Sulphanilic Acid Derivatives as Potential Sensing Materials for Gas Detection

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sulphanilic Acid Derivatives: Background and Objectives

Sulphanilic acid derivatives have emerged as promising candidates for gas sensing materials, attracting significant attention in the field of environmental monitoring and industrial safety. These compounds, derived from sulphanilic acid, possess unique chemical properties that make them particularly suitable for detecting various gases. The development of these materials stems from the increasing demand for efficient, cost-effective, and reliable gas detection systems in diverse applications.

The primary objective of researching sulphanilic acid derivatives as potential sensing materials is to enhance the sensitivity, selectivity, and stability of gas detection devices. These materials offer several advantages over traditional sensing materials, including their versatility in detecting a wide range of gases, their ability to operate at room temperature, and their potential for miniaturization in sensor devices.

The evolution of sulphanilic acid derivatives for gas sensing applications can be traced back to the broader field of conducting polymers and organic semiconductors. As researchers explored new materials for electronic and sensing applications, the unique properties of sulphanilic acid and its derivatives began to gain recognition. The presence of both amino and sulfonic acid groups in these compounds provides a rich platform for chemical modifications, allowing tailored responses to specific gases.

One of the key drivers behind this research is the growing concern over air quality and the need for real-time monitoring of harmful gases in both indoor and outdoor environments. Sulphanilic acid derivatives show promise in detecting a variety of gases, including volatile organic compounds (VOCs), nitrogen oxides, and sulfur dioxide, which are common pollutants associated with industrial emissions and urban air pollution.

The research objectives in this field extend beyond merely developing new sensing materials. Scientists aim to understand the fundamental mechanisms of gas-material interactions, optimize the molecular structure of sulphanilic acid derivatives for enhanced performance, and explore novel fabrication techniques for integrating these materials into practical sensing devices.

Furthermore, the research seeks to address current limitations in gas sensing technology, such as cross-sensitivity issues, long-term stability, and the ability to function in complex gas mixtures. By focusing on sulphanilic acid derivatives, researchers hope to overcome these challenges and develop next-generation gas sensors that are more reliable, sensitive, and adaptable to various environmental conditions.

As the field progresses, there is also a growing interest in combining sulphanilic acid derivatives with other materials, such as metal oxides or carbon nanomaterials, to create hybrid sensing systems with enhanced capabilities. This interdisciplinary approach opens up new avenues for innovation and pushes the boundaries of what is possible in gas detection technology.

The primary objective of researching sulphanilic acid derivatives as potential sensing materials is to enhance the sensitivity, selectivity, and stability of gas detection devices. These materials offer several advantages over traditional sensing materials, including their versatility in detecting a wide range of gases, their ability to operate at room temperature, and their potential for miniaturization in sensor devices.

The evolution of sulphanilic acid derivatives for gas sensing applications can be traced back to the broader field of conducting polymers and organic semiconductors. As researchers explored new materials for electronic and sensing applications, the unique properties of sulphanilic acid and its derivatives began to gain recognition. The presence of both amino and sulfonic acid groups in these compounds provides a rich platform for chemical modifications, allowing tailored responses to specific gases.

One of the key drivers behind this research is the growing concern over air quality and the need for real-time monitoring of harmful gases in both indoor and outdoor environments. Sulphanilic acid derivatives show promise in detecting a variety of gases, including volatile organic compounds (VOCs), nitrogen oxides, and sulfur dioxide, which are common pollutants associated with industrial emissions and urban air pollution.

The research objectives in this field extend beyond merely developing new sensing materials. Scientists aim to understand the fundamental mechanisms of gas-material interactions, optimize the molecular structure of sulphanilic acid derivatives for enhanced performance, and explore novel fabrication techniques for integrating these materials into practical sensing devices.

Furthermore, the research seeks to address current limitations in gas sensing technology, such as cross-sensitivity issues, long-term stability, and the ability to function in complex gas mixtures. By focusing on sulphanilic acid derivatives, researchers hope to overcome these challenges and develop next-generation gas sensors that are more reliable, sensitive, and adaptable to various environmental conditions.

As the field progresses, there is also a growing interest in combining sulphanilic acid derivatives with other materials, such as metal oxides or carbon nanomaterials, to create hybrid sensing systems with enhanced capabilities. This interdisciplinary approach opens up new avenues for innovation and pushes the boundaries of what is possible in gas detection technology.

Gas Detection Market Analysis

The gas detection market has experienced significant growth in recent years, driven by increasing awareness of workplace safety, stringent government regulations, and the rising demand for environmental monitoring. The global gas detection market was valued at approximately $3.2 billion in 2020 and is projected to reach $4.9 billion by 2026, growing at a CAGR of 7.3% during the forecast period.

The market for gas detection technologies is segmented based on product type, technology, and end-user industry. Portable gas detectors dominate the market, accounting for over 60% of the total market share, due to their versatility and ease of use in various applications. Fixed gas detectors follow closely, with increasing adoption in industrial settings for continuous monitoring.

In terms of technology, electrochemical sensors hold the largest market share, followed by infrared sensors and photoionization detectors. However, the development of new sensing materials, such as sulphanilic acid derivatives, presents opportunities for innovation and market disruption.

The oil and gas industry remains the largest end-user segment for gas detection equipment, followed by chemical and petrochemical industries, mining, and wastewater treatment. Emerging applications in smart cities and indoor air quality monitoring are expected to drive further market growth.

Geographically, North America leads the gas detection market, followed by Europe and Asia-Pacific. The Asia-Pacific region is anticipated to witness the highest growth rate due to rapid industrialization, increasing safety regulations, and growing awareness of workplace hazards.

Key market trends include the integration of IoT and cloud-based technologies for real-time monitoring and data analytics, the development of multi-gas detectors for comprehensive safety solutions, and the increasing focus on miniaturization and portability of gas sensing devices.

The competitive landscape of the gas detection market is characterized by the presence of both established players and innovative startups. Major companies such as Honeywell International, MSA Safety, Drägerwerk, and Industrial Scientific Corporation dominate the market. However, there is growing interest in novel sensing materials and technologies, creating opportunities for new entrants and research-driven innovations.

The potential application of sulphanilic acid derivatives as sensing materials for gas detection aligns with the market's demand for improved sensitivity, selectivity, and stability in gas sensors. This research direction could address current limitations in gas detection technologies and potentially lead to the development of more efficient and cost-effective sensing solutions.

The market for gas detection technologies is segmented based on product type, technology, and end-user industry. Portable gas detectors dominate the market, accounting for over 60% of the total market share, due to their versatility and ease of use in various applications. Fixed gas detectors follow closely, with increasing adoption in industrial settings for continuous monitoring.

In terms of technology, electrochemical sensors hold the largest market share, followed by infrared sensors and photoionization detectors. However, the development of new sensing materials, such as sulphanilic acid derivatives, presents opportunities for innovation and market disruption.

The oil and gas industry remains the largest end-user segment for gas detection equipment, followed by chemical and petrochemical industries, mining, and wastewater treatment. Emerging applications in smart cities and indoor air quality monitoring are expected to drive further market growth.

Geographically, North America leads the gas detection market, followed by Europe and Asia-Pacific. The Asia-Pacific region is anticipated to witness the highest growth rate due to rapid industrialization, increasing safety regulations, and growing awareness of workplace hazards.

Key market trends include the integration of IoT and cloud-based technologies for real-time monitoring and data analytics, the development of multi-gas detectors for comprehensive safety solutions, and the increasing focus on miniaturization and portability of gas sensing devices.

The competitive landscape of the gas detection market is characterized by the presence of both established players and innovative startups. Major companies such as Honeywell International, MSA Safety, Drägerwerk, and Industrial Scientific Corporation dominate the market. However, there is growing interest in novel sensing materials and technologies, creating opportunities for new entrants and research-driven innovations.

The potential application of sulphanilic acid derivatives as sensing materials for gas detection aligns with the market's demand for improved sensitivity, selectivity, and stability in gas sensors. This research direction could address current limitations in gas detection technologies and potentially lead to the development of more efficient and cost-effective sensing solutions.

Current Challenges in Gas Sensing Technologies

Gas sensing technologies have made significant strides in recent years, yet several challenges persist in the development and implementation of effective gas detection systems. One of the primary obstacles is the lack of highly selective and sensitive sensing materials. Current sensors often struggle to differentiate between similar gas molecules, leading to false positives or missed detections in complex environments.

Stability and longevity of sensing materials pose another significant challenge. Many existing sensors suffer from drift over time, requiring frequent recalibration or replacement. This issue is particularly problematic in industrial settings where continuous, reliable monitoring is crucial for safety and process control.

The need for miniaturization and power efficiency presents additional hurdles. As the demand for portable and wearable gas sensors grows, researchers face the challenge of developing sensing materials that can operate effectively at room temperature with minimal power consumption. This requirement often conflicts with the need for high sensitivity and selectivity.

Cross-sensitivity to environmental factors such as humidity and temperature variations continues to be a major concern. These external influences can significantly affect sensor performance, leading to inaccurate readings and reduced reliability in real-world applications.

The development of multi-gas sensing capabilities remains a complex task. Many industrial and environmental monitoring scenarios require the simultaneous detection of multiple gases, necessitating the creation of sensor arrays or materials capable of responding differently to various analytes.

Response time is another critical factor that needs improvement. In safety-critical applications, rapid detection of hazardous gases is essential. However, many current sensing materials exhibit slow response and recovery times, limiting their effectiveness in dynamic environments.

Lastly, the cost-effectiveness of gas sensing technologies presents an ongoing challenge. While high-performance sensors exist, their widespread adoption is often hindered by prohibitive costs. Developing affordable yet reliable sensing materials is crucial for expanding the application of gas detection systems across various sectors.

Addressing these challenges requires interdisciplinary research efforts, combining materials science, nanotechnology, and chemical engineering. The exploration of novel materials, such as sulphanilic acid derivatives, holds promise in overcoming some of these limitations, potentially leading to more efficient, reliable, and versatile gas sensing technologies.

Stability and longevity of sensing materials pose another significant challenge. Many existing sensors suffer from drift over time, requiring frequent recalibration or replacement. This issue is particularly problematic in industrial settings where continuous, reliable monitoring is crucial for safety and process control.

The need for miniaturization and power efficiency presents additional hurdles. As the demand for portable and wearable gas sensors grows, researchers face the challenge of developing sensing materials that can operate effectively at room temperature with minimal power consumption. This requirement often conflicts with the need for high sensitivity and selectivity.

Cross-sensitivity to environmental factors such as humidity and temperature variations continues to be a major concern. These external influences can significantly affect sensor performance, leading to inaccurate readings and reduced reliability in real-world applications.

The development of multi-gas sensing capabilities remains a complex task. Many industrial and environmental monitoring scenarios require the simultaneous detection of multiple gases, necessitating the creation of sensor arrays or materials capable of responding differently to various analytes.

Response time is another critical factor that needs improvement. In safety-critical applications, rapid detection of hazardous gases is essential. However, many current sensing materials exhibit slow response and recovery times, limiting their effectiveness in dynamic environments.

Lastly, the cost-effectiveness of gas sensing technologies presents an ongoing challenge. While high-performance sensors exist, their widespread adoption is often hindered by prohibitive costs. Developing affordable yet reliable sensing materials is crucial for expanding the application of gas detection systems across various sectors.

Addressing these challenges requires interdisciplinary research efforts, combining materials science, nanotechnology, and chemical engineering. The exploration of novel materials, such as sulphanilic acid derivatives, holds promise in overcoming some of these limitations, potentially leading to more efficient, reliable, and versatile gas sensing technologies.

Existing Sulphanilic Acid-based Sensing Solutions

01 Synthesis of sulphanilic acid derivatives

Various methods for synthesizing sulphanilic acid derivatives are described. These processes involve different reaction conditions and starting materials to produce a range of sulphanilic acid-based compounds with potential sensing applications.- Synthesis of sulphanilic acid derivatives: Various methods for synthesizing sulphanilic acid derivatives are described. These processes involve different reaction conditions and starting materials to produce a range of sulphanilic acid-based compounds with potential sensing applications.

- Use of sulphanilic acid derivatives in colorimetric sensing: Sulphanilic acid derivatives are utilized in colorimetric sensing applications. These compounds can change color in response to specific analytes or environmental conditions, making them useful for visual detection and monitoring.

- Electrochemical sensors based on sulphanilic acid derivatives: Electrochemical sensors incorporating sulphanilic acid derivatives are developed for various analytical applications. These sensors exploit the electrochemical properties of sulphanilic acid-based compounds to detect and quantify specific analytes.

- Sulphanilic acid derivatives in optical sensing devices: Optical sensing devices utilizing sulphanilic acid derivatives are designed for diverse sensing applications. These compounds exhibit optical properties that change in response to specific stimuli, enabling their use in fluorescence-based or absorbance-based sensing systems.

- Functionalization of sulphanilic acid derivatives for enhanced sensing: Methods for functionalizing sulphanilic acid derivatives to enhance their sensing capabilities are described. These modifications can improve selectivity, sensitivity, or stability of the sensing compounds, expanding their potential applications in various sensing technologies.

02 Use of sulphanilic acid derivatives in colorimetric sensing

Sulphanilic acid derivatives are utilized in colorimetric sensing applications. These compounds can change color in response to specific analytes or environmental conditions, making them useful for visual detection and monitoring.Expand Specific Solutions03 Electrochemical sensors based on sulphanilic acid derivatives

Electrochemical sensors incorporating sulphanilic acid derivatives are developed for various analytical applications. These sensors exploit the electrochemical properties of sulphanilic acid-based compounds to detect and quantify specific analytes.Expand Specific Solutions04 Sulphanilic acid derivatives in optical sensing devices

Optical sensing devices utilizing sulphanilic acid derivatives are designed for diverse applications. These compounds exhibit unique optical properties that can be exploited for sensing purposes in fields such as environmental monitoring and biomedical diagnostics.Expand Specific Solutions05 Functionalization of sulphanilic acid derivatives for enhanced sensing

Methods for functionalizing sulphanilic acid derivatives to enhance their sensing capabilities are described. These modifications can improve selectivity, sensitivity, or other performance characteristics of the sensing compounds.Expand Specific Solutions

Key Players in Gas Detection Industry

The research on sulphanilic acid derivatives for gas detection is in an emerging phase, with a growing market driven by increasing environmental and safety concerns. The global gas sensors market is expected to reach significant growth in the coming years, indicating substantial potential for this technology. The field is characterized by a mix of established players and innovative startups, reflecting a competitive landscape in various stages of technological maturity. Companies like Riken Keiki, N5 Sensors, and Senseair are at the forefront of gas detection technology, while research institutions such as MIT, KAIST, and the Chinese Academy of Sciences are contributing to advancements in sensing materials. The involvement of major corporations like Honeywell and DuPont suggests the industry's recognition of the technology's potential, although full commercialization of sulphanilic acid derivatives for gas sensing is still in progress.

Riken Keiki Co., Ltd.

Technical Solution: Riken Keiki has developed gas detection systems utilizing sulphanilic acid derivatives as sensing materials. Their approach focuses on creating portable and fixed gas detectors for industrial safety applications. The company has engineered sulphanilic acid-based sensing elements that can be integrated into electrochemical sensors. These sensors operate by measuring the current generated when target gases react with the sensing material. Riken Keiki's technology allows for the detection of multiple gases, including hydrogen sulfide, carbon monoxide, and nitrogen dioxide, with high accuracy and fast response times[4]. The company has also implemented advanced signal processing algorithms to minimize false alarms and improve overall sensor reliability[5].

Strengths: Proven track record in industrial gas detection, robust sensor designs for harsh environments. Weaknesses: May be limited to specific gas types, potentially higher cost compared to simpler sensor technologies.

The Regents of the University of California

Technical Solution: The University of California has developed novel sulphanilic acid derivatives for gas sensing applications. Their approach involves synthesizing functionalized sulphanilic acid compounds with tailored side chains to enhance sensitivity and selectivity towards specific gases. The researchers have demonstrated the use of these materials in chemiresistive sensors, where changes in electrical conductivity upon gas adsorption are measured. Their studies have shown promising results for detecting volatile organic compounds (VOCs) and toxic gases at parts-per-billion (ppb) levels[1][3]. The team has also explored incorporating these derivatives into nanostructured materials, such as graphene and metal oxides, to further improve sensor performance[2].

Strengths: High sensitivity and selectivity, potential for detecting multiple gases, compatibility with existing sensor technologies. Weaknesses: May require complex synthesis processes, long-term stability needs further investigation.

Core Innovations in Sulphanilic Acid Derivatives

gas sensor

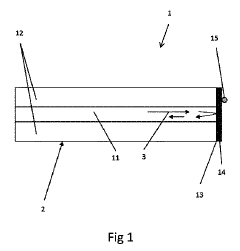

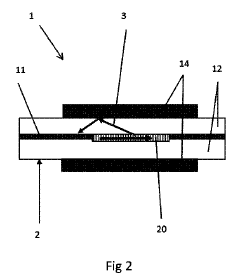

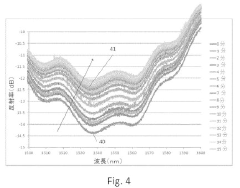

PatentInactiveJP2016539341A

Innovation

- An optical fiber-based gas sensor with a gas-sensitive detection material on its surface, utilizing a porous matrix and reversible optical properties for gas detection, which includes a porous silica matrix and lanthanide phthalocyanine reactants, allowing for rapid and reversible gas sensing.

Gas detection material

PatentWO2022044965A1

Innovation

- A gas detection material comprising porous glass with an alkaline nitrogen compound and a gas detection agent, such as vanillin, which reacts with aldehyde gases, maintaining high sensitivity by avoiding carbonate precipitate formation.

Environmental Impact of Gas Sensing Technologies

The environmental impact of gas sensing technologies, particularly those utilizing sulphanilic acid derivatives, is a crucial aspect to consider in the development and implementation of these systems. These sensing materials offer potential advantages in terms of sensitivity and selectivity for gas detection, but their environmental implications must be carefully evaluated.

One of the primary environmental concerns associated with gas sensing technologies is the production and disposal of sensing materials. Sulphanilic acid derivatives, while effective for gas detection, may pose challenges in terms of their synthesis and end-of-life management. The manufacturing process of these compounds often involves the use of various chemicals and solvents, which can contribute to air and water pollution if not properly managed. Additionally, the disposal of used or expired sensing materials may lead to soil contamination if not handled appropriately.

However, the environmental benefits of advanced gas sensing technologies should also be considered. Improved detection capabilities can lead to more efficient monitoring of air quality and early identification of harmful gas emissions. This, in turn, can contribute to better environmental management practices and reduced pollution levels. For instance, the ability to detect trace amounts of toxic gases in industrial settings can prevent accidental releases and minimize environmental damage.

The energy consumption of gas sensing devices is another important factor to consider. While sulphanilic acid derivatives may offer enhanced sensitivity, the overall energy efficiency of the sensing system must be evaluated. Low-power consumption devices can contribute to reduced carbon footprints and align with sustainable development goals. Research into optimizing the power requirements of these sensing technologies is ongoing and may lead to more environmentally friendly solutions.

Furthermore, the longevity and durability of gas sensing materials play a role in their environmental impact. Sulphanilic acid derivatives that demonstrate high stability and long operational lifetimes can reduce the frequency of sensor replacement, thereby minimizing waste generation and resource consumption. Efforts to improve the robustness of these sensing materials are essential for enhancing their environmental sustainability.

The potential for bioaccumulation and ecotoxicity of sulphanilic acid derivatives and their degradation products should also be thoroughly investigated. While these compounds are designed for specific sensing applications, their potential release into the environment through wear, leaching, or improper disposal must be considered. Comprehensive studies on their environmental fate and effects on ecosystems are necessary to ensure that the benefits of improved gas detection do not come at the cost of ecological harm.

One of the primary environmental concerns associated with gas sensing technologies is the production and disposal of sensing materials. Sulphanilic acid derivatives, while effective for gas detection, may pose challenges in terms of their synthesis and end-of-life management. The manufacturing process of these compounds often involves the use of various chemicals and solvents, which can contribute to air and water pollution if not properly managed. Additionally, the disposal of used or expired sensing materials may lead to soil contamination if not handled appropriately.

However, the environmental benefits of advanced gas sensing technologies should also be considered. Improved detection capabilities can lead to more efficient monitoring of air quality and early identification of harmful gas emissions. This, in turn, can contribute to better environmental management practices and reduced pollution levels. For instance, the ability to detect trace amounts of toxic gases in industrial settings can prevent accidental releases and minimize environmental damage.

The energy consumption of gas sensing devices is another important factor to consider. While sulphanilic acid derivatives may offer enhanced sensitivity, the overall energy efficiency of the sensing system must be evaluated. Low-power consumption devices can contribute to reduced carbon footprints and align with sustainable development goals. Research into optimizing the power requirements of these sensing technologies is ongoing and may lead to more environmentally friendly solutions.

Furthermore, the longevity and durability of gas sensing materials play a role in their environmental impact. Sulphanilic acid derivatives that demonstrate high stability and long operational lifetimes can reduce the frequency of sensor replacement, thereby minimizing waste generation and resource consumption. Efforts to improve the robustness of these sensing materials are essential for enhancing their environmental sustainability.

The potential for bioaccumulation and ecotoxicity of sulphanilic acid derivatives and their degradation products should also be thoroughly investigated. While these compounds are designed for specific sensing applications, their potential release into the environment through wear, leaching, or improper disposal must be considered. Comprehensive studies on their environmental fate and effects on ecosystems are necessary to ensure that the benefits of improved gas detection do not come at the cost of ecological harm.

Regulatory Framework for Gas Detection Devices

The regulatory framework for gas detection devices plays a crucial role in ensuring the safety and reliability of these instruments across various industries. In the context of sulphanilic acid derivatives as potential sensing materials, it is essential to consider the existing regulations and standards that govern the development, manufacturing, and deployment of gas detection systems.

At the international level, organizations such as the International Electrotechnical Commission (IEC) and the International Organization for Standardization (ISO) have established comprehensive guidelines for gas detection equipment. These standards, including IEC 60079 for explosive atmospheres and ISO 26142 for hydrogen detection apparatus, provide a foundation for the design and performance requirements of gas sensors.

In the United States, the Occupational Safety and Health Administration (OSHA) mandates the use of gas detection devices in certain workplace environments. OSHA's regulations, particularly 29 CFR 1910.146 for confined spaces, outline the requirements for gas monitoring equipment. Additionally, the National Fire Protection Association (NFPA) sets standards for gas detection in specific applications, such as NFPA 72 for fire alarm systems.

The European Union has implemented the ATEX Directive (2014/34/EU) for equipment used in potentially explosive atmospheres, which includes gas detection devices. This directive ensures that products meet essential health and safety requirements before being placed on the market. Furthermore, the EU's Measuring Instruments Directive (MID) 2014/32/EU applies to certain gas meters used for billing purposes.

In the context of sulphanilic acid derivatives, researchers and manufacturers must consider these regulatory frameworks when developing new sensing materials. The materials must demonstrate compliance with sensitivity, selectivity, and response time requirements specified in relevant standards. Moreover, they should meet the performance criteria for different environmental conditions and gas concentrations as outlined in regulatory documents.

Certification processes play a vital role in the regulatory landscape. Notified bodies and testing laboratories, such as UL (Underwriters Laboratories) and TÜV, conduct rigorous evaluations to ensure gas detection devices meet the necessary safety and performance standards. For novel sensing materials like sulphanilic acid derivatives, obtaining these certifications may require extensive testing and documentation.

As environmental concerns grow, regulations are evolving to address emerging gases and pollutants. For instance, the U.S. Environmental Protection Agency (EPA) has established monitoring requirements for various air toxics under the Clean Air Act. These regulations may influence the development of new sensing materials capable of detecting a broader range of gases with higher accuracy and lower detection limits.

At the international level, organizations such as the International Electrotechnical Commission (IEC) and the International Organization for Standardization (ISO) have established comprehensive guidelines for gas detection equipment. These standards, including IEC 60079 for explosive atmospheres and ISO 26142 for hydrogen detection apparatus, provide a foundation for the design and performance requirements of gas sensors.

In the United States, the Occupational Safety and Health Administration (OSHA) mandates the use of gas detection devices in certain workplace environments. OSHA's regulations, particularly 29 CFR 1910.146 for confined spaces, outline the requirements for gas monitoring equipment. Additionally, the National Fire Protection Association (NFPA) sets standards for gas detection in specific applications, such as NFPA 72 for fire alarm systems.

The European Union has implemented the ATEX Directive (2014/34/EU) for equipment used in potentially explosive atmospheres, which includes gas detection devices. This directive ensures that products meet essential health and safety requirements before being placed on the market. Furthermore, the EU's Measuring Instruments Directive (MID) 2014/32/EU applies to certain gas meters used for billing purposes.

In the context of sulphanilic acid derivatives, researchers and manufacturers must consider these regulatory frameworks when developing new sensing materials. The materials must demonstrate compliance with sensitivity, selectivity, and response time requirements specified in relevant standards. Moreover, they should meet the performance criteria for different environmental conditions and gas concentrations as outlined in regulatory documents.

Certification processes play a vital role in the regulatory landscape. Notified bodies and testing laboratories, such as UL (Underwriters Laboratories) and TÜV, conduct rigorous evaluations to ensure gas detection devices meet the necessary safety and performance standards. For novel sensing materials like sulphanilic acid derivatives, obtaining these certifications may require extensive testing and documentation.

As environmental concerns grow, regulations are evolving to address emerging gases and pollutants. For instance, the U.S. Environmental Protection Agency (EPA) has established monitoring requirements for various air toxics under the Clean Air Act. These regulations may influence the development of new sensing materials capable of detecting a broader range of gases with higher accuracy and lower detection limits.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!