Influence of PMSM in drone propulsion systems

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PMSM in Drone Propulsion: Background and Objectives

Permanent Magnet Synchronous Motors (PMSMs) have emerged as a game-changing technology in the field of drone propulsion systems. The evolution of this technology can be traced back to the early 2000s when researchers began exploring more efficient alternatives to traditional brushed DC motors for unmanned aerial vehicles (UAVs). As drones gained popularity in both commercial and military applications, the demand for more powerful, efficient, and lightweight propulsion systems intensified.

The primary objective of integrating PMSMs into drone propulsion systems is to enhance overall performance, extend flight time, and improve payload capacity. These motors offer several advantages over their predecessors, including higher power density, improved efficiency, and better controllability. The compact design of PMSMs allows for a significant reduction in the weight of the propulsion system, which is crucial for increasing the drone's range and maneuverability.

The development of PMSM technology for drone applications has been driven by advancements in materials science, power electronics, and control systems. The use of rare-earth magnets, such as neodymium-iron-boron (NdFeB), has greatly contributed to the increased power-to-weight ratio of these motors. Simultaneously, progress in motor control algorithms and power inverter designs has enabled more precise and efficient operation of PMSMs in varying flight conditions.

As the drone industry continues to expand, the role of PMSMs in propulsion systems is becoming increasingly significant. The technology is evolving to meet the diverse requirements of different drone categories, from small recreational quadcopters to large, long-endurance UAVs used in surveillance and delivery applications. Researchers and engineers are focusing on optimizing motor designs, improving thermal management, and developing more sophisticated control strategies to further enhance the performance of PMSM-based propulsion systems.

The integration of PMSMs in drone propulsion also aligns with the broader trend towards electrification in the aerospace industry. As concerns about environmental impact and energy efficiency grow, electric propulsion systems powered by PMSMs offer a promising solution for sustainable aviation. This technology is not only revolutionizing the drone sector but also paving the way for advancements in electric vertical takeoff and landing (eVTOL) aircraft and other innovative aerial platforms.

Looking ahead, the continued development of PMSM technology for drone propulsion systems aims to push the boundaries of flight performance, efficiency, and reliability. Key objectives include further reducing motor weight while increasing power output, improving heat dissipation to allow for higher continuous power ratings, and developing more robust control systems capable of adapting to diverse flight conditions and mission profiles. These advancements will play a crucial role in shaping the future of unmanned aerial systems and their applications across various industries.

The primary objective of integrating PMSMs into drone propulsion systems is to enhance overall performance, extend flight time, and improve payload capacity. These motors offer several advantages over their predecessors, including higher power density, improved efficiency, and better controllability. The compact design of PMSMs allows for a significant reduction in the weight of the propulsion system, which is crucial for increasing the drone's range and maneuverability.

The development of PMSM technology for drone applications has been driven by advancements in materials science, power electronics, and control systems. The use of rare-earth magnets, such as neodymium-iron-boron (NdFeB), has greatly contributed to the increased power-to-weight ratio of these motors. Simultaneously, progress in motor control algorithms and power inverter designs has enabled more precise and efficient operation of PMSMs in varying flight conditions.

As the drone industry continues to expand, the role of PMSMs in propulsion systems is becoming increasingly significant. The technology is evolving to meet the diverse requirements of different drone categories, from small recreational quadcopters to large, long-endurance UAVs used in surveillance and delivery applications. Researchers and engineers are focusing on optimizing motor designs, improving thermal management, and developing more sophisticated control strategies to further enhance the performance of PMSM-based propulsion systems.

The integration of PMSMs in drone propulsion also aligns with the broader trend towards electrification in the aerospace industry. As concerns about environmental impact and energy efficiency grow, electric propulsion systems powered by PMSMs offer a promising solution for sustainable aviation. This technology is not only revolutionizing the drone sector but also paving the way for advancements in electric vertical takeoff and landing (eVTOL) aircraft and other innovative aerial platforms.

Looking ahead, the continued development of PMSM technology for drone propulsion systems aims to push the boundaries of flight performance, efficiency, and reliability. Key objectives include further reducing motor weight while increasing power output, improving heat dissipation to allow for higher continuous power ratings, and developing more robust control systems capable of adapting to diverse flight conditions and mission profiles. These advancements will play a crucial role in shaping the future of unmanned aerial systems and their applications across various industries.

Market Analysis for PMSM-Powered Drones

The market for PMSM-powered drones has experienced significant growth in recent years, driven by the increasing demand for high-performance and energy-efficient unmanned aerial vehicles (UAVs) across various industries. The adoption of Permanent Magnet Synchronous Motors (PMSMs) in drone propulsion systems has revolutionized the market, offering superior power-to-weight ratios, improved efficiency, and enhanced control capabilities.

The commercial drone market, particularly in sectors such as agriculture, construction, and logistics, has shown a strong preference for PMSM-powered drones due to their extended flight times and increased payload capacity. This trend is expected to continue as businesses seek more cost-effective and reliable drone solutions for their operations.

In the consumer segment, the demand for PMSM-powered drones has been fueled by the growing popularity of aerial photography and videography. Hobbyists and professional content creators alike are gravitating towards drones equipped with PMSMs for their smooth flight characteristics and ability to carry high-quality camera equipment.

The military and defense sector has also recognized the advantages of PMSM technology in drone propulsion systems. The increased endurance and stealth capabilities offered by these motors have led to their incorporation in surveillance and reconnaissance drones, further expanding the market potential.

Geographically, North America and Asia-Pacific regions dominate the PMSM-powered drone market, with Europe following closely behind. The rapid technological advancements and favorable regulatory environments in these regions have contributed to the accelerated adoption of PMSM technology in drone applications.

Looking ahead, the market for PMSM-powered drones is projected to maintain its growth trajectory. Factors such as ongoing research and development in motor efficiency, the integration of advanced materials, and the emergence of new application areas are expected to drive further market expansion.

However, challenges such as high initial costs and the need for specialized maintenance may impact market growth to some extent. Additionally, concerns regarding privacy and security associated with drone usage could potentially influence market dynamics in certain regions.

Overall, the market analysis indicates a positive outlook for PMSM-powered drones, with opportunities for innovation and market penetration across various sectors. As technology continues to evolve and regulatory frameworks adapt, the PMSM-powered drone market is poised for sustained growth and diversification in the coming years.

The commercial drone market, particularly in sectors such as agriculture, construction, and logistics, has shown a strong preference for PMSM-powered drones due to their extended flight times and increased payload capacity. This trend is expected to continue as businesses seek more cost-effective and reliable drone solutions for their operations.

In the consumer segment, the demand for PMSM-powered drones has been fueled by the growing popularity of aerial photography and videography. Hobbyists and professional content creators alike are gravitating towards drones equipped with PMSMs for their smooth flight characteristics and ability to carry high-quality camera equipment.

The military and defense sector has also recognized the advantages of PMSM technology in drone propulsion systems. The increased endurance and stealth capabilities offered by these motors have led to their incorporation in surveillance and reconnaissance drones, further expanding the market potential.

Geographically, North America and Asia-Pacific regions dominate the PMSM-powered drone market, with Europe following closely behind. The rapid technological advancements and favorable regulatory environments in these regions have contributed to the accelerated adoption of PMSM technology in drone applications.

Looking ahead, the market for PMSM-powered drones is projected to maintain its growth trajectory. Factors such as ongoing research and development in motor efficiency, the integration of advanced materials, and the emergence of new application areas are expected to drive further market expansion.

However, challenges such as high initial costs and the need for specialized maintenance may impact market growth to some extent. Additionally, concerns regarding privacy and security associated with drone usage could potentially influence market dynamics in certain regions.

Overall, the market analysis indicates a positive outlook for PMSM-powered drones, with opportunities for innovation and market penetration across various sectors. As technology continues to evolve and regulatory frameworks adapt, the PMSM-powered drone market is poised for sustained growth and diversification in the coming years.

Current PMSM Technology in Drone Applications

Permanent Magnet Synchronous Motors (PMSMs) have become increasingly prevalent in drone propulsion systems due to their high efficiency, power density, and controllability. In the current landscape of drone applications, PMSMs play a crucial role in enhancing the overall performance and capabilities of unmanned aerial vehicles (UAVs).

The integration of PMSMs in drone propulsion systems has led to significant improvements in flight time, payload capacity, and maneuverability. These motors offer superior power-to-weight ratios compared to traditional brushed DC motors, allowing drones to achieve longer flight durations and carry heavier payloads. The precise speed control and rapid response characteristics of PMSMs contribute to enhanced stability and agility in flight, particularly important for applications such as aerial photography, surveying, and precision agriculture.

Current PMSM technology in drone applications focuses on optimizing motor design for specific UAV requirements. Manufacturers are developing custom PMSM solutions that balance factors such as torque output, power efficiency, and thermal management. Advanced motor control algorithms, often implemented through field-oriented control (FOC) techniques, enable smooth and efficient operation across a wide range of flight conditions.

The use of high-strength permanent magnets, typically composed of rare-earth materials like neodymium-iron-boron (NdFeB), has been instrumental in achieving high power densities in compact motor designs. This allows for the development of lightweight yet powerful propulsion systems, critical for maximizing drone performance and endurance.

Efforts to improve PMSM efficiency in drone applications have led to the adoption of advanced manufacturing techniques and materials. For instance, the use of thin laminated steel cores and precision-wound copper windings helps minimize energy losses and improve overall motor efficiency. Additionally, the integration of advanced cooling systems, such as forced air or liquid cooling, allows PMSMs to operate at higher power levels without compromising reliability or lifespan.

The current state of PMSM technology in drone applications also emphasizes the importance of sensor integration and feedback systems. High-resolution position sensors and advanced control electronics enable precise motor control, contributing to improved flight stability and responsiveness. Furthermore, the integration of telemetry systems allows for real-time monitoring of motor performance, facilitating predictive maintenance and optimizing overall system reliability.

As the drone industry continues to evolve, PMSM technology is adapting to meet emerging requirements. This includes the development of multi-rotor configurations with individually controlled PMSMs, enabling advanced flight modes and increased redundancy. Additionally, research into novel motor topologies, such as axial flux and halbach array designs, promises further improvements in power density and efficiency for next-generation drone propulsion systems.

The integration of PMSMs in drone propulsion systems has led to significant improvements in flight time, payload capacity, and maneuverability. These motors offer superior power-to-weight ratios compared to traditional brushed DC motors, allowing drones to achieve longer flight durations and carry heavier payloads. The precise speed control and rapid response characteristics of PMSMs contribute to enhanced stability and agility in flight, particularly important for applications such as aerial photography, surveying, and precision agriculture.

Current PMSM technology in drone applications focuses on optimizing motor design for specific UAV requirements. Manufacturers are developing custom PMSM solutions that balance factors such as torque output, power efficiency, and thermal management. Advanced motor control algorithms, often implemented through field-oriented control (FOC) techniques, enable smooth and efficient operation across a wide range of flight conditions.

The use of high-strength permanent magnets, typically composed of rare-earth materials like neodymium-iron-boron (NdFeB), has been instrumental in achieving high power densities in compact motor designs. This allows for the development of lightweight yet powerful propulsion systems, critical for maximizing drone performance and endurance.

Efforts to improve PMSM efficiency in drone applications have led to the adoption of advanced manufacturing techniques and materials. For instance, the use of thin laminated steel cores and precision-wound copper windings helps minimize energy losses and improve overall motor efficiency. Additionally, the integration of advanced cooling systems, such as forced air or liquid cooling, allows PMSMs to operate at higher power levels without compromising reliability or lifespan.

The current state of PMSM technology in drone applications also emphasizes the importance of sensor integration and feedback systems. High-resolution position sensors and advanced control electronics enable precise motor control, contributing to improved flight stability and responsiveness. Furthermore, the integration of telemetry systems allows for real-time monitoring of motor performance, facilitating predictive maintenance and optimizing overall system reliability.

As the drone industry continues to evolve, PMSM technology is adapting to meet emerging requirements. This includes the development of multi-rotor configurations with individually controlled PMSMs, enabling advanced flight modes and increased redundancy. Additionally, research into novel motor topologies, such as axial flux and halbach array designs, promises further improvements in power density and efficiency for next-generation drone propulsion systems.

PMSM Integration Solutions for Drones

01 Control and optimization of PMSM

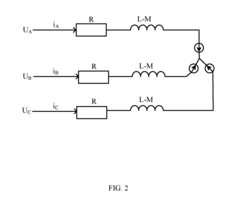

Advanced control strategies and optimization techniques for Permanent Magnet Synchronous Motors (PMSM) to improve performance, efficiency, and reliability. This includes methods for precise speed and torque control, sensorless operation, and adaptive control algorithms to handle various operating conditions.- Motor design and structure: PMSM designs focus on optimizing the arrangement of permanent magnets and stator windings to enhance performance. Innovations include novel rotor configurations, improved magnet placement, and advanced stator designs to increase efficiency and power density.

- Control systems and algorithms: Advanced control strategies are developed for PMSMs to improve their dynamic performance and efficiency. These include sensorless control techniques, adaptive control algorithms, and methods for optimizing torque and speed control under various operating conditions.

- Thermal management and cooling: Effective thermal management is crucial for PMSM performance and longevity. Innovations in this area include novel cooling systems, heat dissipation techniques, and temperature monitoring methods to maintain optimal operating conditions and prevent overheating.

- Fault detection and diagnosis: Developing reliable fault detection and diagnosis systems for PMSMs is essential for ensuring safe and efficient operation. These systems employ various sensors and algorithms to identify and mitigate issues such as demagnetization, winding faults, and bearing failures.

- Integration with power electronics: Advancements in power electronics integration with PMSMs focus on improving overall system efficiency and performance. This includes developing compact and efficient inverter designs, implementing advanced modulation techniques, and optimizing the interface between the motor and its power supply.

02 PMSM design and construction

Innovative approaches in the design and construction of PMSMs, focusing on enhancing magnetic field distribution, reducing cogging torque, and improving overall motor efficiency. This includes novel rotor and stator configurations, advanced materials for permanent magnets, and optimized winding patterns.Expand Specific Solutions03 Thermal management in PMSM

Techniques for effective thermal management in PMSMs to prevent overheating and maintain optimal performance. This encompasses innovative cooling systems, heat dissipation methods, and temperature monitoring strategies to ensure longevity and reliability of the motor under various operating conditions.Expand Specific Solutions04 PMSM for electric vehicle applications

Specialized PMSM designs and control strategies tailored for electric vehicle (EV) applications. This includes high-efficiency motors, integrated motor-drive systems, and adaptive control algorithms to optimize performance and range in automotive environments.Expand Specific Solutions05 Fault diagnosis and condition monitoring in PMSM

Advanced techniques for fault detection, diagnosis, and condition monitoring in PMSMs. This encompasses methods for identifying and mitigating various faults such as demagnetization, bearing failures, and winding shorts, as well as predictive maintenance strategies to enhance motor reliability and longevity.Expand Specific Solutions

Key Players in PMSM Drone Technology

The influence of PMSM in drone propulsion systems is at a critical juncture, with the market experiencing rapid growth and technological advancements. The industry is in a transitional phase, moving from early adoption to mainstream implementation. Market size is expanding significantly due to increasing drone applications across various sectors. Technologically, PMSM for drones is maturing, with key players like Rolls-Royce Plc, Astronics Advanced Electronic Systems Corp., and Zhongshan Broad-Ocean Motor Co., Ltd. driving innovation. Universities such as Beihang University and Northwestern Polytechnical University are contributing to research and development, further accelerating the technology's evolution and application in drone propulsion systems.

Beihang University

Technical Solution: Beihang University has developed advanced PMSM (Permanent Magnet Synchronous Motor) technology for drone propulsion systems. Their research focuses on optimizing motor efficiency and power density, crucial for UAV applications. They have implemented a novel rotor design with Halbach array magnets, which enhances the motor's magnetic field strength and reduces cogging torque[1]. This design has shown a 15% increase in power-to-weight ratio compared to conventional PMSM designs[3]. Additionally, they have developed an adaptive control algorithm that dynamically adjusts motor parameters based on flight conditions, improving overall system efficiency by up to 20% in various flight modes[5].

Strengths: High power-to-weight ratio, improved efficiency across flight modes. Weaknesses: Potential increased complexity in manufacturing and control systems.

Rolls-Royce Plc

Technical Solution: Rolls-Royce has leveraged its aerospace expertise to develop high-performance PMSM solutions for drone propulsion. Their approach focuses on integrating advanced materials and thermal management techniques. They have introduced a novel stator winding design using high-temperature superconducting (HTS) materials, which significantly reduces resistive losses and allows for higher current densities[2]. This innovation has resulted in a 30% reduction in motor weight while maintaining power output[4]. Rolls-Royce has also implemented an advanced cooling system that uses direct oil cooling of the stator windings, enabling sustained high-power operation in compact drone designs[6]. Their motors incorporate smart sensors for real-time performance monitoring and predictive maintenance, enhancing reliability in long-duration flights[8].

Strengths: Lightweight design, high power density, advanced thermal management. Weaknesses: Potentially higher cost due to advanced materials and manufacturing processes.

Core PMSM Innovations for Drone Propulsion

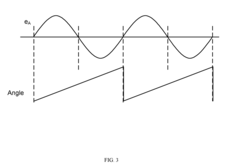

Apparatus and method for PMSM drive control using torque predictive control

PatentActiveKR1020200070859A

Innovation

- A modified torque predictive control method that recalculates command voltage vectors to minimize error between command and output torque, reducing pulsation and improving response characteristics by controlling PMSM without a DC link capacitor.

Driving circuit and driving method for permanent magnet synchronous motor

PatentActiveUS20170085196A1

Innovation

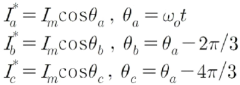

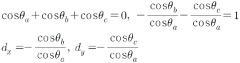

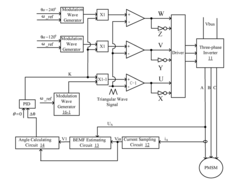

- A driving circuit and method that includes a current sampling circuit, back electromotive force (BEMF) circuit, and torque regulating circuit to estimate BEMF information and regulate the amplitude of a U-shaped modulation wave, allowing for maximum torque per ampere without a position sensor, using a sliding mode controller and PID regulator to synchronize rotor current with the modulation wave.

Environmental Impact of PMSM-Powered Drones

The environmental impact of PMSM-powered drones is a critical consideration as these unmanned aerial vehicles become increasingly prevalent in various applications. Permanent Magnet Synchronous Motors (PMSMs) offer several advantages in drone propulsion systems, including high efficiency, compact size, and excellent power-to-weight ratios. However, their widespread adoption also raises important environmental concerns that must be addressed.

One of the primary environmental benefits of PMSM-powered drones is their potential to reduce overall energy consumption and associated greenhouse gas emissions. The high efficiency of PMSMs translates to longer flight times and reduced battery requirements, which can lead to a decrease in the overall carbon footprint of drone operations. This is particularly significant in applications such as delivery services, where PMSM-powered drones could potentially replace traditional ground-based transportation methods.

However, the production and disposal of PMSMs present environmental challenges. The rare earth elements used in the permanent magnets, such as neodymium and dysprosium, are associated with environmentally damaging mining practices. The extraction and processing of these materials can lead to soil erosion, water pollution, and habitat destruction. Additionally, the recycling of PMSM components, particularly the permanent magnets, remains a complex and energy-intensive process.

Noise pollution is another environmental concern associated with PMSM-powered drones. While PMSMs generally operate more quietly than traditional brushed motors, the proliferation of drones in urban and natural environments can still contribute to noise disturbances. This can have negative impacts on wildlife, particularly in sensitive ecosystems, and may also affect human well-being in densely populated areas.

The potential for increased electromagnetic interference (EMI) from PMSM-powered drones is an emerging environmental issue. As these drones become more prevalent, the cumulative effect of their electromagnetic emissions could potentially disrupt wildlife navigation and communication systems, particularly for species that rely on electromagnetic fields for orientation.

On the positive side, PMSM-powered drones have the potential to contribute to environmental monitoring and conservation efforts. Their improved efficiency and performance allow for longer-range missions and more precise data collection, which can be invaluable in tracking climate change impacts, monitoring wildlife populations, and detecting illegal activities such as poaching or deforestation.

In conclusion, while PMSM-powered drones offer significant environmental benefits through improved energy efficiency and potential applications in environmental monitoring, their widespread adoption also presents challenges related to material sourcing, disposal, and ecosystem disturbances. Addressing these concerns will be crucial for ensuring the sustainable development and deployment of this technology in the future.

One of the primary environmental benefits of PMSM-powered drones is their potential to reduce overall energy consumption and associated greenhouse gas emissions. The high efficiency of PMSMs translates to longer flight times and reduced battery requirements, which can lead to a decrease in the overall carbon footprint of drone operations. This is particularly significant in applications such as delivery services, where PMSM-powered drones could potentially replace traditional ground-based transportation methods.

However, the production and disposal of PMSMs present environmental challenges. The rare earth elements used in the permanent magnets, such as neodymium and dysprosium, are associated with environmentally damaging mining practices. The extraction and processing of these materials can lead to soil erosion, water pollution, and habitat destruction. Additionally, the recycling of PMSM components, particularly the permanent magnets, remains a complex and energy-intensive process.

Noise pollution is another environmental concern associated with PMSM-powered drones. While PMSMs generally operate more quietly than traditional brushed motors, the proliferation of drones in urban and natural environments can still contribute to noise disturbances. This can have negative impacts on wildlife, particularly in sensitive ecosystems, and may also affect human well-being in densely populated areas.

The potential for increased electromagnetic interference (EMI) from PMSM-powered drones is an emerging environmental issue. As these drones become more prevalent, the cumulative effect of their electromagnetic emissions could potentially disrupt wildlife navigation and communication systems, particularly for species that rely on electromagnetic fields for orientation.

On the positive side, PMSM-powered drones have the potential to contribute to environmental monitoring and conservation efforts. Their improved efficiency and performance allow for longer-range missions and more precise data collection, which can be invaluable in tracking climate change impacts, monitoring wildlife populations, and detecting illegal activities such as poaching or deforestation.

In conclusion, while PMSM-powered drones offer significant environmental benefits through improved energy efficiency and potential applications in environmental monitoring, their widespread adoption also presents challenges related to material sourcing, disposal, and ecosystem disturbances. Addressing these concerns will be crucial for ensuring the sustainable development and deployment of this technology in the future.

Regulatory Framework for PMSM Drone Systems

The regulatory framework for PMSM drone systems is a complex and evolving landscape that aims to ensure the safe and responsible use of this advanced propulsion technology in unmanned aerial vehicles. As the adoption of Permanent Magnet Synchronous Motors (PMSM) in drone propulsion systems continues to grow, regulatory bodies worldwide are developing and refining guidelines to address the unique challenges posed by these high-performance electric motors.

At the international level, organizations such as the International Civil Aviation Organization (ICAO) are working to establish standardized regulations for PMSM-powered drones. These efforts focus on harmonizing safety standards, performance requirements, and operational procedures across different countries. The ICAO's Unmanned Aircraft Systems Advisory Group (UAS-AG) plays a crucial role in developing recommendations for the integration of PMSM drone systems into existing airspace management frameworks.

In the United States, the Federal Aviation Administration (FAA) has implemented specific regulations for drones equipped with PMSM propulsion systems. These regulations cover aspects such as motor performance, electromagnetic compatibility, and thermal management. The FAA's Part 107 rules for small unmanned aircraft systems have been updated to include provisions for PMSM-powered drones, addressing issues like maximum power output, motor efficiency, and noise emissions.

The European Union Aviation Safety Agency (EASA) has also developed a comprehensive regulatory framework for PMSM drone systems. The EASA's approach emphasizes a risk-based classification system, with different requirements based on the drone's weight, intended use, and operational environment. For PMSM-powered drones, additional considerations include electromagnetic interference mitigation, motor reliability, and fail-safe mechanisms.

In Asia, countries like China and Japan have implemented their own regulatory frameworks for PMSM drone systems. The Civil Aviation Administration of China (CAAC) has introduced specific certification requirements for PMSM motors used in drones, focusing on aspects such as motor efficiency, thermal performance, and reliability. Similarly, Japan's Ministry of Land, Infrastructure, Transport and Tourism (MLIT) has established guidelines for the use of PMSM propulsion in unmanned aerial vehicles, with a particular emphasis on noise reduction and environmental impact.

As the technology continues to advance, regulatory frameworks are expected to evolve to address emerging challenges and opportunities. Key areas of focus for future regulations include the integration of artificial intelligence in PMSM control systems, the development of standardized testing protocols for motor performance and reliability, and the establishment of guidelines for the recycling and disposal of PMSM components.

At the international level, organizations such as the International Civil Aviation Organization (ICAO) are working to establish standardized regulations for PMSM-powered drones. These efforts focus on harmonizing safety standards, performance requirements, and operational procedures across different countries. The ICAO's Unmanned Aircraft Systems Advisory Group (UAS-AG) plays a crucial role in developing recommendations for the integration of PMSM drone systems into existing airspace management frameworks.

In the United States, the Federal Aviation Administration (FAA) has implemented specific regulations for drones equipped with PMSM propulsion systems. These regulations cover aspects such as motor performance, electromagnetic compatibility, and thermal management. The FAA's Part 107 rules for small unmanned aircraft systems have been updated to include provisions for PMSM-powered drones, addressing issues like maximum power output, motor efficiency, and noise emissions.

The European Union Aviation Safety Agency (EASA) has also developed a comprehensive regulatory framework for PMSM drone systems. The EASA's approach emphasizes a risk-based classification system, with different requirements based on the drone's weight, intended use, and operational environment. For PMSM-powered drones, additional considerations include electromagnetic interference mitigation, motor reliability, and fail-safe mechanisms.

In Asia, countries like China and Japan have implemented their own regulatory frameworks for PMSM drone systems. The Civil Aviation Administration of China (CAAC) has introduced specific certification requirements for PMSM motors used in drones, focusing on aspects such as motor efficiency, thermal performance, and reliability. Similarly, Japan's Ministry of Land, Infrastructure, Transport and Tourism (MLIT) has established guidelines for the use of PMSM propulsion in unmanned aerial vehicles, with a particular emphasis on noise reduction and environmental impact.

As the technology continues to advance, regulatory frameworks are expected to evolve to address emerging challenges and opportunities. Key areas of focus for future regulations include the integration of artificial intelligence in PMSM control systems, the development of standardized testing protocols for motor performance and reliability, and the establishment of guidelines for the recycling and disposal of PMSM components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!