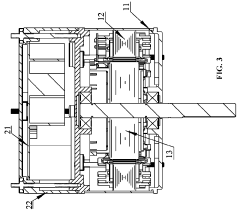

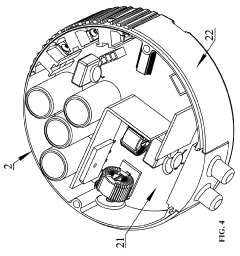

01 Reactive power control in PMSM-driven systems

Permanent Magnet Synchronous Motor (PMSM) driven systems can be optimized for reactive power control. This involves implementing advanced control strategies to manage the reactive power flow, improving overall system efficiency and power factor. The control methods may include vector control techniques and adaptive algorithms to respond to varying load conditions.- Reactive power control in PMSM-driven systems: Permanent Magnet Synchronous Motor (PMSM) driven systems often require precise control of reactive power to optimize efficiency and performance. This involves implementing advanced control algorithms and power electronic converters to manage the flow of reactive power between the motor and the power source.

- Voltage regulation and power factor correction: PMSM systems can be designed to provide voltage regulation and power factor correction by controlling the reactive power flow. This helps maintain grid stability and improves overall system efficiency by reducing losses associated with poor power factor.

- Reactive power compensation techniques: Various compensation techniques can be employed in PMSM-driven systems to manage reactive power. These may include the use of capacitor banks, static VAR compensators, or active front-end converters to dynamically adjust the reactive power flow based on system demands.

- Integration with renewable energy sources: PMSM-driven systems can be integrated with renewable energy sources such as wind turbines or solar panels. In these applications, reactive power control becomes crucial for maintaining grid stability and meeting power quality requirements, especially during fluctuations in renewable energy generation.

- Advanced control strategies for reactive power management: Implementing sophisticated control strategies, such as model predictive control or adaptive control algorithms, can enhance the reactive power management in PMSM-driven systems. These strategies can optimize system performance, improve dynamic response, and ensure stable operation under various load conditions.

02 Voltage regulation in PMSM systems

Voltage regulation is crucial in PMSM-driven systems to maintain stable operation and manage reactive power. This can be achieved through various methods such as using advanced inverter topologies, implementing dynamic voltage control algorithms, and utilizing reactive power compensation techniques. These approaches help to stabilize the grid voltage and improve the overall power quality of the system.Expand Specific Solutions03 Reactive power compensation techniques

Various reactive power compensation techniques can be employed in PMSM-driven systems to optimize performance. These may include the use of static VAR compensators, capacitor banks, or active front-end converters. Such techniques help to reduce reactive power consumption, improve power factor, and enhance overall system efficiency.Expand Specific Solutions04 Sensorless control for reactive power management

Sensorless control strategies can be implemented in PMSM-driven systems to manage reactive power effectively. These methods eliminate the need for additional sensors, reducing system complexity and cost. Advanced estimation algorithms and observers are used to accurately determine rotor position and speed, enabling precise control of reactive power flow without relying on physical sensors.Expand Specific Solutions05 Grid integration of PMSM-driven systems

Integrating PMSM-driven systems with the power grid requires careful consideration of reactive power management. This involves developing control strategies that ensure smooth grid connection, maintain grid stability, and comply with grid codes. Advanced power electronic interfaces and intelligent control algorithms are employed to manage the bidirectional flow of active and reactive power between the PMSM system and the grid.Expand Specific Solutions

Key Players in PMSM Drive Industry

The reactive power compensation in PMSM-driven systems market is in a growth phase, driven by increasing adoption of electric vehicles and renewable energy systems. The global market size is estimated to reach $2.5 billion by 2025, with a CAGR of 6.5%. Technologically, the field is advancing rapidly, with companies like Siemens AG, ABB Group, and Mitsubishi Electric Corp leading innovation. These firms are developing more efficient and compact compensation solutions, integrating advanced power electronics and control algorithms. Academic institutions like Jiangsu University and South China University of Technology are also contributing significantly to research and development in this area.

Fuji Electric Co., Ltd.

Technical Solution: Fuji Electric has developed a reactive power compensation system for PMSM-driven applications focusing on energy efficiency and compact design. Their solution utilizes a hybrid approach combining passive components and active power electronics. The system employs a novel multi-level inverter topology that allows for precise reactive power control with reduced switching losses[8]. Fuji Electric's compensation strategy incorporates adaptive control algorithms that adjust the compensation level based on motor speed and load conditions. The company has also implemented a unique thermal management system that enables high power density and improved reliability in compact installations[9]. Additionally, their solution features integrated power quality monitoring and protection functions to ensure compliance with grid standards.

Strengths: Energy-efficient design, compact form factor, and integrated power quality features. Weaknesses: May have limitations in handling large-scale systems or extreme operating conditions.

Siemens AG

Technical Solution: Siemens AG has developed advanced reactive power compensation solutions for PMSM-driven systems. Their approach utilizes a combination of active front-end (AFE) converters and dynamic reactive power compensation devices. The AFE converter allows bidirectional power flow and provides precise control of the power factor at the grid connection point[1]. Additionally, Siemens implements STATCOM (Static Synchronous Compensator) technology, which can rapidly inject or absorb reactive power to maintain voltage stability in the system[2]. Their solution also incorporates intelligent control algorithms that optimize the reactive power compensation in real-time, considering factors such as load variations, grid conditions, and motor operating points[3].

Strengths: Comprehensive solution integrating multiple technologies, real-time optimization, and grid stability enhancement. Weaknesses: Potentially higher initial cost and complexity compared to simpler compensation methods.

Core Innovations in PMSM Power Factor Correction

Small-capacitance power converter, and grid-side electrical-energy quality control working method and bus voltage suppression control method therefor

PatentPendingGB2610545A

Innovation

- A novel active power decoupling circuit (APDC) with two energy paths and a corresponding control strategy is introduced, utilizing a rectifier unit, APDC, and a three-phase inverter, where the virtual DC-link voltage is composed of AC and DC components, allowing for precise control of capacitor voltages to suppress DC-link voltage fluctuations and improve motor performance.

Method for correcting compensation item of permanent magnet synchronous motor (PMSM)

PatentActiveUS20190245467A1

Innovation

- A method involving offline measurement of error data to create a lookup table of current commands and corresponding compensation values, which is stored in a motor controller memory, allowing for online correction of deadzone errors using an electromagnetic calculation equation, thereby improving control precision and adaptability.

Energy Efficiency Regulations for Electric Drives

Energy efficiency regulations for electric drives have become increasingly stringent in recent years, driven by global efforts to reduce energy consumption and mitigate climate change. These regulations aim to improve the overall efficiency of electric motor systems, including permanent magnet synchronous motors (PMSMs) and their associated drive systems.

The European Union has been at the forefront of implementing energy efficiency standards for electric motors through its Ecodesign Directive. This directive sets minimum efficiency requirements for various types of electric motors, including PMSMs. The regulations are implemented in stages, with each stage introducing more stringent efficiency requirements.

In the United States, the Department of Energy (DOE) has established similar regulations through its Energy Conservation Standards for Electric Motors. These standards cover a wide range of motor types and sizes, including those used in PMSM-driven systems. The DOE regularly updates these standards to reflect advancements in motor technology and to push for greater energy savings.

China, as a major manufacturer and consumer of electric motors, has also implemented its own energy efficiency standards. The China Energy Label program sets efficiency requirements for various electrical products, including electric motors used in industrial applications.

These regulations typically focus on the overall system efficiency, which includes not only the motor itself but also the drive system and any associated components. This holistic approach recognizes that significant energy savings can be achieved by optimizing the entire motor system, rather than focusing solely on the motor's efficiency.

For PMSM-driven systems, reactive power compensation plays a crucial role in meeting these energy efficiency regulations. By effectively managing reactive power, these systems can reduce power losses, improve power factor, and enhance overall system efficiency. This is particularly important as regulations become more stringent and manufacturers seek to comply with higher efficiency standards.

Manufacturers of PMSM-driven systems must now consider reactive power compensation strategies as an integral part of their design process. This may involve implementing advanced control algorithms, utilizing power electronic devices for reactive power management, or incorporating capacitor banks for power factor correction.

As energy efficiency regulations continue to evolve, it is likely that future standards will place even greater emphasis on system-level efficiency and power quality. This may lead to more specific requirements for reactive power compensation in PMSM-driven systems, further driving innovation in this area and promoting the development of more efficient and sustainable electric drive technologies.

The European Union has been at the forefront of implementing energy efficiency standards for electric motors through its Ecodesign Directive. This directive sets minimum efficiency requirements for various types of electric motors, including PMSMs. The regulations are implemented in stages, with each stage introducing more stringent efficiency requirements.

In the United States, the Department of Energy (DOE) has established similar regulations through its Energy Conservation Standards for Electric Motors. These standards cover a wide range of motor types and sizes, including those used in PMSM-driven systems. The DOE regularly updates these standards to reflect advancements in motor technology and to push for greater energy savings.

China, as a major manufacturer and consumer of electric motors, has also implemented its own energy efficiency standards. The China Energy Label program sets efficiency requirements for various electrical products, including electric motors used in industrial applications.

These regulations typically focus on the overall system efficiency, which includes not only the motor itself but also the drive system and any associated components. This holistic approach recognizes that significant energy savings can be achieved by optimizing the entire motor system, rather than focusing solely on the motor's efficiency.

For PMSM-driven systems, reactive power compensation plays a crucial role in meeting these energy efficiency regulations. By effectively managing reactive power, these systems can reduce power losses, improve power factor, and enhance overall system efficiency. This is particularly important as regulations become more stringent and manufacturers seek to comply with higher efficiency standards.

Manufacturers of PMSM-driven systems must now consider reactive power compensation strategies as an integral part of their design process. This may involve implementing advanced control algorithms, utilizing power electronic devices for reactive power management, or incorporating capacitor banks for power factor correction.

As energy efficiency regulations continue to evolve, it is likely that future standards will place even greater emphasis on system-level efficiency and power quality. This may lead to more specific requirements for reactive power compensation in PMSM-driven systems, further driving innovation in this area and promoting the development of more efficient and sustainable electric drive technologies.

Economic Impact of Improved Power Factor in PMSM Systems

The economic impact of improved power factor in Permanent Magnet Synchronous Motor (PMSM) systems is significant and multifaceted. Power factor, a measure of how efficiently electrical power is converted into useful work output, plays a crucial role in the overall performance and cost-effectiveness of PMSM-driven systems. When power factor is improved through reactive power compensation, several economic benefits emerge.

Firstly, improved power factor leads to reduced energy consumption and lower electricity bills. By minimizing reactive power, the system draws less current from the power source, resulting in decreased power losses and improved energy efficiency. This translates directly into cost savings for industrial and commercial applications that rely heavily on PMSM systems.

Furthermore, enhanced power factor contributes to increased system capacity. With a higher power factor, the same electrical infrastructure can support a greater load, potentially delaying or eliminating the need for costly upgrades to power distribution systems. This aspect is particularly valuable in industries where space is at a premium or where expanding electrical infrastructure is challenging.

The reduction in harmonic distortion associated with improved power factor also yields economic benefits. Lower harmonics mean less stress on electrical components, leading to extended equipment lifespan and reduced maintenance costs. This not only decreases direct replacement expenses but also minimizes production downtime, which can be a significant cost factor in many industries.

From a utility perspective, customers with improved power factor in their PMSM systems contribute to a more stable and efficient grid. This can lead to reduced penalties or even incentives from utility companies, further enhancing the economic advantages for end-users. Additionally, the improved grid stability can result in fewer power quality issues, potentially reducing the need for costly power conditioning equipment.

The environmental impact of improved power factor should not be overlooked, as it indirectly affects economic outcomes. By reducing overall energy consumption, PMSM systems with better power factor contribute to lower carbon emissions. This aligns with increasingly stringent environmental regulations and can help companies avoid potential fines or taxes related to carbon emissions.

In conclusion, the economic impact of improved power factor in PMSM systems extends beyond immediate energy savings. It encompasses reduced operational costs, increased system longevity, enhanced grid stability, and alignment with environmental goals. These factors collectively contribute to a compelling economic case for investing in reactive power compensation technologies in PMSM-driven systems.

Firstly, improved power factor leads to reduced energy consumption and lower electricity bills. By minimizing reactive power, the system draws less current from the power source, resulting in decreased power losses and improved energy efficiency. This translates directly into cost savings for industrial and commercial applications that rely heavily on PMSM systems.

Furthermore, enhanced power factor contributes to increased system capacity. With a higher power factor, the same electrical infrastructure can support a greater load, potentially delaying or eliminating the need for costly upgrades to power distribution systems. This aspect is particularly valuable in industries where space is at a premium or where expanding electrical infrastructure is challenging.

The reduction in harmonic distortion associated with improved power factor also yields economic benefits. Lower harmonics mean less stress on electrical components, leading to extended equipment lifespan and reduced maintenance costs. This not only decreases direct replacement expenses but also minimizes production downtime, which can be a significant cost factor in many industries.

From a utility perspective, customers with improved power factor in their PMSM systems contribute to a more stable and efficient grid. This can lead to reduced penalties or even incentives from utility companies, further enhancing the economic advantages for end-users. Additionally, the improved grid stability can result in fewer power quality issues, potentially reducing the need for costly power conditioning equipment.

The environmental impact of improved power factor should not be overlooked, as it indirectly affects economic outcomes. By reducing overall energy consumption, PMSM systems with better power factor contribute to lower carbon emissions. This aligns with increasingly stringent environmental regulations and can help companies avoid potential fines or taxes related to carbon emissions.

In conclusion, the economic impact of improved power factor in PMSM systems extends beyond immediate energy savings. It encompasses reduced operational costs, increased system longevity, enhanced grid stability, and alignment with environmental goals. These factors collectively contribute to a compelling economic case for investing in reactive power compensation technologies in PMSM-driven systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!