Sustainability Claims And Life Cycle Disclosure For Fermented Materials

SEP 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Fermentation Technology Background and Sustainability Goals

Fermentation technology represents one of humanity's oldest biotechnological processes, dating back thousands of years with applications in food preservation, beverage production, and medicine. Traditional fermentation has evolved dramatically in recent decades, transforming into a sophisticated industrial bioprocessing technique with applications spanning pharmaceuticals, chemicals, materials, and sustainable alternatives to conventional manufacturing processes. This evolution has been driven by advances in synthetic biology, bioinformatics, and bioprocess engineering, enabling precise control over microbial metabolism and product formation.

The modern fermentation industry has experienced significant growth due to increasing consumer demand for sustainable products and corporate commitments to reduce environmental footprints. Fermentation offers a promising pathway to sustainability as it typically requires less energy, generates fewer greenhouse gas emissions, and utilizes renewable feedstocks compared to traditional chemical synthesis or animal agriculture. The technology enables the production of materials with similar or enhanced functional properties while potentially reducing land use, water consumption, and waste generation.

Current fermentation technology encompasses several approaches, including traditional fermentation, precision fermentation, and biomass fermentation. Each method presents distinct sustainability advantages and challenges across their life cycles. Traditional fermentation transforms whole food ingredients, while precision fermentation engineers microorganisms to produce specific functional molecules. Biomass fermentation cultivates microbial biomass as a primary product, often serving as protein alternatives.

The sustainability goals associated with fermented materials center on several key objectives. First, reducing the environmental impact of material production by decreasing greenhouse gas emissions, water usage, and land requirements compared to conventional production methods. Second, creating circular economy opportunities by utilizing agricultural side streams, food waste, or industrial by-products as fermentation feedstocks. Third, developing biodegradable or compostable materials that minimize end-of-life environmental impacts.

Despite these promising attributes, the fermentation industry faces challenges in substantiating sustainability claims. Life cycle assessments (LCAs) for fermented materials are often incomplete or inconsistent in methodology, making comparative analyses difficult. Additionally, the rapid pace of innovation in fermentation technology means that sustainability metrics may quickly become outdated as processes improve and scale.

The industry is now working toward establishing standardized frameworks for sustainability claims and life cycle disclosures specific to fermented materials. These efforts aim to provide transparency, prevent greenwashing, and enable meaningful comparisons between fermented products and their conventional counterparts. As the technology continues to mature, comprehensive sustainability evaluation will be essential for guiding research priorities and informing regulatory frameworks.

The modern fermentation industry has experienced significant growth due to increasing consumer demand for sustainable products and corporate commitments to reduce environmental footprints. Fermentation offers a promising pathway to sustainability as it typically requires less energy, generates fewer greenhouse gas emissions, and utilizes renewable feedstocks compared to traditional chemical synthesis or animal agriculture. The technology enables the production of materials with similar or enhanced functional properties while potentially reducing land use, water consumption, and waste generation.

Current fermentation technology encompasses several approaches, including traditional fermentation, precision fermentation, and biomass fermentation. Each method presents distinct sustainability advantages and challenges across their life cycles. Traditional fermentation transforms whole food ingredients, while precision fermentation engineers microorganisms to produce specific functional molecules. Biomass fermentation cultivates microbial biomass as a primary product, often serving as protein alternatives.

The sustainability goals associated with fermented materials center on several key objectives. First, reducing the environmental impact of material production by decreasing greenhouse gas emissions, water usage, and land requirements compared to conventional production methods. Second, creating circular economy opportunities by utilizing agricultural side streams, food waste, or industrial by-products as fermentation feedstocks. Third, developing biodegradable or compostable materials that minimize end-of-life environmental impacts.

Despite these promising attributes, the fermentation industry faces challenges in substantiating sustainability claims. Life cycle assessments (LCAs) for fermented materials are often incomplete or inconsistent in methodology, making comparative analyses difficult. Additionally, the rapid pace of innovation in fermentation technology means that sustainability metrics may quickly become outdated as processes improve and scale.

The industry is now working toward establishing standardized frameworks for sustainability claims and life cycle disclosures specific to fermented materials. These efforts aim to provide transparency, prevent greenwashing, and enable meaningful comparisons between fermented products and their conventional counterparts. As the technology continues to mature, comprehensive sustainability evaluation will be essential for guiding research priorities and informing regulatory frameworks.

Market Analysis for Sustainable Fermented Materials

The fermented materials market is experiencing significant growth driven by increasing consumer demand for sustainable products across various industries. The global market for fermented ingredients was valued at approximately $25.4 billion in 2020 and is projected to reach $38.5 billion by 2027, growing at a CAGR of 6.1%. This growth is particularly pronounced in sectors such as food and beverage, textiles, cosmetics, and packaging materials, where fermentation offers sustainable alternatives to conventional petroleum-based products.

Consumer awareness regarding environmental impact has become a major market driver, with 73% of global consumers willing to change their consumption habits to reduce environmental impact. This shift in consumer behavior has created substantial market opportunities for companies developing fermented materials with verifiable sustainability credentials. Particularly, younger demographics (Gen Z and Millennials) show stronger preference for products with transparent environmental claims, with 85% considering sustainability when making purchasing decisions.

Regional analysis reveals varying market maturity levels. North America and Europe currently lead in adoption of fermented sustainable materials, accounting for approximately 65% of the global market share. However, the Asia-Pacific region is experiencing the fastest growth rate at 8.7% annually, driven by rapid industrialization coupled with increasing environmental regulations in countries like China, Japan, and South Korea.

The competitive landscape features both established players and innovative startups. Traditional fermentation companies are expanding their portfolios to include sustainable materials, while biotechnology startups are securing significant venture capital funding to develop novel fermentation processes. In 2022 alone, investment in fermentation technology companies exceeded $1.7 billion globally.

Market segmentation analysis indicates that food applications currently dominate with 42% market share, followed by textiles (23%), cosmetics (18%), and packaging (12%). However, the packaging segment is projected to grow at the highest rate (9.3% CAGR) as companies seek alternatives to conventional plastics.

Price sensitivity remains a challenge, with sustainable fermented materials typically commanding a 15-30% premium over conventional alternatives. However, economies of scale and technological improvements are gradually reducing this gap. Market research indicates that 58% of consumers are willing to pay up to 10% more for products with verified sustainability claims.

Distribution channels are evolving, with direct-to-consumer models gaining traction alongside traditional B2B channels. E-commerce platforms specializing in sustainable products have seen 47% year-over-year growth, creating new market access points for fermented material producers.

Consumer awareness regarding environmental impact has become a major market driver, with 73% of global consumers willing to change their consumption habits to reduce environmental impact. This shift in consumer behavior has created substantial market opportunities for companies developing fermented materials with verifiable sustainability credentials. Particularly, younger demographics (Gen Z and Millennials) show stronger preference for products with transparent environmental claims, with 85% considering sustainability when making purchasing decisions.

Regional analysis reveals varying market maturity levels. North America and Europe currently lead in adoption of fermented sustainable materials, accounting for approximately 65% of the global market share. However, the Asia-Pacific region is experiencing the fastest growth rate at 8.7% annually, driven by rapid industrialization coupled with increasing environmental regulations in countries like China, Japan, and South Korea.

The competitive landscape features both established players and innovative startups. Traditional fermentation companies are expanding their portfolios to include sustainable materials, while biotechnology startups are securing significant venture capital funding to develop novel fermentation processes. In 2022 alone, investment in fermentation technology companies exceeded $1.7 billion globally.

Market segmentation analysis indicates that food applications currently dominate with 42% market share, followed by textiles (23%), cosmetics (18%), and packaging (12%). However, the packaging segment is projected to grow at the highest rate (9.3% CAGR) as companies seek alternatives to conventional plastics.

Price sensitivity remains a challenge, with sustainable fermented materials typically commanding a 15-30% premium over conventional alternatives. However, economies of scale and technological improvements are gradually reducing this gap. Market research indicates that 58% of consumers are willing to pay up to 10% more for products with verified sustainability claims.

Distribution channels are evolving, with direct-to-consumer models gaining traction alongside traditional B2B channels. E-commerce platforms specializing in sustainable products have seen 47% year-over-year growth, creating new market access points for fermented material producers.

Current Status and Challenges in Fermentation LCA

Life Cycle Assessment (LCA) for fermented materials currently faces significant methodological and practical challenges despite growing industry adoption. The fermentation sector, spanning food products to biomaterials, lacks standardized LCA frameworks specifically tailored to its unique production processes. This creates inconsistency in how environmental impacts are measured and reported across the industry, making comparative analyses difficult.

Data collection represents a primary obstacle, as fermentation processes involve complex biological systems with variable inputs, outputs, and efficiencies. Many manufacturers struggle to obtain accurate data on energy consumption, water usage, and emissions throughout the entire production chain. This is particularly problematic for novel fermentation technologies where historical data is limited or nonexistent.

System boundary definition presents another critical challenge. Determining appropriate boundaries for fermentation LCAs is complicated by the interconnected nature of biological processes and their dependencies on agricultural inputs. Questions persist about how to properly account for land use changes, agricultural practices for feedstock production, and allocation methods for co-products and waste streams.

Methodological inconsistencies further complicate the landscape. Different practitioners employ varying approaches to functional unit definition, allocation procedures, and impact assessment methods. This lack of harmonization makes it difficult to compare sustainability claims across different fermented products or between fermented and conventional alternatives.

The emerging nature of many fermentation technologies introduces additional uncertainty. For novel processes like precision fermentation or biomass fermentation for alternative proteins, limited commercial-scale data exists. Practitioners often rely on laboratory or pilot-scale information, which may not accurately represent industrial-scale environmental performance.

Temporal considerations also present challenges, as fermentation processes can have significant seasonal variations in environmental impacts based on feedstock availability, energy sources, and production conditions. Current LCA methodologies struggle to effectively capture these temporal dynamics.

Regulatory frameworks remain underdeveloped for fermentation-specific LCA requirements. While general sustainability reporting guidelines exist, few specifically address the unique aspects of fermentation processes, creating uncertainty for manufacturers making environmental claims.

Industry collaboration is improving but remains insufficient. While some consortia and industry groups are working toward standardized approaches, many companies still conduct assessments independently using proprietary methodologies, limiting knowledge sharing and benchmarking opportunities.

Data collection represents a primary obstacle, as fermentation processes involve complex biological systems with variable inputs, outputs, and efficiencies. Many manufacturers struggle to obtain accurate data on energy consumption, water usage, and emissions throughout the entire production chain. This is particularly problematic for novel fermentation technologies where historical data is limited or nonexistent.

System boundary definition presents another critical challenge. Determining appropriate boundaries for fermentation LCAs is complicated by the interconnected nature of biological processes and their dependencies on agricultural inputs. Questions persist about how to properly account for land use changes, agricultural practices for feedstock production, and allocation methods for co-products and waste streams.

Methodological inconsistencies further complicate the landscape. Different practitioners employ varying approaches to functional unit definition, allocation procedures, and impact assessment methods. This lack of harmonization makes it difficult to compare sustainability claims across different fermented products or between fermented and conventional alternatives.

The emerging nature of many fermentation technologies introduces additional uncertainty. For novel processes like precision fermentation or biomass fermentation for alternative proteins, limited commercial-scale data exists. Practitioners often rely on laboratory or pilot-scale information, which may not accurately represent industrial-scale environmental performance.

Temporal considerations also present challenges, as fermentation processes can have significant seasonal variations in environmental impacts based on feedstock availability, energy sources, and production conditions. Current LCA methodologies struggle to effectively capture these temporal dynamics.

Regulatory frameworks remain underdeveloped for fermentation-specific LCA requirements. While general sustainability reporting guidelines exist, few specifically address the unique aspects of fermentation processes, creating uncertainty for manufacturers making environmental claims.

Industry collaboration is improving but remains insufficient. While some consortia and industry groups are working toward standardized approaches, many companies still conduct assessments independently using proprietary methodologies, limiting knowledge sharing and benchmarking opportunities.

Current Methodologies for Fermentation Sustainability Assessment

01 Life Cycle Assessment for Fermented Materials

Life cycle assessment methodologies are used to evaluate the environmental impact of fermented materials throughout their entire lifecycle, from raw material extraction to disposal. These assessments quantify sustainability metrics such as carbon footprint, water usage, and energy consumption, providing transparent disclosure of environmental impacts. The data collected can be used to substantiate sustainability claims and identify areas for improvement in the fermentation process.- Life Cycle Assessment for Fermented Materials: Life cycle assessment methodologies are used to evaluate the environmental impact of fermented materials throughout their entire lifecycle. These assessments quantify sustainability metrics such as carbon footprint, water usage, and energy consumption from raw material extraction through production, use, and disposal. The data collected helps companies make transparent sustainability claims about their fermented products and identify areas for environmental improvement.

- Sustainability Certification and Disclosure Systems: Various certification systems and disclosure frameworks have been developed to validate sustainability claims for fermented materials. These systems establish standardized criteria for evaluating environmental performance and provide third-party verification of sustainability claims. Companies can use these certifications to communicate the environmental benefits of their fermented products to consumers and stakeholders, enhancing transparency and credibility.

- Blockchain Technology for Sustainability Verification: Blockchain technology is being implemented to create immutable records of sustainability data for fermented materials. This technology enables transparent tracking of environmental metrics throughout the supply chain, from raw material sourcing to final product. By using blockchain, companies can provide verifiable sustainability claims about their fermented products, allowing consumers to access authenticated information about environmental impacts and sustainable practices.

- Renewable Feedstock for Fermentation Processes: The use of renewable and sustainable feedstocks in fermentation processes significantly impacts the overall sustainability profile of fermented materials. Agricultural waste, food byproducts, and other renewable resources can be utilized as feedstocks for fermentation, reducing dependence on fossil fuels and minimizing waste. Companies are developing innovative approaches to source sustainable feedstocks and are incorporating these practices into their sustainability claims and life cycle disclosures.

- Carbon Footprint Reduction in Fermentation Processes: Advanced fermentation technologies and process optimizations are being developed to reduce the carbon footprint of fermented materials. These innovations include energy-efficient fermentation equipment, carbon capture systems, and renewable energy integration. By implementing these technologies, manufacturers can substantiate claims about reduced greenhouse gas emissions and improved environmental performance of their fermented products, which can be quantified and disclosed through standardized reporting frameworks.

02 Blockchain Technology for Sustainability Verification

Blockchain technology is being implemented to create transparent and immutable records of sustainability claims for fermented materials. This technology enables the tracking of environmental metrics, certification data, and compliance information throughout the supply chain. By providing a secure and verifiable record of sustainability practices, blockchain helps prevent greenwashing and builds consumer trust in sustainability claims related to fermented products.Expand Specific Solutions03 Carbon Footprint Reduction in Fermentation Processes

Innovative approaches to reduce the carbon footprint of fermentation processes include optimizing energy usage, utilizing renewable energy sources, and implementing carbon capture technologies. These methods help minimize greenhouse gas emissions associated with fermentation and support sustainability claims. The environmental benefits can be quantified and disclosed to consumers, providing transparent information about the climate impact of fermented materials.Expand Specific Solutions04 Standardized Sustainability Reporting Frameworks

Standardized frameworks for reporting sustainability metrics related to fermented materials ensure consistency and comparability across products and companies. These frameworks include specific guidelines for disclosing environmental impacts, social responsibility practices, and governance structures. By adhering to recognized reporting standards, companies can make credible sustainability claims about their fermented materials and provide consumers with reliable information for making environmentally conscious choices.Expand Specific Solutions05 Bio-based Alternatives and Circular Economy Integration

Fermented materials are being developed as bio-based alternatives to conventional petroleum-derived products, supporting circular economy principles. These materials can be designed for biodegradability, compostability, or recyclability, reducing waste and environmental impact. Life cycle disclosure for these materials highlights their renewable feedstock sources, reduced resource consumption, and end-of-life options, substantiating sustainability claims related to circular economy benefits.Expand Specific Solutions

Key Industry Players in Sustainable Fermentation

The fermented materials sustainability claims market is in an early growth phase, characterized by increasing demand for transparent life cycle disclosures as industries shift toward bio-based alternatives. The global market for sustainable fermentation technologies is expanding rapidly, projected to reach significant scale as companies respond to regulatory pressures and consumer demand for environmental accountability. Leading players demonstrate varying levels of technical maturity: established chemical giants like BASF and Evonik have advanced sustainability reporting frameworks, while innovative specialists such as LanzaTech and BioLogiQ are pioneering novel fermentation processes with comprehensive life cycle assessments. Academic institutions including Tsinghua University and University of Massachusetts are contributing fundamental research to standardize sustainability metrics for fermented materials.

BASF Corp.

Technical Solution: BASF has developed an integrated sustainability assessment framework specifically for their fermentation-derived materials called "Sustainable Solution Steering." This methodology evaluates products across their entire life cycle, from raw material sourcing through production, use phase, and end-of-life management. For fermented materials, BASF employs a mass balance approach to track bio-based content through complex value chains, ensuring transparency in sustainability claims. Their ecovio® line of biodegradable biopolymers partially produced through fermentation processes comes with detailed environmental product declarations (EPDs) that quantify impacts across multiple categories including carbon footprint, water consumption, and land use. BASF has pioneered the implementation of third-party certification systems for their fermented materials, working with organizations like TÜV to verify claims about biodegradability, compostability, and renewable content. The company has also developed digital solutions that enable customers to access life cycle data for their fermented products through blockchain-secured platforms.

Strengths: Comprehensive assessment methodology covering multiple sustainability dimensions; established third-party verification systems; digital traceability solutions for supply chain transparency. Weaknesses: Complex assessment frameworks may be difficult for consumers to understand; mass balance approach can sometimes obscure the actual bio-based content in specific products; high implementation costs for full life cycle disclosure systems.

Evonik Operations GmbH

Technical Solution: Evonik has developed a sophisticated sustainability assessment framework for their fermentation-derived products called "Sustainability Compass." This system evaluates materials across their entire life cycle using 16 different environmental and social impact categories. For their fermented materials portfolio, which includes amino acids, specialty lipids, and biosurfactants, Evonik provides detailed Product Carbon Footprints (PCFs) following ISO 14067 standards. Their proprietary fermentation processes for producing amino acids like methionine have been optimized to reduce environmental impacts, with documented water usage reductions of up to 40% and energy consumption decreases of 30% compared to chemical synthesis routes. Evonik's life cycle disclosure approach includes transparent reporting on feedstock sourcing, specifying whether agricultural inputs are certified sustainable and detailing land use change implications. The company has implemented a digital product passport system that allows customers to access verified sustainability data for fermented materials, including information on renewable carbon content, biodegradability, and regional environmental impacts specific to production locations.

Strengths: Comprehensive multi-criteria assessment beyond just carbon footprint; ISO-compliant methodology with third-party verification; digital solutions for transparent customer communication. Weaknesses: High complexity of full life cycle assessment may create implementation challenges across diverse product portfolio; regional variations in environmental impacts can complicate standardized claims; potential trade-offs between different sustainability criteria not always clearly communicated.

Critical Patents and Research in Sustainable Fermentation

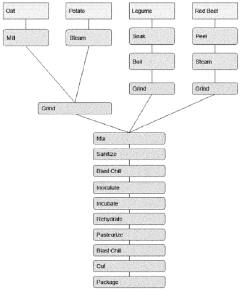

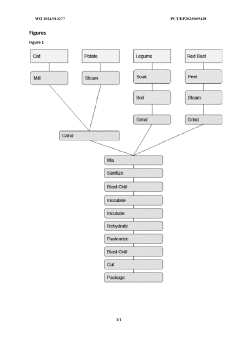

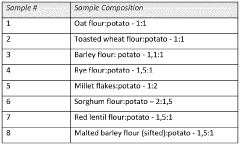

Fermented foods and methods for making same

PatentWO2024013277A1

Innovation

- A method involving the fermentation of vegetable raw materials using filamentous fungi and specific combinations of ingredients like oats, potatoes, red beets, and legumes to create meat-like properties with improved flavor, texture, nutritional value, and reduced carbon footprint.

Fermented material comprising stalk particles of monocotyledonous flowering plants, and its production method

PatentWO2024110019A1

Innovation

- A fermented material comprising stalk particles of monocotyledonous flowering plants, preferably maize, with specific particle size, density, and water content, combined with additives like clay, which enhances water retention and biological stability, and a production method involving harvesting, shredding, dewatering, grinding, and controlled fermentation to create a high-performance, eco-friendly substrate.

Regulatory Framework for Fermentation Sustainability Claims

The regulatory landscape governing sustainability claims for fermented materials is evolving rapidly as these innovative products gain market traction. Currently, there is no unified global framework specifically addressing fermentation-based materials, resulting in a patchwork of regulations that manufacturers must navigate carefully.

In the United States, the Federal Trade Commission's Green Guides provide general principles for environmental marketing claims, though they lack specific provisions for fermentation processes. The FDA and USDA also maintain oversight depending on the end-use application of fermented materials, particularly for food, cosmetic, or textile applications. Companies making carbon footprint reduction claims must ensure these are substantiated with credible life cycle assessment (LCA) data.

The European Union has implemented more stringent requirements through the Product Environmental Footprint (PEF) methodology and the EU Green Claims Directive proposal, which mandates that environmental claims be verified and substantiated. The EU Taxonomy for Sustainable Activities is increasingly influencing disclosure requirements for fermentation-based production systems, particularly regarding their contribution to climate change mitigation.

International standards such as ISO 14040/14044 for life cycle assessment and ISO 14025 for environmental product declarations provide methodological frameworks that companies can follow to validate their sustainability claims. These standards are becoming de facto requirements for market acceptance in many regions.

Emerging economies like China and India are developing their own regulatory frameworks, with China's recent focus on "green manufacturing" certification systems that may soon incorporate fermentation processes. These developments signal a global trend toward more standardized sustainability reporting requirements.

Industry self-regulation is filling gaps where formal regulations are absent. Consortiums like the Sustainable Apparel Coalition and the Biofabricate Alliance have developed sector-specific guidelines for sustainability claims related to fermented materials in textiles and consumer products.

Verification mechanisms are increasingly important, with third-party certification becoming a market expectation. Organizations such as Cradle to Cradle, BlueSign, and SCS Global Services have begun developing certification protocols specifically addressing bio-based and fermented materials.

Looking forward, regulatory convergence is anticipated as fermentation technology matures. The EU's circular economy action plan and the increasing adoption of Extended Producer Responsibility (EPR) schemes will likely drive more comprehensive disclosure requirements for fermented materials' entire life cycle, from feedstock sourcing to end-of-life management.

In the United States, the Federal Trade Commission's Green Guides provide general principles for environmental marketing claims, though they lack specific provisions for fermentation processes. The FDA and USDA also maintain oversight depending on the end-use application of fermented materials, particularly for food, cosmetic, or textile applications. Companies making carbon footprint reduction claims must ensure these are substantiated with credible life cycle assessment (LCA) data.

The European Union has implemented more stringent requirements through the Product Environmental Footprint (PEF) methodology and the EU Green Claims Directive proposal, which mandates that environmental claims be verified and substantiated. The EU Taxonomy for Sustainable Activities is increasingly influencing disclosure requirements for fermentation-based production systems, particularly regarding their contribution to climate change mitigation.

International standards such as ISO 14040/14044 for life cycle assessment and ISO 14025 for environmental product declarations provide methodological frameworks that companies can follow to validate their sustainability claims. These standards are becoming de facto requirements for market acceptance in many regions.

Emerging economies like China and India are developing their own regulatory frameworks, with China's recent focus on "green manufacturing" certification systems that may soon incorporate fermentation processes. These developments signal a global trend toward more standardized sustainability reporting requirements.

Industry self-regulation is filling gaps where formal regulations are absent. Consortiums like the Sustainable Apparel Coalition and the Biofabricate Alliance have developed sector-specific guidelines for sustainability claims related to fermented materials in textiles and consumer products.

Verification mechanisms are increasingly important, with third-party certification becoming a market expectation. Organizations such as Cradle to Cradle, BlueSign, and SCS Global Services have begun developing certification protocols specifically addressing bio-based and fermented materials.

Looking forward, regulatory convergence is anticipated as fermentation technology matures. The EU's circular economy action plan and the increasing adoption of Extended Producer Responsibility (EPR) schemes will likely drive more comprehensive disclosure requirements for fermented materials' entire life cycle, from feedstock sourcing to end-of-life management.

Carbon Footprint Benchmarking for Fermented Materials

Carbon footprint benchmarking for fermented materials has become increasingly critical as industries seek sustainable alternatives to traditional manufacturing processes. Current benchmarking methodologies reveal that fermentation-based production systems generally demonstrate 30-70% lower carbon emissions compared to petroleum-based counterparts, depending on feedstock selection, energy sources, and process efficiencies.

Leading industry standards for carbon footprint assessment of fermented materials include ISO 14067, PAS 2050, and the Greenhouse Gas Protocol Product Standard. These frameworks provide structured approaches to quantifying emissions across the entire life cycle, from raw material acquisition through production, distribution, use, and end-of-life management. However, significant variations exist in how companies implement these standards, creating challenges for consistent comparison across the sector.

Recent comparative analyses indicate that fermented materials derived from agricultural waste streams typically achieve the lowest carbon footprints, with emissions reductions of up to 85% compared to conventional materials. Conversely, fermentation processes utilizing purpose-grown crops as feedstock show more modest benefits, particularly when accounting for land-use change impacts and agricultural inputs.

Energy consumption represents the most significant contributor to carbon emissions in fermentation processes, accounting for 40-60% of the total footprint. Consequently, facilities powered by renewable energy sources demonstrate substantially improved environmental performance. Industry leaders have achieved carbon footprint reductions of 25-40% through strategic transitions to renewable energy infrastructure.

Technological innovations in fermentation efficiency have further reduced carbon intensities. Advanced bioreactor designs with improved mixing and mass transfer capabilities have decreased energy requirements by 15-30%, while novel recovery and purification technologies have reduced solvent usage and associated emissions by up to 50% in certain applications.

Emerging best practices for carbon footprint benchmarking include standardized allocation methodologies for co-products, transparent reporting of biogenic carbon flows, and comprehensive accounting of indirect land-use change impacts. The industry is moving toward dynamic benchmarking systems that account for regional variations in energy grids and agricultural practices, providing more accurate comparisons across different production contexts.

Future benchmarking developments will likely incorporate real-time monitoring technologies and blockchain-based verification systems to enhance data reliability and transparency. These advancements will support more credible sustainability claims and facilitate meaningful comparisons between fermented materials and their conventional counterparts, ultimately accelerating market adoption of truly low-carbon alternatives.

Leading industry standards for carbon footprint assessment of fermented materials include ISO 14067, PAS 2050, and the Greenhouse Gas Protocol Product Standard. These frameworks provide structured approaches to quantifying emissions across the entire life cycle, from raw material acquisition through production, distribution, use, and end-of-life management. However, significant variations exist in how companies implement these standards, creating challenges for consistent comparison across the sector.

Recent comparative analyses indicate that fermented materials derived from agricultural waste streams typically achieve the lowest carbon footprints, with emissions reductions of up to 85% compared to conventional materials. Conversely, fermentation processes utilizing purpose-grown crops as feedstock show more modest benefits, particularly when accounting for land-use change impacts and agricultural inputs.

Energy consumption represents the most significant contributor to carbon emissions in fermentation processes, accounting for 40-60% of the total footprint. Consequently, facilities powered by renewable energy sources demonstrate substantially improved environmental performance. Industry leaders have achieved carbon footprint reductions of 25-40% through strategic transitions to renewable energy infrastructure.

Technological innovations in fermentation efficiency have further reduced carbon intensities. Advanced bioreactor designs with improved mixing and mass transfer capabilities have decreased energy requirements by 15-30%, while novel recovery and purification technologies have reduced solvent usage and associated emissions by up to 50% in certain applications.

Emerging best practices for carbon footprint benchmarking include standardized allocation methodologies for co-products, transparent reporting of biogenic carbon flows, and comprehensive accounting of indirect land-use change impacts. The industry is moving toward dynamic benchmarking systems that account for regional variations in energy grids and agricultural practices, providing more accurate comparisons across different production contexts.

Future benchmarking developments will likely incorporate real-time monitoring technologies and blockchain-based verification systems to enhance data reliability and transparency. These advancements will support more credible sustainability claims and facilitate meaningful comparisons between fermented materials and their conventional counterparts, ultimately accelerating market adoption of truly low-carbon alternatives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!