Noise reduction techniques in PMSM-powered systems

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PMSM Noise Background

Permanent Magnet Synchronous Motors (PMSMs) have gained significant traction in various industrial applications due to their high efficiency, power density, and controllability. However, one of the persistent challenges in PMSM-powered systems is the issue of noise generation. The background of PMSM noise is multifaceted and stems from various sources within the motor's structure and operation.

The primary sources of noise in PMSMs can be categorized into three main types: electromagnetic, mechanical, and aerodynamic. Electromagnetic noise is primarily caused by the interaction between the stator and rotor magnetic fields, resulting in vibrations that propagate through the motor structure. This type of noise is particularly prominent in PMSMs due to the strong magnetic fields generated by permanent magnets.

Mechanical noise in PMSMs originates from various moving components, including bearings, shaft misalignments, and imperfections in the rotor balance. These mechanical factors can lead to vibrations that contribute to the overall noise profile of the motor. Additionally, the precision of manufacturing and assembly processes plays a crucial role in determining the level of mechanical noise produced.

Aerodynamic noise, while less significant in PMSMs compared to other motor types, still contributes to the overall acoustic profile. This noise is generated by the movement of air around the rotor and through cooling channels, becoming more pronounced at higher rotational speeds.

The characteristics of PMSM noise are heavily influenced by the motor's design parameters, including the number of poles, slot configurations, and magnet arrangements. These factors affect the frequency spectrum of the noise, with certain harmonics being more prominent depending on the specific motor design.

Furthermore, the operating conditions of the PMSM, such as load variations, speed changes, and control strategies, significantly impact the noise generation. For instance, certain control algorithms may exacerbate harmonic distortions in the current waveform, leading to increased electromagnetic noise.

The impact of PMSM noise extends beyond mere auditory discomfort. In industrial settings, excessive noise can lead to reduced worker productivity, increased stress levels, and potential health issues. In consumer applications, such as electric vehicles or home appliances, noise can significantly affect user experience and product perception.

As industries increasingly adopt PMSM technology, the demand for quieter operation has intensified. This has led to a growing focus on noise reduction techniques in PMSM-powered systems, spanning across various disciplines including electrical engineering, mechanical design, and control theory. The challenge lies in developing comprehensive solutions that address all aspects of noise generation while maintaining the high performance and efficiency that make PMSMs attractive in the first place.

The primary sources of noise in PMSMs can be categorized into three main types: electromagnetic, mechanical, and aerodynamic. Electromagnetic noise is primarily caused by the interaction between the stator and rotor magnetic fields, resulting in vibrations that propagate through the motor structure. This type of noise is particularly prominent in PMSMs due to the strong magnetic fields generated by permanent magnets.

Mechanical noise in PMSMs originates from various moving components, including bearings, shaft misalignments, and imperfections in the rotor balance. These mechanical factors can lead to vibrations that contribute to the overall noise profile of the motor. Additionally, the precision of manufacturing and assembly processes plays a crucial role in determining the level of mechanical noise produced.

Aerodynamic noise, while less significant in PMSMs compared to other motor types, still contributes to the overall acoustic profile. This noise is generated by the movement of air around the rotor and through cooling channels, becoming more pronounced at higher rotational speeds.

The characteristics of PMSM noise are heavily influenced by the motor's design parameters, including the number of poles, slot configurations, and magnet arrangements. These factors affect the frequency spectrum of the noise, with certain harmonics being more prominent depending on the specific motor design.

Furthermore, the operating conditions of the PMSM, such as load variations, speed changes, and control strategies, significantly impact the noise generation. For instance, certain control algorithms may exacerbate harmonic distortions in the current waveform, leading to increased electromagnetic noise.

The impact of PMSM noise extends beyond mere auditory discomfort. In industrial settings, excessive noise can lead to reduced worker productivity, increased stress levels, and potential health issues. In consumer applications, such as electric vehicles or home appliances, noise can significantly affect user experience and product perception.

As industries increasingly adopt PMSM technology, the demand for quieter operation has intensified. This has led to a growing focus on noise reduction techniques in PMSM-powered systems, spanning across various disciplines including electrical engineering, mechanical design, and control theory. The challenge lies in developing comprehensive solutions that address all aspects of noise generation while maintaining the high performance and efficiency that make PMSMs attractive in the first place.

Market Demand Analysis

The market demand for noise reduction techniques in PMSM-powered systems has been steadily increasing due to the growing adoption of Permanent Magnet Synchronous Motors (PMSMs) across various industries. These motors are widely used in electric vehicles, industrial automation, renewable energy systems, and household appliances due to their high efficiency and power density. However, the inherent noise generated by PMSMs has become a significant concern for manufacturers and end-users alike.

In the automotive sector, the shift towards electric vehicles has amplified the need for effective noise reduction solutions. As internal combustion engines are replaced with electric powertrains, the noise from PMSMs becomes more noticeable, affecting passenger comfort and overall vehicle quality perception. This has led to a surge in demand for advanced noise reduction techniques among electric vehicle manufacturers.

The industrial automation sector also presents a substantial market for PMSM noise reduction technologies. As factories and manufacturing plants strive for quieter and more efficient operations, the demand for low-noise PMSM systems has increased. This is particularly evident in applications such as robotics, CNC machines, and conveyor systems, where noise reduction contributes to improved working conditions and productivity.

In the renewable energy sector, particularly wind turbines, noise reduction in PMSM-powered systems is crucial for meeting stringent environmental regulations and gaining public acceptance. As wind farms expand and move closer to populated areas, the need for quieter operation has become a key factor in turbine design and installation approval.

The consumer appliance market has also shown a growing interest in noise reduction techniques for PMSM-powered devices. Products such as air conditioners, refrigerators, and washing machines are increasingly utilizing PMSMs for improved energy efficiency. However, consumers demand quieter operation, driving manufacturers to invest in noise reduction technologies.

Market analysis indicates that the global demand for noise reduction solutions in PMSM systems is expected to grow significantly in the coming years. This growth is driven by stricter noise regulations, increasing consumer expectations for quieter products, and the expanding applications of PMSMs across various industries.

The market potential for noise reduction techniques in PMSM-powered systems is further enhanced by the trend towards smart and connected devices. As IoT and Industry 4.0 concepts gain traction, the integration of noise reduction technologies with smart monitoring and control systems presents new opportunities for innovation and market growth.

In the automotive sector, the shift towards electric vehicles has amplified the need for effective noise reduction solutions. As internal combustion engines are replaced with electric powertrains, the noise from PMSMs becomes more noticeable, affecting passenger comfort and overall vehicle quality perception. This has led to a surge in demand for advanced noise reduction techniques among electric vehicle manufacturers.

The industrial automation sector also presents a substantial market for PMSM noise reduction technologies. As factories and manufacturing plants strive for quieter and more efficient operations, the demand for low-noise PMSM systems has increased. This is particularly evident in applications such as robotics, CNC machines, and conveyor systems, where noise reduction contributes to improved working conditions and productivity.

In the renewable energy sector, particularly wind turbines, noise reduction in PMSM-powered systems is crucial for meeting stringent environmental regulations and gaining public acceptance. As wind farms expand and move closer to populated areas, the need for quieter operation has become a key factor in turbine design and installation approval.

The consumer appliance market has also shown a growing interest in noise reduction techniques for PMSM-powered devices. Products such as air conditioners, refrigerators, and washing machines are increasingly utilizing PMSMs for improved energy efficiency. However, consumers demand quieter operation, driving manufacturers to invest in noise reduction technologies.

Market analysis indicates that the global demand for noise reduction solutions in PMSM systems is expected to grow significantly in the coming years. This growth is driven by stricter noise regulations, increasing consumer expectations for quieter products, and the expanding applications of PMSMs across various industries.

The market potential for noise reduction techniques in PMSM-powered systems is further enhanced by the trend towards smart and connected devices. As IoT and Industry 4.0 concepts gain traction, the integration of noise reduction technologies with smart monitoring and control systems presents new opportunities for innovation and market growth.

Current Challenges

The current challenges in noise reduction techniques for PMSM-powered systems are multifaceted and complex, requiring innovative solutions to address both electromagnetic and mechanical sources of noise. One of the primary challenges is the accurate identification and characterization of noise sources within the system. PMSM systems generate various types of noise, including electromagnetic noise, mechanical vibrations, and aerodynamic noise, each with distinct frequency characteristics and propagation patterns.

Electromagnetic noise, particularly cogging torque and torque ripple, remains a significant challenge in PMSM systems. These phenomena result from the interaction between the rotor magnets and stator teeth, causing fluctuations in the air gap flux density. Minimizing these effects without compromising the overall performance of the motor is a delicate balancing act that engineers continue to grapple with.

Another major challenge lies in the realm of mechanical noise reduction. Bearing noise, rotor imbalance, and structural resonances contribute significantly to the overall noise profile of PMSM systems. Developing effective isolation and damping techniques that can address these issues across a wide range of operating conditions presents a formidable engineering challenge.

The increasing demand for high-power density and compact PMSM designs further complicates noise reduction efforts. As motors become smaller and more powerful, the proximity of components and the intensity of electromagnetic fields increase, potentially exacerbating noise issues. Balancing the need for compact design with effective noise mitigation strategies is a critical challenge facing engineers in this field.

Moreover, the integration of advanced control algorithms for noise reduction presents its own set of challenges. While active noise control techniques show promise, their implementation in real-time systems with varying operational parameters requires sophisticated signal processing and control strategies. Developing robust, adaptive control algorithms that can effectively reduce noise across different operating modes and environmental conditions remains an ongoing challenge.

The interdisciplinary nature of noise reduction in PMSM systems also poses challenges in terms of expertise and collaboration. Effective solutions often require a combination of electromagnetic design, mechanical engineering, control theory, and acoustics. Bridging these diverse fields and fostering interdisciplinary collaboration is essential for developing comprehensive noise reduction strategies.

Lastly, the economic considerations of implementing advanced noise reduction techniques present a significant challenge. Balancing the cost of sophisticated noise reduction solutions with the market demands for quieter, more efficient motors requires careful consideration of manufacturing processes, material selection, and design optimization. Finding cost-effective solutions that can be scaled for mass production while meeting stringent noise regulations is a key challenge facing the industry.

Electromagnetic noise, particularly cogging torque and torque ripple, remains a significant challenge in PMSM systems. These phenomena result from the interaction between the rotor magnets and stator teeth, causing fluctuations in the air gap flux density. Minimizing these effects without compromising the overall performance of the motor is a delicate balancing act that engineers continue to grapple with.

Another major challenge lies in the realm of mechanical noise reduction. Bearing noise, rotor imbalance, and structural resonances contribute significantly to the overall noise profile of PMSM systems. Developing effective isolation and damping techniques that can address these issues across a wide range of operating conditions presents a formidable engineering challenge.

The increasing demand for high-power density and compact PMSM designs further complicates noise reduction efforts. As motors become smaller and more powerful, the proximity of components and the intensity of electromagnetic fields increase, potentially exacerbating noise issues. Balancing the need for compact design with effective noise mitigation strategies is a critical challenge facing engineers in this field.

Moreover, the integration of advanced control algorithms for noise reduction presents its own set of challenges. While active noise control techniques show promise, their implementation in real-time systems with varying operational parameters requires sophisticated signal processing and control strategies. Developing robust, adaptive control algorithms that can effectively reduce noise across different operating modes and environmental conditions remains an ongoing challenge.

The interdisciplinary nature of noise reduction in PMSM systems also poses challenges in terms of expertise and collaboration. Effective solutions often require a combination of electromagnetic design, mechanical engineering, control theory, and acoustics. Bridging these diverse fields and fostering interdisciplinary collaboration is essential for developing comprehensive noise reduction strategies.

Lastly, the economic considerations of implementing advanced noise reduction techniques present a significant challenge. Balancing the cost of sophisticated noise reduction solutions with the market demands for quieter, more efficient motors requires careful consideration of manufacturing processes, material selection, and design optimization. Finding cost-effective solutions that can be scaled for mass production while meeting stringent noise regulations is a key challenge facing the industry.

Existing Solutions

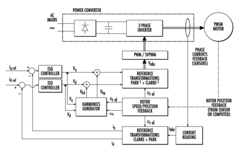

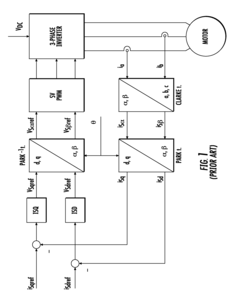

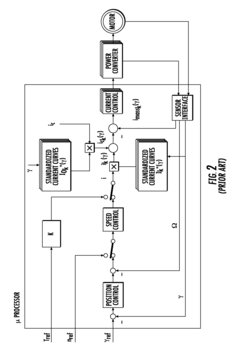

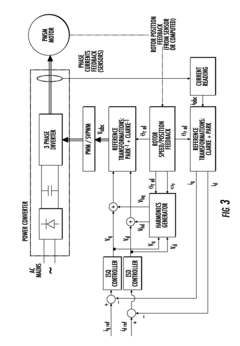

01 Noise reduction in PMSM control systems

Various control strategies and algorithms are implemented to reduce noise in PMSM-powered systems. These may include advanced modulation techniques, optimized current control, and harmonic suppression methods. By improving the control system, the acoustic noise generated by the motor can be significantly reduced.- Noise reduction in PMSM control systems: Various control strategies and algorithms are implemented to reduce noise in PMSM-powered systems. These may include advanced modulation techniques, optimized current control, and harmonic suppression methods. By improving the control system, the acoustic noise generated by the motor can be significantly reduced.

- Mechanical design improvements for noise reduction: Enhancements in the mechanical design of PMSM systems can help minimize noise. This includes optimizing the motor structure, using noise-absorbing materials, and implementing vibration isolation techniques. These mechanical improvements can effectively reduce both electromagnetic and mechanical sources of noise in PMSM-powered systems.

- Electromagnetic noise reduction techniques: Specific methods are employed to reduce electromagnetic noise in PMSM systems. These may include optimizing the stator and rotor designs, using advanced magnetic materials, and implementing electromagnetic shielding techniques. By addressing the electromagnetic sources of noise, the overall acoustic performance of the system can be improved.

- Thermal management for noise reduction: Effective thermal management strategies are implemented to reduce noise in PMSM-powered systems. This includes optimizing cooling systems, using advanced thermal materials, and implementing temperature control algorithms. By managing the thermal aspects of the system, noise caused by thermal expansion and contraction can be minimized.

- Sensor-based noise monitoring and control: Advanced sensor technologies are utilized to monitor and control noise in PMSM systems. This may include the use of acoustic sensors, vibration sensors, and real-time noise analysis algorithms. By implementing sensor-based feedback systems, the noise levels can be continuously monitored and adjusted to maintain optimal performance.

02 Mechanical design improvements for noise reduction

Mechanical design enhancements are employed to minimize noise in PMSM systems. This includes optimizing the motor structure, using noise-absorbing materials, and implementing vibration isolation techniques. These mechanical improvements help to reduce both electromagnetic and mechanical sources of noise.Expand Specific Solutions03 Electromagnetic noise reduction techniques

Specific methods are developed to address electromagnetic noise in PMSM systems. These may include optimizing the stator and rotor designs, using special winding configurations, and implementing magnetic field shaping techniques. By reducing the electromagnetic noise at its source, overall system noise is decreased.Expand Specific Solutions04 Thermal management for noise reduction

Effective thermal management strategies are implemented to reduce noise in PMSM systems. This includes optimizing cooling systems, using advanced thermal materials, and implementing temperature-based control algorithms. By managing heat more effectively, thermal-induced noise and vibrations are minimized.Expand Specific Solutions05 Sensor-based noise monitoring and adaptive control

Advanced sensor systems are integrated into PMSM-powered systems to monitor noise levels in real-time. This data is used to implement adaptive control strategies that dynamically adjust motor operation to minimize noise under varying conditions. The combination of sensors and adaptive algorithms allows for continuous noise optimization.Expand Specific Solutions

Key Industry Players

The noise reduction techniques in PMSM-powered systems market is in a growth phase, driven by increasing demand for high-performance electric motors in various industries. The market size is expanding, with a projected CAGR of 6-8% over the next five years. Technologically, the field is advancing rapidly, with companies like BYD, Robert Bosch, and Continental Automotive Systems leading innovation. These firms are developing sophisticated algorithms and hardware solutions to mitigate electromagnetic noise and vibration in PMSM systems. The technology's maturity varies, with some solutions being commercially available while others are still in the research phase. Key players like Texas Instruments and LG Electronics are also contributing to the advancement of noise reduction techniques, focusing on integrated circuit solutions and motor control algorithms.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced noise reduction techniques for PMSM-powered systems, focusing on both mechanical and electrical noise sources. Their approach includes active noise control (ANC) algorithms that can reduce electromagnetic noise by up to 10 dB[1]. They utilize advanced signal processing techniques, such as adaptive filtering and spectral shaping, to minimize both audible and electromagnetic interference. Bosch's solution also incorporates hardware improvements, including optimized motor design with skewed stator slots and rotor magnets, which can reduce cogging torque by up to 30%[3]. Additionally, they implement sophisticated control strategies like field-oriented control (FOC) with space vector modulation (SVM) to minimize current ripple and torque pulsations, further reducing acoustic noise[5].

Strengths: Comprehensive approach addressing both mechanical and electrical noise sources; proven noise reduction results; integration with existing Bosch automotive systems. Weaknesses: Potentially higher cost due to advanced hardware and software requirements; may require system-specific tuning for optimal performance.

Continental Automotive Systems, Inc.

Technical Solution: Continental has developed a multi-faceted approach to noise reduction in PMSM-powered systems, particularly focusing on automotive applications. Their solution combines advanced motor design, intelligent control algorithms, and innovative materials. Continental's PMSM designs incorporate fractional slot concentrated windings (FSCW) which can reduce cogging torque by up to 40% compared to traditional designs[2]. They also implement active noise cancellation techniques using the motor itself as an actuator, capable of reducing electromagnetic noise by up to 15 dB in specific frequency ranges[4]. Continental's control strategy includes model predictive control (MPC) algorithms that optimize torque production while minimizing current harmonics, resulting in smoother operation and reduced acoustic noise[6]. Additionally, they utilize specialized magnetic materials and lamination designs to reduce core losses and minimize magnetostriction-induced vibrations.

Strengths: Holistic approach combining mechanical, electrical, and control solutions; significant noise reduction achievements; expertise in automotive-grade implementations. Weaknesses: Potential increase in system complexity; may require specialized manufacturing processes for advanced motor designs.

Core Innovations

Method of controlling a three-phase permanent magnet synchronous motor for reducing acoustic noise and relative control device

PatentActiveUS20110298405A1

Innovation

- The method involves injecting additional harmonic components at frequencies corresponding to the 5th and 7th harmonics of the BEMF into the control voltage components, specifically using a compensation harmonics generator to operate on the rotor reference frame or stator reference frame, to counteract the effects of these harmonics, thereby reducing acoustic noise.

Regulatory Compliance

Regulatory compliance plays a crucial role in the development and implementation of noise reduction techniques for Permanent Magnet Synchronous Motor (PMSM) powered systems. As these systems are widely used in various industries, including automotive, aerospace, and industrial applications, adherence to regulatory standards is essential to ensure safety, performance, and environmental protection.

In the context of PMSM-powered systems, noise reduction techniques must comply with several regulatory frameworks. The International Electrotechnical Commission (IEC) has established standards such as IEC 60034-9, which specifies noise limits for rotating electrical machines. This standard provides guidelines for measuring and reporting noise levels, ensuring consistency across different manufacturers and applications.

For automotive applications, regulations like the United Nations Economic Commission for Europe (UNECE) Regulation No. 51 set limits on vehicle noise emissions. These regulations directly impact the design and implementation of noise reduction techniques in PMSM-powered electric vehicles. Manufacturers must demonstrate compliance through standardized testing procedures and documentation.

In industrial settings, occupational health and safety regulations govern noise exposure limits for workers. For instance, the European Union's Directive 2003/10/EC on noise at work sets maximum exposure levels and requires employers to implement noise reduction measures where necessary. This directive influences the design of PMSM-powered systems used in industrial machinery and equipment.

Electromagnetic compatibility (EMC) regulations also intersect with noise reduction techniques in PMSM systems. The European Union's EMC Directive 2014/30/EU and similar regulations worldwide require that electrical equipment does not generate electromagnetic disturbances above a specified level. This necessitates the integration of EMC considerations into noise reduction strategies for PMSM-powered systems.

Environmental regulations, such as the EU's Eco-design Directive 2009/125/EC, indirectly impact noise reduction techniques by promoting energy efficiency in electric motors. As noise reduction often correlates with improved energy efficiency, compliance with these regulations can drive innovation in noise reduction technologies for PMSM systems.

To ensure regulatory compliance, manufacturers and researchers must adopt a holistic approach to noise reduction in PMSM-powered systems. This includes incorporating compliance considerations from the early stages of design, conducting rigorous testing and validation, and maintaining detailed documentation of noise reduction measures and their effectiveness. Regular updates to regulatory knowledge and proactive engagement with standardization bodies are essential to stay ahead of evolving compliance requirements in this rapidly advancing field.

In the context of PMSM-powered systems, noise reduction techniques must comply with several regulatory frameworks. The International Electrotechnical Commission (IEC) has established standards such as IEC 60034-9, which specifies noise limits for rotating electrical machines. This standard provides guidelines for measuring and reporting noise levels, ensuring consistency across different manufacturers and applications.

For automotive applications, regulations like the United Nations Economic Commission for Europe (UNECE) Regulation No. 51 set limits on vehicle noise emissions. These regulations directly impact the design and implementation of noise reduction techniques in PMSM-powered electric vehicles. Manufacturers must demonstrate compliance through standardized testing procedures and documentation.

In industrial settings, occupational health and safety regulations govern noise exposure limits for workers. For instance, the European Union's Directive 2003/10/EC on noise at work sets maximum exposure levels and requires employers to implement noise reduction measures where necessary. This directive influences the design of PMSM-powered systems used in industrial machinery and equipment.

Electromagnetic compatibility (EMC) regulations also intersect with noise reduction techniques in PMSM systems. The European Union's EMC Directive 2014/30/EU and similar regulations worldwide require that electrical equipment does not generate electromagnetic disturbances above a specified level. This necessitates the integration of EMC considerations into noise reduction strategies for PMSM-powered systems.

Environmental regulations, such as the EU's Eco-design Directive 2009/125/EC, indirectly impact noise reduction techniques by promoting energy efficiency in electric motors. As noise reduction often correlates with improved energy efficiency, compliance with these regulations can drive innovation in noise reduction technologies for PMSM systems.

To ensure regulatory compliance, manufacturers and researchers must adopt a holistic approach to noise reduction in PMSM-powered systems. This includes incorporating compliance considerations from the early stages of design, conducting rigorous testing and validation, and maintaining detailed documentation of noise reduction measures and their effectiveness. Regular updates to regulatory knowledge and proactive engagement with standardization bodies are essential to stay ahead of evolving compliance requirements in this rapidly advancing field.

Environmental Impact

The environmental impact of noise reduction techniques in PMSM-powered systems is a critical consideration in the development and implementation of these technologies. As industrial and consumer applications of Permanent Magnet Synchronous Motors (PMSMs) continue to expand, the need for effective noise reduction becomes increasingly important from both a performance and environmental perspective.

Noise pollution from PMSM-powered systems can have significant negative effects on both human health and the surrounding ecosystem. Prolonged exposure to high levels of noise can lead to hearing loss, stress, sleep disturbances, and decreased productivity in humans. In natural environments, excessive noise can disrupt animal communication, breeding patterns, and overall ecosystem balance.

Implementing noise reduction techniques in PMSM systems not only improves the quality of life for those in proximity to these machines but also contributes to the preservation of natural habitats. By minimizing acoustic emissions, these techniques help maintain biodiversity and protect sensitive wildlife populations from the detrimental effects of anthropogenic noise.

From an energy efficiency standpoint, many noise reduction techniques also contribute to improved overall system performance. By optimizing motor design and control strategies to reduce vibrations and acoustic emissions, these methods often lead to reduced energy consumption and increased motor lifespan. This, in turn, translates to lower resource utilization and decreased environmental impact throughout the lifecycle of PMSM-powered equipment.

The materials used in noise reduction solutions, such as acoustic insulation and vibration dampeners, must also be considered from an environmental perspective. Sustainable and recyclable materials should be prioritized to minimize the ecological footprint of these systems. Additionally, the manufacturing processes for noise reduction components should be evaluated and optimized to reduce energy consumption and waste production.

As regulations surrounding noise pollution become more stringent globally, the adoption of effective noise reduction techniques in PMSM-powered systems becomes not only an environmental imperative but also a legal necessity. Companies that proactively implement these technologies may gain a competitive advantage in markets with strict environmental standards, while also contributing to corporate social responsibility goals.

In conclusion, the environmental impact of noise reduction techniques in PMSM-powered systems extends far beyond mere acoustic considerations. These technologies play a crucial role in creating more sustainable and environmentally friendly industrial and consumer products, balancing the needs of technological advancement with ecological preservation and human well-being.

Noise pollution from PMSM-powered systems can have significant negative effects on both human health and the surrounding ecosystem. Prolonged exposure to high levels of noise can lead to hearing loss, stress, sleep disturbances, and decreased productivity in humans. In natural environments, excessive noise can disrupt animal communication, breeding patterns, and overall ecosystem balance.

Implementing noise reduction techniques in PMSM systems not only improves the quality of life for those in proximity to these machines but also contributes to the preservation of natural habitats. By minimizing acoustic emissions, these techniques help maintain biodiversity and protect sensitive wildlife populations from the detrimental effects of anthropogenic noise.

From an energy efficiency standpoint, many noise reduction techniques also contribute to improved overall system performance. By optimizing motor design and control strategies to reduce vibrations and acoustic emissions, these methods often lead to reduced energy consumption and increased motor lifespan. This, in turn, translates to lower resource utilization and decreased environmental impact throughout the lifecycle of PMSM-powered equipment.

The materials used in noise reduction solutions, such as acoustic insulation and vibration dampeners, must also be considered from an environmental perspective. Sustainable and recyclable materials should be prioritized to minimize the ecological footprint of these systems. Additionally, the manufacturing processes for noise reduction components should be evaluated and optimized to reduce energy consumption and waste production.

As regulations surrounding noise pollution become more stringent globally, the adoption of effective noise reduction techniques in PMSM-powered systems becomes not only an environmental imperative but also a legal necessity. Companies that proactively implement these technologies may gain a competitive advantage in markets with strict environmental standards, while also contributing to corporate social responsibility goals.

In conclusion, the environmental impact of noise reduction techniques in PMSM-powered systems extends far beyond mere acoustic considerations. These technologies play a crucial role in creating more sustainable and environmentally friendly industrial and consumer products, balancing the needs of technological advancement with ecological preservation and human well-being.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!