Strategies for Cost-Effective Large-Scale Synthesis of MOFs

AUG 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MOF Synthesis Background and Objectives

Metal-Organic Frameworks (MOFs) have emerged as a revolutionary class of porous materials over the past two decades, garnering significant attention in both academic research and industrial applications. These crystalline compounds, composed of metal ions or clusters coordinated to organic ligands, exhibit exceptional properties such as high surface area, tunable pore size, and diverse functionalities. The development of MOFs has opened up new possibilities in various fields, including gas storage, catalysis, drug delivery, and environmental remediation.

The primary objective of this technical research report is to explore and evaluate strategies for cost-effective large-scale synthesis of MOFs. As the potential applications of MOFs continue to expand, there is an increasing demand for efficient and economical production methods that can bridge the gap between laboratory-scale synthesis and industrial-scale manufacturing. This transition is crucial for realizing the full potential of MOFs in real-world applications and commercialization.

The evolution of MOF synthesis techniques has been marked by significant milestones and innovations. Initially, MOFs were primarily synthesized using traditional solvothermal methods, which often required high temperatures, long reaction times, and expensive solvents. However, as research progressed, new synthetic approaches emerged, including room-temperature synthesis, mechanochemical methods, and continuous flow processes. These advancements have not only improved the efficiency of MOF production but also paved the way for more sustainable and scalable manufacturing techniques.

Despite these developments, several challenges persist in the large-scale synthesis of MOFs. These include the high cost of raw materials, especially organic ligands, the need for precise control over reaction conditions, and the environmental impact of solvent-intensive processes. Additionally, the scalability of synthesis methods while maintaining product quality and consistency remains a significant hurdle.

To address these challenges, researchers and industry professionals are exploring various strategies. These include the development of greener synthesis routes, optimization of reaction parameters for improved yield and quality, and the design of novel reactor systems for continuous production. Furthermore, there is a growing emphasis on utilizing low-cost precursors and recycling strategies to reduce overall production costs.

As we delve deeper into this technical research report, we will examine the current state of MOF synthesis technologies, analyze the market demands and potential applications, and evaluate promising approaches for cost-effective large-scale production. By comprehensively assessing these aspects, we aim to provide valuable insights and recommendations for advancing the field of MOF synthesis towards industrial-scale implementation.

The primary objective of this technical research report is to explore and evaluate strategies for cost-effective large-scale synthesis of MOFs. As the potential applications of MOFs continue to expand, there is an increasing demand for efficient and economical production methods that can bridge the gap between laboratory-scale synthesis and industrial-scale manufacturing. This transition is crucial for realizing the full potential of MOFs in real-world applications and commercialization.

The evolution of MOF synthesis techniques has been marked by significant milestones and innovations. Initially, MOFs were primarily synthesized using traditional solvothermal methods, which often required high temperatures, long reaction times, and expensive solvents. However, as research progressed, new synthetic approaches emerged, including room-temperature synthesis, mechanochemical methods, and continuous flow processes. These advancements have not only improved the efficiency of MOF production but also paved the way for more sustainable and scalable manufacturing techniques.

Despite these developments, several challenges persist in the large-scale synthesis of MOFs. These include the high cost of raw materials, especially organic ligands, the need for precise control over reaction conditions, and the environmental impact of solvent-intensive processes. Additionally, the scalability of synthesis methods while maintaining product quality and consistency remains a significant hurdle.

To address these challenges, researchers and industry professionals are exploring various strategies. These include the development of greener synthesis routes, optimization of reaction parameters for improved yield and quality, and the design of novel reactor systems for continuous production. Furthermore, there is a growing emphasis on utilizing low-cost precursors and recycling strategies to reduce overall production costs.

As we delve deeper into this technical research report, we will examine the current state of MOF synthesis technologies, analyze the market demands and potential applications, and evaluate promising approaches for cost-effective large-scale production. By comprehensively assessing these aspects, we aim to provide valuable insights and recommendations for advancing the field of MOF synthesis towards industrial-scale implementation.

Market Analysis for MOF Applications

The market for Metal-Organic Frameworks (MOFs) has shown significant growth potential across various industries. The global MOF market is expected to expand rapidly due to increasing applications in gas storage, separation, catalysis, and sensing technologies. Key sectors driving demand include energy storage, environmental remediation, and drug delivery systems.

In the energy sector, MOFs are gaining traction for their ability to store hydrogen and natural gas efficiently. This application aligns with the growing focus on clean energy solutions and sustainable transportation. The automotive industry, in particular, is exploring MOFs for hydrogen fuel cell vehicles, potentially revolutionizing the future of transportation.

Environmental applications represent another substantial market for MOFs. Their high surface area and tunable pore structures make them excellent candidates for carbon capture and storage (CCS) technologies. As governments worldwide implement stricter environmental regulations, the demand for effective CCS solutions is expected to surge, positioning MOFs as a critical component in emission reduction strategies.

The pharmaceutical industry is also recognizing the potential of MOFs in drug delivery systems. The controlled release properties of MOFs offer improved efficacy and reduced side effects in medication administration. This application is particularly promising for targeted cancer therapies and other complex treatments.

Water purification is emerging as a significant market for MOF applications. With increasing global concerns about water scarcity and contamination, MOFs' ability to remove pollutants and heavy metals from water sources is attracting attention from both public and private sectors.

The electronics industry is exploring MOFs for next-generation sensors and electronic devices. Their unique properties allow for the development of highly sensitive and selective sensors for various applications, including environmental monitoring and medical diagnostics.

Despite the promising market outlook, challenges remain in scaling up MOF production to meet industrial demands. The cost-effectiveness of large-scale synthesis is a critical factor influencing market adoption. Current production methods often involve expensive precursors and complex processes, limiting widespread commercial use.

To address these challenges, research efforts are focusing on developing more economical synthesis routes and identifying alternative, less expensive precursor materials. Innovations in continuous flow synthesis and mechanochemical methods show promise in reducing production costs and increasing scalability.

The market analysis indicates a growing interest from major chemical companies and startups alike in MOF technology. Strategic partnerships between academic institutions and industry players are accelerating the commercialization of MOF-based products. As production techniques improve and costs decrease, the market is expected to expand rapidly, with some estimates projecting a compound annual growth rate exceeding 10% over the next decade.

In the energy sector, MOFs are gaining traction for their ability to store hydrogen and natural gas efficiently. This application aligns with the growing focus on clean energy solutions and sustainable transportation. The automotive industry, in particular, is exploring MOFs for hydrogen fuel cell vehicles, potentially revolutionizing the future of transportation.

Environmental applications represent another substantial market for MOFs. Their high surface area and tunable pore structures make them excellent candidates for carbon capture and storage (CCS) technologies. As governments worldwide implement stricter environmental regulations, the demand for effective CCS solutions is expected to surge, positioning MOFs as a critical component in emission reduction strategies.

The pharmaceutical industry is also recognizing the potential of MOFs in drug delivery systems. The controlled release properties of MOFs offer improved efficacy and reduced side effects in medication administration. This application is particularly promising for targeted cancer therapies and other complex treatments.

Water purification is emerging as a significant market for MOF applications. With increasing global concerns about water scarcity and contamination, MOFs' ability to remove pollutants and heavy metals from water sources is attracting attention from both public and private sectors.

The electronics industry is exploring MOFs for next-generation sensors and electronic devices. Their unique properties allow for the development of highly sensitive and selective sensors for various applications, including environmental monitoring and medical diagnostics.

Despite the promising market outlook, challenges remain in scaling up MOF production to meet industrial demands. The cost-effectiveness of large-scale synthesis is a critical factor influencing market adoption. Current production methods often involve expensive precursors and complex processes, limiting widespread commercial use.

To address these challenges, research efforts are focusing on developing more economical synthesis routes and identifying alternative, less expensive precursor materials. Innovations in continuous flow synthesis and mechanochemical methods show promise in reducing production costs and increasing scalability.

The market analysis indicates a growing interest from major chemical companies and startups alike in MOF technology. Strategic partnerships between academic institutions and industry players are accelerating the commercialization of MOF-based products. As production techniques improve and costs decrease, the market is expected to expand rapidly, with some estimates projecting a compound annual growth rate exceeding 10% over the next decade.

Current Challenges in Large-Scale MOF Production

The large-scale production of Metal-Organic Frameworks (MOFs) faces several significant challenges that hinder their widespread industrial application. One of the primary obstacles is the high cost of raw materials, particularly organic linkers, which can account for a substantial portion of the overall production expenses. The synthesis of these linkers often involves complex and expensive processes, making it difficult to achieve cost-effective large-scale production.

Another major challenge is the scalability of synthesis methods. Many MOF synthesis techniques that work well in laboratory settings do not translate efficiently to industrial-scale production. This is often due to issues such as long reaction times, the need for high temperatures or pressures, and difficulties in maintaining uniform reaction conditions across large volumes. These factors not only increase production costs but also limit the ability to produce MOFs in quantities required for commercial applications.

The environmental impact of MOF production is also a significant concern. Traditional synthesis methods often involve the use of toxic solvents and generate considerable waste. As environmental regulations become more stringent, there is a growing need for greener synthesis routes that minimize the use of harmful chemicals and reduce waste generation. This challenge is particularly acute when scaling up production, as the environmental footprint becomes more substantial.

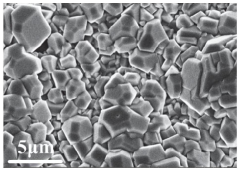

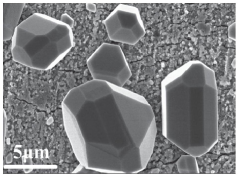

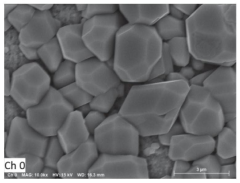

Quality control and reproducibility present another set of challenges in large-scale MOF production. Maintaining consistent product quality across batches is crucial for industrial applications but can be difficult to achieve due to the sensitivity of MOF formation to slight variations in reaction conditions. This issue is exacerbated at larger scales, where maintaining precise control over parameters such as temperature, pressure, and reagent concentrations becomes more challenging.

Furthermore, the post-synthesis processing of MOFs, including activation and shaping, poses additional challenges. Many MOFs require careful activation procedures to remove guest molecules and maximize porosity. Scaling up these processes while maintaining the integrity of the MOF structure is often problematic. Additionally, shaping MOFs into forms suitable for specific applications (e.g., pellets, monoliths, or membranes) without compromising their properties is a significant hurdle in large-scale production.

Lastly, the lack of standardized production methods and quality assessment protocols hampers the industrial adoption of MOFs. Unlike well-established materials, there is often a lack of consensus on the best practices for large-scale MOF synthesis and characterization. This absence of standardization makes it difficult for manufacturers to ensure consistent product quality and for end-users to compare MOFs from different sources reliably.

Another major challenge is the scalability of synthesis methods. Many MOF synthesis techniques that work well in laboratory settings do not translate efficiently to industrial-scale production. This is often due to issues such as long reaction times, the need for high temperatures or pressures, and difficulties in maintaining uniform reaction conditions across large volumes. These factors not only increase production costs but also limit the ability to produce MOFs in quantities required for commercial applications.

The environmental impact of MOF production is also a significant concern. Traditional synthesis methods often involve the use of toxic solvents and generate considerable waste. As environmental regulations become more stringent, there is a growing need for greener synthesis routes that minimize the use of harmful chemicals and reduce waste generation. This challenge is particularly acute when scaling up production, as the environmental footprint becomes more substantial.

Quality control and reproducibility present another set of challenges in large-scale MOF production. Maintaining consistent product quality across batches is crucial for industrial applications but can be difficult to achieve due to the sensitivity of MOF formation to slight variations in reaction conditions. This issue is exacerbated at larger scales, where maintaining precise control over parameters such as temperature, pressure, and reagent concentrations becomes more challenging.

Furthermore, the post-synthesis processing of MOFs, including activation and shaping, poses additional challenges. Many MOFs require careful activation procedures to remove guest molecules and maximize porosity. Scaling up these processes while maintaining the integrity of the MOF structure is often problematic. Additionally, shaping MOFs into forms suitable for specific applications (e.g., pellets, monoliths, or membranes) without compromising their properties is a significant hurdle in large-scale production.

Lastly, the lack of standardized production methods and quality assessment protocols hampers the industrial adoption of MOFs. Unlike well-established materials, there is often a lack of consensus on the best practices for large-scale MOF synthesis and characterization. This absence of standardization makes it difficult for manufacturers to ensure consistent product quality and for end-users to compare MOFs from different sources reliably.

Existing Large-Scale MOF Synthesis Methods

01 Cost-effective synthesis methods for MOFs

Various approaches have been developed to reduce the production costs of MOFs, including using cheaper precursors, optimizing reaction conditions, and employing more efficient synthesis techniques. These methods aim to make MOFs more economically viable for large-scale applications while maintaining their desirable properties.- Cost-effective synthesis methods: Developing efficient and economical synthesis methods for MOFs is crucial for their cost-effectiveness. This includes optimizing reaction conditions, using cheaper precursors, and implementing scalable production techniques. These approaches aim to reduce the overall production costs while maintaining the desired properties of the MOFs.

- Utilization of low-cost raw materials: Incorporating readily available and inexpensive raw materials in MOF synthesis can significantly reduce production costs. This involves exploring alternative metal sources, organic linkers, and solvents that are more economical without compromising the MOF's performance. The use of waste materials or industrial by-products as precursors is also being investigated to enhance cost-effectiveness.

- Improved MOF stability and reusability: Enhancing the stability and reusability of MOFs contributes to their cost-effectiveness by extending their lifespan and reducing the need for frequent replacement. This involves developing MOFs with improved chemical and thermal stability, as well as designing regeneration processes that allow for multiple use cycles without significant loss of performance.

- Large-scale production and industrial applications: Scaling up MOF production for industrial applications is essential for improving cost-effectiveness. This includes developing continuous flow synthesis methods, optimizing reactor designs, and implementing quality control measures for consistent large-scale production. Additionally, identifying and targeting high-value industrial applications can justify the production costs and increase the economic viability of MOFs.

- MOF-based composite materials: Developing MOF-based composite materials can enhance cost-effectiveness by combining the unique properties of MOFs with other materials. This approach allows for the creation of multifunctional materials with improved performance and broader application potential. By optimizing the composition and fabrication processes of these composites, it is possible to achieve a balance between cost and functionality.

02 Scalable production of MOFs

Researchers have focused on developing scalable production methods for MOFs to improve their cost-effectiveness. This includes continuous flow synthesis, mechanochemical approaches, and other innovative techniques that allow for larger-scale manufacturing while reducing energy consumption and waste generation.Expand Specific Solutions03 Recycling and reuse of MOFs

To enhance the cost-effectiveness of MOFs, strategies for recycling and reusing these materials have been explored. This includes developing methods for regenerating spent MOFs, recovering metal ions or organic linkers, and designing MOFs with improved stability and reusability for multiple cycles of use.Expand Specific Solutions04 Low-cost precursors and sustainable sources for MOF synthesis

Research has been conducted on utilizing low-cost precursors and sustainable sources for MOF synthesis to reduce overall production costs. This includes using waste materials, biomass-derived compounds, and abundant natural resources as starting materials for MOF production.Expand Specific Solutions05 Application-specific MOF design for cost-effectiveness

Efforts have been made to design MOFs tailored for specific applications, optimizing their performance while minimizing costs. This approach involves fine-tuning the MOF structure, composition, and properties to achieve the desired functionality with reduced material usage and improved efficiency in the target application.Expand Specific Solutions

Key Players in MOF Industry

The development of cost-effective large-scale synthesis strategies for Metal-Organic Frameworks (MOFs) is in a transitional phase, moving from laboratory-scale to industrial production. The market size is expanding rapidly due to increasing applications in gas storage, catalysis, and drug delivery. Technologically, the field is progressing from proof-of-concept to optimization and scalability. Key players like South China University of Technology, University of Washington, and China Petroleum & Chemical Corp. are advancing continuous flow synthesis methods. Meanwhile, companies such as BASF and ExxonMobil are focusing on improving yield and reducing production costs. The competition is intensifying as academic institutions collaborate with industry partners to bridge the gap between research and commercialization.

China Petroleum & Chemical Corp.

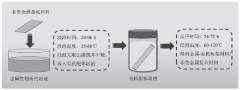

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has focused on developing cost-effective strategies for large-scale MOF synthesis, particularly for applications in gas storage and separation. They have implemented a modular, scalable approach to MOF production, utilizing a combination of continuous flow reactors and spray drying techniques. This method allows for the rapid production of MOF powders with controlled particle size distribution. Sinopec has optimized the synthesis of UiO-66 and ZIF-67, achieving production rates of several hundred kilograms per day[8]. Their process incorporates solvent recycling systems and energy recovery units to minimize operational costs. Additionally, Sinopec has explored the use of industrial by-products and waste streams as precursors for MOF synthesis, further reducing raw material costs and improving sustainability[9].

Strengths: Integration with existing chemical production infrastructure, focus on industrially relevant MOFs, and use of waste streams as precursors. Weaknesses: Limited public disclosure of specific methodologies due to proprietary concerns.

King Abdullah University of Science & Technology

Technical Solution: KAUST has developed a novel approach for large-scale MOF synthesis using flow chemistry techniques. Their method involves continuous flow reactors that allow for precise control of reaction conditions and rapid mixing of reagents. This approach has demonstrated a significant increase in production rates, with some MOFs being synthesized at kilogram-scale per day[1]. Additionally, KAUST researchers have implemented in-line purification and activation processes, reducing post-synthesis processing time and costs. They have also explored the use of alternative solvents and green chemistry principles to further reduce the environmental impact and cost of MOF production[2]. The university has successfully scaled up the synthesis of several commercially relevant MOFs, including ZIF-8 and UiO-66, achieving consistent quality and high surface areas comparable to lab-scale syntheses[3].

Strengths: High production rates, improved quality control, and reduced environmental impact. Weaknesses: Initial setup costs for flow chemistry equipment may be high, and the method may not be universally applicable to all MOF types.

Innovative Cost-Reduction Approaches

Synthesis of metal organic framework (MOF) materials with high adsorption capacity of organic compounds and co2 capture

PatentPendingCA3240753A1

Innovation

- Development of MOFs synthesized using aryl compounds with carboxylate and ether groups, specifically ligands with certain structural configurations, which form stable frameworks with metals, offering high thermostability and enhanced CO2 and organic compound adsorption capacity.

Metal-organic framework material realizing interfacial in-situ growth and preparation method and application of metal-organic framework material

PatentActiveCN112940268A

Innovation

- The non-noble metal material is contacted with a solution containing alkaline substances for corrosion treatment, and fully contacted with an organic ligand solution for an in-situ interface reaction to prepare a porous structure of metal-organic framework materials for use as catalytic electrodes in electrocatalytic reactions.

Environmental Impact of MOF Production

The large-scale production of Metal-Organic Frameworks (MOFs) raises significant environmental concerns that must be addressed for sustainable implementation. The synthesis of MOFs often involves the use of organic solvents, which can have detrimental effects on the environment if not properly managed. These solvents, such as N,N-dimethylformamide (DMF) and methanol, are frequently used in MOF production and can contribute to air and water pollution if released into the environment.

Furthermore, the energy-intensive nature of MOF synthesis processes, particularly those requiring high temperatures or pressures, contributes to increased carbon emissions. This aspect becomes especially critical when considering the scale-up of production to meet industrial demands. The environmental impact of energy consumption in MOF production is an important factor that needs to be carefully evaluated and mitigated through the development of more energy-efficient synthesis methods.

Another environmental consideration is the sourcing of raw materials for MOF production. Some MOFs require rare or precious metals as components, and the mining and extraction of these materials can have significant ecological consequences. Sustainable sourcing practices and the exploration of alternative, more abundant materials are crucial for minimizing the environmental footprint of MOF production.

The disposal and end-of-life management of MOFs also present environmental challenges. While many MOFs are designed for specific applications, their eventual disposal or recycling must be considered to prevent potential contamination of ecosystems. Developing effective recycling methods for MOFs and their precursors is essential for creating a circular economy approach to their production and use.

Water usage in MOF synthesis is another environmental concern, particularly in regions where water scarcity is an issue. Some MOF production methods require substantial amounts of water for synthesis and purification processes. Implementing water-efficient techniques and exploring waterless synthesis methods can help reduce the environmental impact associated with water consumption.

To address these environmental challenges, researchers and industry professionals are exploring greener synthesis routes for MOFs. This includes the development of solvent-free or water-based synthesis methods, the use of renewable energy sources for production, and the implementation of continuous flow processes that can reduce waste and energy consumption. Additionally, life cycle assessments (LCAs) are being conducted to comprehensively evaluate the environmental impact of MOF production from raw material extraction to final disposal.

Furthermore, the energy-intensive nature of MOF synthesis processes, particularly those requiring high temperatures or pressures, contributes to increased carbon emissions. This aspect becomes especially critical when considering the scale-up of production to meet industrial demands. The environmental impact of energy consumption in MOF production is an important factor that needs to be carefully evaluated and mitigated through the development of more energy-efficient synthesis methods.

Another environmental consideration is the sourcing of raw materials for MOF production. Some MOFs require rare or precious metals as components, and the mining and extraction of these materials can have significant ecological consequences. Sustainable sourcing practices and the exploration of alternative, more abundant materials are crucial for minimizing the environmental footprint of MOF production.

The disposal and end-of-life management of MOFs also present environmental challenges. While many MOFs are designed for specific applications, their eventual disposal or recycling must be considered to prevent potential contamination of ecosystems. Developing effective recycling methods for MOFs and their precursors is essential for creating a circular economy approach to their production and use.

Water usage in MOF synthesis is another environmental concern, particularly in regions where water scarcity is an issue. Some MOF production methods require substantial amounts of water for synthesis and purification processes. Implementing water-efficient techniques and exploring waterless synthesis methods can help reduce the environmental impact associated with water consumption.

To address these environmental challenges, researchers and industry professionals are exploring greener synthesis routes for MOFs. This includes the development of solvent-free or water-based synthesis methods, the use of renewable energy sources for production, and the implementation of continuous flow processes that can reduce waste and energy consumption. Additionally, life cycle assessments (LCAs) are being conducted to comprehensively evaluate the environmental impact of MOF production from raw material extraction to final disposal.

Economic Feasibility Analysis

The economic feasibility of large-scale synthesis of Metal-Organic Frameworks (MOFs) is a critical factor in determining their potential for widespread industrial applications. The cost-effectiveness of MOF production depends on several key factors, including raw material costs, energy consumption, synthesis time, and scalability of the production process.

Raw material costs constitute a significant portion of the overall production expenses. Many MOFs require expensive organic linkers and metal salts, which can substantially impact the economic viability of large-scale synthesis. To address this challenge, researchers are exploring the use of more affordable and readily available precursors, such as waste materials or byproducts from other industrial processes.

Energy consumption during synthesis is another crucial economic consideration. Traditional solvothermal methods often require high temperatures and pressures, leading to increased energy costs. Alternative synthesis techniques, such as mechanochemical methods or room-temperature synthesis, are being investigated to reduce energy requirements and improve cost-effectiveness.

The synthesis time also plays a vital role in the economic feasibility of MOF production. Longer reaction times result in lower throughput and increased labor costs. Efforts are being made to develop rapid synthesis methods, such as microwave-assisted synthesis or continuous flow processes, to minimize production time and enhance efficiency.

Scalability is a critical factor in determining the economic viability of large-scale MOF synthesis. Many laboratory-scale synthesis methods face challenges when scaled up to industrial levels. Researchers are focusing on developing scalable production techniques that maintain product quality and yield while minimizing costs. Continuous flow reactors and spray-drying methods show promise in this regard.

The choice of solvent can significantly impact the overall production costs. Many MOF syntheses rely on expensive or environmentally harmful solvents. Developing solvent-free or water-based synthesis methods can reduce both material costs and environmental impact, improving the economic feasibility of large-scale production.

Post-synthesis processing, including activation and purification steps, can contribute substantially to the overall production costs. Optimizing these processes to minimize material loss and energy consumption is crucial for improving economic viability. Innovative activation techniques, such as supercritical CO2 activation, are being explored to reduce costs and enhance efficiency.

Market demand and potential applications also play a crucial role in determining the economic feasibility of large-scale MOF synthesis. As the range of applications for MOFs expands, economies of scale can be achieved, potentially reducing production costs. Identifying high-value applications that can justify higher production costs is essential for the economic viability of MOF synthesis at industrial scales.

Raw material costs constitute a significant portion of the overall production expenses. Many MOFs require expensive organic linkers and metal salts, which can substantially impact the economic viability of large-scale synthesis. To address this challenge, researchers are exploring the use of more affordable and readily available precursors, such as waste materials or byproducts from other industrial processes.

Energy consumption during synthesis is another crucial economic consideration. Traditional solvothermal methods often require high temperatures and pressures, leading to increased energy costs. Alternative synthesis techniques, such as mechanochemical methods or room-temperature synthesis, are being investigated to reduce energy requirements and improve cost-effectiveness.

The synthesis time also plays a vital role in the economic feasibility of MOF production. Longer reaction times result in lower throughput and increased labor costs. Efforts are being made to develop rapid synthesis methods, such as microwave-assisted synthesis or continuous flow processes, to minimize production time and enhance efficiency.

Scalability is a critical factor in determining the economic viability of large-scale MOF synthesis. Many laboratory-scale synthesis methods face challenges when scaled up to industrial levels. Researchers are focusing on developing scalable production techniques that maintain product quality and yield while minimizing costs. Continuous flow reactors and spray-drying methods show promise in this regard.

The choice of solvent can significantly impact the overall production costs. Many MOF syntheses rely on expensive or environmentally harmful solvents. Developing solvent-free or water-based synthesis methods can reduce both material costs and environmental impact, improving the economic feasibility of large-scale production.

Post-synthesis processing, including activation and purification steps, can contribute substantially to the overall production costs. Optimizing these processes to minimize material loss and energy consumption is crucial for improving economic viability. Innovative activation techniques, such as supercritical CO2 activation, are being explored to reduce costs and enhance efficiency.

Market demand and potential applications also play a crucial role in determining the economic feasibility of large-scale MOF synthesis. As the range of applications for MOFs expands, economies of scale can be achieved, potentially reducing production costs. Identifying high-value applications that can justify higher production costs is essential for the economic viability of MOF synthesis at industrial scales.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!