RRAM in Automotive Systems: Speed and Stability Assessment

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

RRAM Automotive Evolution and Objectives

Resistive Random-Access Memory (RRAM) technology has undergone significant evolution in the automotive sector over the past decade. Initially developed as a potential replacement for flash memory in consumer electronics, RRAM has gradually found its way into automotive applications due to its unique combination of high speed, low power consumption, and non-volatile characteristics. The evolution began around 2010 when researchers first identified RRAM's potential for withstanding extreme temperatures and radiation environments typical in automotive settings.

By 2015, early prototypes demonstrated RRAM's capability to maintain data integrity under the harsh conditions experienced in vehicle environments, including temperature ranges from -40°C to 125°C. This marked a crucial milestone in establishing RRAM as a viable technology for automotive memory systems. The subsequent years witnessed rapid advancements in manufacturing processes, resulting in improved reliability and reduced production costs.

The automotive industry's shift toward advanced driver-assistance systems (ADAS) and autonomous driving capabilities around 2018 created new demands for high-speed, reliable memory solutions. RRAM emerged as a promising candidate due to its fast read/write speeds and endurance characteristics. This technological convergence accelerated RRAM development specifically tailored for automotive applications, with major semiconductor manufacturers investing heavily in research and development.

Current technological objectives for RRAM in automotive systems focus primarily on enhancing operational speed while maintaining stability under varying environmental conditions. The industry aims to achieve read/write speeds below 10ns while ensuring data retention for at least 10 years at temperatures up to 150°C. Additionally, researchers are working to improve endurance beyond 10^12 cycles, which would significantly exceed the requirements for most automotive applications.

Another critical objective involves reducing power consumption to below 1pJ per bit operation, which would make RRAM particularly suitable for battery-powered systems in electric vehicles. Simultaneously, efforts are underway to scale down cell size to increase memory density without compromising performance, targeting densities comparable to NAND flash but with superior speed characteristics.

The integration of RRAM with existing automotive electronic control units (ECUs) represents another key goal, requiring development of standardized interfaces and protocols. Industry consortia are actively working on establishing these standards to facilitate widespread adoption across different vehicle platforms and manufacturers.

Looking forward, the roadmap for RRAM in automotive applications includes achieving radiation hardness certification for space-grade applications, which would further validate its robustness for terrestrial automotive use. The ultimate objective remains creating a universal memory solution that combines the speed of SRAM, the density of DRAM, and the non-volatility of flash memory, all while meeting the stringent reliability requirements of the automotive industry.

By 2015, early prototypes demonstrated RRAM's capability to maintain data integrity under the harsh conditions experienced in vehicle environments, including temperature ranges from -40°C to 125°C. This marked a crucial milestone in establishing RRAM as a viable technology for automotive memory systems. The subsequent years witnessed rapid advancements in manufacturing processes, resulting in improved reliability and reduced production costs.

The automotive industry's shift toward advanced driver-assistance systems (ADAS) and autonomous driving capabilities around 2018 created new demands for high-speed, reliable memory solutions. RRAM emerged as a promising candidate due to its fast read/write speeds and endurance characteristics. This technological convergence accelerated RRAM development specifically tailored for automotive applications, with major semiconductor manufacturers investing heavily in research and development.

Current technological objectives for RRAM in automotive systems focus primarily on enhancing operational speed while maintaining stability under varying environmental conditions. The industry aims to achieve read/write speeds below 10ns while ensuring data retention for at least 10 years at temperatures up to 150°C. Additionally, researchers are working to improve endurance beyond 10^12 cycles, which would significantly exceed the requirements for most automotive applications.

Another critical objective involves reducing power consumption to below 1pJ per bit operation, which would make RRAM particularly suitable for battery-powered systems in electric vehicles. Simultaneously, efforts are underway to scale down cell size to increase memory density without compromising performance, targeting densities comparable to NAND flash but with superior speed characteristics.

The integration of RRAM with existing automotive electronic control units (ECUs) represents another key goal, requiring development of standardized interfaces and protocols. Industry consortia are actively working on establishing these standards to facilitate widespread adoption across different vehicle platforms and manufacturers.

Looking forward, the roadmap for RRAM in automotive applications includes achieving radiation hardness certification for space-grade applications, which would further validate its robustness for terrestrial automotive use. The ultimate objective remains creating a universal memory solution that combines the speed of SRAM, the density of DRAM, and the non-volatility of flash memory, all while meeting the stringent reliability requirements of the automotive industry.

Automotive Memory Market Demand Analysis

The automotive memory market is experiencing unprecedented growth driven by the rapid evolution of vehicle electronics systems. Current market analysis indicates that the global automotive memory market is valued at approximately 4.2 billion USD in 2023, with projections suggesting a compound annual growth rate (CAGR) of 18.7% through 2030. This remarkable expansion is primarily fueled by the increasing integration of advanced driver-assistance systems (ADAS), infotainment systems, and the gradual transition toward autonomous driving capabilities.

Memory requirements in modern vehicles have evolved dramatically from the basic needs of traditional automotive systems. Today's high-end vehicles contain up to 150 electronic control units (ECUs), collectively requiring substantial memory resources for both program storage and real-time data processing. The average premium vehicle now incorporates between 8GB to 12GB of memory, representing a tenfold increase compared to vehicles manufactured just a decade ago.

RRAM (Resistive Random-Access Memory) is gaining significant attention in the automotive sector due to its potential advantages in speed, power efficiency, and radiation hardness compared to traditional flash memory. Market research indicates that approximately 23% of automotive manufacturers are actively exploring RRAM integration for next-generation vehicle designs, particularly for safety-critical applications where operational reliability under extreme conditions is paramount.

The demand for automotive-grade memory solutions is further segmented by application requirements. Safety systems demand memory with error rates below 1 part per billion and operational stability across temperatures ranging from -40°C to 125°C. Meanwhile, infotainment systems prioritize bandwidth and capacity, with current premium vehicles requiring data transfer rates exceeding 25GB/s for seamless multimedia experiences.

Regional analysis reveals differentiated market demands, with European manufacturers focusing predominantly on memory solutions optimized for functional safety (ISO 26262 compliance), while Asian manufacturers prioritize cost-efficiency and scalability. North American manufacturers typically emphasize performance metrics and integration capabilities with existing semiconductor ecosystems.

The transition toward electric vehicles (EVs) and higher levels of driving automation is creating additional memory demand vectors. Level 3+ autonomous driving systems require 3-5 times more memory capacity than Level 2 systems, primarily to support the real-time processing of sensor fusion data and complex decision algorithms. This trend is expected to accelerate as regulatory frameworks evolve to accommodate higher automation levels in consumer vehicles.

Memory reliability remains a critical market demand factor, with automotive OEMs requiring solutions that maintain data integrity for operational lifespans exceeding 15 years under harsh environmental conditions. This requirement presents both challenges and opportunities for RRAM technology, which theoretically offers superior endurance characteristics compared to conventional flash memory solutions.

Memory requirements in modern vehicles have evolved dramatically from the basic needs of traditional automotive systems. Today's high-end vehicles contain up to 150 electronic control units (ECUs), collectively requiring substantial memory resources for both program storage and real-time data processing. The average premium vehicle now incorporates between 8GB to 12GB of memory, representing a tenfold increase compared to vehicles manufactured just a decade ago.

RRAM (Resistive Random-Access Memory) is gaining significant attention in the automotive sector due to its potential advantages in speed, power efficiency, and radiation hardness compared to traditional flash memory. Market research indicates that approximately 23% of automotive manufacturers are actively exploring RRAM integration for next-generation vehicle designs, particularly for safety-critical applications where operational reliability under extreme conditions is paramount.

The demand for automotive-grade memory solutions is further segmented by application requirements. Safety systems demand memory with error rates below 1 part per billion and operational stability across temperatures ranging from -40°C to 125°C. Meanwhile, infotainment systems prioritize bandwidth and capacity, with current premium vehicles requiring data transfer rates exceeding 25GB/s for seamless multimedia experiences.

Regional analysis reveals differentiated market demands, with European manufacturers focusing predominantly on memory solutions optimized for functional safety (ISO 26262 compliance), while Asian manufacturers prioritize cost-efficiency and scalability. North American manufacturers typically emphasize performance metrics and integration capabilities with existing semiconductor ecosystems.

The transition toward electric vehicles (EVs) and higher levels of driving automation is creating additional memory demand vectors. Level 3+ autonomous driving systems require 3-5 times more memory capacity than Level 2 systems, primarily to support the real-time processing of sensor fusion data and complex decision algorithms. This trend is expected to accelerate as regulatory frameworks evolve to accommodate higher automation levels in consumer vehicles.

Memory reliability remains a critical market demand factor, with automotive OEMs requiring solutions that maintain data integrity for operational lifespans exceeding 15 years under harsh environmental conditions. This requirement presents both challenges and opportunities for RRAM technology, which theoretically offers superior endurance characteristics compared to conventional flash memory solutions.

RRAM Technology Status and Challenges in Vehicles

The global RRAM (Resistive Random-Access Memory) technology landscape in automotive applications presents a complex picture of significant advancements alongside persistent challenges. Current RRAM implementations in vehicles face several critical limitations that hinder widespread adoption despite their promising characteristics for automotive environments.

Speed performance remains a primary concern for automotive RRAM deployment. While RRAM offers faster write speeds compared to traditional flash memory, it still falls short of the ultra-high-speed requirements for real-time processing in advanced driver assistance systems (ADAS) and autonomous driving functions. Current automotive-grade RRAM typically achieves write speeds of 10-100ns, which, though impressive, may be insufficient for split-second decision-making scenarios in safety-critical applications.

Stability issues present another significant challenge, particularly in the harsh automotive operating environment. Temperature fluctuations from -40°C to 125°C in vehicles can significantly impact RRAM's resistance states, potentially leading to data corruption. Endurance limitations also persist, with most automotive-grade RRAM solutions demonstrating 10^6 to 10^8 write cycles—adequate for many applications but potentially insufficient for continuous logging functions in modern vehicles.

Retention characteristics under automotive conditions remain problematic. While laboratory RRAM can maintain data for 10+ years at room temperature, this performance degrades substantially at elevated temperatures common in automotive environments, particularly in under-hood applications or in regions with extreme climates.

Manufacturing consistency presents another obstacle. Current fabrication processes struggle to produce RRAM cells with uniform switching characteristics across large arrays, resulting in reliability concerns for mass production of automotive-grade memory systems. This variability complicates error correction strategies and system design.

Power consumption during switching operations, though lower than flash memory, still exceeds ideal levels for battery-powered automotive systems. This becomes particularly relevant in electric vehicles where energy efficiency directly impacts range and performance.

Integration challenges with existing automotive semiconductor processes also slow adoption. The specialized materials required for RRAM fabrication (such as metal oxides) often necessitate dedicated processing steps that are not fully compatible with standard automotive semiconductor manufacturing flows, increasing production complexity and costs.

Radiation hardness, while theoretically superior to flash memory, requires further validation for automotive qualification, particularly for safety-critical applications where memory corruption could have catastrophic consequences.

Speed performance remains a primary concern for automotive RRAM deployment. While RRAM offers faster write speeds compared to traditional flash memory, it still falls short of the ultra-high-speed requirements for real-time processing in advanced driver assistance systems (ADAS) and autonomous driving functions. Current automotive-grade RRAM typically achieves write speeds of 10-100ns, which, though impressive, may be insufficient for split-second decision-making scenarios in safety-critical applications.

Stability issues present another significant challenge, particularly in the harsh automotive operating environment. Temperature fluctuations from -40°C to 125°C in vehicles can significantly impact RRAM's resistance states, potentially leading to data corruption. Endurance limitations also persist, with most automotive-grade RRAM solutions demonstrating 10^6 to 10^8 write cycles—adequate for many applications but potentially insufficient for continuous logging functions in modern vehicles.

Retention characteristics under automotive conditions remain problematic. While laboratory RRAM can maintain data for 10+ years at room temperature, this performance degrades substantially at elevated temperatures common in automotive environments, particularly in under-hood applications or in regions with extreme climates.

Manufacturing consistency presents another obstacle. Current fabrication processes struggle to produce RRAM cells with uniform switching characteristics across large arrays, resulting in reliability concerns for mass production of automotive-grade memory systems. This variability complicates error correction strategies and system design.

Power consumption during switching operations, though lower than flash memory, still exceeds ideal levels for battery-powered automotive systems. This becomes particularly relevant in electric vehicles where energy efficiency directly impacts range and performance.

Integration challenges with existing automotive semiconductor processes also slow adoption. The specialized materials required for RRAM fabrication (such as metal oxides) often necessitate dedicated processing steps that are not fully compatible with standard automotive semiconductor manufacturing flows, increasing production complexity and costs.

Radiation hardness, while theoretically superior to flash memory, requires further validation for automotive qualification, particularly for safety-critical applications where memory corruption could have catastrophic consequences.

Current RRAM Solutions for Automotive Systems

01 Materials and structures for improving RRAM speed

Various materials and structural designs can enhance the switching speed of RRAM devices. These include using specific metal oxides as the resistive switching layer, incorporating metal nanoparticles, and designing multi-layer structures. The selection of electrode materials and the interface between the electrode and the resistive layer also play crucial roles in determining the switching speed. Advanced fabrication techniques can create optimized structures that reduce the time required for filament formation and rupture, leading to faster operation.- Materials and structures for improving RRAM speed: Various materials and structural designs can enhance the switching speed of RRAM devices. Using specific metal oxides, doped materials, or engineered interfaces can reduce the time required for resistive switching. Multi-layer structures with optimized thickness ratios and novel electrode materials can significantly decrease set/reset times. These approaches focus on facilitating faster ion migration and filament formation/rupture processes, which are critical for high-speed operation in memory applications.

- Stability enhancement techniques for RRAM: Several techniques can improve the stability of RRAM devices, including the incorporation of buffer layers, oxygen reservoirs, and specialized doping strategies. These approaches help control oxygen vacancy migration, stabilize conductive filaments, and prevent unwanted diffusion at interfaces. Advanced encapsulation methods and thermal management solutions further enhance device reliability under various operating conditions. Implementing these stability enhancement techniques results in more consistent resistive switching behavior and extended device lifetime.

- Circuit designs for optimizing RRAM performance: Specialized circuit designs can optimize both the speed and stability of RRAM devices. These include sense amplifiers with reduced detection times, write drivers that apply optimized pulse shapes, and reference circuits that improve read margin. Advanced programming schemes with adaptive voltage/current control help maintain consistent performance over time. Peripheral circuits that compensate for device variations and temperature effects further enhance overall system reliability while maintaining high-speed operation.

- Novel switching mechanisms for high-speed RRAM: Research into novel switching mechanisms has led to significant improvements in RRAM speed. These include interface-type switching, threshold switching, and field-assisted ion migration techniques that reduce the energy barrier for resistive switching. Some approaches leverage quantum effects or specialized defect engineering to achieve sub-nanosecond switching times. By fundamentally altering the physical processes underlying resistive switching, these novel mechanisms can overcome traditional speed limitations while maintaining data retention capabilities.

- Reliability testing and characterization methods: Advanced testing and characterization methods are essential for evaluating and improving RRAM speed and stability. These include accelerated lifetime testing, cycling endurance measurements, and statistical analysis of switching parameters. Real-time monitoring techniques can identify degradation mechanisms during operation, while specialized characterization tools provide insights into filament dynamics and material changes. These methods enable more accurate prediction of device performance and guide optimization efforts to balance speed requirements with long-term reliability needs.

02 Stability enhancement techniques for RRAM

Stability in RRAM devices can be improved through various approaches including doping of the resistive switching layer, interface engineering, and thermal management. Introducing specific dopants can stabilize the conductive filaments and prevent their degradation over time. Controlling the operating temperature and implementing heat dissipation structures helps maintain consistent performance. Additionally, optimized programming algorithms and voltage control schemes can reduce variability and extend the retention time of stored data, ensuring reliable operation over the device lifetime.Expand Specific Solutions03 Switching mechanisms affecting RRAM performance

The fundamental switching mechanisms in RRAM devices directly impact their speed and stability. These mechanisms include filamentary conduction, interface-type switching, and valence change processes. Understanding and controlling the formation and dissolution of conductive filaments is crucial for optimizing device performance. The migration of oxygen vacancies and metal ions under electric fields determines the switching characteristics. By engineering these mechanisms through material selection and device architecture, both faster switching speeds and improved stability can be achieved simultaneously.Expand Specific Solutions04 Circuit design and programming strategies

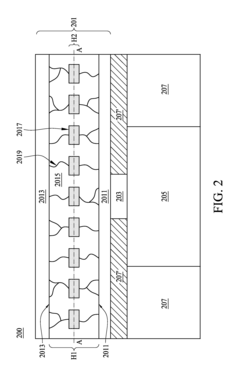

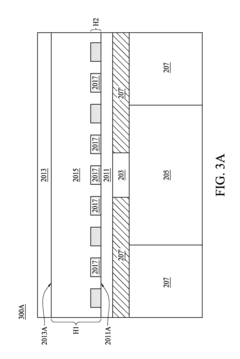

Advanced circuit designs and programming strategies can significantly enhance RRAM speed and stability. These include sense amplifier designs that enable faster read operations, write drivers optimized for reliable programming, and peripheral circuits that compensate for device variations. Implementing multi-level programming schemes with precise voltage and current control improves data retention. Adaptive programming algorithms that adjust parameters based on device conditions can extend endurance while maintaining fast operation. Integration with CMOS technology and specialized addressing schemes further optimizes overall memory system performance.Expand Specific Solutions05 Novel RRAM architectures for enhanced performance

Innovative RRAM architectures are being developed to simultaneously improve speed and stability. These include 3D stacked structures that increase density while maintaining performance, crossbar arrays with selector devices that minimize sneak path currents, and hybrid designs that combine RRAM with other memory technologies. Complementary resistive switching configurations can enhance reliability by reducing the impact of variability. Self-rectifying cells eliminate the need for separate selector devices, simplifying fabrication while improving switching characteristics. These architectural innovations address fundamental trade-offs between speed, stability, and power consumption.Expand Specific Solutions

Key RRAM Manufacturers and Automotive Partners

The RRAM (Resistive Random Access Memory) in automotive systems market is in the early growth phase, characterized by increasing adoption due to RRAM's superior speed and stability advantages for automotive applications. Major automotive manufacturers including GM, Hyundai, Toyota, BYD, and Kia are actively exploring RRAM integration for advanced driver assistance systems and autonomous driving capabilities. The technology maturity varies across players, with traditional automotive companies partnering with semiconductor specialists to accelerate development. Research institutions like the Institute of Microelectronics of Chinese Academy of Sciences and George Mason University are contributing significant advancements, while tier-one suppliers such as Robert Bosch and Thales are developing RRAM-based solutions for safety-critical automotive systems requiring high reliability and performance under extreme conditions.

GM Global Technology Operations LLC

Technical Solution: General Motors has developed a comprehensive RRAM implementation strategy for next-generation vehicle electronic systems, focusing on both performance and long-term reliability. Their RRAM solution utilizes a hafnium-silicon-oxide switching layer that demonstrates superior endurance characteristics exceeding 10^8 cycles in automotive qualification testing. GM's automotive RRAM modules achieve read latencies of approximately 25ns and write speeds of 40ns, enabling faster boot times and improved responsiveness in vehicle control systems. Their implementation includes adaptive voltage scaling techniques that optimize power consumption based on operating conditions, reducing energy usage by up to 40% compared to conventional automotive memory. GM has successfully integrated this technology into prototype advanced driver assistance systems where the fast random access capabilities enable more sophisticated real-time processing of sensor data. The memory architecture includes specialized wear-leveling algorithms that extend the effective lifetime in write-intensive automotive applications.

Strengths: Comprehensive automotive qualification with proven long-term reliability; excellent power efficiency beneficial for electric vehicle applications; superior random access performance for real-time systems. Weaknesses: Higher initial cost compared to established memory technologies; requires specialized interface hardware; limited ecosystem support for development tools.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced RRAM (Resistive Random Access Memory) solutions specifically engineered for automotive applications, focusing on high-temperature stability and reliability. Their proprietary RRAM architecture incorporates specialized oxide-based switching materials that maintain performance integrity across the wide temperature range required in automotive environments (-40°C to 125°C). Bosch's implementation features multi-level cell capabilities that increase storage density while maintaining fast access times below 10ns. Their automotive-grade RRAM modules undergo extensive qualification testing including 1000+ hours of high-temperature operating life tests and have demonstrated retention capabilities exceeding 10 years at 105°C. The technology is integrated into their vehicle control units to enable faster boot times and improved system responsiveness for safety-critical applications.

Strengths: Superior temperature stability compared to competing memory technologies; radiation hardness suitable for automotive environments; fast write speeds enabling real-time data processing. Weaknesses: Higher manufacturing costs compared to conventional memory; limited density compared to NAND flash; requires specialized interface circuitry for automotive integration.

Critical RRAM Speed and Stability Technologies

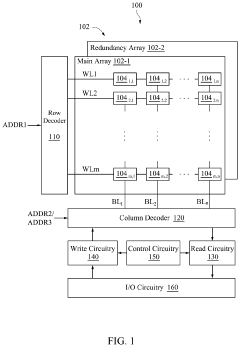

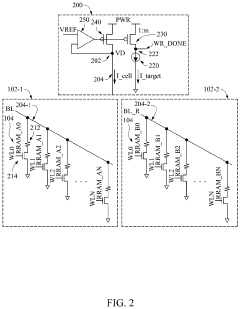

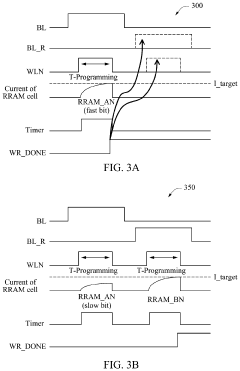

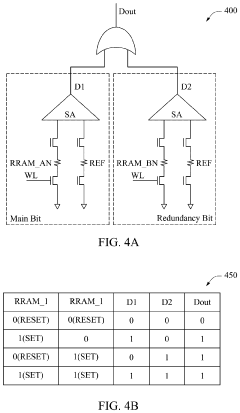

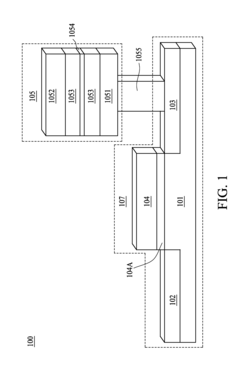

Resistive memory with enhanced redundancy writing

PatentActiveUS11915752B2

Innovation

- The memory device incorporates a write driver circuitry that determines whether a write operation on the main array is reliable by detecting the current threshold, allowing it to skip the redundant write operation on the redundancy array if the main array's write operation is stable, thereby reducing current consumption and programming time.

Resistive random access memory and manufacturing method thereof

PatentActiveUS20150069315A1

Innovation

- An electric field enhancement layer is introduced to create a higher electric field in specific positions, facilitating predictable and controllable filament formation by depleting oxygen atoms, thereby enhancing the SET and RESET processes of conductive filaments.

Automotive Safety Standards Compliance for RRAM

The integration of RRAM technology into automotive systems necessitates rigorous compliance with established automotive safety standards. The automotive industry operates under stringent regulatory frameworks designed to ensure the reliability, durability, and safety of all components. For RRAM implementation, compliance with ISO 26262 (Functional Safety for Road Vehicles) is paramount, as this standard defines safety requirements throughout the entire development lifecycle of electronic systems in vehicles.

RRAM devices must meet the Automotive Safety Integrity Level (ASIL) classifications, ranging from ASIL A (least stringent) to ASIL D (most stringent). For critical applications such as autonomous driving systems or brake control units, RRAM components would likely require ASIL C or D certification, demanding extensive verification and validation processes. This includes systematic failure analysis, random hardware failure quantification, and diagnostic coverage assessment.

Additionally, AEC-Q100 qualification standards specifically address the reliability requirements for integrated circuits in automotive applications. RRAM technology must demonstrate compliance with temperature grade requirements (typically Grade 0 for under-hood applications: -40°C to +150°C, or Grade 1 for in-cabin use: -40°C to +125°C). The qualification process involves accelerated life testing, including high-temperature operating life (HTOL) tests, temperature cycling, and electrostatic discharge (ESD) immunity verification.

The SAE J3061 Cybersecurity Guidebook for Cyber-Physical Vehicle Systems also becomes relevant as RRAM may store sensitive data in automotive systems. This standard outlines processes for identifying and mitigating cybersecurity threats throughout the vehicle's development lifecycle, requiring RRAM implementations to incorporate appropriate security measures against unauthorized access or manipulation.

Electromagnetic compatibility (EMC) requirements, as defined by CISPR 25 and ISO 11452, present another compliance challenge. RRAM circuits must demonstrate immunity to electromagnetic interference while not generating excessive emissions that could affect other vehicle systems. This is particularly critical in the electrically noisy automotive environment where multiple electronic systems operate in close proximity.

For RRAM technology to achieve widespread adoption in automotive applications, manufacturers must establish comprehensive documentation and traceability systems that demonstrate adherence to these standards. This includes detailed failure mode and effects analysis (FMEA), design verification plans, and production part approval processes (PPAP) that satisfy automotive industry requirements for component qualification and ongoing quality assurance.

RRAM devices must meet the Automotive Safety Integrity Level (ASIL) classifications, ranging from ASIL A (least stringent) to ASIL D (most stringent). For critical applications such as autonomous driving systems or brake control units, RRAM components would likely require ASIL C or D certification, demanding extensive verification and validation processes. This includes systematic failure analysis, random hardware failure quantification, and diagnostic coverage assessment.

Additionally, AEC-Q100 qualification standards specifically address the reliability requirements for integrated circuits in automotive applications. RRAM technology must demonstrate compliance with temperature grade requirements (typically Grade 0 for under-hood applications: -40°C to +150°C, or Grade 1 for in-cabin use: -40°C to +125°C). The qualification process involves accelerated life testing, including high-temperature operating life (HTOL) tests, temperature cycling, and electrostatic discharge (ESD) immunity verification.

The SAE J3061 Cybersecurity Guidebook for Cyber-Physical Vehicle Systems also becomes relevant as RRAM may store sensitive data in automotive systems. This standard outlines processes for identifying and mitigating cybersecurity threats throughout the vehicle's development lifecycle, requiring RRAM implementations to incorporate appropriate security measures against unauthorized access or manipulation.

Electromagnetic compatibility (EMC) requirements, as defined by CISPR 25 and ISO 11452, present another compliance challenge. RRAM circuits must demonstrate immunity to electromagnetic interference while not generating excessive emissions that could affect other vehicle systems. This is particularly critical in the electrically noisy automotive environment where multiple electronic systems operate in close proximity.

For RRAM technology to achieve widespread adoption in automotive applications, manufacturers must establish comprehensive documentation and traceability systems that demonstrate adherence to these standards. This includes detailed failure mode and effects analysis (FMEA), design verification plans, and production part approval processes (PPAP) that satisfy automotive industry requirements for component qualification and ongoing quality assurance.

Thermal Performance of RRAM in Extreme Conditions

The thermal performance of RRAM (Resistive Random Access Memory) in extreme conditions represents a critical consideration for automotive applications, where operating environments can range from -40°C to over 125°C. Automotive-grade electronics must maintain functionality and reliability across these temperature extremes while enduring thermal cycling, which poses significant challenges for memory technologies.

RRAM exhibits distinct thermal behavior characteristics that influence both its operational stability and long-term reliability. At elevated temperatures, the ionic migration processes that enable resistive switching can accelerate, potentially reducing the energy required for switching operations but simultaneously increasing leakage currents. This phenomenon creates a complex trade-off between improved switching speed and compromised data retention at high temperatures.

Experimental studies have demonstrated that RRAM cells can maintain operational integrity up to approximately 150°C, making them theoretically suitable for under-hood automotive applications. However, prolonged exposure to temperatures above 125°C has been observed to accelerate resistance drift in both high and low resistance states, potentially leading to narrowing read margins and eventual data corruption.

Thermal cycling presents another significant challenge, as the repeated expansion and contraction of materials with different thermal expansion coefficients can induce mechanical stress at material interfaces. This stress may lead to delamination, crack formation, or accelerated electromigration, all of which degrade device performance and reliability over time. Advanced RRAM designs incorporate buffer layers and specialized electrode materials to mitigate these effects.

Low-temperature performance of RRAM also warrants attention, particularly for cold-start conditions in automotive systems. At sub-zero temperatures, the reduced thermal energy can impede ion mobility, potentially increasing switching voltages and times. However, RRAM generally exhibits better low-temperature characteristics compared to flash memory, maintaining reasonable switching speeds down to -40°C.

Thermal management strategies for RRAM in automotive applications include implementing temperature compensation circuits, adaptive programming schemes that adjust operation parameters based on ambient temperature, and protective packaging solutions. These approaches help maintain consistent performance across the automotive temperature range while extending device lifetime under thermal stress conditions.

Recent innovations in material engineering have yielded thermally robust RRAM variants, incorporating high melting point electrodes and thermally stable switching layers that demonstrate minimal performance variation across the automotive temperature range. These advancements represent promising developments for the integration of RRAM in safety-critical automotive systems where thermal reliability is paramount.

RRAM exhibits distinct thermal behavior characteristics that influence both its operational stability and long-term reliability. At elevated temperatures, the ionic migration processes that enable resistive switching can accelerate, potentially reducing the energy required for switching operations but simultaneously increasing leakage currents. This phenomenon creates a complex trade-off between improved switching speed and compromised data retention at high temperatures.

Experimental studies have demonstrated that RRAM cells can maintain operational integrity up to approximately 150°C, making them theoretically suitable for under-hood automotive applications. However, prolonged exposure to temperatures above 125°C has been observed to accelerate resistance drift in both high and low resistance states, potentially leading to narrowing read margins and eventual data corruption.

Thermal cycling presents another significant challenge, as the repeated expansion and contraction of materials with different thermal expansion coefficients can induce mechanical stress at material interfaces. This stress may lead to delamination, crack formation, or accelerated electromigration, all of which degrade device performance and reliability over time. Advanced RRAM designs incorporate buffer layers and specialized electrode materials to mitigate these effects.

Low-temperature performance of RRAM also warrants attention, particularly for cold-start conditions in automotive systems. At sub-zero temperatures, the reduced thermal energy can impede ion mobility, potentially increasing switching voltages and times. However, RRAM generally exhibits better low-temperature characteristics compared to flash memory, maintaining reasonable switching speeds down to -40°C.

Thermal management strategies for RRAM in automotive applications include implementing temperature compensation circuits, adaptive programming schemes that adjust operation parameters based on ambient temperature, and protective packaging solutions. These approaches help maintain consistent performance across the automotive temperature range while extending device lifetime under thermal stress conditions.

Recent innovations in material engineering have yielded thermally robust RRAM variants, incorporating high melting point electrodes and thermally stable switching layers that demonstrate minimal performance variation across the automotive temperature range. These advancements represent promising developments for the integration of RRAM in safety-critical automotive systems where thermal reliability is paramount.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!