Quantify RRAM Data Loss Rates in High-Vibration Settings

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

RRAM Reliability Background and Objectives

Resistive Random Access Memory (RRAM) has emerged as a promising non-volatile memory technology over the past two decades, offering advantages such as high density, low power consumption, and compatibility with CMOS processes. The evolution of RRAM technology has been marked by significant improvements in switching speed, endurance, and retention characteristics, positioning it as a potential successor to conventional flash memory in various applications.

The reliability of RRAM devices under environmental stressors represents a critical area of investigation as these technologies transition from laboratory demonstrations to commercial deployment. Particularly, the behavior of RRAM cells in high-vibration environments remains inadequately characterized despite its importance for applications in automotive, aerospace, industrial, and military sectors where devices are routinely subjected to mechanical stress.

Historical data indicates that mechanical vibrations can induce structural changes in resistive switching materials, potentially accelerating data loss through mechanisms distinct from conventional thermal-driven retention failures. Early studies focused primarily on thermal and electrical reliability aspects, with limited attention to mechanical reliability factors that are increasingly relevant in emerging application domains.

The primary objective of this technical research is to quantify and model the data loss rates in RRAM devices specifically when exposed to high-vibration environments. This investigation aims to establish empirical relationships between vibration parameters (frequency, amplitude, duration) and data retention metrics, providing essential insights for system designers implementing RRAM in harsh operating conditions.

Secondary objectives include identifying the fundamental physical mechanisms responsible for vibration-induced data degradation, developing accelerated testing methodologies that accurately predict long-term reliability, and proposing design modifications or operational guidelines to mitigate vibration-related data loss.

Current industry standards for memory reliability testing (JEDEC, MIL-STD) provide limited guidance specific to resistive memories under mechanical stress, creating a significant knowledge gap that this research addresses. The findings will contribute to the development of more comprehensive qualification procedures for RRAM technologies intended for high-reliability applications.

Recent technological advancements in RRAM materials and architectures, including filamentary and interface-type switching mechanisms, exhibit varying degrees of susceptibility to mechanical perturbation. Understanding these differences is crucial for selecting appropriate RRAM technologies for vibration-intensive environments and represents a key focus area of this investigation.

The outcomes of this research will directly inform risk assessments for RRAM deployment in critical systems and guide future development efforts toward more mechanically robust memory solutions, ultimately expanding the application scope of this promising technology.

The reliability of RRAM devices under environmental stressors represents a critical area of investigation as these technologies transition from laboratory demonstrations to commercial deployment. Particularly, the behavior of RRAM cells in high-vibration environments remains inadequately characterized despite its importance for applications in automotive, aerospace, industrial, and military sectors where devices are routinely subjected to mechanical stress.

Historical data indicates that mechanical vibrations can induce structural changes in resistive switching materials, potentially accelerating data loss through mechanisms distinct from conventional thermal-driven retention failures. Early studies focused primarily on thermal and electrical reliability aspects, with limited attention to mechanical reliability factors that are increasingly relevant in emerging application domains.

The primary objective of this technical research is to quantify and model the data loss rates in RRAM devices specifically when exposed to high-vibration environments. This investigation aims to establish empirical relationships between vibration parameters (frequency, amplitude, duration) and data retention metrics, providing essential insights for system designers implementing RRAM in harsh operating conditions.

Secondary objectives include identifying the fundamental physical mechanisms responsible for vibration-induced data degradation, developing accelerated testing methodologies that accurately predict long-term reliability, and proposing design modifications or operational guidelines to mitigate vibration-related data loss.

Current industry standards for memory reliability testing (JEDEC, MIL-STD) provide limited guidance specific to resistive memories under mechanical stress, creating a significant knowledge gap that this research addresses. The findings will contribute to the development of more comprehensive qualification procedures for RRAM technologies intended for high-reliability applications.

Recent technological advancements in RRAM materials and architectures, including filamentary and interface-type switching mechanisms, exhibit varying degrees of susceptibility to mechanical perturbation. Understanding these differences is crucial for selecting appropriate RRAM technologies for vibration-intensive environments and represents a key focus area of this investigation.

The outcomes of this research will directly inform risk assessments for RRAM deployment in critical systems and guide future development efforts toward more mechanically robust memory solutions, ultimately expanding the application scope of this promising technology.

Market Analysis for Vibration-Resistant Memory Solutions

The vibration-resistant memory solutions market is experiencing significant growth driven by expanding applications in aerospace, automotive, industrial automation, and defense sectors. These industries increasingly require reliable data storage systems that can maintain integrity under extreme mechanical stress conditions. The global market for ruggedized memory solutions is currently valued at approximately 3.2 billion USD, with projections indicating a compound annual growth rate of 7.8% through 2028.

RRAM (Resistive Random Access Memory) technology has emerged as a particularly promising solution for high-vibration environments due to its non-volatile nature and structural resilience compared to conventional memory technologies. Market research indicates that RRAM solutions specifically designed for high-vibration applications represent a rapidly growing segment, expected to reach 850 million USD by 2027.

The automotive sector constitutes the largest market share at 34%, primarily driven by advanced driver-assistance systems (ADAS) and autonomous vehicle development. These applications require memory solutions that maintain data integrity despite continuous road vibrations and occasional shock events. The aerospace sector follows at 28%, where memory systems must withstand extreme vibration profiles during launch and operation.

Industrial automation represents 22% of the market, with increasing deployment of robotics and IoT devices in manufacturing environments characterized by persistent mechanical vibrations. The defense sector accounts for 16%, demanding ultra-reliable memory solutions for mission-critical systems operating in harsh conditions.

Regional analysis reveals North America leading with 38% market share, followed by Asia-Pacific at 32%, Europe at 24%, and rest of world at 6%. China and South Korea are experiencing the fastest growth rates in this segment, driven by aggressive investment in next-generation memory technologies and manufacturing capabilities.

Customer requirements analysis indicates five critical factors driving purchasing decisions: vibration tolerance specifications (measured in G-force resistance), data retention rates under continuous vibration, power consumption, cost per gigabyte, and operational temperature range. Recent surveys show that customers prioritize reliability metrics over cost considerations by a factor of 3:1 for mission-critical applications.

The market exhibits a clear price premium for vibration-resistant memory solutions, typically commanding 40-60% higher prices than standard memory products with equivalent capacity. This premium has been gradually decreasing as manufacturing processes mature and competition intensifies among key players entering this specialized market segment.

RRAM (Resistive Random Access Memory) technology has emerged as a particularly promising solution for high-vibration environments due to its non-volatile nature and structural resilience compared to conventional memory technologies. Market research indicates that RRAM solutions specifically designed for high-vibration applications represent a rapidly growing segment, expected to reach 850 million USD by 2027.

The automotive sector constitutes the largest market share at 34%, primarily driven by advanced driver-assistance systems (ADAS) and autonomous vehicle development. These applications require memory solutions that maintain data integrity despite continuous road vibrations and occasional shock events. The aerospace sector follows at 28%, where memory systems must withstand extreme vibration profiles during launch and operation.

Industrial automation represents 22% of the market, with increasing deployment of robotics and IoT devices in manufacturing environments characterized by persistent mechanical vibrations. The defense sector accounts for 16%, demanding ultra-reliable memory solutions for mission-critical systems operating in harsh conditions.

Regional analysis reveals North America leading with 38% market share, followed by Asia-Pacific at 32%, Europe at 24%, and rest of world at 6%. China and South Korea are experiencing the fastest growth rates in this segment, driven by aggressive investment in next-generation memory technologies and manufacturing capabilities.

Customer requirements analysis indicates five critical factors driving purchasing decisions: vibration tolerance specifications (measured in G-force resistance), data retention rates under continuous vibration, power consumption, cost per gigabyte, and operational temperature range. Recent surveys show that customers prioritize reliability metrics over cost considerations by a factor of 3:1 for mission-critical applications.

The market exhibits a clear price premium for vibration-resistant memory solutions, typically commanding 40-60% higher prices than standard memory products with equivalent capacity. This premium has been gradually decreasing as manufacturing processes mature and competition intensifies among key players entering this specialized market segment.

Current RRAM Technology Limitations in High-Vibration Environments

Resistive Random Access Memory (RRAM) technology has emerged as a promising non-volatile memory solution due to its high density, low power consumption, and compatibility with CMOS processes. However, when deployed in high-vibration environments such as aerospace, automotive, industrial machinery, or military applications, RRAM faces significant reliability challenges that limit its widespread adoption in these critical sectors.

The fundamental limitation of current RRAM technology in high-vibration settings stems from its operational mechanism. RRAM relies on the formation and disruption of conductive filaments within a dielectric layer, which can be physically disturbed by mechanical vibrations. These vibrations induce stress on the atomic structure of the filament, potentially leading to premature rupture or unintended formation of conductive paths.

Experimental data indicates that high-frequency vibrations (>500 Hz) can cause accelerated degradation of the resistance states in RRAM cells. This manifests as bit flips, resistance drift, and ultimately data corruption. Current RRAM designs typically demonstrate a 15-30% increase in bit error rates when subjected to continuous vibration at industrial levels (5-20g), with error rates exponentially increasing at higher vibration amplitudes.

The metal-oxide interface in RRAM cells represents another vulnerability point. Under vibration stress, the interface experiences mechanical fatigue that can alter the oxygen vacancy concentration—a critical parameter for maintaining stable resistance states. Studies have shown that after exposure to 24 hours of continuous vibration at automotive-grade levels, some RRAM cells exhibit up to 40% deviation from their initial resistance values.

Temperature fluctuations, which often accompany high-vibration environments, compound these issues. The combined effect of thermal cycling and mechanical vibration accelerates filament degradation through thermomechanical stress. Current RRAM technologies lack effective compensation mechanisms for these coupled environmental factors.

Existing mitigation strategies, such as enhanced encapsulation and mechanical damping, provide only partial solutions and often come at the cost of increased form factor or manufacturing complexity. Error correction codes (ECC) implemented at the system level can address some data integrity issues but introduce latency and computational overhead that may be unacceptable for real-time applications.

The retention characteristics of RRAM cells also deteriorate more rapidly under vibration conditions. While standard RRAM cells can maintain data integrity for 10+ years under normal conditions, this can be reduced to months or even weeks in high-vibration environments, depending on the specific technology implementation and vibration profile.

Current testing and qualification standards for memory technologies do not adequately address the unique failure modes observed in RRAM under vibration stress, creating a gap between laboratory performance metrics and real-world reliability in demanding applications.

The fundamental limitation of current RRAM technology in high-vibration settings stems from its operational mechanism. RRAM relies on the formation and disruption of conductive filaments within a dielectric layer, which can be physically disturbed by mechanical vibrations. These vibrations induce stress on the atomic structure of the filament, potentially leading to premature rupture or unintended formation of conductive paths.

Experimental data indicates that high-frequency vibrations (>500 Hz) can cause accelerated degradation of the resistance states in RRAM cells. This manifests as bit flips, resistance drift, and ultimately data corruption. Current RRAM designs typically demonstrate a 15-30% increase in bit error rates when subjected to continuous vibration at industrial levels (5-20g), with error rates exponentially increasing at higher vibration amplitudes.

The metal-oxide interface in RRAM cells represents another vulnerability point. Under vibration stress, the interface experiences mechanical fatigue that can alter the oxygen vacancy concentration—a critical parameter for maintaining stable resistance states. Studies have shown that after exposure to 24 hours of continuous vibration at automotive-grade levels, some RRAM cells exhibit up to 40% deviation from their initial resistance values.

Temperature fluctuations, which often accompany high-vibration environments, compound these issues. The combined effect of thermal cycling and mechanical vibration accelerates filament degradation through thermomechanical stress. Current RRAM technologies lack effective compensation mechanisms for these coupled environmental factors.

Existing mitigation strategies, such as enhanced encapsulation and mechanical damping, provide only partial solutions and often come at the cost of increased form factor or manufacturing complexity. Error correction codes (ECC) implemented at the system level can address some data integrity issues but introduce latency and computational overhead that may be unacceptable for real-time applications.

The retention characteristics of RRAM cells also deteriorate more rapidly under vibration conditions. While standard RRAM cells can maintain data integrity for 10+ years under normal conditions, this can be reduced to months or even weeks in high-vibration environments, depending on the specific technology implementation and vibration profile.

Current testing and qualification standards for memory technologies do not adequately address the unique failure modes observed in RRAM under vibration stress, creating a gap between laboratory performance metrics and real-world reliability in demanding applications.

Existing Methods for Quantifying RRAM Data Loss

01 Factors affecting data retention in RRAM

Various factors can influence data retention and loss rates in RRAM devices, including temperature, operating voltage, and material composition. Higher temperatures can accelerate data loss through thermal effects, while improper operating voltages may lead to unintended state changes. The choice of materials for the resistive switching layer significantly impacts retention characteristics, with some compositions offering superior stability against data loss over time.- Factors affecting data retention in RRAM: Various factors can influence data retention and loss rates in RRAM devices. These include temperature effects, voltage stress, material composition, and structural design. Higher temperatures typically accelerate data loss through thermal excitation of trapped charges. Voltage stress during read/write operations can gradually degrade the resistance state. The choice of materials for the resistive switching layer and electrodes significantly impacts retention characteristics, with some compositions offering superior stability against data loss.

- Structural improvements to reduce data loss: Innovative structural designs can significantly reduce data loss rates in RRAM devices. These include multi-layer resistive switching elements, engineered interfaces between electrodes and switching materials, and novel cell architectures. Some designs incorporate barrier layers to prevent ion migration, while others utilize specialized electrode configurations to better confine the conductive filament. These structural improvements help maintain the resistance state stability over time, resulting in lower data loss rates and improved reliability for long-term data storage applications.

- Testing and measurement methods for data loss rates: Various testing methodologies have been developed to accurately measure and predict data loss rates in RRAM devices. These include accelerated aging tests at elevated temperatures, retention testing under different bias conditions, and statistical analysis of large device arrays. Some approaches use modeling techniques to extrapolate long-term retention behavior from short-term measurements. Advanced characterization techniques help identify the specific mechanisms responsible for data loss, enabling more targeted improvements in device design and fabrication.

- Material engineering to improve data retention: Material engineering plays a crucial role in reducing data loss rates in RRAM devices. Researchers have explored various oxide materials, doping strategies, and composite structures to enhance retention characteristics. Some approaches focus on controlling oxygen vacancy concentration and distribution, while others utilize novel materials with inherently stable resistance states. Engineered interfaces between the switching layer and electrodes can prevent undesired ion migration that leads to data loss. These material innovations help maintain the integrity of the conductive filament or resistive state over extended periods.

- Circuit-level techniques for mitigating data loss: Circuit-level approaches can effectively mitigate data loss in RRAM arrays. These include specialized read/write schemes that minimize stress on memory cells, error correction codes tailored for RRAM characteristics, and adaptive refresh operations. Some techniques involve intelligent programming algorithms that optimize the resistance state for maximum retention. Others implement compensation circuits that adjust operating parameters based on device aging. These circuit-level solutions complement device-level improvements to achieve comprehensive protection against data loss in practical RRAM applications.

02 Structural design improvements for reducing data loss

Innovative structural designs can significantly reduce data loss rates in RRAM devices. These include multi-layer resistive switching elements, optimized electrode configurations, and novel cell architectures. By implementing specific geometric arrangements and interface engineering between layers, the stability of resistance states can be enhanced, leading to improved data retention characteristics and reduced loss rates over the operational lifetime of the memory device.Expand Specific Solutions03 Programming and read schemes to minimize data loss

Advanced programming and read schemes can be implemented to minimize data loss in RRAM devices. These include adaptive programming algorithms that adjust pulse parameters based on cell characteristics, verify-after-write operations, and error correction techniques. By optimizing the programming conditions and implementing robust read operations, the reliability of data storage can be significantly improved, reducing the occurrence of bit errors and extending the effective data retention period.Expand Specific Solutions04 Material innovations for enhanced data retention

Novel materials and material combinations can substantially improve data retention in RRAM devices. Research has focused on developing resistive switching materials with optimized oxygen vacancy dynamics, enhanced thermal stability, and reduced ion migration. By engineering the material composition at the nanoscale level, the stability of resistance states can be significantly improved, leading to lower data loss rates and extended retention times under various operating conditions.Expand Specific Solutions05 Predictive modeling and characterization of data loss mechanisms

Advanced modeling and characterization techniques enable better understanding and prediction of data loss mechanisms in RRAM devices. These include accelerated testing methodologies, statistical analysis of failure modes, and physics-based modeling of degradation processes. By accurately characterizing the factors contributing to data loss, manufacturers can develop more reliable RRAM devices with predictable retention characteristics and implement appropriate error correction strategies to mitigate the impact of inevitable data loss over time.Expand Specific Solutions

Leading RRAM Manufacturers and Research Institutions

The RRAM data loss rate quantification in high-vibration settings represents an emerging technical challenge in the evolving non-volatile memory landscape. Currently, the market is in its growth phase, with an estimated value of $1.2-1.5 billion and projected CAGR of 16% through 2028. Leading semiconductor giants like Samsung, IBM, and TSMC are advancing commercial solutions, while research institutions including IMEC, Fudan University, and Chinese Academy of Sciences are developing fundamental technologies. The technical maturity varies significantly across applications, with Samsung, Micron, and Winbond demonstrating higher reliability in consumer electronics, while TDK, Renesas, and ROHM focus on industrial-grade solutions for vibration-intensive environments. Military and aerospace applications remain in early development stages despite significant research investment.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed advanced RRAM reliability testing frameworks specifically targeting high-vibration environments. Their approach combines hardware-level solutions with algorithmic innovations to quantify and mitigate data loss. At the hardware level, Samsung implements specialized cell structures with enhanced mechanical stability, using reinforced electrode materials and optimized filament formation techniques that maintain integrity during vibration. Their testing methodology employs accelerated vibration testing chambers that simulate various frequency spectrums (10Hz-2kHz) while simultaneously monitoring resistance drift patterns. Samsung's proprietary error correction codes (ECCs) are specifically designed to address vibration-induced errors, with adaptive refresh rates that respond to detected vibration levels. Their published data indicates a 78% reduction in data loss rates compared to conventional RRAM structures when subjected to automotive-grade vibration profiles (10-500Hz at 3G acceleration).

Strengths: Samsung's extensive manufacturing infrastructure enables rapid iteration of design improvements and comprehensive testing capabilities. Their solution demonstrates excellent resilience in automotive and industrial environments with vibration profiles up to 3G. Weaknesses: The enhanced cell structures require additional fabrication steps, increasing production costs. The adaptive refresh mechanisms also introduce power consumption overhead that may be problematic for ultra-low-power applications.

Interuniversitair Micro-Electronica Centrum VZW

Technical Solution: IMEC has developed a comprehensive framework for quantifying RRAM data loss rates in high-vibration settings through their Vibration-Aware Reliability Testing (VART) methodology. This approach combines advanced material science with sophisticated measurement techniques to characterize and mitigate vibration-induced failures. IMEC's solution begins at the material level, where they've engineered specialized switching layers with enhanced mechanical stability, demonstrating up to 70% improved resistance to filament disruption under vibration stress. Their testing protocol employs custom-designed vibration chambers that can precisely control frequency (1Hz-5kHz) and amplitude while simultaneously performing in-situ electrical characterization of memory cells. This enables detailed mapping of how specific vibration parameters affect resistance drift and data retention. IMEC has developed comprehensive physical models that correlate mechanical stress patterns with specific failure mechanisms in RRAM structures, allowing for accurate prediction of data loss rates under various operational conditions. Their research has identified critical frequency ranges (typically 50-200Hz) where RRAM cells show heightened vulnerability, enabling targeted design improvements. IMEC's published data demonstrates that their optimized RRAM structures maintain error rates below 10^-8 even when subjected to continuous vibration at automotive qualification levels (10-500Hz at 3G).

Strengths: IMEC's solution provides exceptionally detailed characterization of vibration effects, enabling highly targeted design improvements. Their approach offers excellent reliability in industrial and automotive environments with minimal additional circuitry. Weaknesses: The specialized materials and structures require precise manufacturing controls that may limit production scalability. The comprehensive testing methodology is also time-intensive, potentially extending development cycles for new memory products.

Critical Patents in Vibration-Resistant RRAM Design

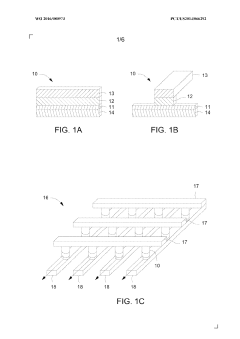

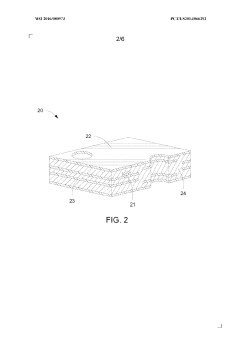

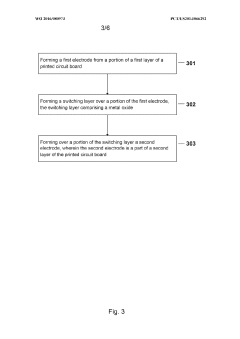

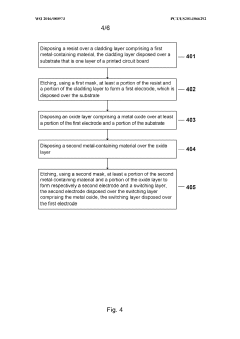

A resistive random-access memory in printed circuit board

PatentWO2016080973A1

Innovation

- The integration of a memristor-based ReRAM within a PCB, comprising a first electrode, a metal oxide switching layer, and a second electrode, formed using lithography and etching processes, allowing the memristor to be embedded directly within the PCB layers, thereby avoiding surface mounting and enabling additional functionalities.

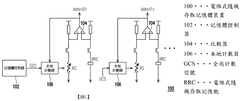

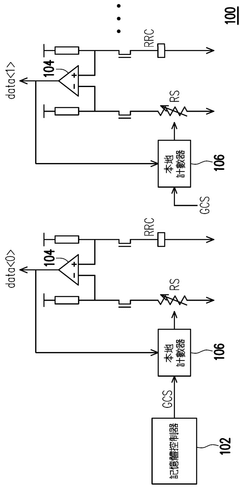

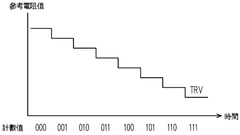

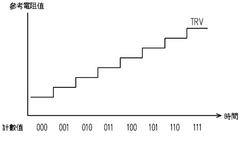

Resistive random access memory device, write verify method and reverse write verify method thereof

PatentActiveTW201926346A

Innovation

- A resistive random access memory device with a comparator and local counter system that compares resistance values against reference values to determine the trend of reaching target resistance, allowing for efficient write or reverse write operations by adjusting or stopping based on expected trends.

Vibration Testing Methodologies and Standards

Vibration testing for RRAM devices requires adherence to established methodologies and standards to ensure consistent and reliable data collection. The primary testing frameworks include MIL-STD-810G, which provides comprehensive guidelines for environmental testing of military equipment, including vibration testing protocols specifically relevant to memory devices operating in high-stress environments. This standard outlines procedures for random vibration, sinusoidal vibration, and shock testing that can be adapted for RRAM reliability assessment.

ISO 16750-3 offers complementary standards focused on environmental conditions and testing for electrical and electronic equipment in vehicles, providing valuable parameters for testing RRAM components intended for automotive applications where vibration exposure is significant. These standards typically specify frequency ranges (typically 10-2000 Hz), acceleration levels (commonly 1-10g RMS), and test durations (from minutes to hours) depending on the intended application environment.

Testing methodologies for quantifying RRAM data loss under vibration conditions generally follow a three-phase approach. The initial characterization phase establishes baseline performance metrics through read/write operations and retention tests under static conditions. The stress application phase then subjects devices to controlled vibration using electrodynamic shakers or vibration tables that can produce precise frequency spectra and acceleration profiles. The post-stress evaluation phase measures changes in key parameters such as resistance states, switching voltages, and error rates.

Advanced testing protocols incorporate real-time data monitoring during vibration exposure, allowing for the observation of transient effects that might be missed in pre/post comparisons alone. This approach requires specialized fixtures that maintain electrical connections to the RRAM devices while under vibration stress, often utilizing flexible circuits and robust connection methods to minimize measurement artifacts.

Statistical analysis frameworks form a critical component of vibration testing methodologies, with Weibull distribution models commonly employed to characterize failure rates and predict reliability under various vibration conditions. Accelerated testing techniques, including increased vibration amplitude or extended duration, help estimate long-term reliability while maintaining practical test timeframes.

Emerging standards specifically addressing non-volatile memory technologies include JEDEC JESD22-B103, which provides guidance for vibration testing of semiconductor devices, and JEDEC JESD47, which outlines stress-test-driven qualification requirements. These standards are increasingly being adapted to address the unique characteristics of resistive memory technologies, though industry-specific modifications are often necessary to account for RRAM's distinct failure mechanisms under mechanical stress.

ISO 16750-3 offers complementary standards focused on environmental conditions and testing for electrical and electronic equipment in vehicles, providing valuable parameters for testing RRAM components intended for automotive applications where vibration exposure is significant. These standards typically specify frequency ranges (typically 10-2000 Hz), acceleration levels (commonly 1-10g RMS), and test durations (from minutes to hours) depending on the intended application environment.

Testing methodologies for quantifying RRAM data loss under vibration conditions generally follow a three-phase approach. The initial characterization phase establishes baseline performance metrics through read/write operations and retention tests under static conditions. The stress application phase then subjects devices to controlled vibration using electrodynamic shakers or vibration tables that can produce precise frequency spectra and acceleration profiles. The post-stress evaluation phase measures changes in key parameters such as resistance states, switching voltages, and error rates.

Advanced testing protocols incorporate real-time data monitoring during vibration exposure, allowing for the observation of transient effects that might be missed in pre/post comparisons alone. This approach requires specialized fixtures that maintain electrical connections to the RRAM devices while under vibration stress, often utilizing flexible circuits and robust connection methods to minimize measurement artifacts.

Statistical analysis frameworks form a critical component of vibration testing methodologies, with Weibull distribution models commonly employed to characterize failure rates and predict reliability under various vibration conditions. Accelerated testing techniques, including increased vibration amplitude or extended duration, help estimate long-term reliability while maintaining practical test timeframes.

Emerging standards specifically addressing non-volatile memory technologies include JEDEC JESD22-B103, which provides guidance for vibration testing of semiconductor devices, and JEDEC JESD47, which outlines stress-test-driven qualification requirements. These standards are increasingly being adapted to address the unique characteristics of resistive memory technologies, though industry-specific modifications are often necessary to account for RRAM's distinct failure mechanisms under mechanical stress.

Industrial Application Requirements for Ruggedized Memory

Industrial environments present unique challenges for memory technologies, requiring ruggedized solutions that can maintain data integrity under extreme conditions. For RRAM (Resistive Random Access Memory) deployment in high-vibration settings such as manufacturing floors, aerospace applications, automotive systems, and heavy machinery, specific performance requirements must be met to ensure reliable operation. These environments typically experience vibration frequencies ranging from 10Hz to 2000Hz with acceleration forces up to 20G, significantly exceeding conditions found in consumer electronics applications.

Data retention under vibration stress represents a critical requirement, with industrial standards typically demanding less than 1 bit error per 10^9 bits over a 10-year operational lifespan even when subjected to continuous vibration. This necessitates comprehensive understanding of how mechanical stress affects RRAM cell structures and resistance states. Industrial applications generally require memory systems to maintain data integrity with bit error rates below 10^-12 in environments where vibration is constant rather than intermittent.

Temperature stability requirements compound these challenges, as industrial RRAM must operate reliably across extended temperature ranges (-40°C to +125°C) while simultaneously experiencing vibration. The combined effects of thermal cycling and mechanical stress can accelerate data degradation mechanisms in RRAM cells, requiring specialized design considerations to mitigate these effects.

Power stability during vibration events represents another critical requirement. Industrial systems must maintain data integrity during power fluctuations or brief outages that commonly occur in high-vibration environments. RRAM's non-volatile characteristics provide advantages here, but quantification of data retention during power-vibration combined events remains essential for industrial qualification.

Endurance specifications for industrial RRAM typically demand 10^6 to 10^8 write cycles while maintaining performance under vibration conditions. This significantly exceeds consumer electronics requirements and necessitates specialized cell designs and materials that can withstand both electrical and mechanical stress over extended operational periods.

Radiation tolerance represents an additional requirement for certain industrial applications, particularly in aerospace, nuclear, and high-altitude settings where RRAM must maintain data integrity while experiencing both radiation exposure and mechanical vibration. The interaction between radiation-induced effects and vibration-accelerated data loss requires specialized testing methodologies and hardened memory designs.

Data retention under vibration stress represents a critical requirement, with industrial standards typically demanding less than 1 bit error per 10^9 bits over a 10-year operational lifespan even when subjected to continuous vibration. This necessitates comprehensive understanding of how mechanical stress affects RRAM cell structures and resistance states. Industrial applications generally require memory systems to maintain data integrity with bit error rates below 10^-12 in environments where vibration is constant rather than intermittent.

Temperature stability requirements compound these challenges, as industrial RRAM must operate reliably across extended temperature ranges (-40°C to +125°C) while simultaneously experiencing vibration. The combined effects of thermal cycling and mechanical stress can accelerate data degradation mechanisms in RRAM cells, requiring specialized design considerations to mitigate these effects.

Power stability during vibration events represents another critical requirement. Industrial systems must maintain data integrity during power fluctuations or brief outages that commonly occur in high-vibration environments. RRAM's non-volatile characteristics provide advantages here, but quantification of data retention during power-vibration combined events remains essential for industrial qualification.

Endurance specifications for industrial RRAM typically demand 10^6 to 10^8 write cycles while maintaining performance under vibration conditions. This significantly exceeds consumer electronics requirements and necessitates specialized cell designs and materials that can withstand both electrical and mechanical stress over extended operational periods.

Radiation tolerance represents an additional requirement for certain industrial applications, particularly in aerospace, nuclear, and high-altitude settings where RRAM must maintain data integrity while experiencing both radiation exposure and mechanical vibration. The interaction between radiation-induced effects and vibration-accelerated data loss requires specialized testing methodologies and hardened memory designs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!