Sodium Alginate's Role in Nutritional Supplement Quality Control

JUL 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Alginate Overview

Sodium alginate, a versatile polysaccharide derived from brown seaweed, has gained significant attention in the nutritional supplement industry due to its unique properties and wide-ranging applications. This natural compound is composed of linear chains of (1-4)-linked β-D-mannuronic acid and α-L-guluronic acid residues, which contribute to its gel-forming capabilities and stability under various conditions.

In the context of nutritional supplement quality control, sodium alginate plays a crucial role in enhancing product formulation, stability, and bioavailability. Its ability to form viscous solutions and gels in the presence of divalent cations, such as calcium, makes it an ideal candidate for controlled release systems and encapsulation of sensitive ingredients.

One of the primary applications of sodium alginate in nutritional supplements is as a thickening and stabilizing agent. It helps maintain the consistency and texture of liquid supplements, preventing separation of ingredients and ensuring a uniform distribution of active components throughout the product's shelf life. This property is particularly valuable in multi-vitamin formulations and protein shakes, where ingredient settling can be a significant quality control issue.

Furthermore, sodium alginate's gel-forming ability has been exploited in the development of advanced delivery systems for nutritional supplements. When exposed to acidic conditions in the stomach, sodium alginate forms a protective gel layer around encapsulated nutrients, shielding them from degradation and promoting their controlled release in the intestines. This characteristic is especially beneficial for supplements containing sensitive compounds, such as probiotics or easily oxidized vitamins.

In addition to its functional properties, sodium alginate contributes to the overall safety and quality of nutritional supplements. As a natural, plant-derived ingredient, it aligns with the growing consumer demand for clean-label products. Its non-toxic nature and GRAS (Generally Recognized as Safe) status by the FDA make it a preferred choice for formulators seeking to enhance product quality without compromising safety.

The role of sodium alginate in quality control extends beyond formulation stability and ingredient protection. Its unique chemical structure allows for the development of innovative dosage forms, such as gummies and soft gels, which can improve consumer compliance and product differentiation in the competitive nutritional supplement market.

As the nutritional supplement industry continues to evolve, sodium alginate's versatility and functionality position it as a key ingredient in addressing quality control challenges and meeting consumer expectations for effective, safe, and high-quality products.

In the context of nutritional supplement quality control, sodium alginate plays a crucial role in enhancing product formulation, stability, and bioavailability. Its ability to form viscous solutions and gels in the presence of divalent cations, such as calcium, makes it an ideal candidate for controlled release systems and encapsulation of sensitive ingredients.

One of the primary applications of sodium alginate in nutritional supplements is as a thickening and stabilizing agent. It helps maintain the consistency and texture of liquid supplements, preventing separation of ingredients and ensuring a uniform distribution of active components throughout the product's shelf life. This property is particularly valuable in multi-vitamin formulations and protein shakes, where ingredient settling can be a significant quality control issue.

Furthermore, sodium alginate's gel-forming ability has been exploited in the development of advanced delivery systems for nutritional supplements. When exposed to acidic conditions in the stomach, sodium alginate forms a protective gel layer around encapsulated nutrients, shielding them from degradation and promoting their controlled release in the intestines. This characteristic is especially beneficial for supplements containing sensitive compounds, such as probiotics or easily oxidized vitamins.

In addition to its functional properties, sodium alginate contributes to the overall safety and quality of nutritional supplements. As a natural, plant-derived ingredient, it aligns with the growing consumer demand for clean-label products. Its non-toxic nature and GRAS (Generally Recognized as Safe) status by the FDA make it a preferred choice for formulators seeking to enhance product quality without compromising safety.

The role of sodium alginate in quality control extends beyond formulation stability and ingredient protection. Its unique chemical structure allows for the development of innovative dosage forms, such as gummies and soft gels, which can improve consumer compliance and product differentiation in the competitive nutritional supplement market.

As the nutritional supplement industry continues to evolve, sodium alginate's versatility and functionality position it as a key ingredient in addressing quality control challenges and meeting consumer expectations for effective, safe, and high-quality products.

Market Demand Analysis

The market demand for sodium alginate in nutritional supplement quality control has been steadily increasing in recent years. This growth is primarily driven by the rising consumer awareness of health and wellness, coupled with the expanding nutritional supplement industry. Sodium alginate, derived from brown seaweed, has gained significant traction in the supplement market due to its versatile properties and potential health benefits.

The global nutritional supplement market is projected to reach substantial growth in the coming years, with a considerable portion attributed to the use of sodium alginate as a quality control agent. This compound plays a crucial role in enhancing the stability, texture, and bioavailability of various supplement formulations, making it an essential ingredient for manufacturers seeking to improve product quality and efficacy.

One of the key factors driving the demand for sodium alginate in supplement quality control is its ability to act as a stabilizer and thickening agent. This property is particularly valuable in liquid supplements, where it helps maintain uniform suspension of active ingredients and prevents sedimentation. As consumers increasingly prefer convenient and easily consumable supplement formats, the demand for liquid formulations has surged, consequently boosting the need for sodium alginate.

Furthermore, sodium alginate's role in controlled release formulations has garnered significant attention in the supplement industry. Its unique gel-forming properties allow for the gradual release of nutrients, potentially improving absorption and bioavailability. This characteristic is especially beneficial for supplements containing sensitive or easily degradable compounds, as it helps protect them from harsh stomach conditions and ensures optimal delivery to the intestines.

The growing trend of clean label and natural ingredients in the supplement industry has also contributed to the increased demand for sodium alginate. As a naturally derived compound, it aligns well with consumer preferences for plant-based and minimally processed ingredients. This trend is particularly pronounced in developed markets, where consumers are increasingly scrutinizing product labels and seeking out natural alternatives.

Geographically, North America and Europe currently dominate the market for sodium alginate in nutritional supplement quality control. However, emerging economies in Asia-Pacific and Latin America are expected to witness rapid growth in demand. This expansion is attributed to rising disposable incomes, increasing health consciousness, and the growing adoption of Western dietary habits in these regions.

Despite the positive market outlook, challenges such as fluctuating raw material prices and the need for sustainable sourcing practices may impact the growth trajectory. Manufacturers are increasingly focusing on developing innovative extraction methods and exploring alternative sources to ensure a stable supply chain and meet the growing demand for sodium alginate in nutritional supplement quality control.

The global nutritional supplement market is projected to reach substantial growth in the coming years, with a considerable portion attributed to the use of sodium alginate as a quality control agent. This compound plays a crucial role in enhancing the stability, texture, and bioavailability of various supplement formulations, making it an essential ingredient for manufacturers seeking to improve product quality and efficacy.

One of the key factors driving the demand for sodium alginate in supplement quality control is its ability to act as a stabilizer and thickening agent. This property is particularly valuable in liquid supplements, where it helps maintain uniform suspension of active ingredients and prevents sedimentation. As consumers increasingly prefer convenient and easily consumable supplement formats, the demand for liquid formulations has surged, consequently boosting the need for sodium alginate.

Furthermore, sodium alginate's role in controlled release formulations has garnered significant attention in the supplement industry. Its unique gel-forming properties allow for the gradual release of nutrients, potentially improving absorption and bioavailability. This characteristic is especially beneficial for supplements containing sensitive or easily degradable compounds, as it helps protect them from harsh stomach conditions and ensures optimal delivery to the intestines.

The growing trend of clean label and natural ingredients in the supplement industry has also contributed to the increased demand for sodium alginate. As a naturally derived compound, it aligns well with consumer preferences for plant-based and minimally processed ingredients. This trend is particularly pronounced in developed markets, where consumers are increasingly scrutinizing product labels and seeking out natural alternatives.

Geographically, North America and Europe currently dominate the market for sodium alginate in nutritional supplement quality control. However, emerging economies in Asia-Pacific and Latin America are expected to witness rapid growth in demand. This expansion is attributed to rising disposable incomes, increasing health consciousness, and the growing adoption of Western dietary habits in these regions.

Despite the positive market outlook, challenges such as fluctuating raw material prices and the need for sustainable sourcing practices may impact the growth trajectory. Manufacturers are increasingly focusing on developing innovative extraction methods and exploring alternative sources to ensure a stable supply chain and meet the growing demand for sodium alginate in nutritional supplement quality control.

Quality Control Challenges

Quality control in the production of nutritional supplements containing sodium alginate presents several significant challenges. One of the primary issues is the variability in the quality and purity of raw sodium alginate sourced from different suppliers. This inconsistency can lead to fluctuations in the final product's viscosity, gel strength, and overall performance, potentially affecting its efficacy as a dietary supplement.

Another major challenge lies in the precise measurement and incorporation of sodium alginate into supplement formulations. Due to its hygroscopic nature, sodium alginate can absorb moisture from the environment, leading to clumping and uneven distribution within the product matrix. This can result in inconsistent dosing and compromised product stability, which are critical factors in maintaining the supplement's quality and shelf life.

The interaction between sodium alginate and other ingredients in the supplement formulation poses additional quality control hurdles. Sodium alginate's gelling properties can be influenced by the presence of certain ions, pH levels, and other excipients, potentially altering the intended release profile of active ingredients. Ensuring consistent and predictable behavior of sodium alginate within complex formulations requires rigorous testing and validation protocols.

Furthermore, the processing conditions during supplement manufacturing can significantly impact the functionality of sodium alginate. Factors such as temperature, shear forces, and pH during mixing and encapsulation processes can affect the polymer's molecular weight and structure, potentially altering its intended properties. Maintaining tight control over these parameters is essential for producing consistent, high-quality supplements.

Quality control challenges also extend to the analytical methods used to assess sodium alginate's properties in the final product. Developing and validating reliable, reproducible testing procedures for parameters such as viscosity, gel strength, and molecular weight distribution can be complex and time-consuming. These methods must be sensitive enough to detect subtle variations that could impact product performance while being robust enough for routine quality control use.

Lastly, ensuring the stability and integrity of sodium alginate-containing supplements throughout their shelf life presents ongoing quality control challenges. Factors such as temperature, humidity, and light exposure during storage and transportation can potentially degrade sodium alginate or alter its properties over time. Implementing appropriate packaging solutions and conducting comprehensive stability studies are crucial steps in maintaining product quality from production to consumption.

Another major challenge lies in the precise measurement and incorporation of sodium alginate into supplement formulations. Due to its hygroscopic nature, sodium alginate can absorb moisture from the environment, leading to clumping and uneven distribution within the product matrix. This can result in inconsistent dosing and compromised product stability, which are critical factors in maintaining the supplement's quality and shelf life.

The interaction between sodium alginate and other ingredients in the supplement formulation poses additional quality control hurdles. Sodium alginate's gelling properties can be influenced by the presence of certain ions, pH levels, and other excipients, potentially altering the intended release profile of active ingredients. Ensuring consistent and predictable behavior of sodium alginate within complex formulations requires rigorous testing and validation protocols.

Furthermore, the processing conditions during supplement manufacturing can significantly impact the functionality of sodium alginate. Factors such as temperature, shear forces, and pH during mixing and encapsulation processes can affect the polymer's molecular weight and structure, potentially altering its intended properties. Maintaining tight control over these parameters is essential for producing consistent, high-quality supplements.

Quality control challenges also extend to the analytical methods used to assess sodium alginate's properties in the final product. Developing and validating reliable, reproducible testing procedures for parameters such as viscosity, gel strength, and molecular weight distribution can be complex and time-consuming. These methods must be sensitive enough to detect subtle variations that could impact product performance while being robust enough for routine quality control use.

Lastly, ensuring the stability and integrity of sodium alginate-containing supplements throughout their shelf life presents ongoing quality control challenges. Factors such as temperature, humidity, and light exposure during storage and transportation can potentially degrade sodium alginate or alter its properties over time. Implementing appropriate packaging solutions and conducting comprehensive stability studies are crucial steps in maintaining product quality from production to consumption.

Current QC Methodologies

01 Physical and chemical property testing

Quality control of sodium alginate involves testing various physical and chemical properties. This includes measuring viscosity, molecular weight, moisture content, and pH levels. These tests ensure the consistency and purity of the sodium alginate, which is crucial for its performance in different applications.- Physicochemical property testing: Quality control of sodium alginate involves testing various physicochemical properties such as viscosity, molecular weight, and gel strength. These tests ensure the consistency and performance of the product for different applications. Methods may include rheological measurements, gel permeation chromatography, and texture analysis.

- Purity and contamination analysis: Assessing the purity of sodium alginate and detecting potential contaminants is crucial for quality control. This includes analyzing for heavy metals, microbiological contaminants, and other impurities. Techniques such as spectroscopy, chromatography, and microbial testing are commonly employed to ensure the product meets safety and regulatory standards.

- Structural characterization: Structural analysis of sodium alginate is important for quality control, involving the determination of its chemical composition, such as the ratio of mannuronic to guluronic acid residues. Methods like NMR spectroscopy and FTIR are used to characterize the polymer structure and ensure batch-to-batch consistency.

- Functional property evaluation: Assessing the functional properties of sodium alginate is essential for its application-specific quality control. This includes testing its gelling ability, film-forming properties, and stability under various conditions. Techniques such as rheometry, mechanical testing, and accelerated stability studies are employed to evaluate these properties.

- Process control and optimization: Quality control of sodium alginate also involves monitoring and optimizing the production process. This includes controlling extraction conditions, purification methods, and drying processes. Implementing in-process controls and statistical process control techniques helps maintain consistent product quality throughout manufacturing.

02 Microbiological testing

Microbiological testing is an essential aspect of sodium alginate quality control. This involves checking for the presence of harmful bacteria, yeasts, and molds. Ensuring microbiological safety is particularly important when sodium alginate is used in food, pharmaceutical, or medical applications.Expand Specific Solutions03 Impurity analysis

Impurity analysis is crucial for maintaining the quality of sodium alginate. This includes testing for heavy metals, insoluble matter, and other contaminants that could affect the product's performance or safety. Advanced analytical techniques such as spectroscopy and chromatography are often employed for this purpose.Expand Specific Solutions04 Functional property assessment

Assessing the functional properties of sodium alginate is vital for quality control. This includes testing its gelling ability, film-forming properties, and stability under various conditions. These tests ensure that the sodium alginate meets the required performance standards for specific applications.Expand Specific Solutions05 Process control and standardization

Implementing process control measures and standardization techniques is essential for consistent sodium alginate quality. This involves monitoring and controlling various parameters during production, such as temperature, pH, and reaction time. Standardized procedures for sampling, testing, and documentation are also crucial for maintaining quality across batches.Expand Specific Solutions

Key Industry Players

The sodium alginate market in nutritional supplement quality control is in a growth phase, driven by increasing demand for natural and functional ingredients. The market size is expanding due to rising health consciousness and the popularity of plant-based products. Technologically, sodium alginate applications are evolving, with companies like Shandong Jiejing Group Co. Ltd. and Qingdao Bright Moon Seaweed Group Co., Ltd. leading innovation in extraction and purification processes. Established multinationals such as Unilever and Colgate-Palmolive are also exploring sodium alginate's potential in their product lines. Research institutions like Shandong University and Cornell University are contributing to advancing the understanding of sodium alginate's properties and applications, further driving market maturity and technological sophistication.

Shandong Jiejing Group Co. Ltd.

Technical Solution: Shandong Jiejing Group Co. Ltd. has developed a proprietary extraction and purification process for sodium alginate from brown seaweed. Their method involves a multi-step procedure including alkali treatment, filtration, precipitation, and drying. The company has implemented advanced quality control measures, including spectroscopic analysis and rheological testing, to ensure consistent viscosity and gel strength of their sodium alginate products[1]. They have also developed a standardized protocol for assessing the heavy metal content and microbial contamination in their alginate supplements, adhering to international food safety standards[2].

Strengths: Consistent product quality, adherence to international standards, and advanced purification techniques. Weaknesses: Potential limitations in seaweed sourcing and higher production costs due to extensive quality control measures.

Unilever NV

Technical Solution: Unilever NV has integrated sodium alginate into their nutritional supplement line, focusing on its potential as a prebiotic fiber. Their research has shown that specific molecular weight fractions of sodium alginate can selectively promote the growth of beneficial gut bacteria[3]. The company has developed a patented encapsulation technology using sodium alginate to protect sensitive nutrients and probiotics from degradation in the stomach, ensuring targeted delivery to the intestines[4]. Unilever's quality control process includes in vitro fermentation studies to verify the prebiotic activity of their alginate-based supplements, as well as stability testing under various storage conditions[5].

Strengths: Innovative applications in prebiotic and encapsulation technologies, extensive research backing. Weaknesses: Higher cost of specialized alginate fractions, potential regulatory challenges in some markets due to novel applications.

Innovative QC Techniques

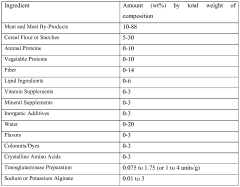

Method of preparing a food composition

PatentWO2014092715A1

Innovation

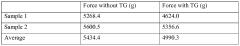

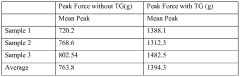

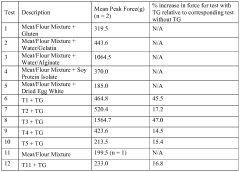

- Treating the food component with transglutaminase and at least one further agent selected from gluten and alginate, either simultaneously or sequentially, at temperatures ranging from 3°C to 23°C and atmospheric pressure, without added heat or pressure, to enhance firmness.

A consumable gel for health ingredients

PatentPendingGB2623158A

Innovation

- A stable, shearable gel dosage form incorporating an agarose-based polymer as a primary gelling agent and an alginate-based polymer, with a high concentration oil/water emulsion that releases oil droplets upon shearing to mask unpleasant tastes, allowing for the delivery of multiple health ingredients in a single, easy-to-consume format.

Regulatory Compliance

Regulatory compliance is a critical aspect of sodium alginate's role in nutritional supplement quality control. As the use of sodium alginate in dietary supplements continues to grow, manufacturers must navigate an increasingly complex regulatory landscape to ensure their products meet stringent safety and quality standards.

In the United States, the Food and Drug Administration (FDA) regulates dietary supplements under the Dietary Supplement Health and Education Act (DSHEA) of 1994. Under this framework, sodium alginate is generally recognized as safe (GRAS) for use in food and dietary supplements. However, manufacturers must still adhere to current Good Manufacturing Practices (cGMPs) to ensure product quality, safety, and efficacy.

The European Union (EU) has its own set of regulations governing the use of sodium alginate in nutritional supplements. The European Food Safety Authority (EFSA) has evaluated sodium alginate and approved its use as a food additive (E401). For dietary supplements, manufacturers must comply with the EU Food Supplements Directive (2002/46/EC) and the Novel Food Regulation (EU) 2015/2283.

In Asia, regulatory requirements vary by country. Japan, for instance, classifies sodium alginate as a food additive and regulates its use through the Food Sanitation Act. China, on the other hand, has specific regulations for health food products, including those containing sodium alginate, under the State Administration for Market Regulation (SAMR).

Quality control measures for sodium alginate in nutritional supplements must address several key regulatory aspects. These include ensuring the purity and identity of the ingredient, establishing appropriate dosage levels, and verifying the absence of contaminants. Manufacturers must also implement robust traceability systems to track the sourcing and processing of sodium alginate throughout the supply chain.

Labeling requirements present another regulatory challenge. In most jurisdictions, manufacturers must accurately declare sodium alginate on product labels, often including its function or purpose. Some regions may also require specific warnings or contraindications, particularly for certain consumer groups.

As regulatory frameworks continue to evolve, manufacturers must stay abreast of changes and adapt their quality control processes accordingly. This may involve regular audits, updating standard operating procedures, and investing in advanced analytical techniques to meet increasingly stringent regulatory requirements.

Compliance with international standards, such as those set by the Joint FAO/WHO Expert Committee on Food Additives (JECFA), can help manufacturers navigate global markets. These standards provide a benchmark for quality and safety that is recognized by many regulatory bodies worldwide.

In conclusion, regulatory compliance is a multifaceted and dynamic aspect of sodium alginate's role in nutritional supplement quality control. Manufacturers must implement comprehensive strategies to ensure their products meet diverse regulatory requirements across different markets, while maintaining the highest standards of quality and safety for consumers.

In the United States, the Food and Drug Administration (FDA) regulates dietary supplements under the Dietary Supplement Health and Education Act (DSHEA) of 1994. Under this framework, sodium alginate is generally recognized as safe (GRAS) for use in food and dietary supplements. However, manufacturers must still adhere to current Good Manufacturing Practices (cGMPs) to ensure product quality, safety, and efficacy.

The European Union (EU) has its own set of regulations governing the use of sodium alginate in nutritional supplements. The European Food Safety Authority (EFSA) has evaluated sodium alginate and approved its use as a food additive (E401). For dietary supplements, manufacturers must comply with the EU Food Supplements Directive (2002/46/EC) and the Novel Food Regulation (EU) 2015/2283.

In Asia, regulatory requirements vary by country. Japan, for instance, classifies sodium alginate as a food additive and regulates its use through the Food Sanitation Act. China, on the other hand, has specific regulations for health food products, including those containing sodium alginate, under the State Administration for Market Regulation (SAMR).

Quality control measures for sodium alginate in nutritional supplements must address several key regulatory aspects. These include ensuring the purity and identity of the ingredient, establishing appropriate dosage levels, and verifying the absence of contaminants. Manufacturers must also implement robust traceability systems to track the sourcing and processing of sodium alginate throughout the supply chain.

Labeling requirements present another regulatory challenge. In most jurisdictions, manufacturers must accurately declare sodium alginate on product labels, often including its function or purpose. Some regions may also require specific warnings or contraindications, particularly for certain consumer groups.

As regulatory frameworks continue to evolve, manufacturers must stay abreast of changes and adapt their quality control processes accordingly. This may involve regular audits, updating standard operating procedures, and investing in advanced analytical techniques to meet increasingly stringent regulatory requirements.

Compliance with international standards, such as those set by the Joint FAO/WHO Expert Committee on Food Additives (JECFA), can help manufacturers navigate global markets. These standards provide a benchmark for quality and safety that is recognized by many regulatory bodies worldwide.

In conclusion, regulatory compliance is a multifaceted and dynamic aspect of sodium alginate's role in nutritional supplement quality control. Manufacturers must implement comprehensive strategies to ensure their products meet diverse regulatory requirements across different markets, while maintaining the highest standards of quality and safety for consumers.

Safety and Bioavailability

Sodium alginate, a widely used ingredient in nutritional supplements, plays a crucial role in quality control, particularly concerning safety and bioavailability. The safety profile of sodium alginate is generally considered favorable, with extensive research supporting its use in various applications, including food and pharmaceutical industries. As a natural polysaccharide derived from brown seaweed, sodium alginate has been recognized as safe by regulatory bodies such as the FDA and EFSA.

In terms of safety, sodium alginate exhibits low toxicity and is well-tolerated by most individuals. Its non-allergenic nature makes it suitable for use in a wide range of nutritional supplements. However, it is essential to consider potential interactions with certain medications, particularly those affecting calcium absorption, as sodium alginate can form complexes with calcium ions. Manufacturers must ensure proper labeling and provide appropriate warnings to consumers regarding these potential interactions.

The bioavailability of nutrients in supplements containing sodium alginate is a critical aspect of quality control. Sodium alginate's gel-forming properties can significantly impact the release and absorption of active ingredients. When exposed to acidic conditions in the stomach, sodium alginate forms a protective gel layer, which can slow down the release of encapsulated nutrients. This controlled-release mechanism can be advantageous for certain supplements, providing sustained delivery of nutrients over time.

However, the gel-forming nature of sodium alginate may also pose challenges in terms of nutrient bioavailability. The protective barrier formed by the alginate gel can potentially reduce the absorption of some nutrients, particularly those that require an acidic environment for optimal absorption. Manufacturers must carefully consider this aspect when formulating supplements and conduct thorough bioavailability studies to ensure that the intended nutritional benefits are achieved.

To address bioavailability concerns, various strategies have been developed. These include the use of specific alginate grades with tailored properties, such as controlled viscosity and gel strength, to optimize nutrient release profiles. Additionally, combining sodium alginate with other excipients or employing advanced formulation techniques can help enhance the bioavailability of encapsulated nutrients.

Quality control measures for sodium alginate in nutritional supplements should include rigorous testing for purity, viscosity, and gel-forming properties. Manufacturers must ensure consistent batch-to-batch quality to maintain the desired safety and bioavailability profiles. Regular monitoring of heavy metal content and microbial contamination is also crucial, given the marine origin of sodium alginate.

In conclusion, while sodium alginate offers numerous benefits in nutritional supplement formulations, careful consideration of its impact on safety and bioavailability is essential for effective quality control. Ongoing research and development efforts continue to refine formulation strategies and testing methods to optimize the use of sodium alginate in nutritional supplements, ensuring both safety and efficacy for consumers.

In terms of safety, sodium alginate exhibits low toxicity and is well-tolerated by most individuals. Its non-allergenic nature makes it suitable for use in a wide range of nutritional supplements. However, it is essential to consider potential interactions with certain medications, particularly those affecting calcium absorption, as sodium alginate can form complexes with calcium ions. Manufacturers must ensure proper labeling and provide appropriate warnings to consumers regarding these potential interactions.

The bioavailability of nutrients in supplements containing sodium alginate is a critical aspect of quality control. Sodium alginate's gel-forming properties can significantly impact the release and absorption of active ingredients. When exposed to acidic conditions in the stomach, sodium alginate forms a protective gel layer, which can slow down the release of encapsulated nutrients. This controlled-release mechanism can be advantageous for certain supplements, providing sustained delivery of nutrients over time.

However, the gel-forming nature of sodium alginate may also pose challenges in terms of nutrient bioavailability. The protective barrier formed by the alginate gel can potentially reduce the absorption of some nutrients, particularly those that require an acidic environment for optimal absorption. Manufacturers must carefully consider this aspect when formulating supplements and conduct thorough bioavailability studies to ensure that the intended nutritional benefits are achieved.

To address bioavailability concerns, various strategies have been developed. These include the use of specific alginate grades with tailored properties, such as controlled viscosity and gel strength, to optimize nutrient release profiles. Additionally, combining sodium alginate with other excipients or employing advanced formulation techniques can help enhance the bioavailability of encapsulated nutrients.

Quality control measures for sodium alginate in nutritional supplements should include rigorous testing for purity, viscosity, and gel-forming properties. Manufacturers must ensure consistent batch-to-batch quality to maintain the desired safety and bioavailability profiles. Regular monitoring of heavy metal content and microbial contamination is also crucial, given the marine origin of sodium alginate.

In conclusion, while sodium alginate offers numerous benefits in nutritional supplement formulations, careful consideration of its impact on safety and bioavailability is essential for effective quality control. Ongoing research and development efforts continue to refine formulation strategies and testing methods to optimize the use of sodium alginate in nutritional supplements, ensuring both safety and efficacy for consumers.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!