Microcrystalline Cellulose as a Scaffold Material for Tissue Engineering

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MCC in Tissue Engineering: Background and Objectives

Microcrystalline cellulose (MCC) has emerged as a promising scaffold material in tissue engineering, attracting significant attention from researchers and industry professionals alike. The field of tissue engineering aims to develop biological substitutes that restore, maintain, or improve tissue function, addressing the critical shortage of donor organs and tissues for transplantation. MCC, derived from natural cellulose sources, offers a unique combination of properties that make it particularly suitable for this application.

The journey of MCC in tissue engineering began with the recognition of its biocompatibility, biodegradability, and mechanical strength. These inherent characteristics align well with the requirements of an ideal scaffold material. As research progressed, scientists discovered that MCC's porous structure could effectively mimic the extracellular matrix, providing an environment conducive to cell adhesion, proliferation, and differentiation.

The evolution of MCC as a scaffold material has been marked by several key milestones. Initially, researchers focused on understanding its basic properties and interactions with cells. This was followed by efforts to modify and functionalize MCC to enhance its performance in specific tissue engineering applications. Recent advancements have seen the integration of MCC with other biomaterials and the development of composite scaffolds that combine the benefits of multiple components.

The primary objective of research in this field is to optimize MCC-based scaffolds for various tissue types, including bone, cartilage, skin, and vascular tissues. This involves tailoring the physical and chemical properties of MCC to meet the specific requirements of each tissue type. Researchers aim to improve the scaffold's mechanical strength, porosity, and degradation rate while ensuring optimal cell attachment and growth.

Another crucial goal is to enhance the bioactivity of MCC scaffolds. This includes incorporating growth factors, cell-signaling molecules, and other bioactive compounds to promote tissue regeneration and integration. Additionally, there is a focus on developing scalable and reproducible manufacturing processes for MCC-based scaffolds, which is essential for their translation from laboratory research to clinical applications.

The future trajectory of MCC in tissue engineering is expected to involve the exploration of advanced fabrication techniques, such as 3D printing and electrospinning, to create more complex and customized scaffold structures. There is also growing interest in combining MCC with smart materials to develop responsive scaffolds that can adapt to changing physiological conditions.

As the field progresses, researchers are increasingly focusing on addressing the challenges associated with MCC-based scaffolds, such as controlling degradation rates, improving vascularization, and enhancing mechanical properties for load-bearing applications. The ultimate aim is to develop MCC-based tissue engineering solutions that can effectively bridge the gap between laboratory research and clinical practice, offering new hope for patients in need of tissue repair and regeneration.

The journey of MCC in tissue engineering began with the recognition of its biocompatibility, biodegradability, and mechanical strength. These inherent characteristics align well with the requirements of an ideal scaffold material. As research progressed, scientists discovered that MCC's porous structure could effectively mimic the extracellular matrix, providing an environment conducive to cell adhesion, proliferation, and differentiation.

The evolution of MCC as a scaffold material has been marked by several key milestones. Initially, researchers focused on understanding its basic properties and interactions with cells. This was followed by efforts to modify and functionalize MCC to enhance its performance in specific tissue engineering applications. Recent advancements have seen the integration of MCC with other biomaterials and the development of composite scaffolds that combine the benefits of multiple components.

The primary objective of research in this field is to optimize MCC-based scaffolds for various tissue types, including bone, cartilage, skin, and vascular tissues. This involves tailoring the physical and chemical properties of MCC to meet the specific requirements of each tissue type. Researchers aim to improve the scaffold's mechanical strength, porosity, and degradation rate while ensuring optimal cell attachment and growth.

Another crucial goal is to enhance the bioactivity of MCC scaffolds. This includes incorporating growth factors, cell-signaling molecules, and other bioactive compounds to promote tissue regeneration and integration. Additionally, there is a focus on developing scalable and reproducible manufacturing processes for MCC-based scaffolds, which is essential for their translation from laboratory research to clinical applications.

The future trajectory of MCC in tissue engineering is expected to involve the exploration of advanced fabrication techniques, such as 3D printing and electrospinning, to create more complex and customized scaffold structures. There is also growing interest in combining MCC with smart materials to develop responsive scaffolds that can adapt to changing physiological conditions.

As the field progresses, researchers are increasingly focusing on addressing the challenges associated with MCC-based scaffolds, such as controlling degradation rates, improving vascularization, and enhancing mechanical properties for load-bearing applications. The ultimate aim is to develop MCC-based tissue engineering solutions that can effectively bridge the gap between laboratory research and clinical practice, offering new hope for patients in need of tissue repair and regeneration.

Market Analysis for MCC-based Scaffolds

The market for microcrystalline cellulose (MCC) based scaffolds in tissue engineering is experiencing significant growth, driven by the increasing demand for regenerative medicine and advanced wound care solutions. This market segment is part of the broader tissue engineering market, which is projected to reach substantial value in the coming years due to the rising prevalence of chronic diseases and an aging global population.

MCC-based scaffolds are gaining traction in various applications within tissue engineering, including bone regeneration, cartilage repair, and soft tissue reconstruction. The unique properties of MCC, such as biocompatibility, biodegradability, and mechanical strength, make it an attractive material for scaffold fabrication. These characteristics align well with the requirements of tissue engineering applications, contributing to the growing market demand.

The healthcare sector, particularly orthopedics and wound care, represents a significant portion of the market for MCC-based scaffolds. With the increasing incidence of musculoskeletal disorders and the need for advanced wound healing solutions, the demand for innovative biomaterials like MCC scaffolds is on the rise. Additionally, the cosmetic and plastic surgery industry is showing interest in MCC-based scaffolds for applications in soft tissue augmentation and reconstruction.

Geographically, North America and Europe currently dominate the market for MCC-based scaffolds, owing to their advanced healthcare infrastructure and higher adoption rates of innovative medical technologies. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by improving healthcare facilities, increasing research and development activities, and a large patient pool.

The market is characterized by intense research and development activities, with academic institutions and biotechnology companies collaborating to develop novel MCC-based scaffold products. This trend is likely to continue, fostering innovation and expanding the application scope of MCC scaffolds in tissue engineering.

Despite the promising growth prospects, the market faces challenges such as stringent regulatory requirements and the high cost associated with scaffold development and production. These factors may impact market penetration, particularly in emerging economies. However, ongoing technological advancements and increasing investments in regenerative medicine are expected to mitigate these challenges over time.

In conclusion, the market for MCC-based scaffolds in tissue engineering presents significant opportunities for growth and innovation. As research progresses and clinical applications expand, the demand for these advanced biomaterials is expected to increase, driving market expansion and potentially revolutionizing approaches to tissue repair and regeneration.

MCC-based scaffolds are gaining traction in various applications within tissue engineering, including bone regeneration, cartilage repair, and soft tissue reconstruction. The unique properties of MCC, such as biocompatibility, biodegradability, and mechanical strength, make it an attractive material for scaffold fabrication. These characteristics align well with the requirements of tissue engineering applications, contributing to the growing market demand.

The healthcare sector, particularly orthopedics and wound care, represents a significant portion of the market for MCC-based scaffolds. With the increasing incidence of musculoskeletal disorders and the need for advanced wound healing solutions, the demand for innovative biomaterials like MCC scaffolds is on the rise. Additionally, the cosmetic and plastic surgery industry is showing interest in MCC-based scaffolds for applications in soft tissue augmentation and reconstruction.

Geographically, North America and Europe currently dominate the market for MCC-based scaffolds, owing to their advanced healthcare infrastructure and higher adoption rates of innovative medical technologies. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by improving healthcare facilities, increasing research and development activities, and a large patient pool.

The market is characterized by intense research and development activities, with academic institutions and biotechnology companies collaborating to develop novel MCC-based scaffold products. This trend is likely to continue, fostering innovation and expanding the application scope of MCC scaffolds in tissue engineering.

Despite the promising growth prospects, the market faces challenges such as stringent regulatory requirements and the high cost associated with scaffold development and production. These factors may impact market penetration, particularly in emerging economies. However, ongoing technological advancements and increasing investments in regenerative medicine are expected to mitigate these challenges over time.

In conclusion, the market for MCC-based scaffolds in tissue engineering presents significant opportunities for growth and innovation. As research progresses and clinical applications expand, the demand for these advanced biomaterials is expected to increase, driving market expansion and potentially revolutionizing approaches to tissue repair and regeneration.

Current Challenges in MCC Scaffold Development

Despite the promising potential of microcrystalline cellulose (MCC) as a scaffold material for tissue engineering, several challenges persist in its development and application. One of the primary obstacles is achieving optimal porosity and pore interconnectivity in MCC scaffolds. While porosity is crucial for cell infiltration, nutrient diffusion, and waste removal, creating a consistent and interconnected pore structure throughout the scaffold remains difficult.

Another significant challenge lies in controlling the degradation rate of MCC scaffolds. Ideally, the scaffold should degrade at a rate that matches the growth of new tissue. However, achieving this balance is complex, as degradation rates can vary depending on factors such as crystallinity, molecular weight, and environmental conditions. Researchers are still working to develop methods to fine-tune the degradation kinetics of MCC scaffolds to ensure optimal tissue regeneration.

Mechanical properties present another hurdle in MCC scaffold development. While MCC offers good mechanical strength, matching the mechanical properties of the scaffold to those of the target tissue remains challenging. This is particularly important for load-bearing applications, where the scaffold must provide adequate support while gradually transferring stress to the newly formed tissue.

Biocompatibility and cell adhesion are critical aspects of scaffold design. Although MCC is generally considered biocompatible, enhancing cell attachment and proliferation on its surface can be challenging. Researchers are exploring various surface modification techniques to improve cell-scaffold interactions, but finding the right balance between maintaining the inherent properties of MCC and enhancing its biological performance is an ongoing challenge.

The scalability of MCC scaffold production is another area of concern. While laboratory-scale production has shown promise, scaling up to industrial levels while maintaining consistent quality and properties poses significant challenges. This includes issues related to batch-to-batch variability, sterilization processes, and cost-effectiveness.

Furthermore, the integration of growth factors and other bioactive molecules into MCC scaffolds presents both opportunities and challenges. While these additions can enhance tissue regeneration, controlling their release kinetics and maintaining their bioactivity during scaffold fabrication and sterilization processes remains difficult.

Lastly, the long-term in vivo performance and safety of MCC scaffolds require further investigation. While short-term studies have shown promising results, comprehensive long-term studies are needed to fully understand the scaffold's behavior, degradation products, and potential long-term effects on tissue function and overall health.

Another significant challenge lies in controlling the degradation rate of MCC scaffolds. Ideally, the scaffold should degrade at a rate that matches the growth of new tissue. However, achieving this balance is complex, as degradation rates can vary depending on factors such as crystallinity, molecular weight, and environmental conditions. Researchers are still working to develop methods to fine-tune the degradation kinetics of MCC scaffolds to ensure optimal tissue regeneration.

Mechanical properties present another hurdle in MCC scaffold development. While MCC offers good mechanical strength, matching the mechanical properties of the scaffold to those of the target tissue remains challenging. This is particularly important for load-bearing applications, where the scaffold must provide adequate support while gradually transferring stress to the newly formed tissue.

Biocompatibility and cell adhesion are critical aspects of scaffold design. Although MCC is generally considered biocompatible, enhancing cell attachment and proliferation on its surface can be challenging. Researchers are exploring various surface modification techniques to improve cell-scaffold interactions, but finding the right balance between maintaining the inherent properties of MCC and enhancing its biological performance is an ongoing challenge.

The scalability of MCC scaffold production is another area of concern. While laboratory-scale production has shown promise, scaling up to industrial levels while maintaining consistent quality and properties poses significant challenges. This includes issues related to batch-to-batch variability, sterilization processes, and cost-effectiveness.

Furthermore, the integration of growth factors and other bioactive molecules into MCC scaffolds presents both opportunities and challenges. While these additions can enhance tissue regeneration, controlling their release kinetics and maintaining their bioactivity during scaffold fabrication and sterilization processes remains difficult.

Lastly, the long-term in vivo performance and safety of MCC scaffolds require further investigation. While short-term studies have shown promising results, comprehensive long-term studies are needed to fully understand the scaffold's behavior, degradation products, and potential long-term effects on tissue function and overall health.

Existing MCC Scaffold Fabrication Techniques

01 Preparation of microcrystalline cellulose scaffolds

Methods for preparing microcrystalline cellulose scaffolds involve processing cellulose sources to create a porous structure suitable for various applications. Techniques may include chemical treatments, mechanical processing, and freeze-drying to achieve desired scaffold properties such as porosity and mechanical strength.- Microcrystalline cellulose as a scaffold material: Microcrystalline cellulose (MCC) is utilized as a scaffold material in various applications due to its biocompatibility, biodegradability, and structural properties. It provides a suitable matrix for cell growth and tissue engineering, offering mechanical support and porosity for cell attachment and proliferation.

- Modification of microcrystalline cellulose scaffolds: Various techniques are employed to modify MCC scaffolds, enhancing their properties for specific applications. These modifications may include chemical treatments, surface functionalization, or incorporation of additional components to improve cell adhesion, mechanical strength, or bioactivity of the scaffolds.

- Composite scaffolds incorporating microcrystalline cellulose: MCC is often combined with other materials to create composite scaffolds with enhanced properties. These composites may include synthetic polymers, natural polymers, or inorganic materials, resulting in scaffolds with improved mechanical strength, bioactivity, or specific functionalities for tissue engineering applications.

- Preparation methods for microcrystalline cellulose scaffolds: Various techniques are employed to prepare MCC scaffolds, including freeze-drying, electrospinning, and 3D printing. These methods allow for control over scaffold porosity, pore size, and overall structure, which are crucial factors in determining the scaffold's performance in tissue engineering applications.

- Applications of microcrystalline cellulose scaffolds: MCC scaffolds find applications in various fields, including tissue engineering, drug delivery, and wound healing. They are used for the regeneration of different tissue types, such as bone, cartilage, and skin, as well as for controlled release of bioactive compounds and as substrates for cell culture and tissue growth.

02 Applications in tissue engineering and regenerative medicine

Microcrystalline cellulose scaffolds are utilized in tissue engineering and regenerative medicine due to their biocompatibility and ability to support cell growth. These scaffolds can be tailored to mimic natural extracellular matrices, promoting cell adhesion, proliferation, and differentiation for various tissue types.Expand Specific Solutions03 Modification and functionalization of scaffolds

Microcrystalline cellulose scaffolds can be modified or functionalized to enhance their properties for specific applications. This may involve surface treatments, incorporation of bioactive molecules, or combining with other materials to improve cell interactions, mechanical properties, or introduce additional functionalities.Expand Specific Solutions04 Drug delivery applications

Microcrystalline cellulose scaffolds are explored for controlled drug delivery systems. The porous structure and modifiable surface of these scaffolds allow for the incorporation and controlled release of various therapeutic agents, offering potential for sustained and targeted drug delivery in medical applications.Expand Specific Solutions05 Composite materials and industrial applications

Microcrystalline cellulose scaffolds are used in the development of composite materials for various industrial applications. These scaffolds can be combined with other materials to create products with enhanced properties, such as improved strength, lightweight structures, or specific functional characteristics for use in packaging, construction, or other industries.Expand Specific Solutions

Key Players in MCC-based Tissue Engineering

The research on microcrystalline cellulose as a scaffold material for tissue engineering is in a growth phase, with increasing market potential due to rising demand for biocompatible materials in regenerative medicine. The global market for tissue engineering scaffolds is expanding, driven by advancements in biomaterials and growing applications in wound healing and organ regeneration. Technologically, the field is progressing rapidly, with universities like Tianjin University, Zhejiang University, and Drexel University leading academic research. Companies such as Ethicon, Inc. and UPM-Kymmene Oyj are actively developing commercial applications, indicating a maturing technology landscape with potential for further innovation and market expansion.

Zhejiang University

Technical Solution: Zhejiang University has developed a novel approach to using microcrystalline cellulose (MCC) as a scaffold material for tissue engineering. Their research focuses on enhancing the mechanical properties and biocompatibility of MCC-based scaffolds. They have successfully created a composite scaffold by combining MCC with other biocompatible polymers, such as chitosan and gelatin[1]. This composite scaffold demonstrates improved cell adhesion and proliferation compared to pure MCC scaffolds. The university has also explored surface modification techniques to further enhance cell attachment and growth on MCC scaffolds[2]. Their recent studies have shown promising results in bone tissue engineering applications, with MCC-based scaffolds supporting osteoblast differentiation and mineralization[3].

Strengths: Enhanced mechanical properties, improved biocompatibility, and versatility in tissue engineering applications. Weaknesses: Potential challenges in scaling up production and ensuring consistent quality across batches.

Drexel University

Technical Solution: Drexel University has made significant advancements in the use of microcrystalline cellulose for tissue engineering scaffolds. Their research team has developed a unique process to create highly porous MCC scaffolds with controlled pore size and distribution[4]. This technique involves freeze-drying MCC suspensions and subsequent crosslinking to improve mechanical stability. The resulting scaffolds have shown excellent biocompatibility and support for cell growth in various tissue engineering applications, including cartilage and skin regeneration[5]. Drexel researchers have also explored the incorporation of growth factors and other bioactive molecules into MCC scaffolds to enhance tissue regeneration[6]. Their recent work has focused on developing MCC-based scaffolds with tunable degradation rates to match the rate of new tissue formation.

Strengths: Highly porous scaffolds with controlled architecture, excellent biocompatibility, and potential for drug delivery. Weaknesses: Possible limitations in load-bearing applications and challenges in achieving uniform drug distribution.

Innovations in MCC Modification for Biocompatibility

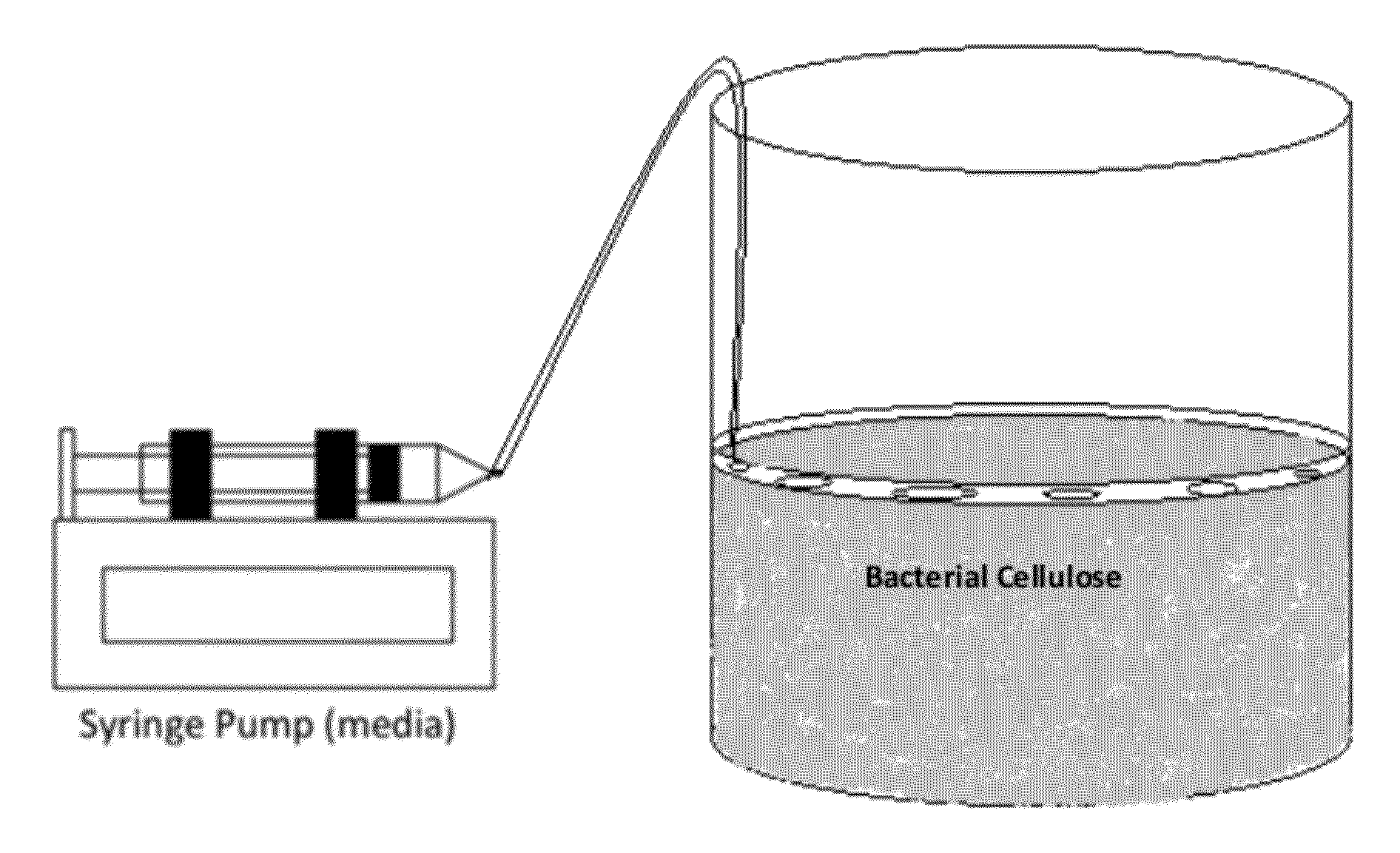

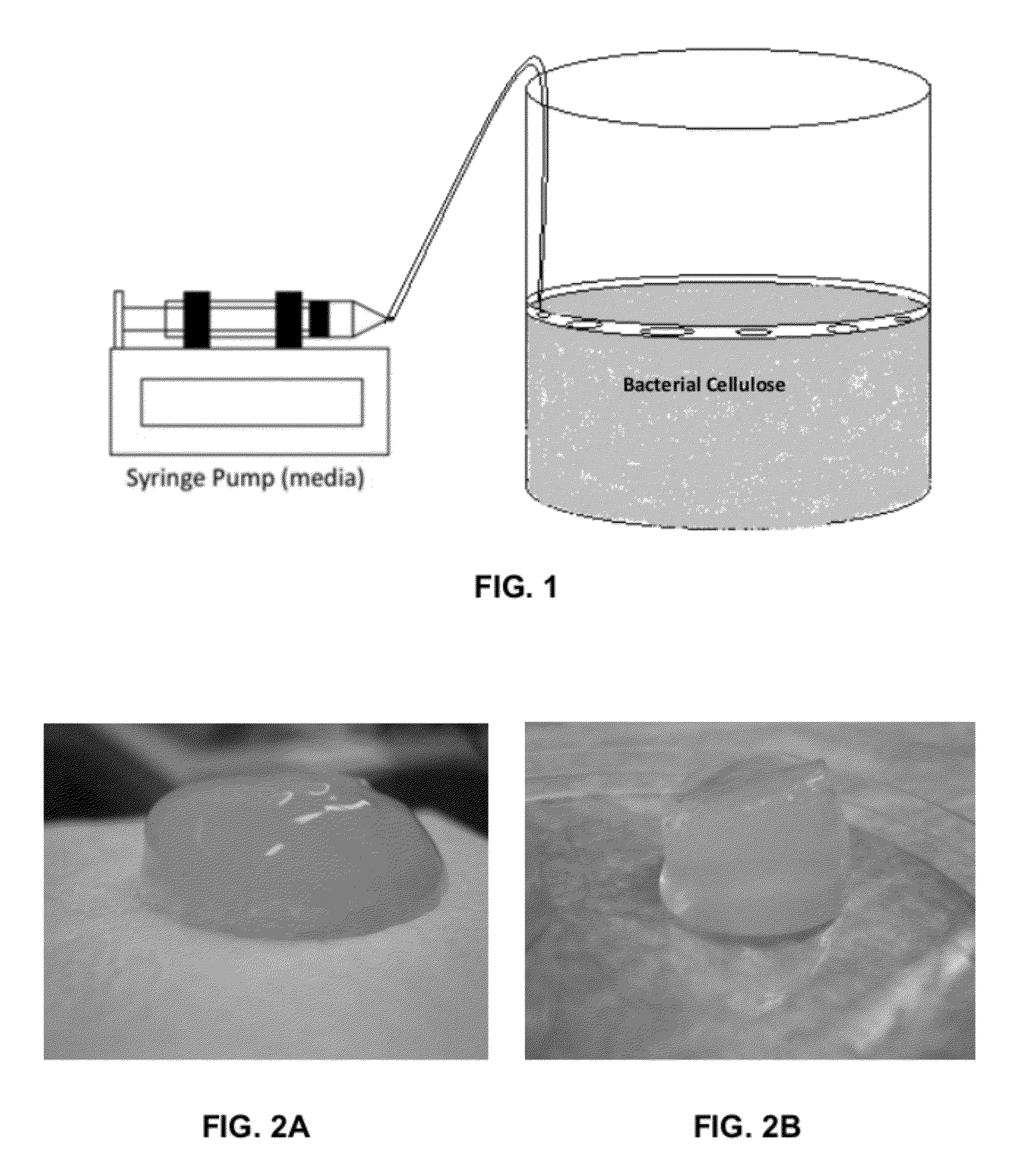

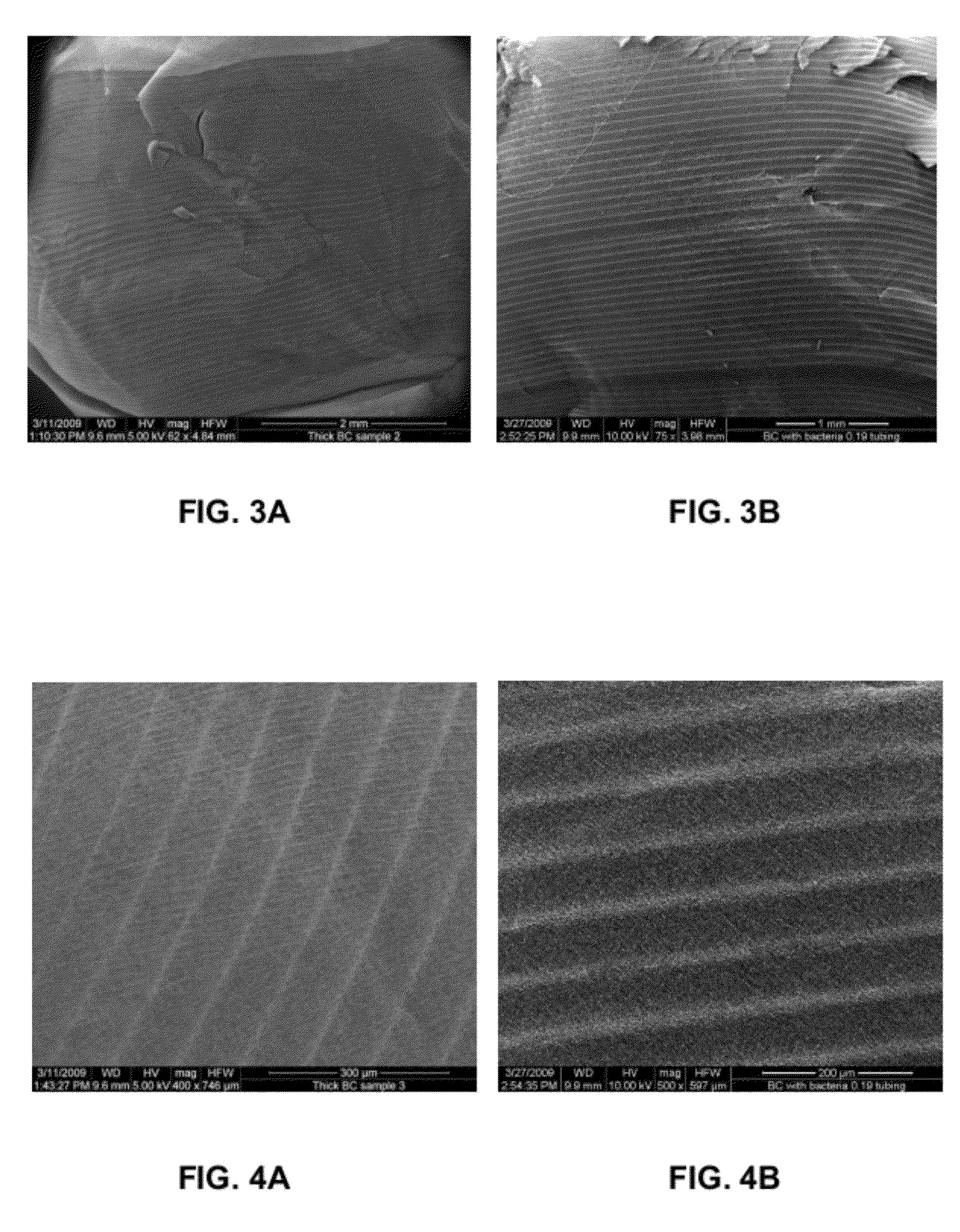

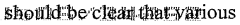

Three-dimensional bioprinting of biosynthetic cellulose (BC) implants and scaffolds for tissue engineering

PatentInactiveUS20120190078A1

Innovation

- A microfluidic medium administration system is used to gradually increase culture media, allowing for controlled cellulose production and porosity introduction through porogen templates, enabling the creation of 3D structures with predetermined shape and strength.

Tissue-engineering scaffolds containing self-assembled-peptide hydrogels

PatentWO2006036826A2

Innovation

- A tissue engineering scaffold combining a microporous scaffold with a nanofibrous, nanoporous hydrogel formed from self-assembling peptides, which provides both mechanical properties and enhanced tissue response, including increased ingrowth and vascularization.

Biocompatibility and Safety Regulations

Biocompatibility and safety are paramount considerations in the development and application of microcrystalline cellulose (MCC) as a scaffold material for tissue engineering. The use of MCC in biomedical applications necessitates rigorous evaluation and compliance with stringent regulatory standards to ensure patient safety and product efficacy.

The biocompatibility of MCC has been extensively studied, with numerous in vitro and in vivo studies demonstrating its non-toxic nature and favorable interaction with various cell types. MCC's natural origin and chemical similarity to native extracellular matrix components contribute to its high biocompatibility. However, the specific processing methods and any modifications made to MCC can significantly impact its biocompatibility profile, necessitating careful characterization for each formulation.

Regulatory bodies such as the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA) have established comprehensive guidelines for the evaluation of biomaterials intended for tissue engineering applications. These guidelines typically require a battery of tests to assess cytotoxicity, genotoxicity, carcinogenicity, and immunogenicity. For MCC-based scaffolds, additional considerations may include degradation kinetics and the potential biological effects of degradation products.

The ISO 10993 series of standards provides a framework for the biological evaluation of medical devices, including tissue-engineered products. Compliance with these standards is often a prerequisite for regulatory approval. Specific tests relevant to MCC scaffolds may include ISO 10993-5 for in vitro cytotoxicity and ISO 10993-6 for local effects after implantation.

Safety regulations also extend to the manufacturing process of MCC-based scaffolds. Good Manufacturing Practice (GMP) guidelines must be adhered to, ensuring consistent quality and purity of the final product. This includes validation of sterilization methods, as improper sterilization can compromise both the scaffold's structure and its biocompatibility.

Long-term safety considerations are particularly crucial for implantable MCC scaffolds. Regulatory bodies typically require extensive preclinical studies and clinical trials to evaluate the long-term performance and safety of these materials in vivo. This may involve monitoring for adverse reactions, assessing the scaffold's integration with host tissue, and evaluating its degradation profile over extended periods.

As the field of tissue engineering advances, regulatory frameworks continue to evolve. Researchers and manufacturers working with MCC scaffolds must stay abreast of these changes and engage in ongoing dialogue with regulatory agencies. This proactive approach ensures that development efforts align with current safety standards and facilitates a smoother path to clinical translation.

The biocompatibility of MCC has been extensively studied, with numerous in vitro and in vivo studies demonstrating its non-toxic nature and favorable interaction with various cell types. MCC's natural origin and chemical similarity to native extracellular matrix components contribute to its high biocompatibility. However, the specific processing methods and any modifications made to MCC can significantly impact its biocompatibility profile, necessitating careful characterization for each formulation.

Regulatory bodies such as the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA) have established comprehensive guidelines for the evaluation of biomaterials intended for tissue engineering applications. These guidelines typically require a battery of tests to assess cytotoxicity, genotoxicity, carcinogenicity, and immunogenicity. For MCC-based scaffolds, additional considerations may include degradation kinetics and the potential biological effects of degradation products.

The ISO 10993 series of standards provides a framework for the biological evaluation of medical devices, including tissue-engineered products. Compliance with these standards is often a prerequisite for regulatory approval. Specific tests relevant to MCC scaffolds may include ISO 10993-5 for in vitro cytotoxicity and ISO 10993-6 for local effects after implantation.

Safety regulations also extend to the manufacturing process of MCC-based scaffolds. Good Manufacturing Practice (GMP) guidelines must be adhered to, ensuring consistent quality and purity of the final product. This includes validation of sterilization methods, as improper sterilization can compromise both the scaffold's structure and its biocompatibility.

Long-term safety considerations are particularly crucial for implantable MCC scaffolds. Regulatory bodies typically require extensive preclinical studies and clinical trials to evaluate the long-term performance and safety of these materials in vivo. This may involve monitoring for adverse reactions, assessing the scaffold's integration with host tissue, and evaluating its degradation profile over extended periods.

As the field of tissue engineering advances, regulatory frameworks continue to evolve. Researchers and manufacturers working with MCC scaffolds must stay abreast of these changes and engage in ongoing dialogue with regulatory agencies. This proactive approach ensures that development efforts align with current safety standards and facilitates a smoother path to clinical translation.

Sustainability Aspects of MCC-based Scaffolds

The sustainability aspects of microcrystalline cellulose (MCC)-based scaffolds for tissue engineering are of paramount importance in the context of environmental concerns and resource management. MCC, derived from abundant and renewable cellulose sources, offers a promising alternative to synthetic materials in scaffold production.

One of the primary advantages of MCC-based scaffolds is their biodegradability. Unlike many synthetic polymers, MCC can be broken down by natural processes, reducing the long-term environmental impact of tissue engineering applications. This characteristic aligns well with the principles of circular economy and waste reduction in healthcare and research settings.

The production of MCC from cellulose sources, such as wood pulp or agricultural residues, generally requires less energy-intensive processes compared to the manufacture of synthetic polymers. This lower energy footprint contributes to the overall sustainability of MCC-based scaffolds. Additionally, the use of agricultural by-products or waste materials as sources for MCC production further enhances its eco-friendly profile.

Water consumption and chemical usage in MCC production are areas that require careful consideration. While cellulose processing typically involves less toxic chemicals than synthetic polymer production, optimizing water use and implementing closed-loop systems for chemical recovery are crucial steps in improving the sustainability of MCC-based scaffold manufacturing.

The potential for recycling and reuse of MCC-based scaffolds is another significant sustainability aspect. In cases where scaffolds are not fully degraded or integrated into regenerated tissue, the remaining material could potentially be recovered and repurposed, further reducing waste and resource consumption.

From a life cycle assessment perspective, MCC-based scaffolds generally demonstrate a lower environmental impact compared to their synthetic counterparts. This includes reduced greenhouse gas emissions, lower ecotoxicity, and decreased depletion of non-renewable resources. However, comprehensive studies are needed to quantify these benefits across different production methods and applications.

The scalability of MCC production is an important factor in its long-term sustainability. As demand for tissue engineering scaffolds grows, ensuring a stable and sustainable supply of MCC without compromising natural ecosystems or competing with food production is crucial. This may involve developing more efficient cellulose extraction methods or exploring alternative biomass sources.

In conclusion, while MCC-based scaffolds offer numerous sustainability advantages, ongoing research and development are necessary to optimize their production processes, enhance their performance, and ensure their long-term viability as a sustainable solution in tissue engineering applications.

One of the primary advantages of MCC-based scaffolds is their biodegradability. Unlike many synthetic polymers, MCC can be broken down by natural processes, reducing the long-term environmental impact of tissue engineering applications. This characteristic aligns well with the principles of circular economy and waste reduction in healthcare and research settings.

The production of MCC from cellulose sources, such as wood pulp or agricultural residues, generally requires less energy-intensive processes compared to the manufacture of synthetic polymers. This lower energy footprint contributes to the overall sustainability of MCC-based scaffolds. Additionally, the use of agricultural by-products or waste materials as sources for MCC production further enhances its eco-friendly profile.

Water consumption and chemical usage in MCC production are areas that require careful consideration. While cellulose processing typically involves less toxic chemicals than synthetic polymer production, optimizing water use and implementing closed-loop systems for chemical recovery are crucial steps in improving the sustainability of MCC-based scaffold manufacturing.

The potential for recycling and reuse of MCC-based scaffolds is another significant sustainability aspect. In cases where scaffolds are not fully degraded or integrated into regenerated tissue, the remaining material could potentially be recovered and repurposed, further reducing waste and resource consumption.

From a life cycle assessment perspective, MCC-based scaffolds generally demonstrate a lower environmental impact compared to their synthetic counterparts. This includes reduced greenhouse gas emissions, lower ecotoxicity, and decreased depletion of non-renewable resources. However, comprehensive studies are needed to quantify these benefits across different production methods and applications.

The scalability of MCC production is an important factor in its long-term sustainability. As demand for tissue engineering scaffolds grows, ensuring a stable and sustainable supply of MCC without compromising natural ecosystems or competing with food production is crucial. This may involve developing more efficient cellulose extraction methods or exploring alternative biomass sources.

In conclusion, while MCC-based scaffolds offer numerous sustainability advantages, ongoing research and development are necessary to optimize their production processes, enhance their performance, and ensure their long-term viability as a sustainable solution in tissue engineering applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!