Advanced control methods for PMSM in electric aircrafts

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PMSM Control Evolution

The evolution of Permanent Magnet Synchronous Motor (PMSM) control in electric aircraft has been marked by significant advancements over the past few decades. Initially, simple scalar control methods were employed, which provided basic speed regulation but lacked precision and efficiency. As the demand for more sophisticated electric propulsion systems in aviation grew, vector control techniques emerged as a superior alternative.

Vector control, also known as Field-Oriented Control (FOC), revolutionized PMSM control by enabling independent manipulation of torque and flux. This breakthrough allowed for improved dynamic performance and energy efficiency, crucial factors in electric aircraft applications. The implementation of FOC in digital signal processors (DSPs) and microcontrollers facilitated more precise and responsive motor control.

The next major milestone in PMSM control evolution was the development of sensorless control techniques. These methods eliminated the need for position sensors, reducing system complexity and enhancing reliability – critical aspects in aviation. Observer-based and back-EMF estimation techniques became prevalent, enabling accurate rotor position and speed estimation without physical sensors.

As computational power increased, more advanced control algorithms emerged. Model Predictive Control (MPC) gained traction in PMSM applications, offering improved transient response and the ability to handle multiple control objectives simultaneously. MPC's predictive nature proved particularly beneficial in optimizing motor performance under varying flight conditions.

Adaptive control strategies marked another significant advancement in PMSM control for electric aircraft. These techniques allowed the control system to adjust parameters in real-time, compensating for variations in motor characteristics due to temperature changes, aging, or manufacturing tolerances. This adaptability ensured consistent performance across a wide range of operating conditions.

Recent years have seen the integration of artificial intelligence and machine learning techniques into PMSM control systems. Neural networks and fuzzy logic controllers have been employed to enhance motor performance, particularly in handling non-linear dynamics and uncertainties inherent in electric aircraft propulsion systems.

The latest frontier in PMSM control evolution is the development of fault-tolerant control strategies. These advanced methods aim to maintain stable operation even in the presence of sensor failures or motor faults, a critical requirement for ensuring the safety and reliability of electric aircraft propulsion systems.

As the aviation industry continues its shift towards electrification, the evolution of PMSM control methods remains ongoing. Current research focuses on further improving efficiency, reliability, and fault tolerance, while also addressing the unique challenges posed by high-altitude operation and extreme environmental conditions encountered in aviation applications.

Vector control, also known as Field-Oriented Control (FOC), revolutionized PMSM control by enabling independent manipulation of torque and flux. This breakthrough allowed for improved dynamic performance and energy efficiency, crucial factors in electric aircraft applications. The implementation of FOC in digital signal processors (DSPs) and microcontrollers facilitated more precise and responsive motor control.

The next major milestone in PMSM control evolution was the development of sensorless control techniques. These methods eliminated the need for position sensors, reducing system complexity and enhancing reliability – critical aspects in aviation. Observer-based and back-EMF estimation techniques became prevalent, enabling accurate rotor position and speed estimation without physical sensors.

As computational power increased, more advanced control algorithms emerged. Model Predictive Control (MPC) gained traction in PMSM applications, offering improved transient response and the ability to handle multiple control objectives simultaneously. MPC's predictive nature proved particularly beneficial in optimizing motor performance under varying flight conditions.

Adaptive control strategies marked another significant advancement in PMSM control for electric aircraft. These techniques allowed the control system to adjust parameters in real-time, compensating for variations in motor characteristics due to temperature changes, aging, or manufacturing tolerances. This adaptability ensured consistent performance across a wide range of operating conditions.

Recent years have seen the integration of artificial intelligence and machine learning techniques into PMSM control systems. Neural networks and fuzzy logic controllers have been employed to enhance motor performance, particularly in handling non-linear dynamics and uncertainties inherent in electric aircraft propulsion systems.

The latest frontier in PMSM control evolution is the development of fault-tolerant control strategies. These advanced methods aim to maintain stable operation even in the presence of sensor failures or motor faults, a critical requirement for ensuring the safety and reliability of electric aircraft propulsion systems.

As the aviation industry continues its shift towards electrification, the evolution of PMSM control methods remains ongoing. Current research focuses on further improving efficiency, reliability, and fault tolerance, while also addressing the unique challenges posed by high-altitude operation and extreme environmental conditions encountered in aviation applications.

Electric Aircraft Market

The electric aircraft market is experiencing rapid growth and transformation, driven by increasing environmental concerns and advancements in electric propulsion technologies. This emerging sector encompasses a wide range of aircraft types, from small personal air vehicles to larger commercial planes, all powered by electric motors and batteries.

The market demand for electric aircraft is primarily fueled by the global push for sustainable transportation solutions and the need to reduce carbon emissions in the aviation industry. Governments and regulatory bodies worldwide are implementing stricter environmental regulations, creating a favorable landscape for electric aircraft adoption. Additionally, the rising costs of conventional aviation fuels and the potential for reduced operating expenses associated with electric propulsion systems are attracting both established aerospace companies and innovative startups to invest in this technology.

Current market trends indicate a growing interest in urban air mobility solutions, with electric vertical takeoff and landing (eVTOL) aircraft gaining significant attention. These vehicles promise to revolutionize short-distance air travel and alleviate urban congestion. Furthermore, the general aviation sector is witnessing increased demand for electric aircraft in flight training and recreational flying applications, driven by lower operating costs and reduced noise pollution.

The potential market size for electric aircraft is substantial, with projections suggesting significant growth over the next decade. However, the market is still in its early stages, and widespread adoption faces several challenges. These include limitations in battery technology, the need for charging infrastructure, and regulatory hurdles related to certification and airspace integration.

Geographically, North America and Europe are leading the electric aircraft market, with numerous companies and research institutions actively developing and testing prototypes. Asia-Pacific is also emerging as a key market, driven by rapid urbanization and government initiatives to promote sustainable transportation solutions.

The electric aircraft market is characterized by intense competition and collaboration among established aerospace manufacturers, technology companies, and startups. This dynamic ecosystem is fostering innovation and accelerating the development of advanced electric propulsion systems, including permanent magnet synchronous motors (PMSM) and their control methods.

As the market evolves, key factors influencing its growth include advancements in battery technology, the development of lightweight materials, and improvements in electric motor efficiency. The integration of artificial intelligence and autonomous flight capabilities is also expected to play a crucial role in shaping the future of electric aircraft, potentially expanding their applications and market reach.

The market demand for electric aircraft is primarily fueled by the global push for sustainable transportation solutions and the need to reduce carbon emissions in the aviation industry. Governments and regulatory bodies worldwide are implementing stricter environmental regulations, creating a favorable landscape for electric aircraft adoption. Additionally, the rising costs of conventional aviation fuels and the potential for reduced operating expenses associated with electric propulsion systems are attracting both established aerospace companies and innovative startups to invest in this technology.

Current market trends indicate a growing interest in urban air mobility solutions, with electric vertical takeoff and landing (eVTOL) aircraft gaining significant attention. These vehicles promise to revolutionize short-distance air travel and alleviate urban congestion. Furthermore, the general aviation sector is witnessing increased demand for electric aircraft in flight training and recreational flying applications, driven by lower operating costs and reduced noise pollution.

The potential market size for electric aircraft is substantial, with projections suggesting significant growth over the next decade. However, the market is still in its early stages, and widespread adoption faces several challenges. These include limitations in battery technology, the need for charging infrastructure, and regulatory hurdles related to certification and airspace integration.

Geographically, North America and Europe are leading the electric aircraft market, with numerous companies and research institutions actively developing and testing prototypes. Asia-Pacific is also emerging as a key market, driven by rapid urbanization and government initiatives to promote sustainable transportation solutions.

The electric aircraft market is characterized by intense competition and collaboration among established aerospace manufacturers, technology companies, and startups. This dynamic ecosystem is fostering innovation and accelerating the development of advanced electric propulsion systems, including permanent magnet synchronous motors (PMSM) and their control methods.

As the market evolves, key factors influencing its growth include advancements in battery technology, the development of lightweight materials, and improvements in electric motor efficiency. The integration of artificial intelligence and autonomous flight capabilities is also expected to play a crucial role in shaping the future of electric aircraft, potentially expanding their applications and market reach.

PMSM Control Challenges

The control of Permanent Magnet Synchronous Motors (PMSMs) in electric aircraft presents unique challenges due to the demanding operational requirements and environmental conditions. One of the primary challenges is maintaining precise speed and torque control across a wide range of operating conditions, including extreme temperatures and altitudes. The high-performance demands of aerospace applications require exceptional dynamic response and efficiency from the motor control system.

Another significant challenge is the need for fault-tolerant control strategies. In aviation, system reliability is paramount, and the control system must be capable of adapting to potential faults or degradations in motor performance without compromising safety or operational capabilities. This necessitates the development of advanced diagnostic algorithms and adaptive control techniques that can detect and mitigate issues in real-time.

Weight and space constraints in aircraft design pose additional challenges for PMSM control systems. The control hardware and associated components must be compact and lightweight, while still delivering the required computational power and reliability. This drives the need for highly integrated and efficient control solutions that can operate within the limited resources available on an aircraft.

Electromagnetic interference (EMI) and electromagnetic compatibility (EMC) are critical concerns in aviation electronics. PMSM control systems must be designed to minimize EMI generation and withstand potential interference from other aircraft systems. This requires careful consideration of control algorithms, power electronics design, and shielding techniques to ensure robust operation in the complex electromagnetic environment of an aircraft.

Energy efficiency is another key challenge, particularly given the limited energy storage capacity of electric aircraft. Advanced control methods must optimize motor efficiency across all operating conditions, including during takeoff, cruise, and landing phases. This involves sophisticated algorithms for field-weakening control, loss minimization, and regenerative braking to maximize the overall range and endurance of the aircraft.

The harsh vibration and acceleration profiles experienced in flight operations present further challenges for PMSM control. The control system must maintain stability and accuracy under these dynamic conditions, necessitating robust mechanical design and advanced filtering techniques to compensate for sensor noise and mechanical disturbances.

Lastly, the regulatory environment in aviation imposes stringent certification requirements on all aircraft systems, including motor controls. Developing control methods that can meet these rigorous standards while still pushing the boundaries of performance is a significant challenge that requires extensive testing, validation, and documentation processes.

Another significant challenge is the need for fault-tolerant control strategies. In aviation, system reliability is paramount, and the control system must be capable of adapting to potential faults or degradations in motor performance without compromising safety or operational capabilities. This necessitates the development of advanced diagnostic algorithms and adaptive control techniques that can detect and mitigate issues in real-time.

Weight and space constraints in aircraft design pose additional challenges for PMSM control systems. The control hardware and associated components must be compact and lightweight, while still delivering the required computational power and reliability. This drives the need for highly integrated and efficient control solutions that can operate within the limited resources available on an aircraft.

Electromagnetic interference (EMI) and electromagnetic compatibility (EMC) are critical concerns in aviation electronics. PMSM control systems must be designed to minimize EMI generation and withstand potential interference from other aircraft systems. This requires careful consideration of control algorithms, power electronics design, and shielding techniques to ensure robust operation in the complex electromagnetic environment of an aircraft.

Energy efficiency is another key challenge, particularly given the limited energy storage capacity of electric aircraft. Advanced control methods must optimize motor efficiency across all operating conditions, including during takeoff, cruise, and landing phases. This involves sophisticated algorithms for field-weakening control, loss minimization, and regenerative braking to maximize the overall range and endurance of the aircraft.

The harsh vibration and acceleration profiles experienced in flight operations present further challenges for PMSM control. The control system must maintain stability and accuracy under these dynamic conditions, necessitating robust mechanical design and advanced filtering techniques to compensate for sensor noise and mechanical disturbances.

Lastly, the regulatory environment in aviation imposes stringent certification requirements on all aircraft systems, including motor controls. Developing control methods that can meet these rigorous standards while still pushing the boundaries of performance is a significant challenge that requires extensive testing, validation, and documentation processes.

Current PMSM Solutions

01 Field-Oriented Control (FOC) for PMSM

Field-Oriented Control is a widely used method for controlling PMSMs. It involves transforming the three-phase stator currents into a two-axis (d-q) reference frame, allowing for independent control of torque and flux. This method provides precise control of motor speed and torque, improving overall system efficiency and dynamic performance.- Field-oriented control (FOC) for PMSM: Field-oriented control is a widely used method for PMSM control. It involves transforming the three-phase stator currents into a two-axis (d-q) reference frame, allowing for independent control of torque and flux. This method provides precise control of motor speed and torque, making it suitable for high-performance applications.

- Sensorless control techniques for PMSM: Sensorless control methods eliminate the need for position sensors, reducing cost and improving reliability. These techniques estimate the rotor position and speed using motor voltage and current measurements. Various algorithms, such as sliding mode observers and extended Kalman filters, are employed for accurate estimation.

- Model predictive control (MPC) for PMSM: Model predictive control is an advanced control strategy that uses a dynamic model of the PMSM to predict future behavior and optimize control actions. This method can handle complex constraints and nonlinearities, offering improved performance in terms of torque ripple reduction and efficiency optimization.

- Adaptive control strategies for PMSM: Adaptive control methods adjust control parameters in real-time to maintain optimal performance under varying operating conditions and motor parameter changes. These techniques can compensate for uncertainties in motor parameters, load variations, and external disturbances, ensuring robust and efficient operation.

- Direct torque control (DTC) for PMSM: Direct torque control is a method that directly controls the motor torque and stator flux without the need for current control loops. It offers fast torque response and simple control structure. Advanced DTC techniques incorporate space vector modulation to reduce torque ripple and improve steady-state performance.

02 Sensorless Control Techniques

Sensorless control methods eliminate the need for position sensors, reducing costs and improving reliability. These techniques estimate the rotor position and speed using motor voltage and current measurements. Common approaches include back-EMF estimation, high-frequency signal injection, and model-based observers.Expand Specific Solutions03 Predictive Current Control

Predictive current control algorithms use a model of the PMSM to predict future motor states and optimize control actions. This method can achieve faster dynamic response and better steady-state performance compared to traditional PI controllers. It often involves solving an optimization problem at each control cycle to determine the optimal voltage vector.Expand Specific Solutions04 Adaptive Control Strategies

Adaptive control methods adjust control parameters in real-time to maintain optimal performance under varying operating conditions and motor parameter changes. These techniques can include online parameter estimation, self-tuning regulators, and model reference adaptive control (MRAC) systems, enhancing the robustness and efficiency of PMSM drives.Expand Specific Solutions05 Fault-Tolerant Control

Fault-tolerant control strategies aim to maintain PMSM operation under various fault conditions, such as sensor failures or phase open-circuit faults. These methods often involve fault detection and isolation algorithms, followed by control reconfiguration to ensure continued operation, albeit with potentially reduced performance.Expand Specific Solutions

Key PMSM Control Players

The advanced control methods for PMSM in electric aircraft represent an emerging field at the intersection of aerospace and electric propulsion technologies. The market is in its early growth stage, with increasing demand driven by the push for sustainable aviation. While the market size is still relatively small, it is expected to expand rapidly in the coming years. Technologically, the field is evolving quickly, with companies like Rolls-Royce, Autel Robotics, and Huawei leading innovation. Universities such as Nanjing University of Aeronautics & Astronautics and Shenyang Aerospace University are contributing significant research. The competition is intensifying as both established aerospace firms and new entrants seek to develop more efficient and reliable PMSM control systems for electric aircraft applications.

Rolls-Royce Plc

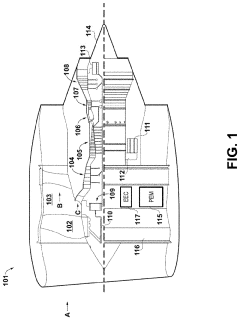

Technical Solution: Rolls-Royce has developed advanced control methods for Permanent Magnet Synchronous Motors (PMSM) in electric aircraft, focusing on high-efficiency and lightweight solutions. Their approach integrates model predictive control (MPC) with adaptive algorithms to optimize motor performance across various flight conditions. The company has implemented a novel sensorless control technique that eliminates the need for position sensors, reducing system complexity and weight[1]. Additionally, Rolls-Royce has developed a fault-tolerant control strategy that ensures continuous operation even in the event of partial system failures, critical for aviation safety[3]. Their control system also incorporates advanced thermal management to maintain optimal motor efficiency and extend component lifespan[5].

Strengths: Extensive aerospace experience, cutting-edge sensorless control, and robust fault-tolerant systems. Weaknesses: Potentially higher cost due to aerospace-grade components and rigorous certification processes.

Huawei Technologies Co., Ltd.

Technical Solution: Huawei has applied its expertise in advanced computing and control systems to develop innovative solutions for PMSM control in electric aircraft. Their approach leverages artificial intelligence and machine learning techniques to optimize motor performance. Huawei has implemented a deep reinforcement learning-based control strategy that continuously adapts to changing flight conditions and motor parameters[10]. Their system utilizes high-performance edge computing devices to execute complex control algorithms in real-time, ensuring rapid response to dynamic changes[11]. Additionally, Huawei has developed a predictive maintenance system that uses data analytics to forecast potential motor issues, enhancing reliability and safety[12].

Strengths: Advanced AI and machine learning integration, powerful edge computing capabilities. Weaknesses: Limited track record in aerospace applications compared to traditional aviation companies.

PMSM Control Innovations

Permanent magnet electric machine control

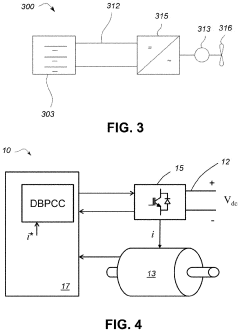

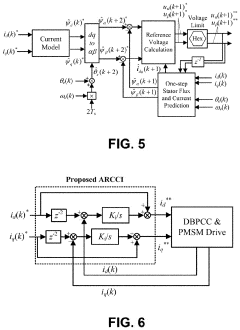

PatentActiveUS20220399841A1

Innovation

- A Deadbeat Predictive Current Control (DBPCC) scheme that determines d-axis and q-axis current correction values independently of machine parameters and power electronics parameters, using adaptive gain values and harmonic correction components to improve control accuracy and robustness, and estimates the inductance of the PMSM to enhance control performance.

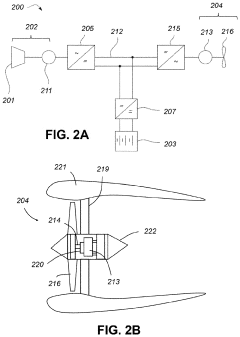

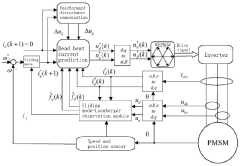

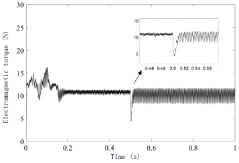

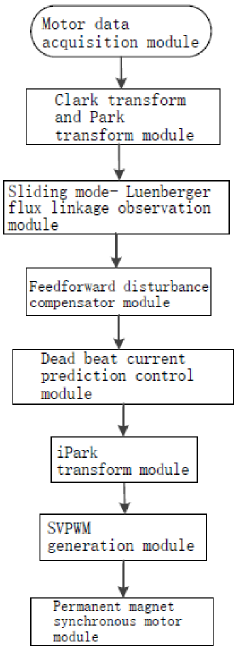

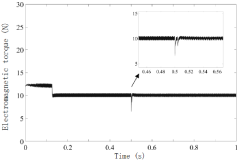

Permanent magnet synchronous motor control apparatus and method based on sliding mode observer and current prediction

PatentActiveNL2032530A

Innovation

- A PMSM control apparatus and method utilizing a sliding mode observer and current prediction, incorporating modules like PI control, Clark and Park transforms, disturbance compensation, and dead beat current prediction, to enhance fault tolerance and dynamic response.

Aerospace Regulations

The aerospace industry is subject to stringent regulations that govern the design, manufacture, and operation of aircraft systems, including electric propulsion systems and their control methods. For advanced control methods of Permanent Magnet Synchronous Motors (PMSM) in electric aircraft, compliance with these regulations is crucial to ensure safety, reliability, and performance.

The Federal Aviation Administration (FAA) in the United States and the European Union Aviation Safety Agency (EASA) are the primary regulatory bodies that set standards for aircraft certification. These agencies have established specific requirements for electric propulsion systems, which include the control methods for PMSM. The FAA's Part 33 and EASA's CS-E regulations cover the certification of aircraft engines, including electric motors and their control systems.

One of the key regulatory considerations for PMSM control in electric aircraft is electromagnetic compatibility (EMC). The control systems must comply with DO-160 standards, which outline environmental conditions and test procedures for airborne equipment. This includes requirements for radiated and conducted emissions, as well as susceptibility to electromagnetic interference.

Safety is paramount in aerospace regulations. The control methods for PMSM must adhere to the principles of functional safety, as outlined in standards such as ARP4754A for aircraft systems development and DO-178C for software considerations. These standards require a systematic approach to risk assessment, fault tolerance, and failure mode analysis in the development of control algorithms and hardware.

Reliability and redundancy are also critical aspects addressed by aerospace regulations. Control systems for PMSM in electric aircraft must demonstrate high levels of reliability through rigorous testing and validation processes. Redundancy in control architectures may be required to ensure continued operation in the event of component failures.

Environmental factors play a significant role in aerospace regulations. Control methods for PMSM must be designed to operate reliably under extreme conditions, including temperature variations, altitude changes, and vibration. Compliance with environmental testing standards, such as DO-160, is essential for certification.

As electric aircraft technology evolves, regulatory bodies are adapting their frameworks to address new challenges. The FAA's Part 23 Amendment 64 and EASA's CS-23 Amendment 5 have introduced performance-based standards that allow for more flexibility in certifying innovative technologies, including advanced control methods for electric propulsion systems.

Cybersecurity has become an increasingly important aspect of aerospace regulations. Control systems for PMSM must incorporate robust security measures to protect against potential cyber threats. Standards such as DO-326A provide guidelines for addressing cybersecurity risks in aircraft systems.

The Federal Aviation Administration (FAA) in the United States and the European Union Aviation Safety Agency (EASA) are the primary regulatory bodies that set standards for aircraft certification. These agencies have established specific requirements for electric propulsion systems, which include the control methods for PMSM. The FAA's Part 33 and EASA's CS-E regulations cover the certification of aircraft engines, including electric motors and their control systems.

One of the key regulatory considerations for PMSM control in electric aircraft is electromagnetic compatibility (EMC). The control systems must comply with DO-160 standards, which outline environmental conditions and test procedures for airborne equipment. This includes requirements for radiated and conducted emissions, as well as susceptibility to electromagnetic interference.

Safety is paramount in aerospace regulations. The control methods for PMSM must adhere to the principles of functional safety, as outlined in standards such as ARP4754A for aircraft systems development and DO-178C for software considerations. These standards require a systematic approach to risk assessment, fault tolerance, and failure mode analysis in the development of control algorithms and hardware.

Reliability and redundancy are also critical aspects addressed by aerospace regulations. Control systems for PMSM in electric aircraft must demonstrate high levels of reliability through rigorous testing and validation processes. Redundancy in control architectures may be required to ensure continued operation in the event of component failures.

Environmental factors play a significant role in aerospace regulations. Control methods for PMSM must be designed to operate reliably under extreme conditions, including temperature variations, altitude changes, and vibration. Compliance with environmental testing standards, such as DO-160, is essential for certification.

As electric aircraft technology evolves, regulatory bodies are adapting their frameworks to address new challenges. The FAA's Part 23 Amendment 64 and EASA's CS-23 Amendment 5 have introduced performance-based standards that allow for more flexibility in certifying innovative technologies, including advanced control methods for electric propulsion systems.

Cybersecurity has become an increasingly important aspect of aerospace regulations. Control systems for PMSM must incorporate robust security measures to protect against potential cyber threats. Standards such as DO-326A provide guidelines for addressing cybersecurity risks in aircraft systems.

Energy Efficiency Impact

The energy efficiency impact of advanced control methods for Permanent Magnet Synchronous Motors (PMSM) in electric aircraft is a critical consideration in the development of sustainable aviation technologies. These control methods play a pivotal role in optimizing the performance of electric propulsion systems, directly influencing the overall energy efficiency of the aircraft.

Advanced control techniques, such as field-oriented control (FOC) and direct torque control (DTC), have demonstrated significant improvements in PMSM efficiency. By precisely managing the motor's magnetic field and torque production, these methods minimize energy losses and maximize power output. This optimization translates to extended flight ranges and reduced energy consumption, addressing key challenges in electric aviation.

The implementation of model predictive control (MPC) algorithms has further enhanced energy efficiency by anticipating and adapting to changing flight conditions. MPC allows for real-time optimization of motor parameters, ensuring optimal performance across various operational scenarios. This adaptive approach results in smoother power delivery and reduced energy waste during transient states, contributing to overall system efficiency.

Sensorless control strategies have emerged as another avenue for improving energy efficiency in PMSM-driven electric aircraft. By eliminating the need for physical position sensors, these methods reduce system complexity and weight while maintaining high levels of control accuracy. The reduction in parasitic losses associated with sensor components leads to incremental gains in overall propulsion system efficiency.

Advanced control methods also enable more effective regenerative braking in electric aircraft. By precisely controlling the motor during deceleration phases, a greater portion of kinetic energy can be recovered and stored for later use. This energy recapture mechanism significantly extends the effective range of electric aircraft and improves overall energy utilization.

The integration of artificial intelligence and machine learning algorithms into PMSM control systems presents promising opportunities for further efficiency gains. These technologies can analyze vast amounts of operational data to continuously refine control parameters, adapting to subtle changes in motor characteristics and environmental conditions over time.

In conclusion, the impact of advanced control methods on energy efficiency in PMSM-driven electric aircraft is substantial and multifaceted. Through precise field management, adaptive control strategies, sensorless operation, and intelligent optimization, these techniques are pushing the boundaries of electric propulsion efficiency. As these control methods continue to evolve, they will play a crucial role in extending the range, payload capacity, and overall viability of electric aircraft, driving the industry towards a more sustainable future.

Advanced control techniques, such as field-oriented control (FOC) and direct torque control (DTC), have demonstrated significant improvements in PMSM efficiency. By precisely managing the motor's magnetic field and torque production, these methods minimize energy losses and maximize power output. This optimization translates to extended flight ranges and reduced energy consumption, addressing key challenges in electric aviation.

The implementation of model predictive control (MPC) algorithms has further enhanced energy efficiency by anticipating and adapting to changing flight conditions. MPC allows for real-time optimization of motor parameters, ensuring optimal performance across various operational scenarios. This adaptive approach results in smoother power delivery and reduced energy waste during transient states, contributing to overall system efficiency.

Sensorless control strategies have emerged as another avenue for improving energy efficiency in PMSM-driven electric aircraft. By eliminating the need for physical position sensors, these methods reduce system complexity and weight while maintaining high levels of control accuracy. The reduction in parasitic losses associated with sensor components leads to incremental gains in overall propulsion system efficiency.

Advanced control methods also enable more effective regenerative braking in electric aircraft. By precisely controlling the motor during deceleration phases, a greater portion of kinetic energy can be recovered and stored for later use. This energy recapture mechanism significantly extends the effective range of electric aircraft and improves overall energy utilization.

The integration of artificial intelligence and machine learning algorithms into PMSM control systems presents promising opportunities for further efficiency gains. These technologies can analyze vast amounts of operational data to continuously refine control parameters, adapting to subtle changes in motor characteristics and environmental conditions over time.

In conclusion, the impact of advanced control methods on energy efficiency in PMSM-driven electric aircraft is substantial and multifaceted. Through precise field management, adaptive control strategies, sensorless operation, and intelligent optimization, these techniques are pushing the boundaries of electric propulsion efficiency. As these control methods continue to evolve, they will play a crucial role in extending the range, payload capacity, and overall viability of electric aircraft, driving the industry towards a more sustainable future.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!