Coil Whine Reduction through Multi-layer Ceramic Capacitors

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Coil Whine Origins and Reduction Objectives

Coil whine is an audible noise phenomenon that occurs in electronic devices, particularly in power supplies and voltage regulators. This high-frequency sound is generated by electromagnetic forces causing vibrations in coils and other components. As electronic devices become more compact and powerful, the issue of coil whine has gained increasing attention in the industry.

The origins of coil whine can be traced back to the fundamental principles of electromagnetism. When alternating current flows through a coil, it creates a fluctuating magnetic field. This field interacts with the coil's physical structure, causing it to vibrate at frequencies that can fall within the audible range for humans. The intensity and frequency of coil whine depend on various factors, including the coil's design, the current flowing through it, and the overall circuit configuration.

In modern electronics, coil whine has become more prevalent due to the widespread use of switch-mode power supplies and high-frequency voltage regulators. These components, while efficient, often operate at frequencies that can produce audible noise. The problem is exacerbated in devices that require rapid changes in power consumption, such as graphics cards in computers or power supplies in gaming consoles.

The primary objective of coil whine reduction research is to minimize or eliminate this unwanted noise while maintaining the efficiency and performance of electronic devices. This goal presents a significant challenge as it requires balancing multiple factors, including electrical performance, thermal management, and cost-effectiveness.

One promising approach in this field is the use of Multi-layer Ceramic Capacitors (MLCCs) to mitigate coil whine. MLCCs offer several advantages that make them suitable for this application. Their compact size, high capacitance, and low equivalent series resistance (ESR) allow them to effectively filter high-frequency noise and stabilize voltage fluctuations that contribute to coil whine.

The research on coil whine reduction through MLCCs aims to develop innovative circuit designs and component arrangements that can effectively suppress the electromagnetic vibrations causing the noise. This involves studying the interaction between MLCCs and other circuit components, optimizing their placement and values, and exploring new materials and manufacturing techniques to enhance their noise-suppression capabilities.

Furthermore, the research seeks to establish comprehensive guidelines for engineers and designers to implement MLCC-based solutions in a wide range of electronic devices. This includes developing standardized testing methodologies to quantify coil whine and evaluate the effectiveness of reduction techniques across different operating conditions and device types.

The origins of coil whine can be traced back to the fundamental principles of electromagnetism. When alternating current flows through a coil, it creates a fluctuating magnetic field. This field interacts with the coil's physical structure, causing it to vibrate at frequencies that can fall within the audible range for humans. The intensity and frequency of coil whine depend on various factors, including the coil's design, the current flowing through it, and the overall circuit configuration.

In modern electronics, coil whine has become more prevalent due to the widespread use of switch-mode power supplies and high-frequency voltage regulators. These components, while efficient, often operate at frequencies that can produce audible noise. The problem is exacerbated in devices that require rapid changes in power consumption, such as graphics cards in computers or power supplies in gaming consoles.

The primary objective of coil whine reduction research is to minimize or eliminate this unwanted noise while maintaining the efficiency and performance of electronic devices. This goal presents a significant challenge as it requires balancing multiple factors, including electrical performance, thermal management, and cost-effectiveness.

One promising approach in this field is the use of Multi-layer Ceramic Capacitors (MLCCs) to mitigate coil whine. MLCCs offer several advantages that make them suitable for this application. Their compact size, high capacitance, and low equivalent series resistance (ESR) allow them to effectively filter high-frequency noise and stabilize voltage fluctuations that contribute to coil whine.

The research on coil whine reduction through MLCCs aims to develop innovative circuit designs and component arrangements that can effectively suppress the electromagnetic vibrations causing the noise. This involves studying the interaction between MLCCs and other circuit components, optimizing their placement and values, and exploring new materials and manufacturing techniques to enhance their noise-suppression capabilities.

Furthermore, the research seeks to establish comprehensive guidelines for engineers and designers to implement MLCC-based solutions in a wide range of electronic devices. This includes developing standardized testing methodologies to quantify coil whine and evaluate the effectiveness of reduction techniques across different operating conditions and device types.

Market Demand for Quiet Electronics

The market demand for quiet electronics has been steadily increasing in recent years, driven by consumer preferences for more comfortable and less intrusive devices. This trend is particularly evident in the personal computing, home entertainment, and mobile device sectors. As users become more sensitive to noise pollution in their living and working environments, manufacturers are under pressure to develop products that operate with minimal acoustic disturbance.

In the personal computing market, there is a growing demand for silent or near-silent desktops and laptops. This is especially true for professionals working in quiet environments, such as home offices or open-plan workspaces. The reduction of coil whine through the use of multi-layer ceramic capacitors (MLCCs) can significantly contribute to meeting this demand, as coil whine is often a source of irritation for users of high-performance computing equipment.

The home entertainment sector is another area where the demand for quiet electronics is prominent. Consumers are increasingly seeking audio-visual equipment, gaming consoles, and streaming devices that do not produce distracting background noise. This is particularly important for immersive experiences in home theaters and gaming setups, where even low-level electronic noise can detract from the overall experience.

In the mobile device market, while noise is generally less of an issue due to the lower power requirements, there is still a preference for devices that operate silently. This is especially relevant for tablets and smartphones used in quiet settings such as libraries, classrooms, or during nighttime usage. The elimination of coil whine in these devices can enhance user satisfaction and potentially provide a competitive edge in a crowded market.

The industrial and medical sectors also present significant opportunities for quiet electronics. In industrial settings, reducing electronic noise can contribute to a safer and more comfortable work environment, potentially increasing productivity. In medical environments, quiet electronic equipment is essential for patient comfort and to prevent interference with sensitive diagnostic procedures.

Market research indicates that consumers are willing to pay a premium for quieter electronic products, suggesting a strong value proposition for manufacturers who can effectively address this demand. This willingness to pay more for silent operation is particularly evident in high-end consumer electronics and professional-grade equipment.

As awareness of noise pollution and its effects on health and well-being continues to grow, regulations and standards regarding electronic noise emissions are likely to become more stringent. This regulatory trend is expected to further drive the demand for technologies that reduce electronic noise, including solutions for coil whine reduction.

In the personal computing market, there is a growing demand for silent or near-silent desktops and laptops. This is especially true for professionals working in quiet environments, such as home offices or open-plan workspaces. The reduction of coil whine through the use of multi-layer ceramic capacitors (MLCCs) can significantly contribute to meeting this demand, as coil whine is often a source of irritation for users of high-performance computing equipment.

The home entertainment sector is another area where the demand for quiet electronics is prominent. Consumers are increasingly seeking audio-visual equipment, gaming consoles, and streaming devices that do not produce distracting background noise. This is particularly important for immersive experiences in home theaters and gaming setups, where even low-level electronic noise can detract from the overall experience.

In the mobile device market, while noise is generally less of an issue due to the lower power requirements, there is still a preference for devices that operate silently. This is especially relevant for tablets and smartphones used in quiet settings such as libraries, classrooms, or during nighttime usage. The elimination of coil whine in these devices can enhance user satisfaction and potentially provide a competitive edge in a crowded market.

The industrial and medical sectors also present significant opportunities for quiet electronics. In industrial settings, reducing electronic noise can contribute to a safer and more comfortable work environment, potentially increasing productivity. In medical environments, quiet electronic equipment is essential for patient comfort and to prevent interference with sensitive diagnostic procedures.

Market research indicates that consumers are willing to pay a premium for quieter electronic products, suggesting a strong value proposition for manufacturers who can effectively address this demand. This willingness to pay more for silent operation is particularly evident in high-end consumer electronics and professional-grade equipment.

As awareness of noise pollution and its effects on health and well-being continues to grow, regulations and standards regarding electronic noise emissions are likely to become more stringent. This regulatory trend is expected to further drive the demand for technologies that reduce electronic noise, including solutions for coil whine reduction.

Current Challenges in Coil Whine Mitigation

Coil whine remains a persistent challenge in electronic devices, particularly in power supplies and voltage regulators. Despite advancements in electronic design, this high-frequency noise continues to plague manufacturers and consumers alike. The primary difficulty lies in the complex interplay of electromagnetic forces within electronic components, making it challenging to eliminate the source of the noise entirely.

One of the main obstacles in mitigating coil whine is the trade-off between performance and noise reduction. As electronic devices become more powerful and compact, the increased current flow and higher switching frequencies exacerbate the problem. Engineers must balance the need for efficient power delivery with the desire for silent operation, often leading to compromises in design.

The variability of coil whine across different units of the same product presents another significant challenge. Due to manufacturing tolerances and slight variations in component properties, some devices may exhibit more pronounced coil whine than others, making it difficult to implement a one-size-fits-all solution. This inconsistency complicates quality control processes and can lead to customer dissatisfaction.

Furthermore, the subjective nature of coil whine perception adds another layer of complexity to the problem. What may be an acceptable level of noise for one user could be intolerable for another, making it challenging to establish universal standards for coil whine reduction. This subjectivity also complicates the testing and validation processes for noise reduction solutions.

The cost implications of implementing effective coil whine reduction techniques pose a significant hurdle for manufacturers. Advanced materials, specialized components, and additional design considerations can substantially increase production costs, potentially affecting the product's market competitiveness. Striking a balance between cost-effective manufacturing and satisfactory noise reduction remains a constant challenge.

Environmental factors and operating conditions also contribute to the complexity of coil whine mitigation. Temperature fluctuations, humidity, and varying load conditions can all influence the occurrence and intensity of coil whine, making it difficult to develop solutions that perform consistently across diverse usage scenarios. Engineers must account for these variables when designing noise reduction strategies, further complicating the development process.

Lastly, the integration of multi-layer ceramic capacitors (MLCCs) as a potential solution for coil whine reduction introduces its own set of challenges. While MLCCs offer promising noise suppression capabilities, their implementation requires careful consideration of factors such as capacitance values, placement within the circuit, and potential interactions with other components. Optimizing MLCC usage for effective coil whine reduction while maintaining overall circuit performance remains an ongoing area of research and development in the field of electronic design.

One of the main obstacles in mitigating coil whine is the trade-off between performance and noise reduction. As electronic devices become more powerful and compact, the increased current flow and higher switching frequencies exacerbate the problem. Engineers must balance the need for efficient power delivery with the desire for silent operation, often leading to compromises in design.

The variability of coil whine across different units of the same product presents another significant challenge. Due to manufacturing tolerances and slight variations in component properties, some devices may exhibit more pronounced coil whine than others, making it difficult to implement a one-size-fits-all solution. This inconsistency complicates quality control processes and can lead to customer dissatisfaction.

Furthermore, the subjective nature of coil whine perception adds another layer of complexity to the problem. What may be an acceptable level of noise for one user could be intolerable for another, making it challenging to establish universal standards for coil whine reduction. This subjectivity also complicates the testing and validation processes for noise reduction solutions.

The cost implications of implementing effective coil whine reduction techniques pose a significant hurdle for manufacturers. Advanced materials, specialized components, and additional design considerations can substantially increase production costs, potentially affecting the product's market competitiveness. Striking a balance between cost-effective manufacturing and satisfactory noise reduction remains a constant challenge.

Environmental factors and operating conditions also contribute to the complexity of coil whine mitigation. Temperature fluctuations, humidity, and varying load conditions can all influence the occurrence and intensity of coil whine, making it difficult to develop solutions that perform consistently across diverse usage scenarios. Engineers must account for these variables when designing noise reduction strategies, further complicating the development process.

Lastly, the integration of multi-layer ceramic capacitors (MLCCs) as a potential solution for coil whine reduction introduces its own set of challenges. While MLCCs offer promising noise suppression capabilities, their implementation requires careful consideration of factors such as capacitance values, placement within the circuit, and potential interactions with other components. Optimizing MLCC usage for effective coil whine reduction while maintaining overall circuit performance remains an ongoing area of research and development in the field of electronic design.

Existing MLCC Solutions for Coil Whine

01 Structural design to reduce coil whine

Implementing specific structural designs in multi-layer ceramic capacitors can help reduce coil whine. This may include using specialized materials, optimizing the internal structure, or incorporating noise-dampening elements within the capacitor design. These structural modifications aim to minimize vibrations and acoustic noise associated with coil whine.- Structural design to reduce coil whine: Implementing specific structural designs in multi-layer ceramic capacitors can help reduce coil whine. This may include optimizing the internal electrode configuration, adjusting the dielectric layer thickness, or incorporating damping materials within the capacitor structure. These design modifications aim to minimize mechanical vibrations that contribute to coil whine.

- Material selection for improved performance: Careful selection of materials used in multi-layer ceramic capacitors can significantly impact their performance and reduce coil whine. This includes choosing appropriate dielectric materials, electrode materials, and terminal materials that exhibit better stability and lower acoustic emissions under varying electrical conditions.

- Mounting and packaging techniques: Employing specific mounting and packaging techniques can help mitigate coil whine in multi-layer ceramic capacitors. This may involve using specialized adhesives, implementing vibration-absorbing mounting methods, or designing circuit board layouts that minimize resonance and acoustic coupling between components.

- Electrical circuit design considerations: Optimizing the electrical circuit design can help reduce coil whine in systems using multi-layer ceramic capacitors. This may include implementing filtering techniques, adjusting power supply designs, or using specialized driving circuits to minimize voltage fluctuations and current spikes that contribute to mechanical vibrations in the capacitors.

- Testing and quality control methods: Developing and implementing advanced testing and quality control methods can help identify and mitigate coil whine issues in multi-layer ceramic capacitors. This may include acoustic emission testing, vibration analysis, and accelerated life testing to ensure capacitors meet performance standards and exhibit minimal coil whine under various operating conditions.

02 Coating and encapsulation techniques

Applying specialized coatings or encapsulation methods to multi-layer ceramic capacitors can help mitigate coil whine. These techniques involve using materials that absorb or dampen vibrations, reducing the transmission of acoustic noise. The coatings or encapsulants can be applied to the capacitor surface or integrated into the manufacturing process.Expand Specific Solutions03 Circuit design and placement strategies

Optimizing the circuit design and capacitor placement within electronic devices can help minimize coil whine. This may involve strategic positioning of capacitors, implementing noise-cancelling circuits, or using specific circuit topologies that reduce the likelihood of coil whine occurrence. Proper circuit design can help distribute electrical stress and minimize resonance effects.Expand Specific Solutions04 Material selection and composition

Careful selection of materials used in multi-layer ceramic capacitors can significantly impact coil whine reduction. This includes choosing dielectric materials with specific properties, optimizing electrode compositions, and incorporating noise-absorbing materials within the capacitor structure. The right material combination can help dampen vibrations and minimize acoustic noise generation.Expand Specific Solutions05 Manufacturing process improvements

Enhancing the manufacturing process of multi-layer ceramic capacitors can contribute to reducing coil whine. This may involve implementing precise control measures during production, optimizing sintering processes, or introducing new fabrication techniques that minimize internal stresses and defects. Improved manufacturing processes can lead to more consistent and reliable capacitors with reduced susceptibility to coil whine.Expand Specific Solutions

Key Players in MLCC and Noise Reduction

The research on coil whine reduction through multi-layer ceramic capacitors is in a mature stage of development, with significant market potential due to the increasing demand for quieter electronic devices. The global market for multi-layer ceramic capacitors is substantial, driven by the growing electronics industry. Technologically, companies like Samsung Electro-Mechanics, Murata Manufacturing, and TDK Corp. are at the forefront, leveraging their expertise in ceramic capacitor manufacturing to address coil whine issues. These industry leaders, along with other key players such as Taiyo Yuden and KEMET Electronics, are continuously innovating to improve capacitor performance and reduce electromagnetic noise, indicating a highly competitive and technologically advanced landscape in this field.

Samsung Electro-Mechanics Co., Ltd.

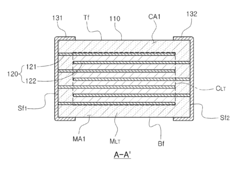

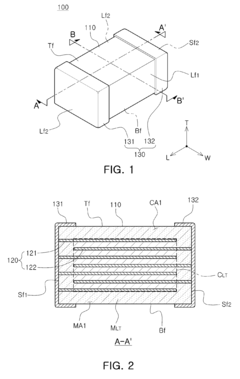

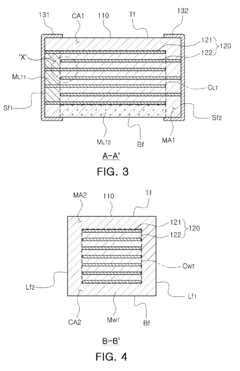

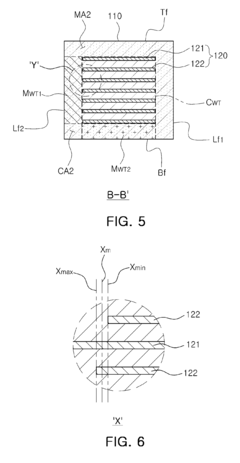

Technical Solution: Samsung Electro-Mechanics has developed advanced multi-layer ceramic capacitors (MLCCs) with enhanced noise reduction capabilities. Their MLCCs utilize a proprietary dielectric material composition and optimized internal electrode structure to minimize coil whine. The company has implemented a high-precision layering technique that allows for thinner dielectric layers and more internal electrodes, increasing capacitance while maintaining a compact size. This design effectively suppresses high-frequency noise and reduces electromagnetic interference (EMI) [1]. Samsung's MLCCs also incorporate a unique termination design that improves reliability and reduces acoustic noise generation under varying voltage conditions [3].

Strengths: Advanced material technology, high capacitance in compact sizes, and improved EMI suppression. Weaknesses: Potentially higher production costs and limited customization options for specific applications.

Murata Manufacturing Co. Ltd.

Technical Solution: Murata has developed a series of low-ESR (Equivalent Series Resistance) MLCCs specifically designed for coil whine reduction. Their approach focuses on minimizing the mechanical vibration of capacitors caused by voltage fluctuations. Murata's MLCCs feature a specialized internal electrode design that reduces the piezoelectric effect, a primary cause of coil whine. The company has also implemented advanced materials with improved dielectric properties, allowing for higher capacitance values in smaller form factors. Murata's MLCCs incorporate a unique stress-relieving structure that mitigates board flex cracking, enhancing overall reliability [2]. Additionally, they have developed a proprietary acoustic dampening coating that further reduces audible noise emissions [4].

Strengths: Excellent noise reduction performance, high reliability, and wide range of capacitance values. Weaknesses: May be more expensive than standard MLCCs and could have limitations in extreme temperature environments.

Core Innovations in MLCC Technology

Multilayer ceramic capacitor

PatentActiveUS20120327556A1

Innovation

- A multilayer ceramic capacitor design with a thickness of 3 μm or less dielectric layers, an average particle diameter of 0.3 μm or less, and specific area ratios of margin parts to capacitance forming parts, which reduces acoustic noise and suppresses delamination, ensuring high capacitance and reliability.

Multilayer ceramic capacitor

PatentWO2007020757A1

Innovation

- The shape of internal electrodes is modified to create low-activity regions with reduced facing area, minimizing electric field-induced strain and noise without altering the dielectric composition or adding new structures.

EMC Regulations and Compliance

Electromagnetic Compatibility (EMC) regulations and compliance play a crucial role in the development and implementation of coil whine reduction techniques using multi-layer ceramic capacitors (MLCCs). These regulations are designed to ensure that electronic devices do not interfere with other equipment or systems and can operate reliably in their intended electromagnetic environment.

In the context of coil whine reduction, EMC regulations primarily focus on limiting electromagnetic emissions and ensuring immunity to external electromagnetic disturbances. The International Electrotechnical Commission (IEC) and the Federal Communications Commission (FCC) are two key organizations that set EMC standards globally.

For consumer electronics, FCC Part 15 in the United States and the EMC Directive (2014/30/EU) in the European Union are particularly relevant. These regulations specify limits for both conducted and radiated emissions across various frequency ranges. Coil whine, being an audible manifestation of electromagnetic noise, falls under the purview of these regulations.

Compliance with EMC regulations requires thorough testing and documentation. For coil whine reduction using MLCCs, manufacturers must ensure that the implemented solutions do not inadvertently increase electromagnetic emissions in other frequency bands. This necessitates a holistic approach to EMC design, considering not only the audible frequency range but also higher frequencies where MLCCs may impact circuit behavior.

Testing for EMC compliance typically involves measurements in specialized chambers, such as anechoic or semi-anechoic rooms. These tests evaluate both emissions and susceptibility across a wide range of frequencies. For coil whine specifically, audio measurements in quiet environments may also be necessary to ensure that the reduction techniques are effective without compromising overall EMC performance.

Manufacturers must also consider the impact of MLCCs on circuit impedance and resonance, as these factors can significantly affect EMC characteristics. Proper selection and placement of MLCCs are critical to achieving both coil whine reduction and EMC compliance. This often involves careful PCB layout design and component selection to minimize parasitic effects and optimize overall system performance.

As technology advances and electronic devices become more complex, EMC regulations continue to evolve. For instance, the increasing prevalence of high-speed digital circuits and wireless communications has led to more stringent requirements in higher frequency ranges. Researchers and engineers working on coil whine reduction must stay abreast of these regulatory changes to ensure that their solutions remain compliant with the latest standards.

In the context of coil whine reduction, EMC regulations primarily focus on limiting electromagnetic emissions and ensuring immunity to external electromagnetic disturbances. The International Electrotechnical Commission (IEC) and the Federal Communications Commission (FCC) are two key organizations that set EMC standards globally.

For consumer electronics, FCC Part 15 in the United States and the EMC Directive (2014/30/EU) in the European Union are particularly relevant. These regulations specify limits for both conducted and radiated emissions across various frequency ranges. Coil whine, being an audible manifestation of electromagnetic noise, falls under the purview of these regulations.

Compliance with EMC regulations requires thorough testing and documentation. For coil whine reduction using MLCCs, manufacturers must ensure that the implemented solutions do not inadvertently increase electromagnetic emissions in other frequency bands. This necessitates a holistic approach to EMC design, considering not only the audible frequency range but also higher frequencies where MLCCs may impact circuit behavior.

Testing for EMC compliance typically involves measurements in specialized chambers, such as anechoic or semi-anechoic rooms. These tests evaluate both emissions and susceptibility across a wide range of frequencies. For coil whine specifically, audio measurements in quiet environments may also be necessary to ensure that the reduction techniques are effective without compromising overall EMC performance.

Manufacturers must also consider the impact of MLCCs on circuit impedance and resonance, as these factors can significantly affect EMC characteristics. Proper selection and placement of MLCCs are critical to achieving both coil whine reduction and EMC compliance. This often involves careful PCB layout design and component selection to minimize parasitic effects and optimize overall system performance.

As technology advances and electronic devices become more complex, EMC regulations continue to evolve. For instance, the increasing prevalence of high-speed digital circuits and wireless communications has led to more stringent requirements in higher frequency ranges. Researchers and engineers working on coil whine reduction must stay abreast of these regulatory changes to ensure that their solutions remain compliant with the latest standards.

Thermal Management Considerations

Thermal management is a critical consideration in the design and implementation of multi-layer ceramic capacitors (MLCCs) for coil whine reduction. The thermal behavior of MLCCs can significantly impact their performance and reliability, especially in high-frequency and high-power applications where coil whine is more prevalent.

MLCCs generate heat during operation due to dielectric losses and resistive losses in the electrodes. This heat generation can lead to temperature increases within the capacitor, potentially affecting its electrical characteristics and long-term reliability. In the context of coil whine reduction, proper thermal management is essential to maintain the capacitor's effectiveness in filtering high-frequency noise and preventing acoustic emissions.

One key aspect of thermal management for MLCCs is the selection of appropriate materials with suitable thermal properties. Ceramic dielectrics with low loss tangents and high thermal conductivity are preferred to minimize heat generation and facilitate heat dissipation. Additionally, the choice of electrode materials and their thickness can influence the capacitor's thermal performance.

The physical design and layout of MLCCs also play a crucial role in thermal management. Proper spacing between capacitors and other components on the PCB allows for better heat dissipation. In some cases, the use of thermal vias or heat sinks may be necessary to improve heat transfer away from the capacitors.

Temperature cycling and thermal shock can affect the mechanical integrity of MLCCs, potentially leading to cracks or delamination. These issues can compromise the capacitor's ability to suppress coil whine effectively. Therefore, designers must consider the operating temperature range and potential thermal stresses when selecting and implementing MLCCs for noise reduction applications.

In high-power applications, where coil whine is more likely to occur, the thermal management of MLCCs becomes even more critical. Techniques such as parallel connection of multiple capacitors or the use of larger case sizes may be employed to distribute the thermal load and improve overall system reliability.

Monitoring and controlling the ambient temperature around MLCCs is also essential for maintaining their performance in coil whine reduction. Proper ventilation and cooling strategies for the entire system can help prevent excessive temperature rises that could degrade the capacitors' noise suppression capabilities.

Furthermore, thermal simulation and modeling tools can be valuable in predicting the thermal behavior of MLCCs in specific circuit designs. These tools can help engineers optimize component placement and identify potential hotspots before physical prototyping, leading to more effective thermal management strategies.

MLCCs generate heat during operation due to dielectric losses and resistive losses in the electrodes. This heat generation can lead to temperature increases within the capacitor, potentially affecting its electrical characteristics and long-term reliability. In the context of coil whine reduction, proper thermal management is essential to maintain the capacitor's effectiveness in filtering high-frequency noise and preventing acoustic emissions.

One key aspect of thermal management for MLCCs is the selection of appropriate materials with suitable thermal properties. Ceramic dielectrics with low loss tangents and high thermal conductivity are preferred to minimize heat generation and facilitate heat dissipation. Additionally, the choice of electrode materials and their thickness can influence the capacitor's thermal performance.

The physical design and layout of MLCCs also play a crucial role in thermal management. Proper spacing between capacitors and other components on the PCB allows for better heat dissipation. In some cases, the use of thermal vias or heat sinks may be necessary to improve heat transfer away from the capacitors.

Temperature cycling and thermal shock can affect the mechanical integrity of MLCCs, potentially leading to cracks or delamination. These issues can compromise the capacitor's ability to suppress coil whine effectively. Therefore, designers must consider the operating temperature range and potential thermal stresses when selecting and implementing MLCCs for noise reduction applications.

In high-power applications, where coil whine is more likely to occur, the thermal management of MLCCs becomes even more critical. Techniques such as parallel connection of multiple capacitors or the use of larger case sizes may be employed to distribute the thermal load and improve overall system reliability.

Monitoring and controlling the ambient temperature around MLCCs is also essential for maintaining their performance in coil whine reduction. Proper ventilation and cooling strategies for the entire system can help prevent excessive temperature rises that could degrade the capacitors' noise suppression capabilities.

Furthermore, thermal simulation and modeling tools can be valuable in predicting the thermal behavior of MLCCs in specific circuit designs. These tools can help engineers optimize component placement and identify potential hotspots before physical prototyping, leading to more effective thermal management strategies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!