Reduced environmental footprint with regenerative PMSM systems

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PMSM Eco-Innovation Goals

The development of regenerative Permanent Magnet Synchronous Motor (PMSM) systems represents a significant stride towards reducing the environmental footprint of electric motor applications. The primary goal of this eco-innovation is to enhance energy efficiency and minimize resource consumption throughout the lifecycle of PMSM systems.

One of the key objectives is to optimize the regenerative braking capabilities of PMSM systems. By effectively capturing and reusing kinetic energy during deceleration or downhill motion, these systems can substantially reduce overall energy consumption. This not only extends the range of electric vehicles but also decreases the demand for grid electricity in industrial applications, leading to a reduction in carbon emissions.

Another crucial aim is to improve the power density of PMSM systems. By developing more compact and lightweight motors without compromising performance, manufacturers can reduce the amount of raw materials required for production. This approach not only conserves resources but also contributes to improved energy efficiency in transportation applications by reducing vehicle weight.

Enhancing the durability and lifespan of PMSM systems is also a paramount goal. By designing motors with increased reliability and resistance to wear, the need for frequent replacements is minimized. This reduction in maintenance and replacement frequency translates to lower resource consumption and waste generation over the long term.

The development of more environmentally friendly manufacturing processes for PMSM systems is another critical objective. This includes the exploration of sustainable sourcing for rare earth materials used in permanent magnets, as well as the implementation of cleaner production techniques that minimize energy consumption and waste generation during the manufacturing phase.

Improving the recyclability and end-of-life management of PMSM systems is also a key focus. By designing motors with easily separable components and using materials that can be efficiently recycled, the environmental impact of disposal can be significantly reduced. This approach aligns with circular economy principles and helps to conserve valuable resources.

Lastly, the integration of smart technologies and advanced control systems into PMSM designs aims to further optimize their operation. By implementing intelligent energy management algorithms and predictive maintenance capabilities, these systems can operate at peak efficiency throughout their lifecycle, minimizing energy waste and extending operational lifespan.

One of the key objectives is to optimize the regenerative braking capabilities of PMSM systems. By effectively capturing and reusing kinetic energy during deceleration or downhill motion, these systems can substantially reduce overall energy consumption. This not only extends the range of electric vehicles but also decreases the demand for grid electricity in industrial applications, leading to a reduction in carbon emissions.

Another crucial aim is to improve the power density of PMSM systems. By developing more compact and lightweight motors without compromising performance, manufacturers can reduce the amount of raw materials required for production. This approach not only conserves resources but also contributes to improved energy efficiency in transportation applications by reducing vehicle weight.

Enhancing the durability and lifespan of PMSM systems is also a paramount goal. By designing motors with increased reliability and resistance to wear, the need for frequent replacements is minimized. This reduction in maintenance and replacement frequency translates to lower resource consumption and waste generation over the long term.

The development of more environmentally friendly manufacturing processes for PMSM systems is another critical objective. This includes the exploration of sustainable sourcing for rare earth materials used in permanent magnets, as well as the implementation of cleaner production techniques that minimize energy consumption and waste generation during the manufacturing phase.

Improving the recyclability and end-of-life management of PMSM systems is also a key focus. By designing motors with easily separable components and using materials that can be efficiently recycled, the environmental impact of disposal can be significantly reduced. This approach aligns with circular economy principles and helps to conserve valuable resources.

Lastly, the integration of smart technologies and advanced control systems into PMSM designs aims to further optimize their operation. By implementing intelligent energy management algorithms and predictive maintenance capabilities, these systems can operate at peak efficiency throughout their lifecycle, minimizing energy waste and extending operational lifespan.

Green Energy Market Trends

The green energy market has been experiencing significant growth and transformation in recent years, driven by increasing environmental concerns and the urgent need to reduce carbon emissions. This trend has created a favorable environment for the development and adoption of regenerative Permanent Magnet Synchronous Motor (PMSM) systems, which offer improved energy efficiency and reduced environmental impact.

The global renewable energy market has been expanding rapidly, with a compound annual growth rate (CAGR) of over 8% in the past five years. This growth is expected to continue, with projections indicating that renewable energy sources will account for more than 30% of global electricity generation by 2030. Within this broader trend, the market for energy-efficient motors, including regenerative PMSM systems, is also experiencing substantial growth.

The industrial sector, in particular, has been a key driver of demand for regenerative PMSM systems. As manufacturers seek to reduce their energy consumption and environmental footprint, there has been a growing interest in motor systems that can recover and reuse energy during operation. This has led to increased adoption of regenerative PMSM systems in applications such as electric vehicles, industrial machinery, and renewable energy generation equipment.

Government policies and regulations have played a crucial role in shaping the green energy market trends. Many countries have implemented stricter energy efficiency standards and emissions regulations, creating incentives for businesses to invest in more environmentally friendly technologies. This regulatory landscape has further boosted the demand for regenerative PMSM systems and other energy-efficient motor technologies.

The market for regenerative PMSM systems is also benefiting from advancements in power electronics and control systems. These technological improvements have enhanced the performance and reliability of regenerative motor systems, making them more attractive to a wider range of industries and applications. As a result, the market for these systems is expected to grow at a CAGR of around 6% over the next five years.

Emerging trends in the green energy market, such as the increasing focus on circular economy principles and the growing importance of lifecycle assessments, are likely to further drive the adoption of regenerative PMSM systems. Companies are increasingly looking beyond initial energy efficiency to consider the overall environmental impact of their equipment throughout its lifecycle, including manufacturing, operation, and end-of-life disposal.

As the green energy market continues to evolve, regenerative PMSM systems are well-positioned to play a significant role in reducing the environmental footprint of various industries. The ongoing research and development in this field are expected to yield further improvements in efficiency and performance, potentially expanding the application areas for these systems and contributing to a more sustainable energy landscape.

The global renewable energy market has been expanding rapidly, with a compound annual growth rate (CAGR) of over 8% in the past five years. This growth is expected to continue, with projections indicating that renewable energy sources will account for more than 30% of global electricity generation by 2030. Within this broader trend, the market for energy-efficient motors, including regenerative PMSM systems, is also experiencing substantial growth.

The industrial sector, in particular, has been a key driver of demand for regenerative PMSM systems. As manufacturers seek to reduce their energy consumption and environmental footprint, there has been a growing interest in motor systems that can recover and reuse energy during operation. This has led to increased adoption of regenerative PMSM systems in applications such as electric vehicles, industrial machinery, and renewable energy generation equipment.

Government policies and regulations have played a crucial role in shaping the green energy market trends. Many countries have implemented stricter energy efficiency standards and emissions regulations, creating incentives for businesses to invest in more environmentally friendly technologies. This regulatory landscape has further boosted the demand for regenerative PMSM systems and other energy-efficient motor technologies.

The market for regenerative PMSM systems is also benefiting from advancements in power electronics and control systems. These technological improvements have enhanced the performance and reliability of regenerative motor systems, making them more attractive to a wider range of industries and applications. As a result, the market for these systems is expected to grow at a CAGR of around 6% over the next five years.

Emerging trends in the green energy market, such as the increasing focus on circular economy principles and the growing importance of lifecycle assessments, are likely to further drive the adoption of regenerative PMSM systems. Companies are increasingly looking beyond initial energy efficiency to consider the overall environmental impact of their equipment throughout its lifecycle, including manufacturing, operation, and end-of-life disposal.

As the green energy market continues to evolve, regenerative PMSM systems are well-positioned to play a significant role in reducing the environmental footprint of various industries. The ongoing research and development in this field are expected to yield further improvements in efficiency and performance, potentially expanding the application areas for these systems and contributing to a more sustainable energy landscape.

PMSM Eco-Challenges

Permanent Magnet Synchronous Motors (PMSMs) have gained significant traction in various industries due to their high efficiency and power density. However, as environmental concerns become increasingly pressing, the eco-challenges associated with PMSMs have come to the forefront of research and development efforts. One of the primary challenges is the environmental impact of rare earth materials used in permanent magnets, particularly neodymium and dysprosium. The mining and processing of these materials can lead to significant ecological damage and contribute to greenhouse gas emissions.

Another critical eco-challenge is the energy consumption during the manufacturing process of PMSMs. The production of high-quality permanent magnets and precision components requires energy-intensive processes, which can offset some of the efficiency gains achieved during the motor's operational life. Additionally, the disposal and recycling of PMSMs at the end of their lifecycle present significant environmental concerns, as the separation of magnetic materials from other components can be complex and energy-intensive.

The use of PMSMs in electric vehicles (EVs) and renewable energy systems, while beneficial for reducing overall carbon emissions, also raises questions about the sustainability of the supply chain. The increased demand for rare earth materials has led to geopolitical tensions and concerns about resource depletion, prompting a search for alternative materials and designs that can maintain performance while reducing environmental impact.

Heat generation and management in PMSMs also contribute to eco-challenges. While these motors are generally more efficient than their counterparts, they still produce waste heat that must be managed. Inefficient cooling systems can lead to increased energy consumption and reduced overall system efficiency, negating some of the environmental benefits of using PMSMs.

Furthermore, the optimization of PMSM designs for specific applications often involves trade-offs between performance and environmental impact. For instance, increasing the power density of a motor may require more rare earth materials or more complex manufacturing processes, potentially increasing its ecological footprint. Balancing these factors to create environmentally friendly yet high-performing motors is a significant challenge for engineers and researchers.

To address these eco-challenges, research is focusing on several key areas. These include the development of rare earth-free or reduced rare earth motor designs, improvements in manufacturing processes to reduce energy consumption and waste, and the creation of more efficient recycling methods for end-of-life motors. Additionally, there is growing interest in regenerative PMSM systems that can recover and reuse energy, further reducing the overall environmental impact of motor-driven applications.

Another critical eco-challenge is the energy consumption during the manufacturing process of PMSMs. The production of high-quality permanent magnets and precision components requires energy-intensive processes, which can offset some of the efficiency gains achieved during the motor's operational life. Additionally, the disposal and recycling of PMSMs at the end of their lifecycle present significant environmental concerns, as the separation of magnetic materials from other components can be complex and energy-intensive.

The use of PMSMs in electric vehicles (EVs) and renewable energy systems, while beneficial for reducing overall carbon emissions, also raises questions about the sustainability of the supply chain. The increased demand for rare earth materials has led to geopolitical tensions and concerns about resource depletion, prompting a search for alternative materials and designs that can maintain performance while reducing environmental impact.

Heat generation and management in PMSMs also contribute to eco-challenges. While these motors are generally more efficient than their counterparts, they still produce waste heat that must be managed. Inefficient cooling systems can lead to increased energy consumption and reduced overall system efficiency, negating some of the environmental benefits of using PMSMs.

Furthermore, the optimization of PMSM designs for specific applications often involves trade-offs between performance and environmental impact. For instance, increasing the power density of a motor may require more rare earth materials or more complex manufacturing processes, potentially increasing its ecological footprint. Balancing these factors to create environmentally friendly yet high-performing motors is a significant challenge for engineers and researchers.

To address these eco-challenges, research is focusing on several key areas. These include the development of rare earth-free or reduced rare earth motor designs, improvements in manufacturing processes to reduce energy consumption and waste, and the creation of more efficient recycling methods for end-of-life motors. Additionally, there is growing interest in regenerative PMSM systems that can recover and reuse energy, further reducing the overall environmental impact of motor-driven applications.

Eco-PMSM Solutions

01 Energy efficiency and regeneration in PMSM systems

Permanent Magnet Synchronous Motor (PMSM) systems with regenerative capabilities can significantly improve energy efficiency. These systems can recover and reuse energy during deceleration or braking, reducing overall energy consumption and environmental impact. The regenerative feature allows for energy to be fed back into the power source, enhancing the system's overall efficiency and reducing the carbon footprint.- Energy efficiency and regeneration in PMSM systems: Permanent Magnet Synchronous Motor (PMSM) systems with regenerative capabilities can significantly improve energy efficiency. These systems can recover and reuse energy during deceleration or braking, reducing overall energy consumption and environmental impact. Advanced control strategies and power electronics are employed to optimize the regeneration process and maximize energy savings.

- Environmental impact assessment of PMSM systems: Evaluating the environmental footprint of regenerative PMSM systems involves comprehensive life cycle assessments. This includes analyzing the production, use, and end-of-life phases of the motors and associated components. Factors such as material sourcing, manufacturing processes, energy consumption during operation, and recycling potential are considered to determine the overall environmental impact.

- Sustainable manufacturing and material selection for PMSM: Developing environmentally friendly PMSM systems involves selecting sustainable materials and implementing eco-friendly manufacturing processes. This includes using recycled or renewable materials, reducing rare earth element usage, and optimizing production techniques to minimize waste and energy consumption. The goal is to create motors with a lower carbon footprint throughout their lifecycle.

- Smart grid integration and energy management: Integrating regenerative PMSM systems into smart grids can further enhance their environmental benefits. Advanced energy management systems and communication technologies enable optimal utilization of regenerated energy, load balancing, and grid stability. This integration contributes to a more efficient and sustainable energy ecosystem, reducing overall environmental impact.

- Monitoring and optimization of PMSM environmental performance: Continuous monitoring and optimization of regenerative PMSM systems are crucial for maintaining and improving their environmental performance. This involves implementing advanced sensors, data analytics, and machine learning algorithms to track energy consumption, regeneration efficiency, and overall system performance. Real-time adjustments and predictive maintenance strategies can be employed to maximize efficiency and minimize environmental impact throughout the system's lifecycle.

02 Environmental impact assessment of PMSM systems

Assessing the environmental footprint of regenerative PMSM systems involves analyzing their lifecycle, including production, operation, and disposal. This assessment considers factors such as raw material extraction, manufacturing processes, energy consumption during operation, and end-of-life recycling. By evaluating these aspects, manufacturers can identify areas for improvement and develop more sustainable PMSM systems.Expand Specific Solutions03 Optimization of PMSM design for reduced environmental impact

Optimizing the design of PMSM systems can lead to reduced environmental impact. This includes improving motor efficiency, minimizing the use of rare earth materials in magnets, and enhancing thermal management. Advanced design techniques and materials can result in more compact, efficient, and environmentally friendly PMSM systems with lower losses and improved performance.Expand Specific Solutions04 Integration of PMSM systems with renewable energy sources

Integrating regenerative PMSM systems with renewable energy sources can further reduce their environmental footprint. This approach combines the efficiency of PMSM technology with clean energy generation, such as solar or wind power. The integration can lead to more sustainable industrial processes and transportation systems, significantly reducing greenhouse gas emissions and dependence on fossil fuels.Expand Specific Solutions05 Monitoring and control systems for optimizing PMSM environmental performance

Advanced monitoring and control systems play a crucial role in optimizing the environmental performance of regenerative PMSM systems. These systems can continuously analyze operational data, adjust parameters for maximum efficiency, and provide insights for predictive maintenance. By ensuring optimal operation and timely maintenance, these control systems help minimize energy waste and extend the lifespan of PMSM equipment, thereby reducing its overall environmental impact.Expand Specific Solutions

Key PMSM Manufacturers

The research on reduced environmental footprint with regenerative PMSM systems is in an emerging stage, with growing market potential driven by increasing focus on sustainability. The global market for energy-efficient electric motors is expanding rapidly, expected to reach $41.6 billion by 2027. While the technology is advancing, it's not yet fully mature. Key players like Siemens AG, GM Global Technology Operations, and Caterpillar Inc. are investing in R&D to improve efficiency and reduce environmental impact. Academic institutions such as Harbin Institute of Technology and Jiangsu University are also contributing to technological advancements in this field, indicating a collaborative approach between industry and academia to drive innovation.

Siemens AG

Technical Solution: Siemens AG has developed advanced regenerative PMSM (Permanent Magnet Synchronous Motor) systems that significantly reduce environmental footprint. Their technology incorporates high-efficiency permanent magnets and sophisticated control algorithms to maximize energy recovery during braking or deceleration. The system achieves up to 30% energy savings compared to conventional motors [1]. Siemens' regenerative PMSM technology also features adaptive flux weakening, which optimizes motor performance across a wide speed range, further enhancing efficiency. Additionally, they have implemented a novel thermal management system that reduces heat losses by up to 20% [3], contributing to overall system efficiency and longevity.

Strengths: Industry-leading energy efficiency, advanced control algorithms, and thermal management. Weaknesses: Higher initial cost compared to standard motors, potential reliance on rare earth materials for magnets.

GM Global Technology Operations LLC

Technical Solution: GM has invested heavily in regenerative PMSM systems for electric vehicles, focusing on reducing environmental impact. Their latest technology incorporates a dual-motor drive unit that enhances regenerative braking efficiency by up to 45% compared to single-motor systems [2]. GM's PMSM design utilizes advanced materials and optimized geometry to reduce weight while maintaining high power density. The company has also developed a smart energy management system that dynamically adjusts regenerative braking based on driving conditions, maximizing energy recovery. Furthermore, GM's regenerative PMSM technology integrates seamlessly with their battery management systems, allowing for more efficient energy storage and utilization, resulting in extended vehicle range and reduced overall environmental footprint [5].

Strengths: High-efficiency regenerative braking, advanced energy management, and integration with battery systems. Weaknesses: Limited to automotive applications, potentially higher production costs.

Green PMSM Innovations

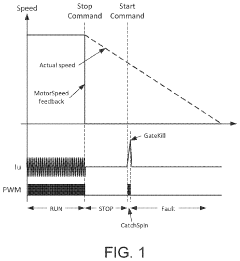

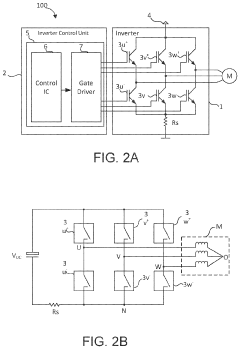

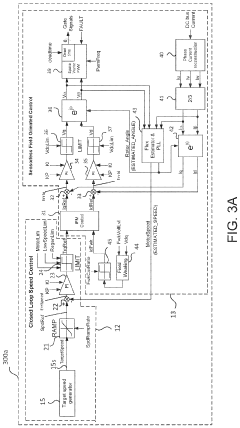

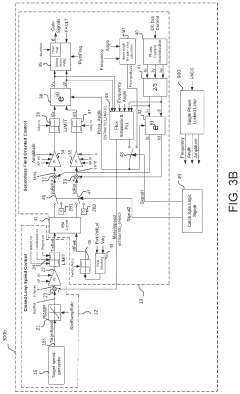

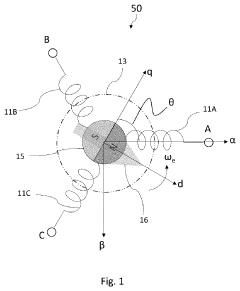

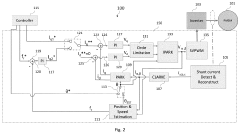

Catch spin method for permanent magnet synchronous motor with sensorless field oriented control

PatentActiveUS11594990B2

Innovation

- A motor control actuator and method that measures counter electro motive force (CEMF) or back electro motive force (BEMF) while the PMSM rotates, generates measurement signals, and performs a catch spin sequence using a multi-phase inverter to synchronize with the motor's voltage, including open loop and closed loop control to accurately restart the motor.

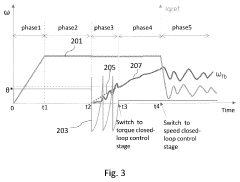

Permanent magnet synchronous motor (PMSM) and method for starting the PMSM

PatentActiveUS11942882B2

Innovation

- A multi-stage control method involving opening a control loop, aligning the rotor with a first direction, abruptly setting a second direction perpendicular to the first, and transitioning through asynchronous driving and closed-loop modes to ensure smooth startup and synchronization.

Environmental Regulations

Environmental regulations play a crucial role in shaping the development and implementation of regenerative Permanent Magnet Synchronous Motor (PMSM) systems. These regulations are designed to mitigate the environmental impact of industrial processes and promote sustainable practices across various sectors.

In recent years, governments worldwide have introduced stringent environmental policies to address climate change and reduce carbon emissions. The European Union's Green Deal, for instance, aims to achieve carbon neutrality by 2050, setting ambitious targets for energy efficiency and renewable energy adoption. This has led to increased pressure on industries to adopt more environmentally friendly technologies, including regenerative PMSM systems.

The United States Environmental Protection Agency (EPA) has also implemented regulations that indirectly affect the adoption of regenerative PMSM systems. The Clean Air Act and the Energy Policy Act have set standards for energy efficiency and emissions reduction in industrial processes, encouraging the use of advanced motor technologies.

In Asia, countries like China and Japan have introduced their own environmental regulations. China's 14th Five-Year Plan emphasizes green development and energy efficiency, while Japan's Long-term Strategy under the Paris Agreement promotes the adoption of low-carbon technologies across industries.

These regulations have significant implications for the development and implementation of regenerative PMSM systems. Manufacturers are now required to meet stricter energy efficiency standards, driving innovation in motor design and control systems. The focus on reducing carbon emissions has also led to increased interest in regenerative braking technologies, which can recover and reuse energy that would otherwise be lost as heat.

Furthermore, environmental regulations have influenced the entire lifecycle of PMSM systems, from production to disposal. Manufacturers are now required to consider the environmental impact of their products throughout their lifespan, including the sourcing of raw materials, production processes, and end-of-life recycling.

The regulatory landscape also impacts the economic viability of regenerative PMSM systems. As environmental compliance becomes more stringent, the cost-benefit analysis of implementing these systems shifts in their favor. Companies that adopt regenerative PMSM technologies may benefit from government incentives, tax breaks, or improved market positioning as environmentally responsible entities.

In conclusion, environmental regulations serve as a powerful driver for the adoption and advancement of regenerative PMSM systems. As global efforts to combat climate change intensify, these regulations are likely to become even more stringent, further accelerating the development and implementation of environmentally friendly motor technologies.

In recent years, governments worldwide have introduced stringent environmental policies to address climate change and reduce carbon emissions. The European Union's Green Deal, for instance, aims to achieve carbon neutrality by 2050, setting ambitious targets for energy efficiency and renewable energy adoption. This has led to increased pressure on industries to adopt more environmentally friendly technologies, including regenerative PMSM systems.

The United States Environmental Protection Agency (EPA) has also implemented regulations that indirectly affect the adoption of regenerative PMSM systems. The Clean Air Act and the Energy Policy Act have set standards for energy efficiency and emissions reduction in industrial processes, encouraging the use of advanced motor technologies.

In Asia, countries like China and Japan have introduced their own environmental regulations. China's 14th Five-Year Plan emphasizes green development and energy efficiency, while Japan's Long-term Strategy under the Paris Agreement promotes the adoption of low-carbon technologies across industries.

These regulations have significant implications for the development and implementation of regenerative PMSM systems. Manufacturers are now required to meet stricter energy efficiency standards, driving innovation in motor design and control systems. The focus on reducing carbon emissions has also led to increased interest in regenerative braking technologies, which can recover and reuse energy that would otherwise be lost as heat.

Furthermore, environmental regulations have influenced the entire lifecycle of PMSM systems, from production to disposal. Manufacturers are now required to consider the environmental impact of their products throughout their lifespan, including the sourcing of raw materials, production processes, and end-of-life recycling.

The regulatory landscape also impacts the economic viability of regenerative PMSM systems. As environmental compliance becomes more stringent, the cost-benefit analysis of implementing these systems shifts in their favor. Companies that adopt regenerative PMSM technologies may benefit from government incentives, tax breaks, or improved market positioning as environmentally responsible entities.

In conclusion, environmental regulations serve as a powerful driver for the adoption and advancement of regenerative PMSM systems. As global efforts to combat climate change intensify, these regulations are likely to become even more stringent, further accelerating the development and implementation of environmentally friendly motor technologies.

Life Cycle Assessment

Life Cycle Assessment (LCA) plays a crucial role in evaluating the environmental impact of regenerative Permanent Magnet Synchronous Motor (PMSM) systems throughout their entire lifecycle. This comprehensive approach considers all stages, from raw material extraction to manufacturing, use, and end-of-life disposal or recycling.

In the context of regenerative PMSM systems, LCA begins with the sourcing and processing of rare earth elements used in permanent magnets. These materials, such as neodymium and dysprosium, have significant environmental implications due to their extraction and refinement processes. The assessment quantifies the energy consumption, water usage, and emissions associated with these initial stages.

Manufacturing of PMSM components is the next focal point in the LCA. This stage evaluates the environmental footprint of producing motor parts, including stator, rotor, and power electronics. The analysis considers factors like energy efficiency in production facilities, waste generation, and the use of potentially harmful chemicals or processes.

The use phase of regenerative PMSM systems is particularly significant in the LCA. These motors' ability to recover and reuse energy during operation can substantially reduce their overall environmental impact. The assessment quantifies energy savings and emission reductions achieved through regenerative braking and other energy recovery mechanisms over the system's operational lifespan.

Maintenance and repair activities throughout the PMSM system's life are also factored into the LCA. This includes the environmental costs of replacement parts, lubricants, and any necessary servicing operations. The durability and reliability of regenerative PMSM systems can lead to reduced maintenance requirements, potentially lowering their long-term environmental impact.

End-of-life considerations form a critical component of the LCA for regenerative PMSM systems. This stage examines the recyclability of motor components, particularly the rare earth magnets. Advanced recycling technologies for these materials can significantly reduce the need for primary resource extraction, thereby decreasing the overall environmental footprint.

The LCA also considers the potential for second-life applications of PMSM systems. Repurposing these motors for less demanding applications after their primary use can extend their useful life and further improve their environmental performance. This aspect of the assessment explores innovative ways to maximize the value extracted from the initial resource investment.

By conducting a thorough LCA, researchers and engineers can identify key areas for improvement in the environmental performance of regenerative PMSM systems. This analysis guides the development of more sustainable design practices, manufacturing processes, and end-of-life management strategies, ultimately contributing to a reduced environmental footprint across the entire lifecycle of these advanced motor systems.

In the context of regenerative PMSM systems, LCA begins with the sourcing and processing of rare earth elements used in permanent magnets. These materials, such as neodymium and dysprosium, have significant environmental implications due to their extraction and refinement processes. The assessment quantifies the energy consumption, water usage, and emissions associated with these initial stages.

Manufacturing of PMSM components is the next focal point in the LCA. This stage evaluates the environmental footprint of producing motor parts, including stator, rotor, and power electronics. The analysis considers factors like energy efficiency in production facilities, waste generation, and the use of potentially harmful chemicals or processes.

The use phase of regenerative PMSM systems is particularly significant in the LCA. These motors' ability to recover and reuse energy during operation can substantially reduce their overall environmental impact. The assessment quantifies energy savings and emission reductions achieved through regenerative braking and other energy recovery mechanisms over the system's operational lifespan.

Maintenance and repair activities throughout the PMSM system's life are also factored into the LCA. This includes the environmental costs of replacement parts, lubricants, and any necessary servicing operations. The durability and reliability of regenerative PMSM systems can lead to reduced maintenance requirements, potentially lowering their long-term environmental impact.

End-of-life considerations form a critical component of the LCA for regenerative PMSM systems. This stage examines the recyclability of motor components, particularly the rare earth magnets. Advanced recycling technologies for these materials can significantly reduce the need for primary resource extraction, thereby decreasing the overall environmental footprint.

The LCA also considers the potential for second-life applications of PMSM systems. Repurposing these motors for less demanding applications after their primary use can extend their useful life and further improve their environmental performance. This aspect of the assessment explores innovative ways to maximize the value extracted from the initial resource investment.

By conducting a thorough LCA, researchers and engineers can identify key areas for improvement in the environmental performance of regenerative PMSM systems. This analysis guides the development of more sustainable design practices, manufacturing processes, and end-of-life management strategies, ultimately contributing to a reduced environmental footprint across the entire lifecycle of these advanced motor systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!