Crankcase Ventilation Technology for Enhanced LS Engine Health

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS Engine Crankcase Ventilation Evolution

The evolution of crankcase ventilation technology in LS engines represents a significant advancement in engine health and performance. Initially, early LS engines utilized a simple positive crankcase ventilation (PCV) system, which was primarily designed to reduce emissions and prevent oil leaks. This basic system consisted of a PCV valve and associated hoses to route crankcase gases back into the intake manifold.

As engine designs progressed, the importance of effective crankcase ventilation became increasingly apparent. The introduction of the LS2 engine in 2005 marked a notable improvement in the ventilation system. This iteration featured a more sophisticated PCV system with enhanced oil separation capabilities, reducing the amount of oil vapor entering the intake system and improving overall engine efficiency.

The LS3 engine, introduced in 2008, further refined the crankcase ventilation system. It incorporated a revised PCV valve design and optimized routing of ventilation hoses. These improvements resulted in better management of crankcase pressure and more effective removal of harmful gases and contaminants from the engine's internal environment.

A significant leap forward came with the development of the LS7 engine, which featured a dry-sump oiling system. This design inherently improved crankcase ventilation by reducing the amount of oil in the crankcase and allowing for more efficient gas evacuation. The LS7's ventilation system was integrated with its unique oiling architecture, setting a new standard for high-performance engine breathing.

The introduction of the Gen V LT1 engine in 2014 brought about a revolutionary change in crankcase ventilation technology for LS-based engines. This new system incorporated an innovative active fuel management (AFM) system, which required a more sophisticated approach to crankcase ventilation. The LT1 featured a dual-path PCV system that could adapt to different engine operating conditions, providing optimal ventilation during both full and partial cylinder operation modes.

Recent developments in LS engine crankcase ventilation have focused on integrating advanced materials and design techniques. Modern systems often utilize composite materials for PCV valves and hoses, offering improved durability and resistance to heat and chemical degradation. Additionally, computational fluid dynamics (CFD) modeling has been employed to optimize the flow paths of crankcase gases, ensuring more efficient evacuation and reduced oil consumption.

The latest iterations of LS engines have also seen the integration of electronic control systems into crankcase ventilation management. These systems can dynamically adjust ventilation parameters based on real-time engine data, further enhancing engine health and performance across a wide range of operating conditions.

As engine designs progressed, the importance of effective crankcase ventilation became increasingly apparent. The introduction of the LS2 engine in 2005 marked a notable improvement in the ventilation system. This iteration featured a more sophisticated PCV system with enhanced oil separation capabilities, reducing the amount of oil vapor entering the intake system and improving overall engine efficiency.

The LS3 engine, introduced in 2008, further refined the crankcase ventilation system. It incorporated a revised PCV valve design and optimized routing of ventilation hoses. These improvements resulted in better management of crankcase pressure and more effective removal of harmful gases and contaminants from the engine's internal environment.

A significant leap forward came with the development of the LS7 engine, which featured a dry-sump oiling system. This design inherently improved crankcase ventilation by reducing the amount of oil in the crankcase and allowing for more efficient gas evacuation. The LS7's ventilation system was integrated with its unique oiling architecture, setting a new standard for high-performance engine breathing.

The introduction of the Gen V LT1 engine in 2014 brought about a revolutionary change in crankcase ventilation technology for LS-based engines. This new system incorporated an innovative active fuel management (AFM) system, which required a more sophisticated approach to crankcase ventilation. The LT1 featured a dual-path PCV system that could adapt to different engine operating conditions, providing optimal ventilation during both full and partial cylinder operation modes.

Recent developments in LS engine crankcase ventilation have focused on integrating advanced materials and design techniques. Modern systems often utilize composite materials for PCV valves and hoses, offering improved durability and resistance to heat and chemical degradation. Additionally, computational fluid dynamics (CFD) modeling has been employed to optimize the flow paths of crankcase gases, ensuring more efficient evacuation and reduced oil consumption.

The latest iterations of LS engines have also seen the integration of electronic control systems into crankcase ventilation management. These systems can dynamically adjust ventilation parameters based on real-time engine data, further enhancing engine health and performance across a wide range of operating conditions.

Market Demand Analysis

The market demand for advanced crankcase ventilation technology in LS engines has been steadily increasing due to stricter emissions regulations and a growing focus on engine efficiency and longevity. As automotive manufacturers strive to meet these stringent standards while maintaining performance, the need for innovative solutions in engine health management has become paramount.

The global automotive industry has witnessed a significant shift towards cleaner and more efficient engines, with the LS engine platform remaining a popular choice among performance enthusiasts and manufacturers alike. This has created a substantial market for crankcase ventilation systems that can effectively manage oil contamination and reduce harmful emissions.

In recent years, the aftermarket sector has experienced robust growth in demand for high-performance crankcase ventilation systems. Performance-oriented consumers are increasingly seeking solutions that not only comply with emissions standards but also enhance engine output and reliability. This trend has led to a proliferation of specialized products targeting the LS engine market.

The commercial vehicle sector has also contributed to the expanding market for crankcase ventilation technology. Fleet operators are recognizing the long-term benefits of improved engine health, including reduced maintenance costs and extended engine life. This has driven demand for more effective ventilation systems in heavy-duty applications using LS-based engines.

Environmental concerns and regulatory pressures have further amplified the market demand. Governments worldwide are implementing stricter emissions standards, compelling manufacturers to invest in advanced crankcase ventilation technologies. This regulatory landscape has created opportunities for innovative solutions that can effectively capture and recirculate oil vapors, reducing both environmental impact and fuel consumption.

The automotive industry's shift towards electrification has paradoxically increased the value of efficient internal combustion engines in certain market segments. As manufacturers allocate resources to electric vehicle development, there is a growing need to maximize the performance and efficiency of existing engine platforms like the LS. This has led to increased investment in technologies that can extend the viability and competitiveness of these engines.

Market analysis indicates that the demand for advanced crankcase ventilation systems is not limited to new vehicle production. A significant portion of the market consists of retrofit solutions for existing LS engines, driven by owners seeking to upgrade their vehicles' performance and emissions compliance. This aftermarket segment presents substantial growth opportunities for manufacturers and suppliers of crankcase ventilation technology.

The global automotive industry has witnessed a significant shift towards cleaner and more efficient engines, with the LS engine platform remaining a popular choice among performance enthusiasts and manufacturers alike. This has created a substantial market for crankcase ventilation systems that can effectively manage oil contamination and reduce harmful emissions.

In recent years, the aftermarket sector has experienced robust growth in demand for high-performance crankcase ventilation systems. Performance-oriented consumers are increasingly seeking solutions that not only comply with emissions standards but also enhance engine output and reliability. This trend has led to a proliferation of specialized products targeting the LS engine market.

The commercial vehicle sector has also contributed to the expanding market for crankcase ventilation technology. Fleet operators are recognizing the long-term benefits of improved engine health, including reduced maintenance costs and extended engine life. This has driven demand for more effective ventilation systems in heavy-duty applications using LS-based engines.

Environmental concerns and regulatory pressures have further amplified the market demand. Governments worldwide are implementing stricter emissions standards, compelling manufacturers to invest in advanced crankcase ventilation technologies. This regulatory landscape has created opportunities for innovative solutions that can effectively capture and recirculate oil vapors, reducing both environmental impact and fuel consumption.

The automotive industry's shift towards electrification has paradoxically increased the value of efficient internal combustion engines in certain market segments. As manufacturers allocate resources to electric vehicle development, there is a growing need to maximize the performance and efficiency of existing engine platforms like the LS. This has led to increased investment in technologies that can extend the viability and competitiveness of these engines.

Market analysis indicates that the demand for advanced crankcase ventilation systems is not limited to new vehicle production. A significant portion of the market consists of retrofit solutions for existing LS engines, driven by owners seeking to upgrade their vehicles' performance and emissions compliance. This aftermarket segment presents substantial growth opportunities for manufacturers and suppliers of crankcase ventilation technology.

Current Challenges

The current challenges in crankcase ventilation technology for LS engines primarily revolve around the need for more efficient and effective management of blow-by gases. As engine performance continues to improve, the volume and composition of these gases have become increasingly complex, putting greater strain on traditional ventilation systems.

One of the main challenges is the accumulation of oil mist and particulates in the blow-by gases. These contaminants can lead to carbon deposits in the intake system, reducing engine efficiency and potentially causing long-term damage. Current filtration methods struggle to effectively capture these fine particles without restricting airflow, creating a delicate balance between filtration efficiency and system performance.

Another significant challenge is the management of pressure fluctuations within the crankcase. Modern high-performance LS engines generate substantial pressure variations during operation, which can overwhelm conventional PCV (Positive Crankcase Ventilation) systems. This can result in oil leaks, increased emissions, and reduced engine longevity. Developing a system that can handle these pressure variations while maintaining optimal crankcase pressure is a key area of focus for researchers and engineers.

The integration of crankcase ventilation systems with increasingly stringent emissions regulations presents another hurdle. As environmental standards become more rigorous, there is a growing need for ventilation systems that not only manage blow-by gases effectively but also contribute to overall emissions reduction. This requires innovative approaches to gas treatment and recirculation that go beyond traditional PCV designs.

Temperature management within the crankcase ventilation system is also a pressing challenge. The heat generated by high-performance LS engines can cause oil vapors to condense within the ventilation lines, leading to blockages and reduced system efficiency. Developing materials and designs that can withstand high temperatures while preventing oil condensation is crucial for enhancing system reliability and longevity.

Furthermore, the compact nature of modern engine bays poses spatial constraints for crankcase ventilation systems. Engineers must develop solutions that are not only effective but also compact and easily integrated into existing engine architectures. This challenge is particularly acute in performance applications where space is at a premium due to the presence of additional components such as turbochargers or superchargers.

Lastly, there is an ongoing challenge in quantifying and monitoring the performance of crankcase ventilation systems in real-time. Current diagnostic tools often lack the sensitivity to detect subtle changes in system efficiency, making it difficult to optimize performance and predict maintenance needs accurately. Developing advanced sensing and monitoring technologies that can provide detailed insights into system operation is essential for future improvements in crankcase ventilation technology.

One of the main challenges is the accumulation of oil mist and particulates in the blow-by gases. These contaminants can lead to carbon deposits in the intake system, reducing engine efficiency and potentially causing long-term damage. Current filtration methods struggle to effectively capture these fine particles without restricting airflow, creating a delicate balance between filtration efficiency and system performance.

Another significant challenge is the management of pressure fluctuations within the crankcase. Modern high-performance LS engines generate substantial pressure variations during operation, which can overwhelm conventional PCV (Positive Crankcase Ventilation) systems. This can result in oil leaks, increased emissions, and reduced engine longevity. Developing a system that can handle these pressure variations while maintaining optimal crankcase pressure is a key area of focus for researchers and engineers.

The integration of crankcase ventilation systems with increasingly stringent emissions regulations presents another hurdle. As environmental standards become more rigorous, there is a growing need for ventilation systems that not only manage blow-by gases effectively but also contribute to overall emissions reduction. This requires innovative approaches to gas treatment and recirculation that go beyond traditional PCV designs.

Temperature management within the crankcase ventilation system is also a pressing challenge. The heat generated by high-performance LS engines can cause oil vapors to condense within the ventilation lines, leading to blockages and reduced system efficiency. Developing materials and designs that can withstand high temperatures while preventing oil condensation is crucial for enhancing system reliability and longevity.

Furthermore, the compact nature of modern engine bays poses spatial constraints for crankcase ventilation systems. Engineers must develop solutions that are not only effective but also compact and easily integrated into existing engine architectures. This challenge is particularly acute in performance applications where space is at a premium due to the presence of additional components such as turbochargers or superchargers.

Lastly, there is an ongoing challenge in quantifying and monitoring the performance of crankcase ventilation systems in real-time. Current diagnostic tools often lack the sensitivity to detect subtle changes in system efficiency, making it difficult to optimize performance and predict maintenance needs accurately. Developing advanced sensing and monitoring technologies that can provide detailed insights into system operation is essential for future improvements in crankcase ventilation technology.

Existing Solutions

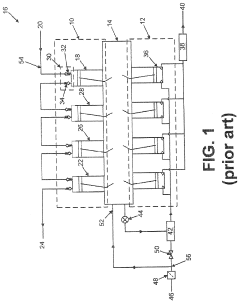

01 Improved crankcase ventilation systems

Advanced crankcase ventilation systems are designed to enhance engine health by effectively managing blow-by gases. These systems incorporate innovative components and designs to separate oil particles from the gases, reduce pressure buildup, and minimize oil consumption. Improved ventilation helps maintain cleaner engine internals and prolongs engine life.- Improved crankcase ventilation systems: Advanced crankcase ventilation systems are designed to enhance engine health by effectively managing blow-by gases. These systems incorporate innovative components and designs to separate oil particles from the gases, reduce pressure buildup, and minimize oil consumption. Such improvements contribute to better engine performance, reduced emissions, and increased longevity.

- Oil separation techniques in ventilation systems: Various oil separation techniques are employed in crankcase ventilation systems to prevent oil from entering the intake system. These methods include centrifugal separation, baffles, and advanced filtration media. Effective oil separation helps maintain engine cleanliness, reduces oil consumption, and prevents fouling of downstream components, thereby promoting overall engine health.

- Integration of sensors and diagnostic systems: Modern crankcase ventilation systems incorporate sensors and diagnostic capabilities to monitor system performance and detect potential issues. These technologies enable real-time monitoring of pressure, flow rates, and oil contamination levels. By providing early warning of system malfunctions or degradation, they allow for timely maintenance interventions, thus preserving engine health.

- Pressure regulation and flow control mechanisms: Advanced pressure regulation and flow control mechanisms are implemented in crankcase ventilation systems to optimize performance across various operating conditions. These include variable orifices, pressure-responsive valves, and electronic control systems. By maintaining appropriate crankcase pressure and managing gas flow, these mechanisms contribute to improved engine efficiency and reduced wear.

- Integration with engine control and emissions systems: Crankcase ventilation systems are increasingly integrated with overall engine control and emissions management systems. This integration allows for coordinated operation with other engine subsystems, such as EGR and turbocharging. By optimizing the interaction between these systems, engine performance is enhanced while emissions are reduced, contributing to better engine health and environmental compliance.

02 Oil separation techniques in ventilation systems

Various oil separation techniques are employed in crankcase ventilation systems to prevent oil from entering the intake system. These may include centrifugal separators, baffles, or advanced filtration media. Effective oil separation ensures cleaner air recirculation, reduces engine deposits, and maintains optimal engine performance.Expand Specific Solutions03 Pressure regulation in crankcase ventilation

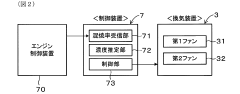

Pressure regulation mechanisms in crankcase ventilation systems help maintain optimal pressure within the crankcase. These systems may include pressure relief valves or variable flow control devices. Proper pressure regulation prevents oil leaks, reduces stress on seals, and contributes to overall engine health and efficiency.Expand Specific Solutions04 Integration with engine control systems

Modern crankcase ventilation systems are increasingly integrated with engine control systems. This integration allows for real-time monitoring and adjustment of ventilation parameters based on engine operating conditions. Advanced sensors and control algorithms optimize ventilation performance, contributing to improved engine health and emissions control.Expand Specific Solutions05 Condensation management in ventilation systems

Effective condensation management in crankcase ventilation systems is crucial for maintaining engine health. Advanced designs incorporate features to prevent water accumulation, which can lead to corrosion and oil contamination. These may include heating elements, drainage systems, or special coatings to manage condensation and protect engine components.Expand Specific Solutions

Key Industry Players

The crankcase ventilation technology for LS engines is in a mature stage of development, with a well-established market and significant competition among key players. The market size is substantial, given the widespread use of LS engines in various automotive applications. Major automotive manufacturers like General Motors, Ford, and BMW are actively involved in refining this technology, indicating its importance in engine health and performance. Companies such as Caterpillar and Cummins are also contributing to advancements in this field, particularly for heavy-duty applications. The technology's maturity is evident from the continuous improvements and patents filed by these companies, focusing on enhancing efficiency, reducing emissions, and improving overall engine longevity.

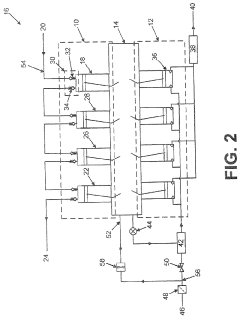

GM Global Technology Operations LLC

Technical Solution: GM has developed an advanced crankcase ventilation system for LS engines that incorporates a multi-stage oil separation process. This system utilizes a combination of centrifugal force and baffles to separate oil particles from the crankcase gases. The separated oil is then returned to the oil pan, while the cleaned gases are recirculated back into the engine's intake system. GM's system also includes a pressure regulation valve to maintain optimal crankcase pressure across various operating conditions[1][3]. The company has further enhanced this technology by integrating smart sensors that monitor the system's performance and adjust parameters in real-time, ensuring optimal engine health and efficiency[5].

Strengths: Highly efficient oil separation, adaptive pressure regulation, and real-time monitoring capabilities. Weaknesses: Potentially higher initial cost and complexity compared to simpler systems.

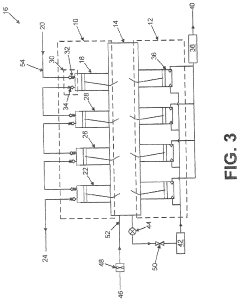

Bayerische Motoren Werke AG

Technical Solution: BMW has developed a sophisticated crankcase ventilation system for their high-performance engines, which is applicable to LS engine configurations. Their system utilizes a multi-stage separation process that combines cyclonic separation with fine mesh filters. The first stage employs a cyclone separator to remove larger oil droplets, while subsequent stages use progressively finer mesh filters to capture smaller particles. BMW's system also incorporates a variable flow control valve that adjusts the ventilation rate based on engine load and speed, optimizing performance and reducing oil consumption[7]. The company has recently introduced a heating element in the ventilation path to prevent ice formation in cold climates, ensuring consistent operation in all weather conditions[8]. Furthermore, BMW has integrated their crankcase ventilation system with their engine management software, allowing for predictive maintenance and performance optimization[9].

Strengths: High-efficiency multi-stage separation, adaptive flow control, and integration with engine management systems. Weaknesses: Potentially higher cost and complexity, may require more frequent maintenance of filter elements.

Core Innovations

Crankcase ventilation systems

PatentActiveUS20200032682A1

Innovation

- Enhancing crankcase ventilation by routing outside air through the crankcase at a rate equal to or greater than the leakage rate, either using a blower to increase airflow or ensuring all outside air passes through the crankcase before entering the intake manifold, thereby preventing the concentration of combustible gas mixtures.

Crankcase ventilation system

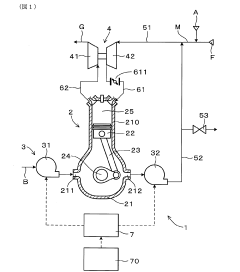

PatentPendingJP2024021720A

Innovation

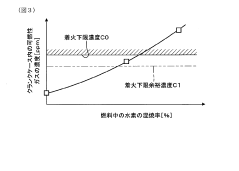

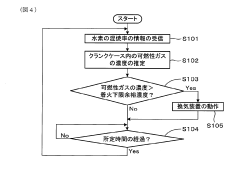

- A crankcase ventilation system that estimates hydrogen concentration based on the co-combustion rate of hydrocarbons and hydrogen in the engine, using a ventilation device controlled by a control unit to ventilate the crankcase without a concentration sensor.

Environmental Impact

The environmental impact of crankcase ventilation technology in LS engines is a critical consideration in the automotive industry's efforts to reduce emissions and improve overall engine efficiency. Crankcase ventilation systems play a crucial role in managing blow-by gases, which are a mixture of combustion byproducts, unburned fuel, and oil vapors that escape past the piston rings during engine operation.

Traditional crankcase ventilation systems often release these gases into the atmosphere, contributing to air pollution and potentially violating stringent environmental regulations. However, modern closed crankcase ventilation (CCV) systems in LS engines recirculate these gases back into the engine's intake system, significantly reducing harmful emissions.

The implementation of advanced crankcase ventilation technology in LS engines has led to a notable reduction in hydrocarbon emissions. These systems effectively capture and redirect oil vapors and other volatile organic compounds (VOCs) that would otherwise be released into the environment. By doing so, they help mitigate the formation of ground-level ozone and smog, which are known to have detrimental effects on air quality and human health.

Furthermore, the recirculation of crankcase gases contributes to improved fuel efficiency. By reintroducing these gases into the combustion process, the engine can utilize any unburned fuel components, thereby maximizing energy extraction and reducing overall fuel consumption. This not only benefits the environment by lowering carbon dioxide emissions but also aligns with global efforts to conserve fossil fuel resources.

The environmental benefits of enhanced crankcase ventilation technology extend beyond air quality improvements. By preventing oil vapors from escaping into the atmosphere, these systems help reduce the deposition of oil particles on road surfaces. This, in turn, minimizes the potential for oil runoff into water systems during rainfall, protecting aquatic ecosystems from contamination.

Advanced crankcase ventilation systems also contribute to the longevity of engine components. By effectively managing blow-by gases and reducing oil contamination, these systems help maintain optimal engine performance over time. This increased durability translates to fewer engine replacements and rebuilds, ultimately reducing the environmental impact associated with manufacturing and disposing of engine components.

In the context of global environmental regulations, the development and implementation of improved crankcase ventilation technology in LS engines demonstrate the automotive industry's commitment to meeting and exceeding emission standards. These advancements play a crucial role in helping vehicle manufacturers comply with increasingly stringent environmental policies, such as the Corporate Average Fuel Economy (CAFE) standards in the United States and similar regulations worldwide.

Traditional crankcase ventilation systems often release these gases into the atmosphere, contributing to air pollution and potentially violating stringent environmental regulations. However, modern closed crankcase ventilation (CCV) systems in LS engines recirculate these gases back into the engine's intake system, significantly reducing harmful emissions.

The implementation of advanced crankcase ventilation technology in LS engines has led to a notable reduction in hydrocarbon emissions. These systems effectively capture and redirect oil vapors and other volatile organic compounds (VOCs) that would otherwise be released into the environment. By doing so, they help mitigate the formation of ground-level ozone and smog, which are known to have detrimental effects on air quality and human health.

Furthermore, the recirculation of crankcase gases contributes to improved fuel efficiency. By reintroducing these gases into the combustion process, the engine can utilize any unburned fuel components, thereby maximizing energy extraction and reducing overall fuel consumption. This not only benefits the environment by lowering carbon dioxide emissions but also aligns with global efforts to conserve fossil fuel resources.

The environmental benefits of enhanced crankcase ventilation technology extend beyond air quality improvements. By preventing oil vapors from escaping into the atmosphere, these systems help reduce the deposition of oil particles on road surfaces. This, in turn, minimizes the potential for oil runoff into water systems during rainfall, protecting aquatic ecosystems from contamination.

Advanced crankcase ventilation systems also contribute to the longevity of engine components. By effectively managing blow-by gases and reducing oil contamination, these systems help maintain optimal engine performance over time. This increased durability translates to fewer engine replacements and rebuilds, ultimately reducing the environmental impact associated with manufacturing and disposing of engine components.

In the context of global environmental regulations, the development and implementation of improved crankcase ventilation technology in LS engines demonstrate the automotive industry's commitment to meeting and exceeding emission standards. These advancements play a crucial role in helping vehicle manufacturers comply with increasingly stringent environmental policies, such as the Corporate Average Fuel Economy (CAFE) standards in the United States and similar regulations worldwide.

Performance Metrics

Performance metrics play a crucial role in evaluating the effectiveness of crankcase ventilation systems for LS engines. These metrics provide quantitative and qualitative measures to assess the system's ability to maintain engine health, optimize performance, and reduce emissions.

One of the primary performance metrics for crankcase ventilation systems is blow-by gas flow rate. This metric measures the volume of gases escaping from the combustion chamber into the crankcase. A well-designed ventilation system should effectively manage and reduce blow-by gas, preventing excessive pressure buildup within the crankcase. Typical flow rates for LS engines range from 1 to 3 cubic feet per minute (CFM) at idle, increasing to 5-10 CFM at higher engine speeds.

Oil consumption is another critical metric closely related to crankcase ventilation performance. Effective ventilation systems minimize oil carryover into the intake system, reducing overall oil consumption. LS engines with properly functioning ventilation systems typically exhibit oil consumption rates of 0.5 to 1 quart per 1,000 miles under normal operating conditions.

Crankcase pressure is a key indicator of ventilation system efficiency. Optimal crankcase pressure should be maintained slightly below atmospheric pressure, typically between -0.5 and -2 inches of water column. This slight vacuum helps prevent oil leaks and ensures proper sealing of gaskets and seals.

Particulate matter (PM) removal efficiency is an important metric for evaluating the filtration capabilities of the ventilation system. High-performance systems should achieve PM removal rates of 95% or higher for particles larger than 1 micron, effectively preventing oil mist and contaminants from entering the intake system.

Hydrocarbon (HC) emissions reduction is another crucial performance metric. Effective crankcase ventilation systems can reduce HC emissions by up to 50% compared to engines without such systems. This reduction contributes significantly to overall engine emissions compliance and environmental performance.

Engine power output and fuel efficiency are indirect performance metrics influenced by crankcase ventilation. A well-designed system can help maintain optimal combustion conditions, potentially improving power output by 1-2% and fuel efficiency by 0.5-1% compared to engines with poorly functioning ventilation systems.

Durability and service life of the ventilation system components are also important long-term performance metrics. High-quality systems should maintain their effectiveness for at least 100,000 miles before requiring major maintenance or replacement of key components.

One of the primary performance metrics for crankcase ventilation systems is blow-by gas flow rate. This metric measures the volume of gases escaping from the combustion chamber into the crankcase. A well-designed ventilation system should effectively manage and reduce blow-by gas, preventing excessive pressure buildup within the crankcase. Typical flow rates for LS engines range from 1 to 3 cubic feet per minute (CFM) at idle, increasing to 5-10 CFM at higher engine speeds.

Oil consumption is another critical metric closely related to crankcase ventilation performance. Effective ventilation systems minimize oil carryover into the intake system, reducing overall oil consumption. LS engines with properly functioning ventilation systems typically exhibit oil consumption rates of 0.5 to 1 quart per 1,000 miles under normal operating conditions.

Crankcase pressure is a key indicator of ventilation system efficiency. Optimal crankcase pressure should be maintained slightly below atmospheric pressure, typically between -0.5 and -2 inches of water column. This slight vacuum helps prevent oil leaks and ensures proper sealing of gaskets and seals.

Particulate matter (PM) removal efficiency is an important metric for evaluating the filtration capabilities of the ventilation system. High-performance systems should achieve PM removal rates of 95% or higher for particles larger than 1 micron, effectively preventing oil mist and contaminants from entering the intake system.

Hydrocarbon (HC) emissions reduction is another crucial performance metric. Effective crankcase ventilation systems can reduce HC emissions by up to 50% compared to engines without such systems. This reduction contributes significantly to overall engine emissions compliance and environmental performance.

Engine power output and fuel efficiency are indirect performance metrics influenced by crankcase ventilation. A well-designed system can help maintain optimal combustion conditions, potentially improving power output by 1-2% and fuel efficiency by 0.5-1% compared to engines with poorly functioning ventilation systems.

Durability and service life of the ventilation system components are also important long-term performance metrics. High-quality systems should maintain their effectiveness for at least 100,000 miles before requiring major maintenance or replacement of key components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!