Supercharging Versus Turbocharging in 2JZ Applications

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

2JZ Forced Induction Evolution

The evolution of forced induction systems for the 2JZ engine has been a fascinating journey, marked by significant technological advancements and performance breakthroughs. Initially, the 2JZ-GTE, found in the iconic Toyota Supra, came factory-equipped with sequential twin turbochargers, setting a high standard for performance and reliability.

As enthusiasts and tuners began to explore the engine's potential, the focus shifted towards single turbo conversions. This transition was driven by the desire for simpler setups, reduced lag, and higher power outputs. The single turbo configuration allowed for larger turbine wheels and compressor housings, enabling greater airflow and boost pressure.

In the early 2000s, advancements in turbocharger technology led to the development of ball bearing turbos, which significantly reduced spool-up times and improved overall efficiency. This innovation addressed one of the primary criticisms of turbocharging – lag – and made single turbo setups even more appealing for 2JZ applications.

Concurrently, supercharging began to gain traction as an alternative forced induction method for the 2JZ. Centrifugal superchargers, in particular, offered instant throttle response and linear power delivery, attributes that were highly valued in certain racing disciplines and street applications. The Vortech V-2 and Paxton NOVI series became popular choices among 2JZ enthusiasts seeking a different power delivery characteristic.

As turbocharger technology continued to evolve, variable geometry turbos (VGTs) entered the scene. These advanced units offered the best of both worlds – quick spool-up at low RPMs and high flow capacity at higher engine speeds. While initially more common in diesel applications, VGTs began to find their way into high-performance gasoline engines, including modified 2JZs.

The late 2000s and early 2010s saw a resurgence of interest in twin-turbo setups, but with a twist. Instead of the sequential factory configuration, parallel twin-turbo systems became popular. This setup utilized two identical, smaller turbos that spooled quickly and provided a broad powerband. The advent of modern ECUs and advanced engine management systems made it easier to control and optimize these complex setups.

Most recently, electric forced induction systems have begun to make inroads in the 2JZ tuning world. Electric superchargers and hybrid turbo systems, which combine traditional exhaust-driven turbines with electric compressors, offer near-instantaneous boost and the ability to fine-tune power delivery across the entire RPM range.

As enthusiasts and tuners began to explore the engine's potential, the focus shifted towards single turbo conversions. This transition was driven by the desire for simpler setups, reduced lag, and higher power outputs. The single turbo configuration allowed for larger turbine wheels and compressor housings, enabling greater airflow and boost pressure.

In the early 2000s, advancements in turbocharger technology led to the development of ball bearing turbos, which significantly reduced spool-up times and improved overall efficiency. This innovation addressed one of the primary criticisms of turbocharging – lag – and made single turbo setups even more appealing for 2JZ applications.

Concurrently, supercharging began to gain traction as an alternative forced induction method for the 2JZ. Centrifugal superchargers, in particular, offered instant throttle response and linear power delivery, attributes that were highly valued in certain racing disciplines and street applications. The Vortech V-2 and Paxton NOVI series became popular choices among 2JZ enthusiasts seeking a different power delivery characteristic.

As turbocharger technology continued to evolve, variable geometry turbos (VGTs) entered the scene. These advanced units offered the best of both worlds – quick spool-up at low RPMs and high flow capacity at higher engine speeds. While initially more common in diesel applications, VGTs began to find their way into high-performance gasoline engines, including modified 2JZs.

The late 2000s and early 2010s saw a resurgence of interest in twin-turbo setups, but with a twist. Instead of the sequential factory configuration, parallel twin-turbo systems became popular. This setup utilized two identical, smaller turbos that spooled quickly and provided a broad powerband. The advent of modern ECUs and advanced engine management systems made it easier to control and optimize these complex setups.

Most recently, electric forced induction systems have begun to make inroads in the 2JZ tuning world. Electric superchargers and hybrid turbo systems, which combine traditional exhaust-driven turbines with electric compressors, offer near-instantaneous boost and the ability to fine-tune power delivery across the entire RPM range.

Market Demand Analysis

The market demand for supercharging and turbocharging solutions in 2JZ applications has seen significant growth in recent years, driven by the enduring popularity of the Toyota 2JZ engine among performance enthusiasts and motorsport professionals. This iconic inline-six engine, known for its robust design and high tuning potential, continues to be a preferred choice for aftermarket modifications and high-performance builds.

The automotive aftermarket industry has witnessed a surge in demand for forced induction systems specifically tailored for 2JZ engines. This trend is fueled by the desire for increased horsepower and torque output without sacrificing reliability. Both supercharging and turbocharging options have garnered substantial interest, each offering unique advantages that cater to different performance goals and driving preferences.

Supercharging solutions for 2JZ applications have gained traction among enthusiasts seeking immediate throttle response and linear power delivery. The market has responded with a variety of centrifugal and positive displacement supercharger kits designed to bolt onto 2JZ engines with minimal modifications. These systems appeal to drivers who prioritize street performance and daily drivability, as they provide instant boost and predictable power characteristics.

Conversely, turbocharging remains a dominant force in the 2JZ market, particularly for high-horsepower builds and competitive racing applications. The adaptability of turbocharger systems to various power goals has led to a diverse range of products, from single turbo setups for moderate power increases to twin-turbo configurations capable of producing over 1000 horsepower. This versatility has contributed to the sustained demand for turbocharging solutions in the 2JZ aftermarket.

The market has also seen a growing interest in hybrid forced induction setups, combining the benefits of both supercharging and turbocharging. These complex systems aim to eliminate the weaknesses of each method while maximizing performance across the entire RPM range. Although niche, this segment represents an emerging trend in high-end 2JZ builds and showcases the market's appetite for innovative forced induction solutions.

Global market trends indicate a steady increase in the adoption of forced induction systems for 2JZ engines, with notable growth in regions with strong automotive enthusiast communities, such as North America, Europe, and parts of Asia. The aftermarket industry has responded by expanding product lines and improving the accessibility of high-quality forced induction kits for 2JZ applications, catering to a wide range of budgets and performance targets.

The automotive aftermarket industry has witnessed a surge in demand for forced induction systems specifically tailored for 2JZ engines. This trend is fueled by the desire for increased horsepower and torque output without sacrificing reliability. Both supercharging and turbocharging options have garnered substantial interest, each offering unique advantages that cater to different performance goals and driving preferences.

Supercharging solutions for 2JZ applications have gained traction among enthusiasts seeking immediate throttle response and linear power delivery. The market has responded with a variety of centrifugal and positive displacement supercharger kits designed to bolt onto 2JZ engines with minimal modifications. These systems appeal to drivers who prioritize street performance and daily drivability, as they provide instant boost and predictable power characteristics.

Conversely, turbocharging remains a dominant force in the 2JZ market, particularly for high-horsepower builds and competitive racing applications. The adaptability of turbocharger systems to various power goals has led to a diverse range of products, from single turbo setups for moderate power increases to twin-turbo configurations capable of producing over 1000 horsepower. This versatility has contributed to the sustained demand for turbocharging solutions in the 2JZ aftermarket.

The market has also seen a growing interest in hybrid forced induction setups, combining the benefits of both supercharging and turbocharging. These complex systems aim to eliminate the weaknesses of each method while maximizing performance across the entire RPM range. Although niche, this segment represents an emerging trend in high-end 2JZ builds and showcases the market's appetite for innovative forced induction solutions.

Global market trends indicate a steady increase in the adoption of forced induction systems for 2JZ engines, with notable growth in regions with strong automotive enthusiast communities, such as North America, Europe, and parts of Asia. The aftermarket industry has responded by expanding product lines and improving the accessibility of high-quality forced induction kits for 2JZ applications, catering to a wide range of budgets and performance targets.

Current Tech Challenges

The current technical challenges in comparing supercharging versus turbocharging for 2JZ applications stem from the inherent differences between these forced induction methods and their interaction with the iconic 2JZ engine architecture. One primary challenge is optimizing boost pressure and delivery for each system. Turbochargers, relying on exhaust gases, often suffer from lag at lower RPMs, while superchargers provide more immediate boost but may struggle with efficiency at higher engine speeds.

Heat management presents another significant hurdle. Turbochargers generate considerable heat, necessitating advanced intercooling solutions to maintain charge air density. Superchargers, while generally running cooler, still contribute to increased underhood temperatures, requiring careful consideration of heat dissipation strategies to prevent performance degradation and potential engine damage.

The 2JZ's robust bottom end can handle substantial power increases, but the stock fuel system becomes a limiting factor when pushing either forced induction method to its limits. Upgrading fuel injectors, pumps, and management systems to cope with increased air volume and maintain proper air-fuel ratios across the entire RPM range is a complex task that requires precise calibration.

Durability and longevity concerns arise when significantly increasing power output. While the 2JZ is renowned for its strength, prolonged operation under high boost conditions can accelerate wear on internal components, particularly valve train elements and piston rings. Balancing performance gains with long-term reliability remains a persistent challenge for both supercharging and turbocharging applications.

Integration with modern engine management systems poses another technical hurdle. Adapting aftermarket ECUs or modifying stock systems to effectively control boost, fueling, and ignition timing for either forced induction method requires extensive tuning expertise and often custom solutions tailored to specific setups.

Packaging constraints within the engine bay of vehicles originally equipped with 2JZ engines create additional complications. Accommodating larger turbochargers or belt-driven superchargers, along with associated plumbing and intercoolers, often necessitates creative mounting solutions or extensive modifications to surrounding components.

Emissions compliance represents an increasingly important challenge, particularly in regions with stringent regulations. Ensuring that heavily modified 2JZ engines with either supercharging or turbocharging can meet emissions standards without sacrificing performance is a complex engineering task that requires sophisticated catalytic converter designs and precise engine management strategies.

Heat management presents another significant hurdle. Turbochargers generate considerable heat, necessitating advanced intercooling solutions to maintain charge air density. Superchargers, while generally running cooler, still contribute to increased underhood temperatures, requiring careful consideration of heat dissipation strategies to prevent performance degradation and potential engine damage.

The 2JZ's robust bottom end can handle substantial power increases, but the stock fuel system becomes a limiting factor when pushing either forced induction method to its limits. Upgrading fuel injectors, pumps, and management systems to cope with increased air volume and maintain proper air-fuel ratios across the entire RPM range is a complex task that requires precise calibration.

Durability and longevity concerns arise when significantly increasing power output. While the 2JZ is renowned for its strength, prolonged operation under high boost conditions can accelerate wear on internal components, particularly valve train elements and piston rings. Balancing performance gains with long-term reliability remains a persistent challenge for both supercharging and turbocharging applications.

Integration with modern engine management systems poses another technical hurdle. Adapting aftermarket ECUs or modifying stock systems to effectively control boost, fueling, and ignition timing for either forced induction method requires extensive tuning expertise and often custom solutions tailored to specific setups.

Packaging constraints within the engine bay of vehicles originally equipped with 2JZ engines create additional complications. Accommodating larger turbochargers or belt-driven superchargers, along with associated plumbing and intercoolers, often necessitates creative mounting solutions or extensive modifications to surrounding components.

Emissions compliance represents an increasingly important challenge, particularly in regions with stringent regulations. Ensuring that heavily modified 2JZ engines with either supercharging or turbocharging can meet emissions standards without sacrificing performance is a complex engineering task that requires sophisticated catalytic converter designs and precise engine management strategies.

Existing 2JZ Boost Solutions

01 Engine management systems for power output control

Advanced engine management systems are employed to optimize the power output of 2JZ engines. These systems control various parameters such as fuel injection, ignition timing, and boost pressure to maximize performance while maintaining reliability. By fine-tuning these aspects, the engine's power output can be significantly increased from its stock configuration.- Engine management systems for power output control: Advanced engine management systems are utilized to optimize the power output of the 2JZ engine. These systems control various parameters such as fuel injection, ignition timing, and boost pressure to maximize performance while maintaining reliability. By fine-tuning these aspects, the engine's power output can be significantly increased from its stock configuration.

- Turbocharger modifications for increased power: Modifications to the turbocharger system can substantially boost the 2JZ engine's power output. This may involve upgrading to larger turbochargers, implementing twin-turbo setups, or adjusting boost pressure. These changes allow for increased airflow into the engine, resulting in higher power production.

- Fuel system enhancements: Improving the fuel system is crucial for increasing the 2JZ engine's power output. This can include upgrading fuel injectors, fuel pumps, and fuel pressure regulators to ensure adequate fuel delivery at higher power levels. Additionally, modifying the engine management system to optimize fuel mapping can further enhance power output.

- Internal engine modifications for increased performance: Various internal modifications can be made to the 2JZ engine to increase its power output. These may include installing forged pistons, stronger connecting rods, performance camshafts, and ported cylinder heads. Such modifications allow the engine to withstand higher pressures and rev limits, ultimately producing more power.

- Exhaust system optimization: Optimizing the exhaust system can significantly improve the 2JZ engine's power output. This may involve installing larger diameter exhaust pipes, high-flow catalytic converters, and performance mufflers. Reducing back pressure in the exhaust system allows the engine to expel exhaust gases more efficiently, resulting in increased power production.

02 Turbocharger modifications for increased power

Modifications to the turbocharger system can substantially boost the 2JZ engine's power output. This may involve upgrading to larger turbochargers, implementing twin-turbo setups, or adjusting boost pressure. These changes allow for increased airflow and combustion efficiency, resulting in higher horsepower and torque figures.Expand Specific Solutions03 Fuel system enhancements

Upgrading the fuel system is crucial for supporting increased power output in 2JZ engines. This includes installing larger fuel injectors, high-flow fuel pumps, and modifying the fuel rail. These improvements ensure adequate fuel delivery to match the increased air intake, allowing for proper air-fuel ratios at higher power levels.Expand Specific Solutions04 Intake and exhaust system modifications

Optimizing the intake and exhaust systems can significantly improve the 2JZ engine's power output. This may involve installing high-flow air filters, larger intake manifolds, and performance exhaust systems. These modifications reduce restrictions and improve overall engine breathing, leading to increased horsepower and torque.Expand Specific Solutions05 Internal engine component upgrades

To achieve higher power outputs, internal engine components may need to be upgraded. This can include forged pistons, stronger connecting rods, and reinforced cylinder heads. These upgrades allow the engine to withstand higher cylinder pressures and RPMs, enabling more aggressive tuning for increased power output.Expand Specific Solutions

Key Industry Players

The competition in supercharging versus turbocharging for 2JZ applications is at a mature stage, with established players and ongoing innovation. The market size is significant, driven by performance enthusiasts and racing applications. Technologically, both supercharging and turbocharging are well-developed, with companies like Toyota, Ford, and Mitsubishi Heavy Industries leading in turbocharging technology. Specialized firms such as SuperTurbo Technologies are pushing boundaries in hybrid turbocharging systems. The landscape is competitive, with major automotive manufacturers and aftermarket suppliers vying for market share through continuous improvements in efficiency, power output, and reliability.

Ford Global Technologies LLC

Technical Solution: Ford has developed a unique approach to forced induction for high-performance engines like the 2JZ, combining elements of both supercharging and turbocharging. Their "TwinForce" technology utilizes a twin-turbocharger system supplemented by an electric supercharger[1]. The electric supercharger provides instant boost at low RPMs, eliminating turbo lag, while the turbochargers take over at higher engine speeds for maximum power[2]. Ford's system incorporates advanced electronic control units to manage boost pressure and air-fuel ratios across the entire rev range[3]. They have also implemented a water-to-air charge cooling system to maintain optimal intake temperatures under high-load conditions[4]. This hybrid forced induction approach aims to combine the best aspects of supercharging and turbocharging for 2JZ-like applications.

Strengths: Excellent low-end response and high-end power, reduced turbo lag. Weaknesses: Increased system complexity and potential reliability concerns due to multiple forced induction components.

Toyota Motor Corp.

Technical Solution: Toyota has developed advanced turbocharging technology for their 2JZ engine, focusing on improving efficiency and performance. Their system utilizes a twin-scroll turbocharger design, which separates exhaust pulses to reduce turbo lag and improve low-end torque[1]. Toyota has also implemented variable nozzle technology (VNT) in their turbochargers, allowing for optimized exhaust flow across a wider range of engine speeds[2]. Additionally, they have integrated an air-to-water intercooler system to enhance charge cooling efficiency, resulting in improved power output and fuel economy[3]. Toyota's turbocharging solution for the 2JZ engine includes advanced materials such as heat-resistant alloys for the turbine wheel and ceramic ball bearings to reduce friction and improve durability[4].

Strengths: Proven reliability, excellent low-end torque, and seamless power delivery. Weaknesses: Potentially higher manufacturing costs and complexity compared to simpler forced induction systems.

Core Innovations Analysis

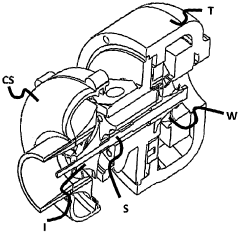

A turbine wheel, a turbine and use thereof

PatentWO2012114058A1

Innovation

- A novel turbine wheel design with a specific area ratio of outlet to inlet area (A2/A1) less than approximately 0.4, combined with a shroud covering the wheel, and optimized exit relative flow angle between -41 degrees and -55 degrees, which allows for high performance at low pressure ratios by optimizing the geometry and flow conditions.

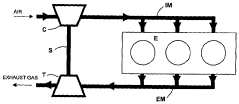

Variable speed compressor and control system

PatentWO2012103431A1

Innovation

- A variable speed compressor system integrated with an alternator and electric machine, utilizing a three-shaft drive system and a controller to provide three operating modes: boosting, neutral, and charging, allowing for intelligent electric power generation and control of compressor speed and torque across the entire engine speed range.

Performance Benchmarking

Performance benchmarking is a critical aspect of evaluating the effectiveness of supercharging versus turbocharging in 2JZ applications. This process involves comprehensive testing and analysis to compare the performance characteristics of both forced induction methods.

To conduct a thorough performance benchmark, researchers typically begin by establishing baseline measurements for a stock 2JZ engine. This includes dyno testing to determine horsepower, torque, and power delivery across the RPM range. Additionally, acceleration times, quarter-mile performance, and top speed are recorded.

Once baseline data is collected, separate 2JZ engines are fitted with comparable supercharger and turbocharger systems. Care is taken to ensure that both setups are optimized for similar boost levels and overall performance goals. This allows for a fair comparison between the two forced induction methods.

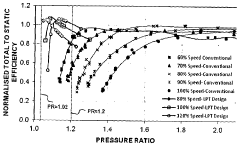

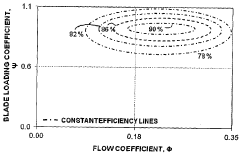

Dyno testing is then performed on both the supercharged and turbocharged engines. Power curves are analyzed to compare not only peak horsepower and torque figures but also the characteristics of power delivery throughout the RPM range. Supercharged engines often exhibit a more linear power curve, while turbocharged setups may show a more pronounced power spike at higher RPMs.

Real-world performance testing is equally important. This includes measuring 0-60 mph times, quarter-mile times and trap speeds, and top speed runs. These tests help quantify the differences in acceleration and overall performance between supercharged and turbocharged 2JZ applications.

Throttle response and lag are also crucial factors in the benchmarking process. Superchargers typically provide more immediate throttle response, while turbochargers may exhibit some lag before full boost is achieved. Specialized testing equipment can measure the time between throttle input and power delivery to quantify these differences.

Fuel efficiency and emissions are additional considerations in modern performance benchmarking. Both supercharged and turbocharged setups are evaluated for their impact on fuel consumption and emissions output compared to the stock engine. This data is particularly relevant for street-driven applications and vehicles that must meet emissions regulations.

Lastly, durability testing is conducted to assess the long-term reliability of both forced induction methods. This involves extended dyno runs and real-world driving scenarios to evaluate component wear, heat management, and overall system longevity.

By compiling and analyzing this comprehensive set of performance data, engineers and enthusiasts can make informed decisions about the most suitable forced induction method for their specific 2JZ application, whether it be for street use, racing, or a combination of both.

To conduct a thorough performance benchmark, researchers typically begin by establishing baseline measurements for a stock 2JZ engine. This includes dyno testing to determine horsepower, torque, and power delivery across the RPM range. Additionally, acceleration times, quarter-mile performance, and top speed are recorded.

Once baseline data is collected, separate 2JZ engines are fitted with comparable supercharger and turbocharger systems. Care is taken to ensure that both setups are optimized for similar boost levels and overall performance goals. This allows for a fair comparison between the two forced induction methods.

Dyno testing is then performed on both the supercharged and turbocharged engines. Power curves are analyzed to compare not only peak horsepower and torque figures but also the characteristics of power delivery throughout the RPM range. Supercharged engines often exhibit a more linear power curve, while turbocharged setups may show a more pronounced power spike at higher RPMs.

Real-world performance testing is equally important. This includes measuring 0-60 mph times, quarter-mile times and trap speeds, and top speed runs. These tests help quantify the differences in acceleration and overall performance between supercharged and turbocharged 2JZ applications.

Throttle response and lag are also crucial factors in the benchmarking process. Superchargers typically provide more immediate throttle response, while turbochargers may exhibit some lag before full boost is achieved. Specialized testing equipment can measure the time between throttle input and power delivery to quantify these differences.

Fuel efficiency and emissions are additional considerations in modern performance benchmarking. Both supercharged and turbocharged setups are evaluated for their impact on fuel consumption and emissions output compared to the stock engine. This data is particularly relevant for street-driven applications and vehicles that must meet emissions regulations.

Lastly, durability testing is conducted to assess the long-term reliability of both forced induction methods. This involves extended dyno runs and real-world driving scenarios to evaluate component wear, heat management, and overall system longevity.

By compiling and analyzing this comprehensive set of performance data, engineers and enthusiasts can make informed decisions about the most suitable forced induction method for their specific 2JZ application, whether it be for street use, racing, or a combination of both.

Emissions Compliance Strategies

Emissions compliance strategies play a crucial role in the development and implementation of supercharging and turbocharging systems for 2JZ applications. As environmental regulations become increasingly stringent, manufacturers and aftermarket tuners must adapt their forced induction solutions to meet these standards while maintaining performance.

One key strategy for emissions compliance is the integration of advanced catalytic converter systems. These systems are designed to reduce harmful emissions by converting pollutants into less harmful substances. In the context of supercharged and turbocharged 2JZ engines, high-flow catalytic converters are often employed to handle the increased exhaust flow while still meeting emissions requirements.

Another important approach is the use of electronic engine management systems. These sophisticated control units allow for precise tuning of fuel injection and ignition timing, optimizing combustion efficiency and minimizing emissions. Advanced engine management systems can also incorporate closed-loop feedback from oxygen sensors to continuously adjust the air-fuel ratio, ensuring optimal performance and emissions compliance across various operating conditions.

Exhaust gas recirculation (EGR) systems are also commonly employed to reduce nitrogen oxide (NOx) emissions. By recirculating a portion of the exhaust gases back into the combustion chamber, peak combustion temperatures are lowered, resulting in reduced NOx formation. In forced induction applications, careful integration of EGR systems is necessary to balance emissions reduction with performance goals.

The use of high-quality, low-sulfur fuels is another critical strategy for emissions compliance. These fuels not only reduce sulfur dioxide emissions but also help maintain the efficiency of catalytic converters and other emissions control devices. For supercharged and turbocharged 2JZ engines, the selection of appropriate fuel becomes even more critical due to the higher combustion pressures and temperatures involved.

Intercooling systems play a dual role in emissions compliance and performance enhancement. By reducing the temperature of the compressed air entering the engine, intercoolers not only improve power output but also help lower NOx emissions by reducing peak combustion temperatures. The design and efficiency of intercooling systems can significantly impact both performance and emissions characteristics of forced induction 2JZ applications.

Lastly, the implementation of on-board diagnostics (OBD) systems is crucial for ensuring long-term emissions compliance. These systems continuously monitor various engine parameters and emissions control components, alerting the driver to any malfunctions that could lead to increased emissions. For supercharged and turbocharged 2JZ engines, robust OBD systems are essential to maintain compliance with increasingly stringent emissions regulations while preserving the high-performance characteristics that enthusiasts demand.

One key strategy for emissions compliance is the integration of advanced catalytic converter systems. These systems are designed to reduce harmful emissions by converting pollutants into less harmful substances. In the context of supercharged and turbocharged 2JZ engines, high-flow catalytic converters are often employed to handle the increased exhaust flow while still meeting emissions requirements.

Another important approach is the use of electronic engine management systems. These sophisticated control units allow for precise tuning of fuel injection and ignition timing, optimizing combustion efficiency and minimizing emissions. Advanced engine management systems can also incorporate closed-loop feedback from oxygen sensors to continuously adjust the air-fuel ratio, ensuring optimal performance and emissions compliance across various operating conditions.

Exhaust gas recirculation (EGR) systems are also commonly employed to reduce nitrogen oxide (NOx) emissions. By recirculating a portion of the exhaust gases back into the combustion chamber, peak combustion temperatures are lowered, resulting in reduced NOx formation. In forced induction applications, careful integration of EGR systems is necessary to balance emissions reduction with performance goals.

The use of high-quality, low-sulfur fuels is another critical strategy for emissions compliance. These fuels not only reduce sulfur dioxide emissions but also help maintain the efficiency of catalytic converters and other emissions control devices. For supercharged and turbocharged 2JZ engines, the selection of appropriate fuel becomes even more critical due to the higher combustion pressures and temperatures involved.

Intercooling systems play a dual role in emissions compliance and performance enhancement. By reducing the temperature of the compressed air entering the engine, intercoolers not only improve power output but also help lower NOx emissions by reducing peak combustion temperatures. The design and efficiency of intercooling systems can significantly impact both performance and emissions characteristics of forced induction 2JZ applications.

Lastly, the implementation of on-board diagnostics (OBD) systems is crucial for ensuring long-term emissions compliance. These systems continuously monitor various engine parameters and emissions control components, alerting the driver to any malfunctions that could lead to increased emissions. For supercharged and turbocharged 2JZ engines, robust OBD systems are essential to maintain compliance with increasingly stringent emissions regulations while preserving the high-performance characteristics that enthusiasts demand.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!