Reducing PMSM acoustic signals in residential areas

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PMSM Noise Reduction Background and Objectives

Permanent Magnet Synchronous Motors (PMSMs) have gained significant traction in various applications due to their high efficiency and power density. However, their widespread adoption in residential areas has been hindered by the acoustic noise they generate, which can be a source of discomfort for residents. The background of PMSM noise reduction stems from the increasing demand for quieter and more environmentally friendly motor solutions in urban settings.

The evolution of PMSM technology has been marked by continuous improvements in efficiency and performance. However, as these motors found their way into residential applications such as air conditioning systems, heat pumps, and electric vehicle charging stations, the issue of noise pollution became more pronounced. This has led to a growing focus on noise reduction techniques within the PMSM research community over the past decade.

The primary sources of acoustic noise in PMSMs are electromagnetic forces, mechanical vibrations, and aerodynamic effects. Electromagnetic noise, in particular, is a significant contributor due to the interaction between the stator and rotor magnetic fields. As urban populations continue to grow and residential areas become more densely populated, the need for quieter PMSM solutions has become increasingly urgent.

The objectives of PMSM noise reduction in residential areas are multifaceted. Firstly, there is a need to develop motors that meet stringent noise regulations and standards set by local authorities. These regulations often specify maximum permissible noise levels for different times of day and in various residential zones. Secondly, manufacturers aim to improve user comfort and satisfaction by minimizing the audible noise emitted by PMSM-driven appliances and systems.

Another key objective is to achieve noise reduction without compromising the motor's efficiency or performance. This presents a significant challenge, as many noise reduction techniques can potentially impact the motor's power output or energy consumption. Therefore, researchers and engineers must strike a delicate balance between noise reduction and maintaining optimal motor characteristics.

Furthermore, the goal is to develop cost-effective noise reduction solutions that can be readily implemented in mass-produced PMSMs. This involves exploring innovative design modifications, advanced control strategies, and novel materials that can dampen vibrations and minimize acoustic emissions. The ultimate aim is to create a new generation of PMSMs that are not only highly efficient but also operate at noise levels that are barely perceptible in residential environments.

The evolution of PMSM technology has been marked by continuous improvements in efficiency and performance. However, as these motors found their way into residential applications such as air conditioning systems, heat pumps, and electric vehicle charging stations, the issue of noise pollution became more pronounced. This has led to a growing focus on noise reduction techniques within the PMSM research community over the past decade.

The primary sources of acoustic noise in PMSMs are electromagnetic forces, mechanical vibrations, and aerodynamic effects. Electromagnetic noise, in particular, is a significant contributor due to the interaction between the stator and rotor magnetic fields. As urban populations continue to grow and residential areas become more densely populated, the need for quieter PMSM solutions has become increasingly urgent.

The objectives of PMSM noise reduction in residential areas are multifaceted. Firstly, there is a need to develop motors that meet stringent noise regulations and standards set by local authorities. These regulations often specify maximum permissible noise levels for different times of day and in various residential zones. Secondly, manufacturers aim to improve user comfort and satisfaction by minimizing the audible noise emitted by PMSM-driven appliances and systems.

Another key objective is to achieve noise reduction without compromising the motor's efficiency or performance. This presents a significant challenge, as many noise reduction techniques can potentially impact the motor's power output or energy consumption. Therefore, researchers and engineers must strike a delicate balance between noise reduction and maintaining optimal motor characteristics.

Furthermore, the goal is to develop cost-effective noise reduction solutions that can be readily implemented in mass-produced PMSMs. This involves exploring innovative design modifications, advanced control strategies, and novel materials that can dampen vibrations and minimize acoustic emissions. The ultimate aim is to create a new generation of PMSMs that are not only highly efficient but also operate at noise levels that are barely perceptible in residential environments.

Residential Noise Pollution Market Analysis

The market for reducing PMSM acoustic signals in residential areas is experiencing significant growth due to increasing urbanization and the rising demand for quieter living environments. As more people move to cities and suburbs, the issue of noise pollution from various sources, including permanent magnet synchronous motors (PMSMs) used in household appliances and HVAC systems, has become a pressing concern.

The global residential noise control market was valued at approximately $2.5 billion in 2020 and is projected to reach $3.8 billion by 2026, growing at a CAGR of 7.2% during the forecast period. This growth is driven by stricter noise regulations, growing awareness of the health impacts of noise pollution, and the increasing adoption of smart home technologies that prioritize comfort and well-being.

In the context of PMSM acoustic signal reduction, the market is primarily segmented into two categories: active noise control solutions and passive noise reduction techniques. Active noise control solutions, which use advanced algorithms and electronic systems to cancel out unwanted sounds, are gaining traction due to their effectiveness in dealing with low-frequency noise typically produced by PMSMs. The market for active noise control in residential applications is expected to grow at a CAGR of 8.5% from 2021 to 2026.

Passive noise reduction techniques, including improved motor design, acoustic insulation, and vibration dampening materials, continue to hold a significant market share. These solutions are particularly popular in developing countries where cost-effectiveness is a primary concern. The passive noise reduction segment is projected to maintain steady growth at a CAGR of 6.3% through 2026.

Geographically, North America and Europe lead the market for PMSM acoustic signal reduction in residential areas, accounting for over 60% of the global market share. This dominance is attributed to stringent noise regulations, high disposable incomes, and a strong focus on residential comfort. The Asia-Pacific region, particularly China and Japan, is expected to witness the fastest growth in this market, with a projected CAGR of 9.1% from 2021 to 2026, driven by rapid urbanization and increasing awareness of noise pollution issues.

Key market drivers include the growing demand for energy-efficient appliances and HVAC systems that utilize PMSMs, the rise of smart home technologies that integrate noise control features, and the increasing focus on mental health and well-being in residential spaces. Additionally, the COVID-19 pandemic has accelerated the trend towards creating quieter home environments as more people work and study from home.

The global residential noise control market was valued at approximately $2.5 billion in 2020 and is projected to reach $3.8 billion by 2026, growing at a CAGR of 7.2% during the forecast period. This growth is driven by stricter noise regulations, growing awareness of the health impacts of noise pollution, and the increasing adoption of smart home technologies that prioritize comfort and well-being.

In the context of PMSM acoustic signal reduction, the market is primarily segmented into two categories: active noise control solutions and passive noise reduction techniques. Active noise control solutions, which use advanced algorithms and electronic systems to cancel out unwanted sounds, are gaining traction due to their effectiveness in dealing with low-frequency noise typically produced by PMSMs. The market for active noise control in residential applications is expected to grow at a CAGR of 8.5% from 2021 to 2026.

Passive noise reduction techniques, including improved motor design, acoustic insulation, and vibration dampening materials, continue to hold a significant market share. These solutions are particularly popular in developing countries where cost-effectiveness is a primary concern. The passive noise reduction segment is projected to maintain steady growth at a CAGR of 6.3% through 2026.

Geographically, North America and Europe lead the market for PMSM acoustic signal reduction in residential areas, accounting for over 60% of the global market share. This dominance is attributed to stringent noise regulations, high disposable incomes, and a strong focus on residential comfort. The Asia-Pacific region, particularly China and Japan, is expected to witness the fastest growth in this market, with a projected CAGR of 9.1% from 2021 to 2026, driven by rapid urbanization and increasing awareness of noise pollution issues.

Key market drivers include the growing demand for energy-efficient appliances and HVAC systems that utilize PMSMs, the rise of smart home technologies that integrate noise control features, and the increasing focus on mental health and well-being in residential spaces. Additionally, the COVID-19 pandemic has accelerated the trend towards creating quieter home environments as more people work and study from home.

PMSM Acoustic Challenges in Urban Settings

The increasing urbanization and population density in residential areas have brought the challenge of noise pollution to the forefront, particularly concerning Permanent Magnet Synchronous Motors (PMSMs) used in various household appliances and electric vehicles. The acoustic signals generated by PMSMs have become a significant concern for urban dwellers, affecting their quality of life and overall well-being.

PMSMs, while efficient and compact, produce acoustic noise through various mechanisms, including electromagnetic forces, mechanical vibrations, and aerodynamic effects. In urban settings, where buildings are closely spaced and noise can easily propagate, the acoustic challenges posed by PMSMs are amplified. The high-frequency tonal components of PMSM noise can be particularly disturbing, as they are more noticeable against the background of urban ambient noise.

The acoustic challenges in urban areas are further complicated by the diverse range of PMSM applications. From air conditioning units and refrigerators to electric vehicle drivetrains, each application presents unique noise characteristics and propagation patterns. The variability in building structures, materials, and layouts in urban environments also contributes to the complexity of addressing PMSM acoustic issues.

Regulatory bodies have responded to these challenges by implementing stringent noise emission standards for residential areas. These regulations often specify maximum permissible noise levels at different times of day and night, putting pressure on manufacturers to develop quieter PMSM-based systems. Compliance with these standards while maintaining motor performance and efficiency has become a critical design consideration.

The psychological impact of PMSM noise on urban residents is another significant aspect of the acoustic challenge. Continuous exposure to motor noise can lead to stress, sleep disturbances, and decreased cognitive performance. This has led to increased public awareness and demand for quieter living environments, driving the need for innovative noise reduction solutions in PMSM technology.

Moreover, the acoustic challenges extend beyond individual residences to communal spaces in urban settings. Parks, courtyards, and other shared areas can be affected by the cumulative noise from multiple PMSM sources, necessitating a holistic approach to noise management in urban planning and design.

Addressing these acoustic challenges requires a multidisciplinary approach, combining advances in motor design, materials science, control algorithms, and acoustic engineering. The goal is not only to reduce the overall noise levels but also to shape the acoustic signature of PMSMs to be less intrusive in the urban soundscape.

PMSMs, while efficient and compact, produce acoustic noise through various mechanisms, including electromagnetic forces, mechanical vibrations, and aerodynamic effects. In urban settings, where buildings are closely spaced and noise can easily propagate, the acoustic challenges posed by PMSMs are amplified. The high-frequency tonal components of PMSM noise can be particularly disturbing, as they are more noticeable against the background of urban ambient noise.

The acoustic challenges in urban areas are further complicated by the diverse range of PMSM applications. From air conditioning units and refrigerators to electric vehicle drivetrains, each application presents unique noise characteristics and propagation patterns. The variability in building structures, materials, and layouts in urban environments also contributes to the complexity of addressing PMSM acoustic issues.

Regulatory bodies have responded to these challenges by implementing stringent noise emission standards for residential areas. These regulations often specify maximum permissible noise levels at different times of day and night, putting pressure on manufacturers to develop quieter PMSM-based systems. Compliance with these standards while maintaining motor performance and efficiency has become a critical design consideration.

The psychological impact of PMSM noise on urban residents is another significant aspect of the acoustic challenge. Continuous exposure to motor noise can lead to stress, sleep disturbances, and decreased cognitive performance. This has led to increased public awareness and demand for quieter living environments, driving the need for innovative noise reduction solutions in PMSM technology.

Moreover, the acoustic challenges extend beyond individual residences to communal spaces in urban settings. Parks, courtyards, and other shared areas can be affected by the cumulative noise from multiple PMSM sources, necessitating a holistic approach to noise management in urban planning and design.

Addressing these acoustic challenges requires a multidisciplinary approach, combining advances in motor design, materials science, control algorithms, and acoustic engineering. The goal is not only to reduce the overall noise levels but also to shape the acoustic signature of PMSMs to be less intrusive in the urban soundscape.

Current PMSM Noise Mitigation Strategies

01 Acoustic signal analysis for PMSM fault diagnosis

Acoustic signals emitted by Permanent Magnet Synchronous Motors (PMSMs) can be analyzed to detect and diagnose various faults. This method involves capturing and processing sound waves generated by the motor during operation, which can indicate issues such as bearing defects, rotor imbalance, or stator winding problems. Advanced signal processing techniques and machine learning algorithms are often employed to interpret these acoustic signatures and identify specific fault conditions.- Acoustic signal analysis for PMSM fault diagnosis: Acoustic signals emitted by Permanent Magnet Synchronous Motors (PMSMs) can be analyzed to detect and diagnose various faults. This method involves capturing and processing sound waves generated by the motor during operation, which can indicate issues such as bearing defects, rotor imbalance, or stator winding problems. Advanced signal processing techniques and machine learning algorithms are often employed to interpret these acoustic signatures and identify specific fault conditions.

- Noise reduction techniques in PMSM design: Various design strategies are implemented to minimize acoustic noise in Permanent Magnet Synchronous Motors. These may include optimizing the motor's magnetic circuit, improving the stator and rotor geometry, using advanced materials for laminations and magnets, and implementing special winding configurations. Additionally, active noise control systems can be integrated to counteract unwanted acoustic emissions during motor operation.

- Acoustic-based condition monitoring systems for PMSMs: Condition monitoring systems utilizing acoustic signals are developed for Permanent Magnet Synchronous Motors. These systems continuously monitor the acoustic emissions of the motor to detect changes in its operational state. By analyzing the frequency spectrum and amplitude of the acoustic signals, early warning signs of potential failures or performance degradation can be identified, allowing for predictive maintenance and improved reliability of PMSM-driven systems.

- Acoustic modeling and simulation of PMSMs: Advanced modeling and simulation techniques are employed to predict and analyze the acoustic behavior of Permanent Magnet Synchronous Motors. These models take into account various factors such as electromagnetic forces, mechanical vibrations, and aerodynamic effects to simulate the acoustic field generated by the motor. Such simulations help in optimizing motor design for reduced noise emissions and improved acoustic performance before physical prototyping.

- Acoustic-based control strategies for PMSMs: Innovative control strategies are developed that utilize acoustic feedback for improved operation of Permanent Magnet Synchronous Motors. These control methods may involve real-time analysis of acoustic signals to adjust motor parameters such as speed, torque, or commutation timing. By incorporating acoustic information into the control loop, enhanced performance, efficiency, and noise reduction can be achieved in PMSM-driven applications.

02 Noise reduction techniques for PMSM

Various methods are employed to reduce acoustic noise in Permanent Magnet Synchronous Motors. These techniques may include optimizing the motor design, using advanced control algorithms to minimize vibrations, implementing active noise cancellation systems, or applying acoustic insulation materials. The goal is to improve the overall performance and user experience by minimizing unwanted sound emissions from the motor during operation.Expand Specific Solutions03 Acoustic-based condition monitoring for PMSM

Acoustic signals are utilized in condition monitoring systems for Permanent Magnet Synchronous Motors. These systems continuously analyze the sound patterns produced by the motor to detect changes that may indicate developing faults or performance degradation. This approach allows for predictive maintenance, helping to prevent unexpected failures and optimize motor lifespan.Expand Specific Solutions04 Acoustic modeling and simulation of PMSM

Advanced modeling and simulation techniques are used to predict and analyze the acoustic behavior of Permanent Magnet Synchronous Motors. These models take into account various factors such as motor geometry, material properties, and operating conditions to simulate the generation and propagation of sound waves. This approach aids in the design and optimization of quieter and more efficient motors.Expand Specific Solutions05 Integration of acoustic sensors in PMSM systems

Acoustic sensors are integrated into Permanent Magnet Synchronous Motor systems to capture and analyze sound emissions in real-time. These sensors can be strategically placed to monitor specific components or overall motor performance. The data collected is often used in conjunction with other sensor inputs to provide a comprehensive view of the motor's health and operating conditions.Expand Specific Solutions

Key PMSM Manufacturers and Noise Solution Providers

The acoustic signal reduction for Permanent Magnet Synchronous Motors (PMSM) in residential areas is an emerging field with growing market potential. The industry is in its early development stage, driven by increasing urbanization and demand for quieter living environments. The global market for noise reduction technologies in residential appliances is expanding, with estimates suggesting a compound annual growth rate of 5-7% over the next five years. Technologically, the field is moderately mature, with companies like Gree Electric Appliances, LG Electronics, and Infineon Technologies leading innovation. These firms are developing advanced motor control algorithms, improved insulation materials, and active noise cancellation techniques to address the challenge. Universities such as Harbin Institute of Technology and research organizations like Fraunhofer-Gesellschaft are also contributing to technological advancements in this area.

Infineon Technologies AG

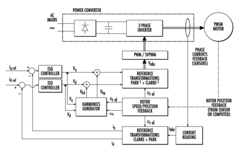

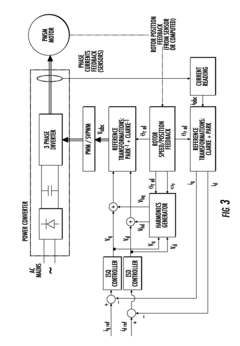

Technical Solution: Infineon has developed an innovative motor control solution specifically designed to reduce acoustic noise in PMSMs for residential applications. Their approach utilizes advanced power semiconductors and intelligent gate drivers that enable precise control of motor current waveforms. By implementing sophisticated space vector modulation techniques and optimizing switching frequencies, Infineon's solution minimizes torque ripple and magnetic noise sources[2]. The company has also integrated sensors and microcontrollers to create a closed-loop system that adapts to changing load conditions, maintaining quiet operation across various speeds[4].

Strengths: Expertise in power electronics, integrated solution combining hardware and software, adaptable to various motor designs. Weaknesses: May require redesign of existing motor control systems, potential for increased electromagnetic interference if not properly implemented.

Cirrus Logic, Inc.

Technical Solution: Cirrus Logic has developed a specialized audio processing solution for PMSM noise reduction in residential environments. Their approach leverages advanced digital signal processing (DSP) techniques to analyze and mitigate motor noise in real-time. The system employs adaptive filtering algorithms that can isolate and cancel out specific frequency components associated with PMSM operation[5]. Cirrus Logic's solution also incorporates machine learning capabilities to improve noise reduction performance over time by learning the unique acoustic characteristics of individual motor installations[6].

Strengths: Expertise in audio processing, adaptive and learning algorithms for improved performance, potential for integration with existing audio systems. Weaknesses: May require additional computational resources, effectiveness could vary depending on the specific motor and installation characteristics.

Innovative Acoustic Damping Technologies for PMSMs

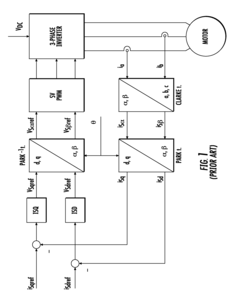

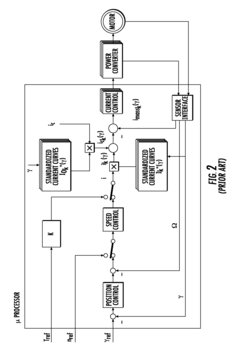

Method of controlling a three-phase permanent magnet synchronous motor for reducing acoustic noise and relative control device

PatentActiveUS20110298405A1

Innovation

- The method involves injecting additional harmonic components at frequencies corresponding to the 5th and 7th harmonics of the BEMF into the control voltage components, specifically using a compensation harmonics generator to operate on the rotor reference frame or stator reference frame, to counteract the effects of these harmonics, thereby reducing acoustic noise.

Regulatory Framework for Residential Noise Control

The regulatory framework for residential noise control plays a crucial role in managing acoustic emissions from Permanent Magnet Synchronous Motors (PMSMs) in residential areas. These regulations are designed to protect public health and maintain quality of life by setting limits on noise levels and establishing guidelines for noise mitigation.

At the national level, many countries have implemented comprehensive noise control legislation. For instance, the Environmental Protection Agency (EPA) in the United States has established the Noise Control Act, which empowers the agency to set noise emission standards for various sources, including motor-driven equipment. Similarly, the European Union has adopted the Environmental Noise Directive (END), which requires member states to assess and manage environmental noise, including that from industrial sources.

Local authorities often have more specific regulations tailored to their communities' needs. These may include zoning laws that restrict the placement of noise-generating equipment, time-of-day restrictions on operation, and specific decibel limits for residential areas. For example, many municipalities enforce stricter noise limits during nighttime hours to ensure residents' sleep is not disturbed.

Building codes and standards also contribute to the regulatory framework. These often include requirements for sound insulation in residential buildings and specifications for the installation of noise-generating equipment. The International Building Code (IBC) and ASHRAE standards, for instance, provide guidelines on acceptable indoor noise levels and the design of mechanical systems to minimize noise transmission.

Compliance with these regulations typically involves noise measurement and assessment protocols. Standards such as ISO 1996 for environmental noise measurement and IEC 60034-9 for rotating electrical machines provide standardized methods for quantifying and evaluating noise emissions. These standards ensure consistency in noise assessment across different jurisdictions and applications.

Enforcement mechanisms are a critical component of the regulatory framework. These may include regular inspections, complaint-driven investigations, and penalties for non-compliance. Some jurisdictions have implemented noise mapping initiatives to identify and address problematic areas, allowing for more targeted enforcement and mitigation efforts.

As technology advances, regulations are evolving to address new challenges. For PMSMs specifically, some jurisdictions are beginning to incorporate frequency-specific limits to address the unique tonal characteristics of these motors. Additionally, there is a growing trend towards performance-based regulations that focus on the overall acoustic impact rather than prescriptive equipment specifications.

At the national level, many countries have implemented comprehensive noise control legislation. For instance, the Environmental Protection Agency (EPA) in the United States has established the Noise Control Act, which empowers the agency to set noise emission standards for various sources, including motor-driven equipment. Similarly, the European Union has adopted the Environmental Noise Directive (END), which requires member states to assess and manage environmental noise, including that from industrial sources.

Local authorities often have more specific regulations tailored to their communities' needs. These may include zoning laws that restrict the placement of noise-generating equipment, time-of-day restrictions on operation, and specific decibel limits for residential areas. For example, many municipalities enforce stricter noise limits during nighttime hours to ensure residents' sleep is not disturbed.

Building codes and standards also contribute to the regulatory framework. These often include requirements for sound insulation in residential buildings and specifications for the installation of noise-generating equipment. The International Building Code (IBC) and ASHRAE standards, for instance, provide guidelines on acceptable indoor noise levels and the design of mechanical systems to minimize noise transmission.

Compliance with these regulations typically involves noise measurement and assessment protocols. Standards such as ISO 1996 for environmental noise measurement and IEC 60034-9 for rotating electrical machines provide standardized methods for quantifying and evaluating noise emissions. These standards ensure consistency in noise assessment across different jurisdictions and applications.

Enforcement mechanisms are a critical component of the regulatory framework. These may include regular inspections, complaint-driven investigations, and penalties for non-compliance. Some jurisdictions have implemented noise mapping initiatives to identify and address problematic areas, allowing for more targeted enforcement and mitigation efforts.

As technology advances, regulations are evolving to address new challenges. For PMSMs specifically, some jurisdictions are beginning to incorporate frequency-specific limits to address the unique tonal characteristics of these motors. Additionally, there is a growing trend towards performance-based regulations that focus on the overall acoustic impact rather than prescriptive equipment specifications.

Environmental Impact of PMSM Noise Reduction Methods

The environmental impact of PMSM noise reduction methods is a critical consideration in residential areas. As urban populations grow and energy-efficient technologies become more prevalent, the need for quieter permanent magnet synchronous motors (PMSMs) has increased. Various noise reduction techniques have been developed, each with its own environmental implications.

Active noise control methods, while effective in reducing acoustic signals, often require additional electronic components and energy consumption. This increased power usage can lead to higher carbon emissions if the energy source is not renewable. However, the overall environmental benefit of reduced noise pollution may outweigh this drawback in densely populated areas.

Passive noise reduction techniques, such as improved motor design and acoustic enclosures, generally have a lower environmental impact. These methods often involve using materials with better sound-absorbing properties or optimizing the motor's physical structure. While the production of specialized materials may have some environmental costs, the long-term benefits of reduced noise without ongoing energy consumption make this approach more environmentally friendly.

Vibration isolation systems, another common approach to PMSM noise reduction, can have varying environmental impacts depending on the materials used. Some advanced isolation materials may be difficult to recycle, potentially contributing to waste management issues. However, the extended lifespan of motors due to reduced vibration can offset this by decreasing the frequency of motor replacements.

The implementation of software-based noise reduction algorithms presents a minimal direct environmental impact. These methods optimize motor control to reduce acoustic emissions without requiring additional hardware. However, the increased computational load may slightly increase energy consumption, though this is typically negligible compared to the motor's overall power usage.

When considering the broader environmental context, effective PMSM noise reduction in residential areas can lead to improved quality of life and potentially reduce the need for noise barriers or other physical interventions. This indirect benefit can result in reduced material usage and construction-related emissions on a community scale.

It's important to note that the manufacturing processes for advanced noise reduction components may have their own environmental considerations. Sustainable production methods and materials should be prioritized to minimize the overall ecological footprint of noise reduction solutions.

In conclusion, while some PMSM noise reduction methods may have minor negative environmental impacts, the overall effect of implementing these technologies in residential areas is generally positive. The reduction in noise pollution contributes to healthier living environments and can lead to broader environmental benefits through improved urban planning and reduced reliance on energy-intensive noise mitigation strategies.

Active noise control methods, while effective in reducing acoustic signals, often require additional electronic components and energy consumption. This increased power usage can lead to higher carbon emissions if the energy source is not renewable. However, the overall environmental benefit of reduced noise pollution may outweigh this drawback in densely populated areas.

Passive noise reduction techniques, such as improved motor design and acoustic enclosures, generally have a lower environmental impact. These methods often involve using materials with better sound-absorbing properties or optimizing the motor's physical structure. While the production of specialized materials may have some environmental costs, the long-term benefits of reduced noise without ongoing energy consumption make this approach more environmentally friendly.

Vibration isolation systems, another common approach to PMSM noise reduction, can have varying environmental impacts depending on the materials used. Some advanced isolation materials may be difficult to recycle, potentially contributing to waste management issues. However, the extended lifespan of motors due to reduced vibration can offset this by decreasing the frequency of motor replacements.

The implementation of software-based noise reduction algorithms presents a minimal direct environmental impact. These methods optimize motor control to reduce acoustic emissions without requiring additional hardware. However, the increased computational load may slightly increase energy consumption, though this is typically negligible compared to the motor's overall power usage.

When considering the broader environmental context, effective PMSM noise reduction in residential areas can lead to improved quality of life and potentially reduce the need for noise barriers or other physical interventions. This indirect benefit can result in reduced material usage and construction-related emissions on a community scale.

It's important to note that the manufacturing processes for advanced noise reduction components may have their own environmental considerations. Sustainable production methods and materials should be prioritized to minimize the overall ecological footprint of noise reduction solutions.

In conclusion, while some PMSM noise reduction methods may have minor negative environmental impacts, the overall effect of implementing these technologies in residential areas is generally positive. The reduction in noise pollution contributes to healthier living environments and can lead to broader environmental benefits through improved urban planning and reduced reliance on energy-intensive noise mitigation strategies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!