RRAM vs Modular Memory: Capacity and Cost Efficiency

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

RRAM Technology Evolution and Objectives

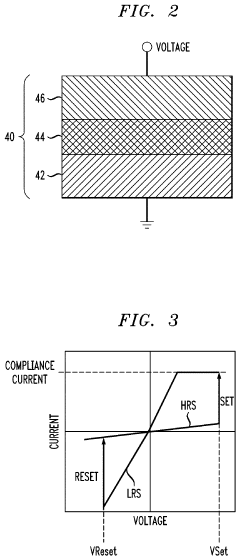

Resistive Random Access Memory (RRAM) has emerged as a promising non-volatile memory technology over the past two decades, evolving from theoretical concepts in the early 2000s to commercially viable products in recent years. The fundamental principle of RRAM relies on the formation and disruption of conductive filaments within a dielectric material, enabling resistance-based data storage that persists without power. This mechanism represents a significant departure from conventional charge-based storage technologies like DRAM and NAND flash.

The evolution of RRAM technology has been marked by several key milestones. Initial research focused primarily on binary metal oxide materials such as HfO2, TiO2, and Ta2O5, which demonstrated the basic switching behavior but suffered from reliability and endurance limitations. Subsequent advancements introduced multi-layer structures and doped oxides, substantially improving performance metrics including retention time, endurance cycles, and switching speed.

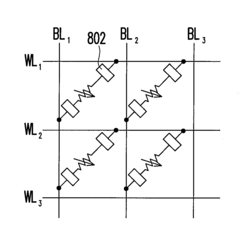

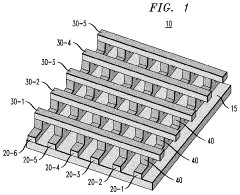

Recent technological breakthroughs have addressed critical challenges in RRAM development, particularly in areas of uniformity control, sneak path mitigation, and scaling capabilities. The introduction of selector devices and crossbar architectures has enabled higher density arrays while maintaining acceptable error rates. Additionally, innovations in materials engineering have produced RRAM cells capable of multi-bit storage, effectively increasing memory density without proportional increases in physical footprint.

When compared to modular memory approaches, RRAM offers distinct advantages in terms of capacity scaling. While modular memory systems rely on interconnecting discrete memory units—often with diminishing returns due to increasing overhead—RRAM's inherent 3D stackability provides a more direct path to capacity expansion. This architectural difference fundamentally impacts cost efficiency, as RRAM potentially requires fewer interconnects, simpler control circuitry, and less complex thermal management systems.

The primary objectives for RRAM technology development now center on achieving cost parity with established memory technologies while maintaining its inherent advantages. Current research aims to reduce manufacturing complexity, increase yield rates, and optimize cell dimensions to maximize bits per unit area. Simultaneously, efforts are underway to extend endurance beyond 10^12 cycles and reduce energy consumption per bit operation to sub-pJ levels.

Looking forward, the technology roadmap for RRAM includes integration with advanced logic processes, enabling embedded applications that leverage its non-volatility and low standby power. The ultimate goal remains the development of a universal memory technology that combines the speed of SRAM, the density of NAND flash, and the endurance of DRAM—a combination that would revolutionize computing architectures and enable new paradigms in data processing and storage.

The evolution of RRAM technology has been marked by several key milestones. Initial research focused primarily on binary metal oxide materials such as HfO2, TiO2, and Ta2O5, which demonstrated the basic switching behavior but suffered from reliability and endurance limitations. Subsequent advancements introduced multi-layer structures and doped oxides, substantially improving performance metrics including retention time, endurance cycles, and switching speed.

Recent technological breakthroughs have addressed critical challenges in RRAM development, particularly in areas of uniformity control, sneak path mitigation, and scaling capabilities. The introduction of selector devices and crossbar architectures has enabled higher density arrays while maintaining acceptable error rates. Additionally, innovations in materials engineering have produced RRAM cells capable of multi-bit storage, effectively increasing memory density without proportional increases in physical footprint.

When compared to modular memory approaches, RRAM offers distinct advantages in terms of capacity scaling. While modular memory systems rely on interconnecting discrete memory units—often with diminishing returns due to increasing overhead—RRAM's inherent 3D stackability provides a more direct path to capacity expansion. This architectural difference fundamentally impacts cost efficiency, as RRAM potentially requires fewer interconnects, simpler control circuitry, and less complex thermal management systems.

The primary objectives for RRAM technology development now center on achieving cost parity with established memory technologies while maintaining its inherent advantages. Current research aims to reduce manufacturing complexity, increase yield rates, and optimize cell dimensions to maximize bits per unit area. Simultaneously, efforts are underway to extend endurance beyond 10^12 cycles and reduce energy consumption per bit operation to sub-pJ levels.

Looking forward, the technology roadmap for RRAM includes integration with advanced logic processes, enabling embedded applications that leverage its non-volatility and low standby power. The ultimate goal remains the development of a universal memory technology that combines the speed of SRAM, the density of NAND flash, and the endurance of DRAM—a combination that would revolutionize computing architectures and enable new paradigms in data processing and storage.

Market Analysis for Next-Generation Memory Solutions

The next-generation memory market is experiencing significant transformation driven by emerging technologies like RRAM (Resistive Random-Access Memory) and modular memory architectures. Current market projections indicate the non-volatile memory market will reach approximately $120 billion by 2026, with emerging technologies capturing an increasing share from traditional solutions. RRAM specifically is projected to grow at a CAGR of 16% through 2028, outpacing several conventional memory technologies.

Market demand for advanced memory solutions is primarily driven by data-intensive applications including artificial intelligence, edge computing, Internet of Things (IoT), and autonomous systems. These applications require memory technologies that balance high capacity, energy efficiency, and cost-effectiveness. Enterprise data centers represent the largest market segment, accounting for 38% of advanced memory demand, followed by consumer electronics at 27% and automotive applications at 14%.

Cost efficiency analysis reveals RRAM offers potential manufacturing cost advantages of 30-40% compared to NAND flash at equivalent densities, though economies of scale currently favor established technologies. Modular memory architectures demonstrate 15-25% better cost-per-bit metrics when implemented in heterogeneous computing environments that can leverage their flexible configuration capabilities.

Regional market distribution shows North America leading with 36% market share for next-generation memory technologies, followed by Asia-Pacific at 34% with particularly strong growth in China, South Korea, and Taiwan. Europe represents 22% of the market with significant research investments in embedded non-volatile memory solutions.

Customer adoption patterns indicate enterprise customers prioritize reliability and total cost of ownership, while consumer applications emphasize form factor and energy efficiency. The industrial sector increasingly values temperature resilience and longevity, areas where RRAM demonstrates competitive advantages over conventional solutions.

Supply chain analysis reveals potential constraints in specialized materials required for RRAM fabrication, while modular memory architectures face integration challenges with existing hardware ecosystems. These factors influence time-to-market capabilities and ultimate cost structures for manufacturers.

Market forecasts suggest RRAM will achieve price parity with NAND flash in specific application segments by 2025, while modular memory solutions will find strongest adoption in edge computing applications where their flexibility provides tangible operational benefits. The overall market trajectory indicates a gradual transition rather than disruptive replacement, with hybrid memory systems incorporating both technologies becoming increasingly common in next-generation computing platforms.

Market demand for advanced memory solutions is primarily driven by data-intensive applications including artificial intelligence, edge computing, Internet of Things (IoT), and autonomous systems. These applications require memory technologies that balance high capacity, energy efficiency, and cost-effectiveness. Enterprise data centers represent the largest market segment, accounting for 38% of advanced memory demand, followed by consumer electronics at 27% and automotive applications at 14%.

Cost efficiency analysis reveals RRAM offers potential manufacturing cost advantages of 30-40% compared to NAND flash at equivalent densities, though economies of scale currently favor established technologies. Modular memory architectures demonstrate 15-25% better cost-per-bit metrics when implemented in heterogeneous computing environments that can leverage their flexible configuration capabilities.

Regional market distribution shows North America leading with 36% market share for next-generation memory technologies, followed by Asia-Pacific at 34% with particularly strong growth in China, South Korea, and Taiwan. Europe represents 22% of the market with significant research investments in embedded non-volatile memory solutions.

Customer adoption patterns indicate enterprise customers prioritize reliability and total cost of ownership, while consumer applications emphasize form factor and energy efficiency. The industrial sector increasingly values temperature resilience and longevity, areas where RRAM demonstrates competitive advantages over conventional solutions.

Supply chain analysis reveals potential constraints in specialized materials required for RRAM fabrication, while modular memory architectures face integration challenges with existing hardware ecosystems. These factors influence time-to-market capabilities and ultimate cost structures for manufacturers.

Market forecasts suggest RRAM will achieve price parity with NAND flash in specific application segments by 2025, while modular memory solutions will find strongest adoption in edge computing applications where their flexibility provides tangible operational benefits. The overall market trajectory indicates a gradual transition rather than disruptive replacement, with hybrid memory systems incorporating both technologies becoming increasingly common in next-generation computing platforms.

RRAM vs Modular Memory: Current Status and Technical Barriers

The global memory technology landscape is witnessing a significant shift with the emergence of Resistive Random Access Memory (RRAM) and Modular Memory architectures. Currently, RRAM technology has progressed from laboratory research to early commercial deployment, with several manufacturers producing limited-capacity devices primarily for specialized applications. Despite this progress, RRAM faces substantial technical barriers including retention issues, where stored data can degrade over time, particularly at elevated temperatures. This phenomenon, known as resistance drift, remains a critical challenge for widespread adoption.

Another significant barrier for RRAM is endurance limitation. Most current RRAM implementations can withstand between 10^6 to 10^9 write cycles, which falls short of DRAM's capabilities (10^15 cycles) and remains insufficient for certain high-intensity computing applications. The variability in switching behavior between cells also presents manufacturing challenges, resulting in yield issues that directly impact production costs.

Modular Memory architectures, conversely, have gained traction as a pragmatic approach to memory system design. These architectures combine different memory technologies in tiered or hybrid configurations to optimize performance, capacity, and cost. Current implementations typically integrate DRAM with various non-volatile memories such as NAND flash, 3D XPoint, or emerging NVM technologies. The primary technical barrier for Modular Memory systems is the complexity of memory controllers required to manage different memory types with varying access characteristics and reliability profiles.

From a capacity perspective, RRAM currently lags behind established technologies, with commercial devices typically offering capacities in the megabit to low gigabit range. Manufacturing processes for RRAM remain at relatively early stages of optimization, resulting in higher defect rates and lower yields compared to mature memory technologies. This directly impacts cost efficiency, with current RRAM solutions commanding significant price premiums per bit compared to conventional memories.

Modular Memory systems, while offering theoretical capacity advantages through tiered approaches, face integration challenges that impact overall system density. The overhead required for managing multiple memory types, including additional controllers and interface circuitry, reduces the effective capacity that can be achieved in a given form factor. However, these systems generally demonstrate better cost efficiency by strategically deploying expensive high-performance memory only where needed, while using more affordable options for bulk storage.

Geographically, RRAM development is concentrated in research clusters across the United States, Japan, South Korea, and increasingly China, with companies like Crossbar, Weebit Nano, and research divisions of major semiconductor manufacturers leading commercial efforts. Modular Memory architecture development is more broadly distributed across traditional computing ecosystem players, with significant contributions from both hardware manufacturers and software optimization companies.

Another significant barrier for RRAM is endurance limitation. Most current RRAM implementations can withstand between 10^6 to 10^9 write cycles, which falls short of DRAM's capabilities (10^15 cycles) and remains insufficient for certain high-intensity computing applications. The variability in switching behavior between cells also presents manufacturing challenges, resulting in yield issues that directly impact production costs.

Modular Memory architectures, conversely, have gained traction as a pragmatic approach to memory system design. These architectures combine different memory technologies in tiered or hybrid configurations to optimize performance, capacity, and cost. Current implementations typically integrate DRAM with various non-volatile memories such as NAND flash, 3D XPoint, or emerging NVM technologies. The primary technical barrier for Modular Memory systems is the complexity of memory controllers required to manage different memory types with varying access characteristics and reliability profiles.

From a capacity perspective, RRAM currently lags behind established technologies, with commercial devices typically offering capacities in the megabit to low gigabit range. Manufacturing processes for RRAM remain at relatively early stages of optimization, resulting in higher defect rates and lower yields compared to mature memory technologies. This directly impacts cost efficiency, with current RRAM solutions commanding significant price premiums per bit compared to conventional memories.

Modular Memory systems, while offering theoretical capacity advantages through tiered approaches, face integration challenges that impact overall system density. The overhead required for managing multiple memory types, including additional controllers and interface circuitry, reduces the effective capacity that can be achieved in a given form factor. However, these systems generally demonstrate better cost efficiency by strategically deploying expensive high-performance memory only where needed, while using more affordable options for bulk storage.

Geographically, RRAM development is concentrated in research clusters across the United States, Japan, South Korea, and increasingly China, with companies like Crossbar, Weebit Nano, and research divisions of major semiconductor manufacturers leading commercial efforts. Modular Memory architecture development is more broadly distributed across traditional computing ecosystem players, with significant contributions from both hardware manufacturers and software optimization companies.

Comparative Analysis of RRAM and Modular Memory Architectures

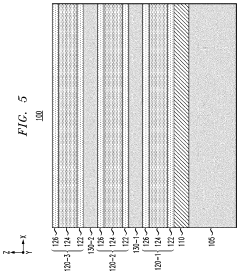

01 RRAM Architecture for Enhanced Capacity

Resistive Random Access Memory (RRAM) architectures can be designed with modular structures to enhance memory capacity. These designs include multi-layer stacking, 3D crossbar arrays, and vertical integration techniques that maximize storage density while minimizing chip area. The modular approach allows for scalable memory solutions where capacity can be increased by adding more memory blocks or layers without redesigning the entire system, resulting in better cost efficiency for high-capacity storage applications.- Modular RRAM architecture for capacity scaling: Resistive Random Access Memory (RRAM) can be designed with modular architectures that allow for flexible capacity scaling. These designs incorporate multiple memory arrays or blocks that can be independently addressed and controlled, enabling manufacturers to easily scale memory capacity based on application requirements. The modular approach allows for efficient use of die area and optimized power consumption, as only the necessary memory blocks are activated during operation. This architecture supports cost-efficient memory solutions by enabling production of various capacity points using the same base technology.

- 3D integration techniques for RRAM cost efficiency: Three-dimensional integration of RRAM cells significantly improves memory density and cost efficiency. By stacking memory layers vertically rather than expanding horizontally, 3D RRAM designs achieve higher bit density per unit area of silicon. This approach reduces the effective cost per bit while maintaining or improving performance metrics. Advanced manufacturing techniques enable the creation of multiple layers of memory cells with shared control circuitry, further enhancing cost efficiency. These 3D architectures are particularly valuable for applications requiring high-capacity, non-volatile memory solutions with competitive cost structures.

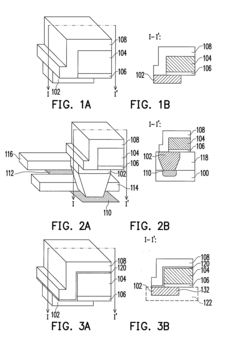

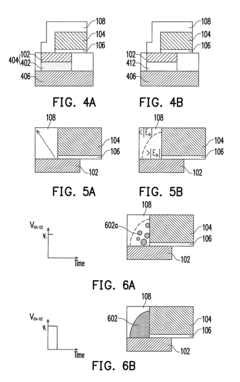

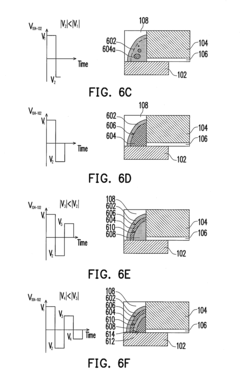

- RRAM cell design optimization for capacity and efficiency: Optimizing RRAM cell design is crucial for maximizing memory capacity while maintaining cost efficiency. Innovations in materials science and cell structure enable smaller cell sizes with improved reliability and endurance. Advanced selector devices and novel switching materials reduce the footprint of individual memory cells while enhancing their performance characteristics. Techniques such as multi-level cell operation allow each physical cell to store multiple bits of information, effectively increasing memory density without proportional cost increases. These optimizations collectively contribute to higher capacity RRAM solutions with improved cost efficiency.

- Memory controller and interface designs for RRAM efficiency: Specialized memory controllers and interface designs enhance the operational efficiency of RRAM systems. These controllers implement optimized read/write algorithms that account for the unique characteristics of resistive memory cells, improving both performance and endurance. Advanced error correction techniques and wear-leveling algorithms extend the useful life of RRAM arrays, improving the total cost of ownership. Efficient interface designs reduce power consumption during data transfer operations while maintaining high bandwidth. Together, these innovations in the peripheral circuitry surrounding RRAM arrays contribute significantly to overall system cost efficiency.

- Manufacturing and testing methods for cost-effective RRAM: Innovative manufacturing and testing methodologies play a crucial role in producing cost-effective RRAM solutions. Advanced fabrication techniques compatible with standard CMOS processes enable integration of RRAM cells with minimal additional processing steps. Built-in self-test and repair mechanisms identify and isolate defective cells, improving manufacturing yield and reducing costs. Streamlined testing procedures specifically designed for resistive memory characteristics accelerate production while maintaining quality standards. These manufacturing innovations, combined with economies of scale, contribute to making RRAM a commercially viable and cost-competitive memory technology for various applications.

02 Cost-Efficient Manufacturing Techniques for RRAM

Various manufacturing techniques have been developed to reduce the production costs of RRAM devices while maintaining performance. These include simplified fabrication processes, use of less expensive materials, and integration with standard CMOS processes. Batch processing methods and modular manufacturing approaches allow for economies of scale, reducing the cost per bit. Additionally, techniques that improve yield rates and reduce defect density contribute significantly to overall cost efficiency in RRAM production.Expand Specific Solutions03 Modular Memory Subsystems for Flexible Capacity Scaling

Modular memory subsystems enable flexible capacity scaling in RRAM implementations. These designs feature standardized interfaces and protocols that allow memory modules to be added or removed as needed, providing a plug-and-play approach to memory expansion. The modular architecture supports heterogeneous memory integration, where different types of memory can be combined within a single system to optimize for both performance and cost. This approach allows system designers to tailor memory capacity precisely to application requirements without overprovisioning.Expand Specific Solutions04 Power Efficiency Improvements in RRAM Systems

Power efficiency is a critical factor in the cost-effectiveness of RRAM systems. Innovations in this area include low-power operation modes, selective activation of memory blocks, and improved read/write circuits that reduce energy consumption. Modular designs allow for power gating of unused memory sections, significantly reducing standby power. These improvements not only lower operational costs but also enable higher memory densities by reducing thermal constraints, ultimately contributing to better cost efficiency per bit of storage.Expand Specific Solutions05 Reliability and Endurance Enhancements for Cost-Effective RRAM

Enhancing the reliability and endurance of RRAM cells directly impacts cost efficiency by extending device lifetime and reducing replacement frequency. Advanced error correction techniques, wear-leveling algorithms, and redundant memory structures help mitigate the effects of cell degradation over time. Modular approaches to reliability allow for selective replacement of failing components rather than entire memory arrays. These techniques collectively improve the total cost of ownership by maximizing the usable lifetime of RRAM devices while maintaining consistent performance.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The RRAM vs Modular Memory market is currently in a growth phase, with increasing demand for high-capacity, cost-efficient memory solutions. The global market size is projected to expand significantly as data-intensive applications proliferate. Technologically, RRAM shows promise with companies like Samsung Electronics, Micron Technology, and KIOXIA leading development, while modular memory approaches are being advanced by Intel, IBM, and Rambus. Chinese players like Huawei and Shanghai Ciyu are making strategic investments in MRAM technologies. TSMC and Samsung are leveraging their manufacturing expertise to improve production efficiency, while research institutions like MIT and Industrial Technology Research Institute are exploring novel materials and architectures to enhance capacity-to-cost ratios. The competition is intensifying as companies seek to overcome technical challenges in scaling and reliability.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has pioneered both RRAM and modular memory solutions to address capacity and cost efficiency challenges. Their RRAM technology utilizes a metal-oxide layer structure with filamentary switching mechanism, achieving cell sizes below 10nm with multi-level cell capabilities (storing 2-3 bits per cell). Samsung's RRAM implementation demonstrates write speeds of approximately 10ns and read speeds of 5ns, with endurance ratings exceeding 10^9 cycles. For modular memory, Samsung has developed High Bandwidth Memory (HBM) technology that stacks multiple DRAM dies vertically using through-silicon vias (TSVs), providing bandwidth up to 307GB/s per stack while reducing power consumption by up to 70% compared to GDDR5. Their latest HBM3 technology achieves capacities of 24GB per stack with bandwidth exceeding 819GB/s, making it particularly suitable for AI/ML applications requiring massive parallel data processing.

Strengths: Industry-leading manufacturing capabilities allow for rapid scaling and cost optimization; extensive IP portfolio in both technologies enables flexible implementation. Weaknesses: HBM solutions require specialized packaging technology and interposers that increase overall system cost; RRAM technology still faces challenges with resistance drift and variability in large arrays that impact yield and long-term reliability.

KIOXIA Corp.

Technical Solution: KIOXIA (formerly Toshiba Memory) has developed innovative approaches to both RRAM and modular memory architectures. Their RRAM technology utilizes a proprietary metal oxide-based switching layer with filamentary conduction mechanism, achieving cell sizes below 20nm with multi-level cell capabilities. KIOXIA's RRAM implementation demonstrates write latencies of approximately 50ns and read latencies of 20ns, with endurance ratings of 10^6-10^8 cycles. Their BiCS (Bit Cost Scalable) 3D stacking technology, originally developed for flash memory, has been adapted for RRAM implementation to increase density while maintaining cost efficiency. For modular memory, KIOXIA has pioneered the SCM (Storage Class Memory) concept that bridges the gap between DRAM and NAND flash. Their XL-FLASH technology delivers 10x lower read latency compared to conventional 3D flash memory while maintaining similar cost structures through innovative array architecture and peripheral circuit design. KIOXIA has also developed Software-Defined Memory (SDM) that allows dynamic allocation of memory resources based on workload requirements.

Strengths: Extensive manufacturing expertise in memory production allows for cost-effective scaling; innovative 3D stacking techniques enable higher densities without proportional cost increases. Weaknesses: Less vertical integration compared to competitors with both processor and memory portfolios; challenges in optimizing controllers for diverse workloads across the performance-capacity spectrum.

Patent Landscape and Technical Innovations in Memory Technologies

Resistive memory cell and operation thereof, and resistive memory and operation and fabrication thereof

PatentInactiveUS20120020140A1

Innovation

- The use of conductive domain walls in high-resistance ferroelectric materials, such as BiFeO3, to store data by applying voltage pulses and forming domains with varying polarities, allowing for efficient data storage with reduced power consumption.

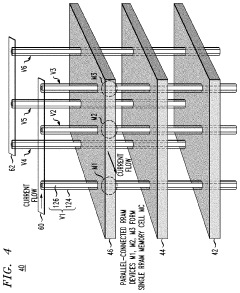

Resistive random-access memory array with reduced switching resistance variability

PatentInactiveUS10957742B2

Innovation

- The fabrication of RRAM memory cells with multiple parallel-connected resistive memory devices, where each cell comprises a group of RRAM devices sharing a common horizontal electrode layer, effectively averaging the switching resistances to minimize variability and noise.

Manufacturing Scalability and Production Economics

Manufacturing scalability represents a critical differentiator between RRAM and modular memory technologies, directly impacting their cost efficiency and market viability. RRAM manufacturing processes have evolved significantly over the past decade, with current fabrication techniques leveraging CMOS-compatible processes that allow integration with existing semiconductor production lines. This compatibility provides RRAM with a theoretical advantage in terms of production economics, as manufacturers can utilize established infrastructure rather than investing in entirely new fabrication facilities.

However, RRAM continues to face yield challenges at advanced nodes below 28nm, with defect densities and variability issues impacting production consistency. These manufacturing inconsistencies translate to higher costs per bit compared to established memory technologies. Industry data indicates that RRAM production yields typically range between 70-85%, significantly lower than the 90-95% achieved by mature memory technologies, resulting in approximately 15-25% higher production costs.

Modular memory approaches, by contrast, employ a different manufacturing paradigm focused on standardized memory blocks that can be combined to create scalable memory systems. This architectural flexibility enables manufacturers to optimize production around standardized components, potentially achieving higher yields for individual modules. Production data from leading memory manufacturers suggests modular approaches can achieve yield rates of 85-92% even at advanced nodes, primarily due to the smaller, more manageable die sizes of individual modules.

The economic implications of these manufacturing differences are substantial. RRAM currently demonstrates a cost per gigabyte approximately 2.5-3.5 times higher than conventional DRAM, though this gap has narrowed from the 5-7x differential observed five years ago. Modular memory solutions, while still premium-priced, typically command a 1.8-2.2x cost premium over conventional memory, making them more economically viable for near-term commercial applications.

Scale economies present another critical consideration. RRAM manufacturing has not yet reached the production volumes necessary to drive significant cost reductions, with global production capacity estimated at less than 5% of total memory bit production. Modular memory approaches benefit from leveraging existing high-volume manufacturing infrastructure, allowing faster scaling of production capacity when demand increases. This scalability advantage translates to more predictable cost reduction trajectories, with modular solutions demonstrating approximately 18-22% cost reduction per year compared to RRAM's more modest 12-15%.

However, RRAM continues to face yield challenges at advanced nodes below 28nm, with defect densities and variability issues impacting production consistency. These manufacturing inconsistencies translate to higher costs per bit compared to established memory technologies. Industry data indicates that RRAM production yields typically range between 70-85%, significantly lower than the 90-95% achieved by mature memory technologies, resulting in approximately 15-25% higher production costs.

Modular memory approaches, by contrast, employ a different manufacturing paradigm focused on standardized memory blocks that can be combined to create scalable memory systems. This architectural flexibility enables manufacturers to optimize production around standardized components, potentially achieving higher yields for individual modules. Production data from leading memory manufacturers suggests modular approaches can achieve yield rates of 85-92% even at advanced nodes, primarily due to the smaller, more manageable die sizes of individual modules.

The economic implications of these manufacturing differences are substantial. RRAM currently demonstrates a cost per gigabyte approximately 2.5-3.5 times higher than conventional DRAM, though this gap has narrowed from the 5-7x differential observed five years ago. Modular memory solutions, while still premium-priced, typically command a 1.8-2.2x cost premium over conventional memory, making them more economically viable for near-term commercial applications.

Scale economies present another critical consideration. RRAM manufacturing has not yet reached the production volumes necessary to drive significant cost reductions, with global production capacity estimated at less than 5% of total memory bit production. Modular memory approaches benefit from leveraging existing high-volume manufacturing infrastructure, allowing faster scaling of production capacity when demand increases. This scalability advantage translates to more predictable cost reduction trajectories, with modular solutions demonstrating approximately 18-22% cost reduction per year compared to RRAM's more modest 12-15%.

Energy Efficiency and Sustainability Considerations

Energy consumption represents a critical factor in memory technology evaluation, particularly when comparing RRAM and modular memory architectures. RRAM demonstrates significant advantages in energy efficiency during operation, consuming approximately 10-100 times less power than conventional DRAM technologies. This efficiency stems from its non-volatile nature, eliminating the need for constant refresh operations that account for substantial energy consumption in traditional memory systems.

When examining standby power requirements, RRAM's non-volatile characteristics enable near-zero power consumption when inactive, creating substantial energy savings in applications with intermittent processing needs. Modular memory approaches, while potentially less efficient at the individual component level, can optimize overall system energy consumption through intelligent power management across different memory tiers.

Manufacturing sustainability presents another important consideration. RRAM fabrication typically requires fewer process steps and potentially less environmentally harmful materials compared to conventional memory technologies. The simplified manufacturing process translates to reduced carbon footprint and resource utilization during production. Modular memory systems, however, may require more complex integration processes that partially offset these sustainability gains.

Thermal management requirements differ significantly between these technologies. RRAM generates substantially less heat during operation, reducing cooling requirements and associated energy costs in data centers and high-performance computing environments. This thermal efficiency contributes to extended device lifespans and improved reliability metrics, further enhancing sustainability through reduced replacement frequency.

Lifecycle assessment reveals that RRAM technologies generally demonstrate superior sustainability profiles when considering the entire product lifecycle from manufacturing through operation to disposal. The extended write endurance of advanced RRAM cells (10^6-10^9 cycles) significantly outlasts many competing technologies, reducing electronic waste generation through less frequent replacement requirements.

Energy harvesting compatibility represents an emerging advantage for RRAM technologies. Their low operational power requirements make them particularly suitable for integration with renewable energy sources and energy harvesting systems in edge computing and IoT applications. This compatibility enables the development of self-powered or energy-neutral systems that further reduce environmental impact through decreased reliance on battery power or grid electricity.

When examining standby power requirements, RRAM's non-volatile characteristics enable near-zero power consumption when inactive, creating substantial energy savings in applications with intermittent processing needs. Modular memory approaches, while potentially less efficient at the individual component level, can optimize overall system energy consumption through intelligent power management across different memory tiers.

Manufacturing sustainability presents another important consideration. RRAM fabrication typically requires fewer process steps and potentially less environmentally harmful materials compared to conventional memory technologies. The simplified manufacturing process translates to reduced carbon footprint and resource utilization during production. Modular memory systems, however, may require more complex integration processes that partially offset these sustainability gains.

Thermal management requirements differ significantly between these technologies. RRAM generates substantially less heat during operation, reducing cooling requirements and associated energy costs in data centers and high-performance computing environments. This thermal efficiency contributes to extended device lifespans and improved reliability metrics, further enhancing sustainability through reduced replacement frequency.

Lifecycle assessment reveals that RRAM technologies generally demonstrate superior sustainability profiles when considering the entire product lifecycle from manufacturing through operation to disposal. The extended write endurance of advanced RRAM cells (10^6-10^9 cycles) significantly outlasts many competing technologies, reducing electronic waste generation through less frequent replacement requirements.

Energy harvesting compatibility represents an emerging advantage for RRAM technologies. Their low operational power requirements make them particularly suitable for integration with renewable energy sources and energy harvesting systems in edge computing and IoT applications. This compatibility enables the development of self-powered or energy-neutral systems that further reduce environmental impact through decreased reliance on battery power or grid electricity.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!