Strategies for distributing PMSM in remote locations

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PMSM Remote Distribution Background and Objectives

Permanent Magnet Synchronous Motors (PMSMs) have emerged as a crucial technology in various industries due to their high efficiency, power density, and reliability. The challenge of distributing PMSMs in remote locations has become increasingly important as industries expand into less accessible areas. This technological evolution is driven by the growing demand for efficient and sustainable power solutions in remote regions, where traditional power distribution methods may be impractical or cost-prohibitive.

The development of PMSM distribution strategies for remote locations can be traced back to the early 2000s when advancements in power electronics and control systems enabled more flexible and robust motor applications. As renewable energy sources gained prominence, the need for efficient motor systems in off-grid and microgrid applications further accelerated the development of remote PMSM distribution techniques.

The primary objective of remote PMSM distribution is to provide reliable, high-performance motor solutions in areas with limited infrastructure and challenging environmental conditions. This includes addressing issues such as power quality, grid stability, and maintenance in locations where traditional support systems may be absent or unreliable.

Key technological trends in this field include the integration of smart grid technologies, the development of ruggedized PMSM designs for harsh environments, and the implementation of advanced control algorithms for improved efficiency and reliability. Additionally, the incorporation of energy storage systems and hybrid power solutions has become increasingly important in ensuring consistent power supply to PMSMs in remote settings.

The market demand for remote PMSM distribution solutions has seen significant growth in sectors such as mining, oil and gas exploration, remote industrial facilities, and off-grid renewable energy projects. This demand is driven by the need for energy-efficient, low-maintenance motor systems that can operate reliably in isolated locations with minimal on-site support.

As the technology continues to evolve, several key objectives have emerged for remote PMSM distribution strategies. These include improving the resilience of motor systems to power fluctuations and environmental stressors, enhancing remote monitoring and diagnostics capabilities, and developing more efficient power transmission methods for long-distance applications.

Furthermore, the integration of renewable energy sources with PMSM systems in remote locations has become a critical focus area. This integration aims to reduce reliance on fossil fuels, lower operational costs, and minimize the environmental impact of remote industrial operations. The development of hybrid systems that combine solar, wind, or other renewable sources with energy storage and efficient PMSM technology is a key trend in addressing the challenges of remote power distribution.

The development of PMSM distribution strategies for remote locations can be traced back to the early 2000s when advancements in power electronics and control systems enabled more flexible and robust motor applications. As renewable energy sources gained prominence, the need for efficient motor systems in off-grid and microgrid applications further accelerated the development of remote PMSM distribution techniques.

The primary objective of remote PMSM distribution is to provide reliable, high-performance motor solutions in areas with limited infrastructure and challenging environmental conditions. This includes addressing issues such as power quality, grid stability, and maintenance in locations where traditional support systems may be absent or unreliable.

Key technological trends in this field include the integration of smart grid technologies, the development of ruggedized PMSM designs for harsh environments, and the implementation of advanced control algorithms for improved efficiency and reliability. Additionally, the incorporation of energy storage systems and hybrid power solutions has become increasingly important in ensuring consistent power supply to PMSMs in remote settings.

The market demand for remote PMSM distribution solutions has seen significant growth in sectors such as mining, oil and gas exploration, remote industrial facilities, and off-grid renewable energy projects. This demand is driven by the need for energy-efficient, low-maintenance motor systems that can operate reliably in isolated locations with minimal on-site support.

As the technology continues to evolve, several key objectives have emerged for remote PMSM distribution strategies. These include improving the resilience of motor systems to power fluctuations and environmental stressors, enhancing remote monitoring and diagnostics capabilities, and developing more efficient power transmission methods for long-distance applications.

Furthermore, the integration of renewable energy sources with PMSM systems in remote locations has become a critical focus area. This integration aims to reduce reliance on fossil fuels, lower operational costs, and minimize the environmental impact of remote industrial operations. The development of hybrid systems that combine solar, wind, or other renewable sources with energy storage and efficient PMSM technology is a key trend in addressing the challenges of remote power distribution.

Market Analysis for Remote PMSM Applications

The market for Permanent Magnet Synchronous Motors (PMSM) in remote locations is experiencing significant growth, driven by the increasing demand for efficient and reliable power solutions in areas with limited infrastructure. Remote locations, including rural communities, off-grid industrial sites, and isolated research stations, present unique challenges and opportunities for PMSM applications.

The primary market segments for remote PMSM applications include renewable energy systems, water pumping stations, telecommunications infrastructure, and small-scale manufacturing facilities. In the renewable energy sector, PMSMs are increasingly used in wind turbines and micro-hydro systems, providing efficient power generation in areas without access to conventional grid electricity. The water pumping market is particularly promising, as remote communities and agricultural operations require reliable water supply solutions that can operate with minimal maintenance.

Telecommunications companies are also driving demand for PMSMs in remote locations, as they expand their networks to cover underserved areas. These motors are used in cooling systems for cellular towers and satellite ground stations, ensuring reliable operation in harsh environments. Additionally, small-scale manufacturing facilities in remote areas are adopting PMSMs for various applications, including milling, textile production, and food processing, due to their high efficiency and low maintenance requirements.

The market size for remote PMSM applications is expected to grow substantially in the coming years. Factors contributing to this growth include government initiatives to electrify rural areas, increasing investments in renewable energy projects, and the expansion of telecommunications infrastructure in developing countries. The Asia-Pacific region is anticipated to be the fastest-growing market, followed by Africa and Latin America, where large populations still lack access to reliable electricity.

Key market drivers include the superior efficiency of PMSMs compared to traditional motor technologies, their ability to operate in harsh environments, and their compatibility with renewable energy systems. The long lifespan and reduced maintenance requirements of PMSMs make them particularly attractive for remote applications where regular servicing can be challenging and costly.

However, the market also faces several challenges. The high initial cost of PMSMs compared to conventional motors can be a barrier to adoption, especially in cost-sensitive markets. Limited awareness of PMSM technology and its benefits among potential end-users in remote areas is another obstacle. Additionally, the lack of skilled technicians for installation and maintenance in remote locations can hinder market growth.

To address these challenges and capitalize on market opportunities, manufacturers and distributors are developing strategies such as partnering with local organizations for training and support, offering financing options to reduce upfront costs, and creating modular, easy-to-install PMSM systems tailored for remote applications. As the technology continues to advance and costs decrease, the market for PMSMs in remote locations is poised for substantial expansion, playing a crucial role in improving energy access and economic development in underserved areas worldwide.

The primary market segments for remote PMSM applications include renewable energy systems, water pumping stations, telecommunications infrastructure, and small-scale manufacturing facilities. In the renewable energy sector, PMSMs are increasingly used in wind turbines and micro-hydro systems, providing efficient power generation in areas without access to conventional grid electricity. The water pumping market is particularly promising, as remote communities and agricultural operations require reliable water supply solutions that can operate with minimal maintenance.

Telecommunications companies are also driving demand for PMSMs in remote locations, as they expand their networks to cover underserved areas. These motors are used in cooling systems for cellular towers and satellite ground stations, ensuring reliable operation in harsh environments. Additionally, small-scale manufacturing facilities in remote areas are adopting PMSMs for various applications, including milling, textile production, and food processing, due to their high efficiency and low maintenance requirements.

The market size for remote PMSM applications is expected to grow substantially in the coming years. Factors contributing to this growth include government initiatives to electrify rural areas, increasing investments in renewable energy projects, and the expansion of telecommunications infrastructure in developing countries. The Asia-Pacific region is anticipated to be the fastest-growing market, followed by Africa and Latin America, where large populations still lack access to reliable electricity.

Key market drivers include the superior efficiency of PMSMs compared to traditional motor technologies, their ability to operate in harsh environments, and their compatibility with renewable energy systems. The long lifespan and reduced maintenance requirements of PMSMs make them particularly attractive for remote applications where regular servicing can be challenging and costly.

However, the market also faces several challenges. The high initial cost of PMSMs compared to conventional motors can be a barrier to adoption, especially in cost-sensitive markets. Limited awareness of PMSM technology and its benefits among potential end-users in remote areas is another obstacle. Additionally, the lack of skilled technicians for installation and maintenance in remote locations can hinder market growth.

To address these challenges and capitalize on market opportunities, manufacturers and distributors are developing strategies such as partnering with local organizations for training and support, offering financing options to reduce upfront costs, and creating modular, easy-to-install PMSM systems tailored for remote applications. As the technology continues to advance and costs decrease, the market for PMSMs in remote locations is poised for substantial expansion, playing a crucial role in improving energy access and economic development in underserved areas worldwide.

Technical Challenges in Remote PMSM Distribution

The distribution of Permanent Magnet Synchronous Motors (PMSM) in remote locations presents several significant technical challenges. One of the primary obstacles is the lack of robust infrastructure in these areas, which complicates the transportation and installation of PMSM systems. Remote locations often have limited access to reliable power grids, making it difficult to ensure consistent energy supply for motor operation and maintenance.

Environmental factors pose another set of challenges. Extreme temperatures, high humidity, dust, and corrosive atmospheres common in remote areas can adversely affect the performance and longevity of PMSM components. These conditions necessitate the development of specialized protective measures and materials to ensure the motors can withstand harsh operating environments.

Maintenance and repair issues are particularly acute in remote settings. The scarcity of skilled technicians and the logistical difficulties in transporting replacement parts can lead to extended downtime and reduced operational efficiency. This challenge is compounded by the need for specialized tools and diagnostic equipment, which may not be readily available in remote locations.

Communication and control systems for PMSM in remote areas face unique hurdles. The lack of reliable internet connectivity and cellular networks can impede remote monitoring and control capabilities, essential for optimal motor performance and predictive maintenance. Implementing robust, low-bandwidth communication solutions becomes crucial in these scenarios.

Power quality and stability issues are more pronounced in remote locations. Voltage fluctuations, harmonics, and power interruptions can significantly impact PMSM performance and lifespan. Developing advanced power conditioning systems and energy storage solutions becomes essential to mitigate these challenges and ensure consistent motor operation.

The integration of PMSM with local renewable energy sources, such as solar or wind power, presents both opportunities and challenges. While it can enhance energy independence in remote areas, it also requires sophisticated control systems to manage the variability of renewable energy sources and maintain stable motor operation.

Lastly, the cost factor remains a significant challenge. The expenses associated with transporting, installing, and maintaining PMSM in remote locations can be substantially higher than in more accessible areas. This necessitates the development of cost-effective solutions and innovative business models to make PMSM technology viable in these challenging environments.

Environmental factors pose another set of challenges. Extreme temperatures, high humidity, dust, and corrosive atmospheres common in remote areas can adversely affect the performance and longevity of PMSM components. These conditions necessitate the development of specialized protective measures and materials to ensure the motors can withstand harsh operating environments.

Maintenance and repair issues are particularly acute in remote settings. The scarcity of skilled technicians and the logistical difficulties in transporting replacement parts can lead to extended downtime and reduced operational efficiency. This challenge is compounded by the need for specialized tools and diagnostic equipment, which may not be readily available in remote locations.

Communication and control systems for PMSM in remote areas face unique hurdles. The lack of reliable internet connectivity and cellular networks can impede remote monitoring and control capabilities, essential for optimal motor performance and predictive maintenance. Implementing robust, low-bandwidth communication solutions becomes crucial in these scenarios.

Power quality and stability issues are more pronounced in remote locations. Voltage fluctuations, harmonics, and power interruptions can significantly impact PMSM performance and lifespan. Developing advanced power conditioning systems and energy storage solutions becomes essential to mitigate these challenges and ensure consistent motor operation.

The integration of PMSM with local renewable energy sources, such as solar or wind power, presents both opportunities and challenges. While it can enhance energy independence in remote areas, it also requires sophisticated control systems to manage the variability of renewable energy sources and maintain stable motor operation.

Lastly, the cost factor remains a significant challenge. The expenses associated with transporting, installing, and maintaining PMSM in remote locations can be substantially higher than in more accessible areas. This necessitates the development of cost-effective solutions and innovative business models to make PMSM technology viable in these challenging environments.

Current Remote PMSM Distribution Strategies

01 Control systems for PMSM

Advanced control systems are developed for Permanent Magnet Synchronous Motors to improve their performance and efficiency. These systems may include sensorless control techniques, adaptive control algorithms, and advanced motor drive technologies to enhance speed regulation, torque control, and overall motor operation.- Control systems for PMSM: Advanced control systems are developed for Permanent Magnet Synchronous Motors to improve their performance and efficiency. These systems may include sensorless control techniques, adaptive control algorithms, and advanced motor drive technologies to optimize motor operation under various conditions.

- PMSM design optimization: Innovations in PMSM design focus on optimizing motor structure, magnetic circuit design, and materials to enhance power density, efficiency, and thermal management. This includes advancements in rotor and stator configurations, permanent magnet arrangements, and the use of novel materials.

- PMSM applications in electric vehicles: PMSMs are increasingly used in electric vehicle powertrains due to their high efficiency and power density. Developments in this area include specialized motor designs for automotive applications, integration with vehicle control systems, and optimization for various driving conditions.

- Fault diagnosis and reliability improvement: Research focuses on developing methods for fault diagnosis, condition monitoring, and reliability improvement of PMSMs. This includes techniques for detecting and mitigating issues such as demagnetization, bearing faults, and winding failures to enhance motor longevity and performance.

- Energy efficiency and power management: Innovations in energy efficiency and power management for PMSMs involve developing advanced control strategies, optimizing power electronics, and implementing intelligent energy management systems. These advancements aim to reduce energy consumption and improve overall system efficiency in various applications.

02 PMSM design optimization

Innovations in PMSM design focus on optimizing motor structure, magnetic circuit design, and materials to enhance power density, efficiency, and thermal management. This includes improvements in rotor and stator configurations, magnet arrangements, and the use of advanced materials for core and windings.Expand Specific Solutions03 Integration of PMSM in electric vehicles

PMSM technology is being adapted for electric vehicle applications, focusing on high-power density, extended range, and improved efficiency. This involves developing specialized motor designs, cooling systems, and control strategies tailored for automotive use.Expand Specific Solutions04 Fault diagnosis and protection for PMSM

Advanced fault diagnosis and protection systems are being developed for PMSMs to enhance reliability and safety. These systems use various sensors, data analysis techniques, and intelligent algorithms to detect and mitigate faults in real-time, ensuring continuous operation and preventing damage to the motor.Expand Specific Solutions05 Energy efficiency improvements in PMSM

Research is focused on improving the energy efficiency of PMSMs through various methods such as loss reduction techniques, optimal control strategies, and the use of high-performance materials. This includes advancements in magnetic designs, winding configurations, and power electronics to minimize losses and maximize overall system efficiency.Expand Specific Solutions

Key Players in Remote PMSM Solutions

The market for distributing Permanent Magnet Synchronous Motors (PMSM) in remote locations is in a growth phase, driven by increasing demand for efficient and reliable motor systems in areas with limited infrastructure. The global market size is expanding, with significant potential in developing regions. Technologically, the field is advancing rapidly, with companies like Huawei, ZTE, and Ericsson leading innovations in remote connectivity solutions. State Grid Corp. of China and Jiangsu Electric Power Co. are leveraging their extensive power distribution networks to facilitate PMSM deployment. Universities such as Zhejiang University of Technology and Southeast University are contributing to R&D efforts, enhancing the technology's adaptability to challenging environments.

Telefonaktiebolaget LM Ericsson

Technical Solution: Ericsson's strategy for distributing Permanent Magnet Synchronous Motors (PMSM) in remote locations focuses on leveraging their extensive telecommunications infrastructure and expertise. They integrate PMSM technology into their remote site power solutions, utilizing advanced control systems and IoT connectivity. Ericsson's approach includes the use of hybrid power systems that combine PMSM with renewable energy sources like solar and wind, optimizing energy efficiency in off-grid locations[1]. The company also employs predictive maintenance algorithms and remote monitoring capabilities to ensure reliable operation of PMSM in hard-to-reach areas[3]. Additionally, Ericsson has developed compact, modular PMSM units specifically designed for easy transportation and installation in remote sites[5].

Strengths: Extensive global telecommunications network, expertise in remote site management, advanced IoT and connectivity solutions. Weaknesses: Limited direct experience with motor manufacturing, potential high costs for specialized PMSM units.

Huawei Technologies Co., Ltd.

Technical Solution: Huawei's approach to distributing PMSM in remote locations leverages their expertise in 5G technology and edge computing. They have developed a smart PMSM system that integrates advanced sensors and AI-driven control algorithms, enabling real-time monitoring and optimization of motor performance[2]. Huawei's solution includes a distributed edge computing architecture that allows for local processing of PMSM data, reducing latency and improving responsiveness in remote areas[4]. The company also utilizes their 5G network capabilities to ensure reliable communication between distributed PMSM units and central control systems, even in challenging environments[6]. Furthermore, Huawei has implemented energy harvesting technologies to power the control and communication systems of PMSM in off-grid locations, enhancing overall system autonomy[8].

Strengths: Strong 5G and edge computing capabilities, extensive experience in remote communication solutions. Weaknesses: Potential security concerns in some markets, less experience in traditional motor manufacturing.

Innovative Remote PMSM Distribution Technologies

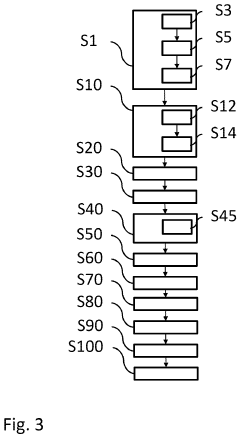

Method for adapting the control parameters of an electric traction machine being a permanent magnetic synchronous motor

PatentActiveUS11870374B2

Innovation

- A method that involves estimating the linked magnetic flux as a function of current, combining it with the permanent magnet flux, and adapting control parameters to optimize PMSM operation, including current control, by performing standstill characterization and retardation tests to determine flux characteristics and no-load power losses.

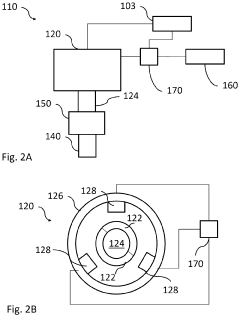

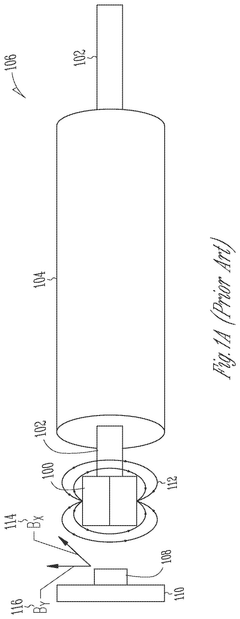

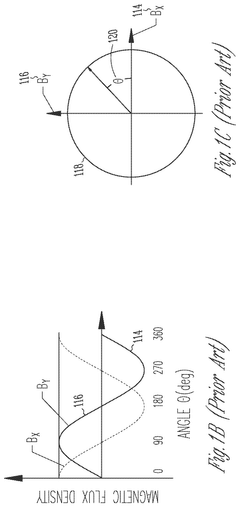

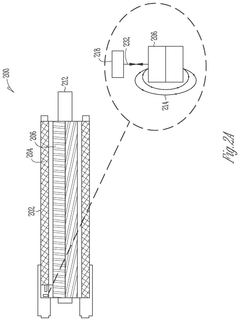

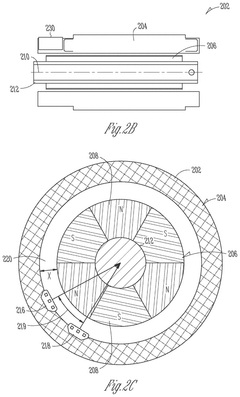

Permanent magnet synchronous motor (PMSM) integrated position sensing

PatentActiveUS12212257B2

Innovation

- The integration of analog magnetic flux sensors within the hollow cylindrical stator of the PMSM, arranged concentrically around the rotational axis at a constant mechanical angle relative to each other, allows for direct measurement of the magnetic flux from the rotor without external obstructions, enabling accurate rotor position sensing and reducing motor size and cost.

Environmental Impact of Remote PMSM Distribution

The distribution of Permanent Magnet Synchronous Motors (PMSM) in remote locations presents significant environmental challenges and impacts that must be carefully considered. The transportation and installation of these motors in isolated areas often require extensive infrastructure development, which can lead to habitat disruption and biodiversity loss. The construction of access roads, power lines, and support facilities may fragment ecosystems and disrupt wildlife migration patterns.

Furthermore, the operation of PMSM in remote locations can contribute to noise pollution, potentially affecting local fauna and their behavioral patterns. This is particularly concerning in sensitive ecological areas where the introduction of industrial equipment may disrupt the delicate balance of natural ecosystems. The electromagnetic fields generated by PMSM and associated power systems may also have unforeseen impacts on local wildlife, although more research is needed to fully understand these effects.

The energy requirements for operating PMSM in remote areas often necessitate the use of diesel generators or other fossil fuel-based power sources, contributing to greenhouse gas emissions and air pollution. This contradicts the generally eco-friendly nature of PMSM technology and highlights the need for integrated renewable energy solutions in remote distribution strategies.

Waste management is another critical environmental concern. The maintenance and eventual decommissioning of PMSM in remote locations can generate hazardous materials, including lubricants and electronic waste. Proper disposal of these materials is challenging in isolated areas and may lead to soil and water contamination if not managed correctly.

On the positive side, the high efficiency of PMSM can lead to reduced overall energy consumption compared to traditional motor systems, potentially mitigating some environmental impacts. Additionally, the long lifespan and reliability of PMSM may reduce the frequency of replacement and maintenance operations, minimizing the need for repeated environmental disturbances.

To address these environmental challenges, strategies for remote PMSM distribution must incorporate comprehensive environmental impact assessments and mitigation plans. This includes utilizing renewable energy sources for power supply, implementing wildlife-friendly design principles, and developing robust waste management protocols. Innovative approaches such as modular, easily transportable PMSM systems can reduce the need for extensive on-site construction, thereby minimizing environmental disturbance.

Furthermore, the operation of PMSM in remote locations can contribute to noise pollution, potentially affecting local fauna and their behavioral patterns. This is particularly concerning in sensitive ecological areas where the introduction of industrial equipment may disrupt the delicate balance of natural ecosystems. The electromagnetic fields generated by PMSM and associated power systems may also have unforeseen impacts on local wildlife, although more research is needed to fully understand these effects.

The energy requirements for operating PMSM in remote areas often necessitate the use of diesel generators or other fossil fuel-based power sources, contributing to greenhouse gas emissions and air pollution. This contradicts the generally eco-friendly nature of PMSM technology and highlights the need for integrated renewable energy solutions in remote distribution strategies.

Waste management is another critical environmental concern. The maintenance and eventual decommissioning of PMSM in remote locations can generate hazardous materials, including lubricants and electronic waste. Proper disposal of these materials is challenging in isolated areas and may lead to soil and water contamination if not managed correctly.

On the positive side, the high efficiency of PMSM can lead to reduced overall energy consumption compared to traditional motor systems, potentially mitigating some environmental impacts. Additionally, the long lifespan and reliability of PMSM may reduce the frequency of replacement and maintenance operations, minimizing the need for repeated environmental disturbances.

To address these environmental challenges, strategies for remote PMSM distribution must incorporate comprehensive environmental impact assessments and mitigation plans. This includes utilizing renewable energy sources for power supply, implementing wildlife-friendly design principles, and developing robust waste management protocols. Innovative approaches such as modular, easily transportable PMSM systems can reduce the need for extensive on-site construction, thereby minimizing environmental disturbance.

Regulatory Framework for Remote PMSM Deployment

The regulatory framework for remote PMSM (Permanent Magnet Synchronous Motor) deployment is a critical aspect of implementing strategies for distributing these motors in remote locations. This framework encompasses a range of legal, environmental, and safety considerations that must be addressed to ensure successful and compliant deployment.

One of the primary regulatory concerns is environmental impact. Remote locations often include sensitive ecosystems, and the installation of PMSM systems must adhere to strict environmental protection guidelines. These may include regulations on land use, wildlife protection, and habitat preservation. Environmental impact assessments are typically required before deployment, and ongoing monitoring may be mandated to ensure minimal ecological disruption.

Safety regulations form another crucial component of the framework. Given the remote nature of these installations, safety standards must be particularly rigorous. This includes regulations on equipment design, installation procedures, and operational safety protocols. Specific requirements may vary depending on the geographical location and local environmental conditions, such as extreme temperatures or high-altitude operations.

Energy regulations also play a significant role in the deployment of PMSM in remote areas. Many regions have specific requirements for energy efficiency and power generation in off-grid locations. These regulations may dictate the type of power sources that can be used in conjunction with PMSM systems, such as solar or wind energy, and may set standards for energy storage and distribution.

Telecommunications regulations are another important consideration, especially for remote monitoring and control of PMSM systems. These regulations govern the use of wireless communication technologies and may impact the design and implementation of remote management systems. Compliance with radio frequency regulations and data privacy laws is essential in this context.

Import and export regulations can significantly affect the distribution of PMSM in remote locations, particularly in cross-border scenarios. These regulations may include tariffs, trade restrictions, and technology transfer laws that could impact the feasibility and cost-effectiveness of deploying PMSM systems in certain regions.

Labor regulations are also relevant, especially concerning the installation and maintenance of PMSM systems in remote areas. These may include requirements for worker safety, training certifications, and local employment quotas. In some cases, regulations may mandate the use of local labor or partnerships with local businesses, which can affect project planning and execution.

Finally, the regulatory framework must address end-of-life considerations for PMSM systems. This includes regulations on decommissioning, recycling, and disposal of components, ensuring that the environmental impact is minimized even after the system's operational life has ended. These regulations are particularly important in remote locations where proper disposal facilities may be limited.

One of the primary regulatory concerns is environmental impact. Remote locations often include sensitive ecosystems, and the installation of PMSM systems must adhere to strict environmental protection guidelines. These may include regulations on land use, wildlife protection, and habitat preservation. Environmental impact assessments are typically required before deployment, and ongoing monitoring may be mandated to ensure minimal ecological disruption.

Safety regulations form another crucial component of the framework. Given the remote nature of these installations, safety standards must be particularly rigorous. This includes regulations on equipment design, installation procedures, and operational safety protocols. Specific requirements may vary depending on the geographical location and local environmental conditions, such as extreme temperatures or high-altitude operations.

Energy regulations also play a significant role in the deployment of PMSM in remote areas. Many regions have specific requirements for energy efficiency and power generation in off-grid locations. These regulations may dictate the type of power sources that can be used in conjunction with PMSM systems, such as solar or wind energy, and may set standards for energy storage and distribution.

Telecommunications regulations are another important consideration, especially for remote monitoring and control of PMSM systems. These regulations govern the use of wireless communication technologies and may impact the design and implementation of remote management systems. Compliance with radio frequency regulations and data privacy laws is essential in this context.

Import and export regulations can significantly affect the distribution of PMSM in remote locations, particularly in cross-border scenarios. These regulations may include tariffs, trade restrictions, and technology transfer laws that could impact the feasibility and cost-effectiveness of deploying PMSM systems in certain regions.

Labor regulations are also relevant, especially concerning the installation and maintenance of PMSM systems in remote areas. These may include requirements for worker safety, training certifications, and local employment quotas. In some cases, regulations may mandate the use of local labor or partnerships with local businesses, which can affect project planning and execution.

Finally, the regulatory framework must address end-of-life considerations for PMSM systems. This includes regulations on decommissioning, recycling, and disposal of components, ensuring that the environmental impact is minimized even after the system's operational life has ended. These regulations are particularly important in remote locations where proper disposal facilities may be limited.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!