Research on Hybrid Oxide Semiconductor Materials for Advanced Devices

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hybrid Oxide Semiconductor Evolution and Objectives

Hybrid oxide semiconductor materials have emerged as a revolutionary technology in the field of advanced electronic devices over the past two decades. The evolution of these materials can be traced back to the early 2000s when researchers began exploring alternatives to conventional silicon-based semiconductors to overcome performance limitations in display technologies. The initial breakthrough came with the development of amorphous indium gallium zinc oxide (a-IGZO) by Hosono's group in Japan, which demonstrated superior electron mobility compared to amorphous silicon while maintaining excellent uniformity and low processing temperatures.

The technological trajectory has since expanded from simple binary oxides to increasingly complex multicomponent systems, enabling precise tuning of electronic properties through compositional engineering. This evolution has been driven by the growing demand for high-performance, energy-efficient devices in various applications including displays, sensors, and power electronics. The hybrid nature of these materials—combining multiple metal oxides—allows for synergistic effects that cannot be achieved with single-component systems.

A significant milestone in this evolution was the transition from purely amorphous structures to nanocrystalline and heterogeneous architectures, which offered enhanced carrier mobility while maintaining the advantages of large-area uniformity. This development opened new possibilities for applications requiring both high performance and low-cost manufacturing processes.

The current research objectives in hybrid oxide semiconductor materials focus on several key areas. First, enhancing carrier mobility while maintaining stability under various environmental conditions remains a primary goal. Second, developing p-type oxide semiconductors with performance comparable to their n-type counterparts would enable complementary circuit designs, significantly expanding application possibilities. Third, improving the interface properties between oxide semiconductors and dielectric layers is crucial for device reliability and performance.

Another important objective is the integration of these materials with flexible and stretchable substrates for next-generation wearable and foldable electronics. This requires developing low-temperature processing techniques compatible with temperature-sensitive substrates while maintaining excellent electrical properties. Additionally, researchers aim to understand and control defect states in these materials, which significantly influence carrier transport and device stability.

The long-term vision for hybrid oxide semiconductor research includes developing materials systems that can be processed at room temperature with performance comparable to single-crystal semiconductors, enabling truly ubiquitous electronics that can be integrated into everyday objects. This would revolutionize fields ranging from healthcare monitoring to environmental sensing and human-machine interfaces, supporting the broader technological trends toward Internet of Things and ambient intelligence.

The technological trajectory has since expanded from simple binary oxides to increasingly complex multicomponent systems, enabling precise tuning of electronic properties through compositional engineering. This evolution has been driven by the growing demand for high-performance, energy-efficient devices in various applications including displays, sensors, and power electronics. The hybrid nature of these materials—combining multiple metal oxides—allows for synergistic effects that cannot be achieved with single-component systems.

A significant milestone in this evolution was the transition from purely amorphous structures to nanocrystalline and heterogeneous architectures, which offered enhanced carrier mobility while maintaining the advantages of large-area uniformity. This development opened new possibilities for applications requiring both high performance and low-cost manufacturing processes.

The current research objectives in hybrid oxide semiconductor materials focus on several key areas. First, enhancing carrier mobility while maintaining stability under various environmental conditions remains a primary goal. Second, developing p-type oxide semiconductors with performance comparable to their n-type counterparts would enable complementary circuit designs, significantly expanding application possibilities. Third, improving the interface properties between oxide semiconductors and dielectric layers is crucial for device reliability and performance.

Another important objective is the integration of these materials with flexible and stretchable substrates for next-generation wearable and foldable electronics. This requires developing low-temperature processing techniques compatible with temperature-sensitive substrates while maintaining excellent electrical properties. Additionally, researchers aim to understand and control defect states in these materials, which significantly influence carrier transport and device stability.

The long-term vision for hybrid oxide semiconductor research includes developing materials systems that can be processed at room temperature with performance comparable to single-crystal semiconductors, enabling truly ubiquitous electronics that can be integrated into everyday objects. This would revolutionize fields ranging from healthcare monitoring to environmental sensing and human-machine interfaces, supporting the broader technological trends toward Internet of Things and ambient intelligence.

Market Analysis for Advanced Oxide Semiconductor Devices

The global market for advanced oxide semiconductor devices is experiencing robust growth, driven by increasing demand for high-performance electronics across multiple sectors. Current market valuation stands at approximately $5.7 billion as of 2023, with projections indicating a compound annual growth rate (CAGR) of 12.3% through 2028. This growth trajectory is primarily fueled by the expanding applications in display technologies, power electronics, and emerging IoT devices.

Consumer electronics represents the largest market segment, accounting for nearly 42% of the total market share. Within this segment, display technologies—particularly those utilizing indium gallium zinc oxide (IGZO) semiconductors—dominate due to their superior electron mobility and transparency characteristics. Major smartphone and television manufacturers have increasingly adopted these materials to achieve higher resolution displays with lower power consumption.

The automotive sector presents the fastest-growing market opportunity, with demand increasing at 16.8% annually. This surge is attributed to the rapid electrification of vehicles and the integration of advanced driver assistance systems (ADAS), both requiring high-performance, temperature-stable semiconductor components. Hybrid oxide semiconductors offer significant advantages in these applications due to their excellent thermal stability and reliability under harsh operating conditions.

Geographically, East Asia continues to lead the market with approximately 58% share, housing major manufacturing facilities and research centers focused on oxide semiconductor technologies. North America and Europe follow with 22% and 15% respectively, with particular strength in specialized applications and advanced research initiatives.

Supply chain dynamics have evolved significantly in recent years, with increased vertical integration among key players. Raw material constraints, particularly for indium and gallium, have prompted research into alternative compositions and more efficient manufacturing processes. These developments have partially mitigated price volatility but continue to present challenges for market expansion.

End-user preferences are increasingly favoring devices with lower power consumption, higher processing capabilities, and improved durability—all areas where hybrid oxide semiconductors demonstrate competitive advantages over traditional silicon-based alternatives. This shift in consumer demand has accelerated research investment, with major technology companies allocating substantial resources to develop next-generation oxide semiconductor materials.

Market penetration faces challenges from established silicon technologies, which benefit from decades of manufacturing optimization and ecosystem development. However, the unique properties of hybrid oxide semiconductors—particularly their compatibility with flexible substrates and transparent applications—continue to open new market niches previously unaddressable by conventional semiconductor technologies.

Consumer electronics represents the largest market segment, accounting for nearly 42% of the total market share. Within this segment, display technologies—particularly those utilizing indium gallium zinc oxide (IGZO) semiconductors—dominate due to their superior electron mobility and transparency characteristics. Major smartphone and television manufacturers have increasingly adopted these materials to achieve higher resolution displays with lower power consumption.

The automotive sector presents the fastest-growing market opportunity, with demand increasing at 16.8% annually. This surge is attributed to the rapid electrification of vehicles and the integration of advanced driver assistance systems (ADAS), both requiring high-performance, temperature-stable semiconductor components. Hybrid oxide semiconductors offer significant advantages in these applications due to their excellent thermal stability and reliability under harsh operating conditions.

Geographically, East Asia continues to lead the market with approximately 58% share, housing major manufacturing facilities and research centers focused on oxide semiconductor technologies. North America and Europe follow with 22% and 15% respectively, with particular strength in specialized applications and advanced research initiatives.

Supply chain dynamics have evolved significantly in recent years, with increased vertical integration among key players. Raw material constraints, particularly for indium and gallium, have prompted research into alternative compositions and more efficient manufacturing processes. These developments have partially mitigated price volatility but continue to present challenges for market expansion.

End-user preferences are increasingly favoring devices with lower power consumption, higher processing capabilities, and improved durability—all areas where hybrid oxide semiconductors demonstrate competitive advantages over traditional silicon-based alternatives. This shift in consumer demand has accelerated research investment, with major technology companies allocating substantial resources to develop next-generation oxide semiconductor materials.

Market penetration faces challenges from established silicon technologies, which benefit from decades of manufacturing optimization and ecosystem development. However, the unique properties of hybrid oxide semiconductors—particularly their compatibility with flexible substrates and transparent applications—continue to open new market niches previously unaddressable by conventional semiconductor technologies.

Global Research Status and Technical Barriers

Hybrid oxide semiconductor materials have emerged as a critical research focus globally, with significant advancements occurring across different regions. The United States leads in fundamental research through institutions like MIT, Stanford, and national laboratories, focusing on novel material compositions and interface engineering. Their work has resulted in breakthrough developments in high-mobility oxide thin-film transistors and transparent conducting oxides with record performance metrics.

In East Asia, particularly Japan and South Korea, research efforts concentrate on industrial applications, with companies like Samsung, LG, and Sharp pioneering commercial implementations. Japanese researchers have made substantial contributions to amorphous oxide semiconductors, while Korean institutions have advanced flexible oxide electronics and large-area fabrication techniques.

European research centers, including those in Germany, the UK, and Switzerland, emphasize sustainable manufacturing processes and specialized applications in medical devices and environmental sensors. Their distinctive approach integrates oxide semiconductors with other material systems to create multifunctional devices.

Despite these advancements, significant technical barriers persist in the development of hybrid oxide semiconductor materials. The most challenging obstacle remains the stability and reliability of these materials under various operational conditions. Oxide semiconductors often exhibit performance degradation under prolonged bias stress, temperature fluctuations, and humidity exposure, limiting their practical applications in mission-critical systems.

Another major barrier is the precise control of interface properties between different oxide layers and with other semiconductor materials. These interfaces critically determine carrier transport mechanisms and overall device performance, yet achieving atomically clean and well-defined interfaces remains technically demanding.

The scalable manufacturing of hybrid oxide semiconductor devices presents additional challenges. Current deposition techniques struggle to maintain uniform material properties across large substrates, creating yield issues for commercial production. The industry lacks standardized fabrication protocols that can ensure consistent performance across different manufacturing facilities.

Furthermore, fundamental understanding of defect physics in these materials remains incomplete. Point defects, oxygen vacancies, and grain boundaries significantly influence electrical properties, but their formation mechanisms and control methods are not fully characterized. This knowledge gap hinders the rational design of next-generation materials with optimized properties.

The integration of hybrid oxide semiconductors with conventional silicon-based technologies also presents compatibility challenges, particularly regarding thermal budgets, chemical compatibility, and process integration sequences. Overcoming these barriers requires interdisciplinary approaches combining materials science, device physics, and manufacturing engineering.

In East Asia, particularly Japan and South Korea, research efforts concentrate on industrial applications, with companies like Samsung, LG, and Sharp pioneering commercial implementations. Japanese researchers have made substantial contributions to amorphous oxide semiconductors, while Korean institutions have advanced flexible oxide electronics and large-area fabrication techniques.

European research centers, including those in Germany, the UK, and Switzerland, emphasize sustainable manufacturing processes and specialized applications in medical devices and environmental sensors. Their distinctive approach integrates oxide semiconductors with other material systems to create multifunctional devices.

Despite these advancements, significant technical barriers persist in the development of hybrid oxide semiconductor materials. The most challenging obstacle remains the stability and reliability of these materials under various operational conditions. Oxide semiconductors often exhibit performance degradation under prolonged bias stress, temperature fluctuations, and humidity exposure, limiting their practical applications in mission-critical systems.

Another major barrier is the precise control of interface properties between different oxide layers and with other semiconductor materials. These interfaces critically determine carrier transport mechanisms and overall device performance, yet achieving atomically clean and well-defined interfaces remains technically demanding.

The scalable manufacturing of hybrid oxide semiconductor devices presents additional challenges. Current deposition techniques struggle to maintain uniform material properties across large substrates, creating yield issues for commercial production. The industry lacks standardized fabrication protocols that can ensure consistent performance across different manufacturing facilities.

Furthermore, fundamental understanding of defect physics in these materials remains incomplete. Point defects, oxygen vacancies, and grain boundaries significantly influence electrical properties, but their formation mechanisms and control methods are not fully characterized. This knowledge gap hinders the rational design of next-generation materials with optimized properties.

The integration of hybrid oxide semiconductors with conventional silicon-based technologies also presents compatibility challenges, particularly regarding thermal budgets, chemical compatibility, and process integration sequences. Overcoming these barriers requires interdisciplinary approaches combining materials science, device physics, and manufacturing engineering.

Current Fabrication Methods and Material Systems

01 Composition and structure of hybrid oxide semiconductor materials

Hybrid oxide semiconductor materials combine different metal oxides to create materials with enhanced properties. These materials typically consist of a primary metal oxide (such as zinc oxide, indium oxide, or tin oxide) combined with one or more secondary metal oxides. The resulting hybrid structures can exhibit improved electrical conductivity, optical transparency, and stability compared to single-component oxide semiconductors. The specific composition and ratio of metal oxides can be tailored to achieve desired properties for various applications.- Composition and structure of hybrid oxide semiconductor materials: Hybrid oxide semiconductor materials combine different metal oxides to achieve enhanced electrical properties. These materials typically consist of a primary oxide semiconductor (such as zinc oxide, indium oxide, or tin oxide) combined with one or more secondary metal oxides. The specific composition and atomic arrangement significantly influence the material's performance characteristics, including carrier mobility, stability, and band gap. Various synthesis methods can be employed to control the microstructure and crystallinity of these hybrid materials.

- Thin-film transistor applications of hybrid oxide semiconductors: Hybrid oxide semiconductor materials are widely used in thin-film transistors (TFTs) for display technologies. These materials offer advantages such as high electron mobility, good uniformity, and low-temperature processability compared to conventional silicon-based semiconductors. The performance of TFTs can be optimized by controlling the composition ratio of different metal oxides in the hybrid material, which affects parameters such as threshold voltage, on/off current ratio, and operational stability under various environmental conditions.

- Deposition and fabrication techniques for hybrid oxide semiconductors: Various deposition techniques are employed for fabricating hybrid oxide semiconductor films, including sputtering, chemical vapor deposition, solution processing, and atomic layer deposition. Each method offers different advantages in terms of film quality, uniformity, and scalability. Post-deposition treatments such as annealing in different atmospheres can significantly modify the electrical properties of these materials by altering oxygen vacancy concentration and crystalline structure. The choice of substrate and processing temperature also plays a crucial role in determining the final performance characteristics.

- Energy applications of hybrid oxide semiconductor materials: Hybrid oxide semiconductor materials find applications in various energy-related technologies, including photovoltaics, photocatalysis, and energy storage devices. These materials can be engineered to have specific band gaps and electronic structures suitable for efficient light absorption and charge separation. In solar cells, hybrid oxide semiconductors can serve as electron transport layers or photoactive materials. For photocatalytic applications, these materials can be designed to facilitate water splitting or degradation of environmental pollutants under light irradiation.

- Doping strategies for enhanced performance of hybrid oxide semiconductors: Doping is a critical strategy for modifying the electrical and optical properties of hybrid oxide semiconductor materials. Various dopants, including other metal ions, non-metal elements, or nanoparticles, can be incorporated into the oxide matrix to control carrier concentration, mobility, and band structure. Controlled doping can enhance conductivity, modify the optical band gap, improve stability, and enable specific functionalities such as gas sensing or UV detection. The concentration and distribution of dopants significantly influence the overall performance of the semiconductor material.

02 Fabrication methods for hybrid oxide semiconductor materials

Various fabrication techniques are employed to produce hybrid oxide semiconductor materials with controlled properties. These methods include solution processing (sol-gel, hydrothermal synthesis), vapor deposition techniques (chemical vapor deposition, atomic layer deposition), sputtering, and pulsed laser deposition. Post-deposition treatments such as annealing in different atmospheres can significantly influence the crystallinity, defect concentration, and interface properties of the hybrid oxide semiconductors. Advanced fabrication approaches enable precise control over composition, thickness, and microstructure.Expand Specific Solutions03 Applications in thin-film transistors and electronic devices

Hybrid oxide semiconductor materials are widely used in thin-film transistors (TFTs) for display technologies and flexible electronics. These materials offer advantages such as high electron mobility, good uniformity, low processing temperatures, and stability under bias stress. The performance of TFTs can be optimized by controlling the composition of the hybrid oxide semiconductor, interface engineering, and device architecture. These materials enable the development of high-performance, transparent, and flexible electronic devices including displays, sensors, and integrated circuits.Expand Specific Solutions04 Energy applications of hybrid oxide semiconductors

Hybrid oxide semiconductor materials play crucial roles in various energy applications including photovoltaics, photocatalysis, and energy storage. In solar cells, these materials can serve as electron transport layers, buffer layers, or photoactive components. For photocatalytic applications, hybrid oxide semiconductors with engineered band gaps can efficiently harvest solar energy for water splitting, hydrogen production, or environmental remediation. Additionally, these materials are utilized in batteries, supercapacitors, and thermoelectric devices due to their tunable electronic properties and stability under various operating conditions.Expand Specific Solutions05 Doping and defect engineering in hybrid oxide semiconductors

Doping and defect engineering are essential strategies for tailoring the properties of hybrid oxide semiconductor materials. Intentional incorporation of dopants can modify carrier concentration, mobility, and band structure. Common dopants include metals (Al, Ga, In), non-metals (N, S), and rare earth elements. Defect engineering involves controlling oxygen vacancies, interstitials, and grain boundaries to optimize electrical and optical properties. These approaches enable the development of hybrid oxide semiconductors with enhanced conductivity, transparency, and stability for specific applications while minimizing undesirable characteristics such as persistent photoconductivity.Expand Specific Solutions

Leading Research Institutions and Industrial Players

The hybrid oxide semiconductor materials market is in a growth phase, characterized by increasing demand for advanced electronic devices. The market size is expanding rapidly, driven by applications in display technologies, power electronics, and optoelectronics. Technologically, the field shows varying maturity levels across applications, with companies like Taiwan Semiconductor, Applied Materials, and GLOBALFOUNDRIES leading industrial implementation. Research institutions such as Semiconductor Energy Laboratory, Fudan University, and EPFL are advancing fundamental innovations. Corning and SOITEC are developing specialized substrate technologies, while FLOSFIA and Raynergy Tek represent emerging players focusing on novel oxide semiconductor compositions. The competitive landscape reflects a balance between established semiconductor giants and specialized materials innovators working to overcome performance and manufacturing challenges.

Semiconductor Energy Laboratory Co., Ltd.

Technical Solution: Semiconductor Energy Laboratory (SEL) has pioneered advanced oxide semiconductor materials, particularly focusing on IGZO (Indium Gallium Zinc Oxide) technology for thin-film transistors (TFTs). Their approach involves creating highly uniform amorphous oxide semiconductor films with optimized carrier mobility and stability. SEL has developed proprietary deposition techniques that enable precise control of oxygen vacancies and metal stoichiometry, critical factors affecting device performance. Their c-axis aligned crystalline (CAAC) IGZO technology represents a significant breakthrough, offering higher electron mobility while maintaining low off-state current[1]. SEL has also innovated in creating multi-component oxide systems that combine the benefits of different metal oxides to achieve tailored electronic properties for specific applications, particularly in flexible displays and low-power electronics.

Strengths: Superior electron mobility compared to amorphous silicon, excellent uniformity across large substrates, and exceptional stability under bias stress. Their technology enables ultra-low power consumption displays and memory devices. Weaknesses: Higher manufacturing complexity compared to conventional silicon technologies, and some materials require rare elements like indium which may face supply constraints.

FLOSFIA, Inc.

Technical Solution: FLOSFIA has pioneered the development and commercialization of gallium oxide (Ga2O3) and related materials for power semiconductor applications. Their proprietary "mist CVD" technology enables the growth of high-quality corundum-structured α-Ga2O3 thin films at significantly lower temperatures than conventional methods, making it compatible with a wider range of substrates and processing conditions[4]. FLOSFIA's approach focuses on exploiting the ultra-wide bandgap (approximately 5.3 eV) of α-Ga2O3, which theoretically enables power devices with breakdown voltages exceeding those of conventional silicon carbide and gallium nitride. Their technology incorporates controlled doping strategies to achieve desired carrier concentrations while maintaining high crystal quality. FLOSFIA has also developed innovative device architectures specifically optimized for the unique properties of oxide semiconductors, including specialized contact structures that address the challenges of forming low-resistance ohmic contacts to wide-bandgap oxides.

Strengths: Breakthrough material system with theoretical performance exceeding existing wide-bandgap semiconductors, proprietary low-temperature deposition technology enabling cost-effective manufacturing, and strong IP position in α-Ga2O3 device structures. Weaknesses: Relatively new technology with limited field reliability data compared to established semiconductor materials, and challenges in achieving high-volume manufacturing consistency for complex oxide compositions.

Key Patents and Scientific Breakthroughs

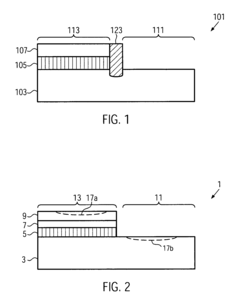

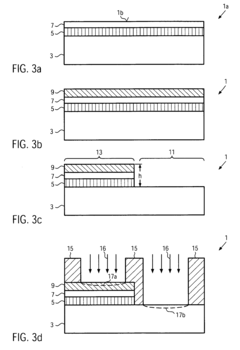

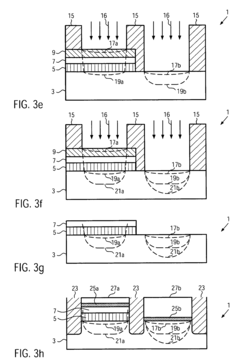

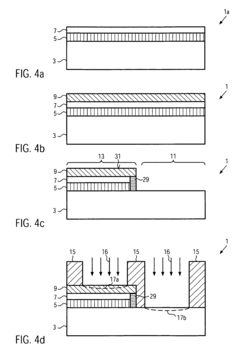

Fabrication process of a hybrid semiconductor substrate

PatentActiveEP2254148A1

Innovation

- A method for manufacturing hybrid semiconductor substrates where both regions are doped simultaneously using the same implant conditions, with impurity levels contained within a mask layer to suppress threshold voltage fluctuations and simplify the process, allowing for improved SRAM stability and reduced manufacturing costs.

Low-voltage, n-channel hybrid transistors

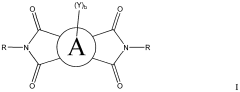

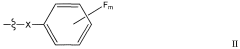

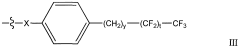

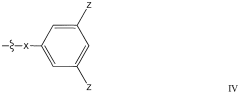

PatentWO2009089283A2

Innovation

- The development of hybrid semiconducting-dielectric materials with tetracarboxylic diimide compounds that integrate n-type semiconducting properties with dielectric side chains, eliminating the need for separate gate dielectrics and enhancing electron mobility and stability, allowing for sub-1 V transistor operation and high on/off ratios.

Sustainability and Environmental Impact Assessment

The environmental impact of hybrid oxide semiconductor materials represents a critical dimension in their development trajectory. These materials offer significant sustainability advantages compared to conventional semiconductors, particularly in terms of reduced energy consumption during operation. Devices incorporating hybrid oxide semiconductors typically require lower operating voltages and demonstrate improved power efficiency, contributing to decreased carbon footprints across various applications from consumer electronics to industrial systems.

Raw material sourcing for hybrid oxide semiconductors presents both challenges and opportunities from a sustainability perspective. While some constituent elements may involve resource-intensive mining operations, the materials often utilize earth-abundant elements like zinc, tin, and indium in optimized proportions, potentially reducing reliance on scarce resources. The manufacturing processes for these materials have evolved to incorporate more environmentally friendly approaches, including solution-based processing methods that minimize hazardous waste generation and reduce energy requirements compared to traditional vacuum-based deposition techniques.

Life cycle assessment (LCA) studies indicate that hybrid oxide semiconductor devices generally demonstrate favorable environmental profiles when evaluated across their entire lifespan. The extended operational stability of these materials translates to longer device lifetimes, reducing electronic waste generation. Additionally, many hybrid oxide formulations exhibit lower toxicity profiles than conventional semiconductor materials, presenting reduced end-of-life environmental hazards.

Recycling and material recovery represent emerging areas of focus in the sustainability framework for hybrid oxide semiconductors. Research indicates promising avenues for reclaiming valuable elements from end-of-life devices, though commercial-scale recovery systems remain underdeveloped. The potential for circular economy approaches is significant, particularly as manufacturing volumes increase and recovery technologies mature.

Water usage in production processes remains a concern, with certain solution-based fabrication methods requiring substantial quantities of ultrapure water. Innovations in closed-loop water recycling systems and alternative processing techniques are actively being pursued to address this challenge. Similarly, energy-efficient annealing and crystallization methods are being developed to reduce the carbon intensity of manufacturing operations.

Regulatory frameworks worldwide are increasingly incorporating sustainability metrics into materials approval processes, with particular attention to restricted substances and energy efficiency standards. Hybrid oxide semiconductor technologies generally align well with these evolving requirements, positioning them favorably in markets where environmental compliance carries significant weight in technology adoption decisions.

Raw material sourcing for hybrid oxide semiconductors presents both challenges and opportunities from a sustainability perspective. While some constituent elements may involve resource-intensive mining operations, the materials often utilize earth-abundant elements like zinc, tin, and indium in optimized proportions, potentially reducing reliance on scarce resources. The manufacturing processes for these materials have evolved to incorporate more environmentally friendly approaches, including solution-based processing methods that minimize hazardous waste generation and reduce energy requirements compared to traditional vacuum-based deposition techniques.

Life cycle assessment (LCA) studies indicate that hybrid oxide semiconductor devices generally demonstrate favorable environmental profiles when evaluated across their entire lifespan. The extended operational stability of these materials translates to longer device lifetimes, reducing electronic waste generation. Additionally, many hybrid oxide formulations exhibit lower toxicity profiles than conventional semiconductor materials, presenting reduced end-of-life environmental hazards.

Recycling and material recovery represent emerging areas of focus in the sustainability framework for hybrid oxide semiconductors. Research indicates promising avenues for reclaiming valuable elements from end-of-life devices, though commercial-scale recovery systems remain underdeveloped. The potential for circular economy approaches is significant, particularly as manufacturing volumes increase and recovery technologies mature.

Water usage in production processes remains a concern, with certain solution-based fabrication methods requiring substantial quantities of ultrapure water. Innovations in closed-loop water recycling systems and alternative processing techniques are actively being pursued to address this challenge. Similarly, energy-efficient annealing and crystallization methods are being developed to reduce the carbon intensity of manufacturing operations.

Regulatory frameworks worldwide are increasingly incorporating sustainability metrics into materials approval processes, with particular attention to restricted substances and energy efficiency standards. Hybrid oxide semiconductor technologies generally align well with these evolving requirements, positioning them favorably in markets where environmental compliance carries significant weight in technology adoption decisions.

Integration Challenges with Existing Semiconductor Technologies

The integration of hybrid oxide semiconductor materials with conventional silicon-based technologies presents significant challenges that must be addressed for successful commercialization. The fundamental differences in material properties, processing requirements, and electronic characteristics create compatibility issues that impact manufacturing feasibility and device performance.

Process temperature compatibility remains one of the most critical challenges. While silicon-based processes typically require high temperatures (800-1000°C), many hybrid oxide semiconductors exhibit optimal performance when processed at lower temperatures (200-400°C). This temperature mismatch necessitates the development of specialized processing techniques that can accommodate both material systems without degrading their respective properties.

Interface engineering between hybrid oxides and traditional semiconductors presents another substantial hurdle. The formation of high-quality interfaces with minimal defects and optimal band alignment is essential for efficient charge transport. Lattice mismatches and differences in surface chemistry often lead to interface states that trap charges and degrade device performance. Advanced deposition techniques such as atomic layer deposition (ALD) and pulsed laser deposition (PLD) show promise in addressing these interface challenges.

Contamination control represents a significant integration concern. Hybrid oxide semiconductors are particularly sensitive to impurities, especially hydrogen and moisture, which can dramatically alter their electrical properties. Existing semiconductor fabrication facilities must implement enhanced contamination protocols to maintain the integrity of these materials throughout the manufacturing process.

Scaling and uniformity issues also emerge when integrating hybrid oxide semiconductors into conventional manufacturing lines. Achieving consistent material properties across large-area substrates remains challenging, particularly for complex oxide compositions. Variations in stoichiometry, crystallinity, and defect density can lead to device-to-device performance variations that are unacceptable for commercial applications.

Equipment compatibility presents additional complications. Many existing semiconductor manufacturing tools are not optimized for handling oxide materials, requiring either significant modifications or the development of new equipment. This adaptation increases manufacturing costs and complexity, potentially limiting widespread adoption of hybrid oxide semiconductor technologies.

Reliability and long-term stability concerns further complicate integration efforts. Hybrid oxide semiconductors may exhibit different degradation mechanisms compared to silicon, including sensitivity to bias stress, illumination, and environmental factors. Comprehensive reliability testing and qualification protocols must be developed to ensure these materials meet the stringent requirements of commercial electronic devices.

Process temperature compatibility remains one of the most critical challenges. While silicon-based processes typically require high temperatures (800-1000°C), many hybrid oxide semiconductors exhibit optimal performance when processed at lower temperatures (200-400°C). This temperature mismatch necessitates the development of specialized processing techniques that can accommodate both material systems without degrading their respective properties.

Interface engineering between hybrid oxides and traditional semiconductors presents another substantial hurdle. The formation of high-quality interfaces with minimal defects and optimal band alignment is essential for efficient charge transport. Lattice mismatches and differences in surface chemistry often lead to interface states that trap charges and degrade device performance. Advanced deposition techniques such as atomic layer deposition (ALD) and pulsed laser deposition (PLD) show promise in addressing these interface challenges.

Contamination control represents a significant integration concern. Hybrid oxide semiconductors are particularly sensitive to impurities, especially hydrogen and moisture, which can dramatically alter their electrical properties. Existing semiconductor fabrication facilities must implement enhanced contamination protocols to maintain the integrity of these materials throughout the manufacturing process.

Scaling and uniformity issues also emerge when integrating hybrid oxide semiconductors into conventional manufacturing lines. Achieving consistent material properties across large-area substrates remains challenging, particularly for complex oxide compositions. Variations in stoichiometry, crystallinity, and defect density can lead to device-to-device performance variations that are unacceptable for commercial applications.

Equipment compatibility presents additional complications. Many existing semiconductor manufacturing tools are not optimized for handling oxide materials, requiring either significant modifications or the development of new equipment. This adaptation increases manufacturing costs and complexity, potentially limiting widespread adoption of hybrid oxide semiconductor technologies.

Reliability and long-term stability concerns further complicate integration efforts. Hybrid oxide semiconductors may exhibit different degradation mechanisms compared to silicon, including sensitivity to bias stress, illumination, and environmental factors. Comprehensive reliability testing and qualification protocols must be developed to ensure these materials meet the stringent requirements of commercial electronic devices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!