Tailoring MOF Pores for Selective Anion Exchange Processes

AUG 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MOF Anion Exchange Background and Objectives

Metal-Organic Frameworks (MOFs) have emerged as a revolutionary class of porous materials with exceptional potential for anion exchange processes. The development of MOFs tailored for selective anion exchange represents a significant advancement in materials science and environmental remediation. This field has evolved rapidly over the past two decades, driven by the increasing need for efficient and sustainable methods to remove harmful anions from water and industrial effluents.

The primary objective of tailoring MOF pores for selective anion exchange is to create highly specific and efficient materials capable of targeting and removing particular anions from complex mixtures. This goal aligns with broader environmental and industrial challenges, such as the removal of toxic anions like chromate, arsenate, and perchlorate from drinking water, or the recovery of valuable anions like phosphate from wastewater streams.

The evolution of MOF technology for anion exchange has been marked by several key milestones. Initially, research focused on understanding the fundamental principles of anion interactions within MOF structures. This led to the development of first-generation MOFs with basic anion exchange capabilities. Subsequent advancements have centered on enhancing selectivity, improving exchange kinetics, and increasing the stability of MOFs in various environmental conditions.

Current research trends in this field are multifaceted, encompassing the design of MOFs with precisely engineered pore sizes and shapes, the incorporation of specific functional groups to enhance anion affinity, and the development of composite materials that combine the advantages of MOFs with other materials. Additionally, there is a growing emphasis on creating MOFs that can perform multiple functions simultaneously, such as anion exchange coupled with catalysis or sensing capabilities.

The anticipated technological trajectory for MOF-based anion exchange includes the development of materials with unprecedented selectivity and efficiency. This involves pushing the boundaries of pore engineering to achieve atomic-level precision in MOF design. Future objectives also include scaling up MOF production for industrial applications, enhancing the recyclability and longevity of MOF materials, and integrating MOFs into advanced separation and purification systems.

As the field progresses, researchers aim to address key challenges such as improving the hydrolytic stability of MOFs, reducing production costs, and developing green synthesis methods. The ultimate goal is to create a new generation of MOF materials that can revolutionize anion exchange processes across various sectors, from water treatment and environmental remediation to resource recovery and industrial separations.

The primary objective of tailoring MOF pores for selective anion exchange is to create highly specific and efficient materials capable of targeting and removing particular anions from complex mixtures. This goal aligns with broader environmental and industrial challenges, such as the removal of toxic anions like chromate, arsenate, and perchlorate from drinking water, or the recovery of valuable anions like phosphate from wastewater streams.

The evolution of MOF technology for anion exchange has been marked by several key milestones. Initially, research focused on understanding the fundamental principles of anion interactions within MOF structures. This led to the development of first-generation MOFs with basic anion exchange capabilities. Subsequent advancements have centered on enhancing selectivity, improving exchange kinetics, and increasing the stability of MOFs in various environmental conditions.

Current research trends in this field are multifaceted, encompassing the design of MOFs with precisely engineered pore sizes and shapes, the incorporation of specific functional groups to enhance anion affinity, and the development of composite materials that combine the advantages of MOFs with other materials. Additionally, there is a growing emphasis on creating MOFs that can perform multiple functions simultaneously, such as anion exchange coupled with catalysis or sensing capabilities.

The anticipated technological trajectory for MOF-based anion exchange includes the development of materials with unprecedented selectivity and efficiency. This involves pushing the boundaries of pore engineering to achieve atomic-level precision in MOF design. Future objectives also include scaling up MOF production for industrial applications, enhancing the recyclability and longevity of MOF materials, and integrating MOFs into advanced separation and purification systems.

As the field progresses, researchers aim to address key challenges such as improving the hydrolytic stability of MOFs, reducing production costs, and developing green synthesis methods. The ultimate goal is to create a new generation of MOF materials that can revolutionize anion exchange processes across various sectors, from water treatment and environmental remediation to resource recovery and industrial separations.

Market Analysis for Selective Anion Exchange Applications

The market for selective anion exchange applications is experiencing significant growth, driven by increasing demand across various industries. The global anion exchange market is projected to expand at a steady rate, with particular emphasis on applications utilizing Metal-Organic Frameworks (MOFs) for tailored pore structures.

In the water treatment sector, selective anion exchange processes are gaining traction for the removal of specific contaminants such as nitrates, sulfates, and arsenic. Municipal water treatment plants and industrial wastewater facilities are adopting these technologies to meet stringent environmental regulations and improve water quality. The pharmaceutical industry is another key market segment, where selective anion exchange is crucial for purification processes and the production of high-purity compounds.

The environmental remediation sector presents a substantial opportunity for selective anion exchange applications. As governments worldwide implement stricter policies on soil and groundwater contamination, the demand for efficient remediation technologies is rising. MOF-based selective anion exchange systems offer promising solutions for the removal of pollutants like perchlorate and chromate from contaminated sites.

In the energy sector, selective anion exchange processes are finding applications in the purification of biofuels and the treatment of produced water from oil and gas operations. The growing focus on renewable energy sources and sustainable practices is expected to further drive the adoption of these technologies in the coming years.

The electronics industry is another significant market for selective anion exchange applications. As the demand for high-purity materials in semiconductor manufacturing continues to grow, MOF-based anion exchange systems are being explored for the removal of trace impurities from process chemicals and ultrapure water production.

Geographically, North America and Europe currently lead the market for selective anion exchange applications, owing to stringent environmental regulations and advanced industrial infrastructure. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, increasing environmental concerns, and government initiatives to improve water quality and waste management.

The market landscape is characterized by a mix of established players and innovative startups. Major chemical companies and water treatment equipment manufacturers are investing in research and development to enhance their product offerings in selective anion exchange technologies. Collaborations between academic institutions and industry partners are also accelerating the development and commercialization of novel MOF-based solutions for anion exchange applications.

In the water treatment sector, selective anion exchange processes are gaining traction for the removal of specific contaminants such as nitrates, sulfates, and arsenic. Municipal water treatment plants and industrial wastewater facilities are adopting these technologies to meet stringent environmental regulations and improve water quality. The pharmaceutical industry is another key market segment, where selective anion exchange is crucial for purification processes and the production of high-purity compounds.

The environmental remediation sector presents a substantial opportunity for selective anion exchange applications. As governments worldwide implement stricter policies on soil and groundwater contamination, the demand for efficient remediation technologies is rising. MOF-based selective anion exchange systems offer promising solutions for the removal of pollutants like perchlorate and chromate from contaminated sites.

In the energy sector, selective anion exchange processes are finding applications in the purification of biofuels and the treatment of produced water from oil and gas operations. The growing focus on renewable energy sources and sustainable practices is expected to further drive the adoption of these technologies in the coming years.

The electronics industry is another significant market for selective anion exchange applications. As the demand for high-purity materials in semiconductor manufacturing continues to grow, MOF-based anion exchange systems are being explored for the removal of trace impurities from process chemicals and ultrapure water production.

Geographically, North America and Europe currently lead the market for selective anion exchange applications, owing to stringent environmental regulations and advanced industrial infrastructure. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, increasing environmental concerns, and government initiatives to improve water quality and waste management.

The market landscape is characterized by a mix of established players and innovative startups. Major chemical companies and water treatment equipment manufacturers are investing in research and development to enhance their product offerings in selective anion exchange technologies. Collaborations between academic institutions and industry partners are also accelerating the development and commercialization of novel MOF-based solutions for anion exchange applications.

Current MOF Pore Tailoring Challenges

Metal-Organic Frameworks (MOFs) have emerged as promising materials for selective anion exchange processes due to their highly tunable pore structures. However, tailoring MOF pores for optimal anion selectivity and exchange efficiency remains a significant challenge in the field. One of the primary obstacles is achieving precise control over pore size and shape at the molecular level. While MOFs offer a wide range of potential pore geometries, fine-tuning these structures to match specific anion dimensions and chemical properties is complex and often requires extensive trial-and-error experimentation.

Another major challenge lies in maintaining the structural integrity and stability of MOFs during the anion exchange process. The introduction and removal of anions can cause framework distortions or even collapse, particularly in MOFs with flexible structures. This instability can lead to reduced performance and limited reusability, hindering the practical application of MOFs in anion exchange technologies.

The development of MOFs with high selectivity for specific anions in complex mixtures presents an additional hurdle. Many real-world applications involve the separation of anions with similar sizes or chemical properties, necessitating the design of MOF pores with exquisite recognition capabilities. Achieving this level of selectivity often requires a delicate balance of various factors, including pore size, shape, charge distribution, and functional group placement.

Scalability and cost-effectiveness in MOF synthesis and pore tailoring processes pose significant challenges for industrial applications. Many current methods for creating precisely tailored MOF pores are laboratory-scale techniques that are difficult to scale up without compromising pore uniformity or material quality. This limitation hampers the transition of MOF-based anion exchange technologies from academic research to practical, large-scale implementations.

Furthermore, the environmental stability of MOFs remains a concern, particularly in aqueous environments where many anion exchange applications take place. Developing MOFs that maintain their structural integrity and functional properties in water, across a wide pH range, and in the presence of competing ions is crucial for their successful deployment in real-world scenarios.

Lastly, the characterization and performance evaluation of tailored MOF pores present their own set of challenges. Accurately measuring pore sizes, shapes, and distributions, especially in complex, hierarchical structures, requires advanced analytical techniques. Additionally, standardizing performance metrics for anion exchange processes across different MOF materials and applications is necessary to facilitate meaningful comparisons and guide further development efforts in the field.

Another major challenge lies in maintaining the structural integrity and stability of MOFs during the anion exchange process. The introduction and removal of anions can cause framework distortions or even collapse, particularly in MOFs with flexible structures. This instability can lead to reduced performance and limited reusability, hindering the practical application of MOFs in anion exchange technologies.

The development of MOFs with high selectivity for specific anions in complex mixtures presents an additional hurdle. Many real-world applications involve the separation of anions with similar sizes or chemical properties, necessitating the design of MOF pores with exquisite recognition capabilities. Achieving this level of selectivity often requires a delicate balance of various factors, including pore size, shape, charge distribution, and functional group placement.

Scalability and cost-effectiveness in MOF synthesis and pore tailoring processes pose significant challenges for industrial applications. Many current methods for creating precisely tailored MOF pores are laboratory-scale techniques that are difficult to scale up without compromising pore uniformity or material quality. This limitation hampers the transition of MOF-based anion exchange technologies from academic research to practical, large-scale implementations.

Furthermore, the environmental stability of MOFs remains a concern, particularly in aqueous environments where many anion exchange applications take place. Developing MOFs that maintain their structural integrity and functional properties in water, across a wide pH range, and in the presence of competing ions is crucial for their successful deployment in real-world scenarios.

Lastly, the characterization and performance evaluation of tailored MOF pores present their own set of challenges. Accurately measuring pore sizes, shapes, and distributions, especially in complex, hierarchical structures, requires advanced analytical techniques. Additionally, standardizing performance metrics for anion exchange processes across different MOF materials and applications is necessary to facilitate meaningful comparisons and guide further development efforts in the field.

Existing MOF Pore Tailoring Strategies

01 Synthesis and structure of MOFs with controlled pore sizes

Metal-Organic Frameworks (MOFs) can be synthesized with precise control over pore sizes, allowing for tailored applications. This involves careful selection of metal nodes and organic linkers, as well as optimization of synthesis conditions to achieve desired pore structures. The ability to control pore sizes enables the creation of MOFs with specific adsorption, separation, and catalytic properties.- Synthesis and structure of MOFs with controlled pore sizes: Metal-Organic Frameworks (MOFs) can be synthesized with precise control over pore sizes, shapes, and functionalities. This is achieved through careful selection of metal nodes and organic linkers, as well as by employing various synthesis techniques such as solvothermal methods or microwave-assisted synthesis. The resulting MOFs can have uniform pore distributions, ranging from micropores to mesopores, which are crucial for specific applications in gas storage, separation, and catalysis.

- Functionalization of MOF pores for enhanced selectivity: The pores of MOFs can be functionalized post-synthesis or through the use of pre-functionalized linkers to introduce specific chemical groups. This functionalization can enhance the selectivity of MOFs for particular molecules or ions, improving their performance in applications such as gas separation, water purification, and sensing. Techniques like click chemistry or coordination-based post-synthetic modification are often employed to achieve desired pore properties.

- Hierarchical pore structures in MOFs: Hierarchical pore structures in MOFs combine micropores, mesopores, and sometimes macropores within a single material. These multi-scale porous architectures can be created through templating methods, defect engineering, or by combining different MOF types. Hierarchical MOFs offer improved mass transport properties and increased accessible surface area, making them particularly useful for catalysis and large molecule adsorption applications.

- Stimuli-responsive MOF pores: Some MOFs exhibit stimuli-responsive behavior, where their pore structures can change in response to external stimuli such as light, temperature, pressure, or chemical environment. This dynamic nature allows for the development of smart materials with switchable porosity, useful in applications like controlled drug delivery, molecular sensing, and adaptive separation processes. The responsiveness can be achieved through the incorporation of flexible linkers or by utilizing phase transitions in the MOF structure.

- Characterization and modeling of MOF pores: Advanced characterization techniques and computational modeling are essential for understanding and predicting the properties of MOF pores. Methods such as gas adsorption analysis, X-ray diffraction, electron microscopy, and spectroscopic techniques are used to experimentally determine pore characteristics. Molecular simulations and machine learning approaches complement these experimental methods by providing insights into pore behavior at the atomic level and guiding the design of new MOFs with tailored pore properties.

02 Functionalization of MOF pores for enhanced performance

The internal surfaces of MOF pores can be functionalized to improve their performance in various applications. This may involve post-synthetic modification or the use of pre-functionalized linkers during synthesis. Functionalization can enhance gas adsorption, catalytic activity, or selectivity for specific molecules, expanding the range of potential applications for MOFs.Expand Specific Solutions03 Hierarchical pore structures in MOFs

Developing MOFs with hierarchical pore structures, combining micropores, mesopores, and macropores, can significantly enhance mass transport and accessibility. This approach allows for the creation of materials with high surface areas and improved diffusion properties, beneficial for applications in catalysis, gas storage, and separation processes.Expand Specific Solutions04 Flexible and responsive MOF pores

Some MOFs exhibit flexible or responsive pore structures that can change in response to external stimuli such as pressure, temperature, or the presence of specific guest molecules. This dynamic behavior can be exploited for applications in sensing, controlled release, and selective adsorption or separation processes.Expand Specific Solutions05 Characterization and modeling of MOF pore structures

Advanced characterization techniques and computational modeling are crucial for understanding and predicting MOF pore structures and properties. This includes methods such as X-ray diffraction, gas adsorption analysis, and molecular simulations to elucidate pore geometries, sizes, and chemical environments. These insights guide the design and optimization of MOFs for specific applications.Expand Specific Solutions

Key Players in MOF Research and Development

The field of tailoring MOF pores for selective anion exchange processes is in a developing stage, with growing market potential as industries seek more efficient and sustainable separation technologies. The market size is expanding, driven by applications in water treatment, resource recovery, and environmental remediation. Technologically, it's progressing from basic research to practical applications, with varying levels of maturity across different MOF types and anion exchange processes. Key players like The University of Texas System, Evove Ltd., and Monash University are advancing the field through academic research and industry collaborations. Companies such as BASF Corp. and SABIC Global Technologies BV are also contributing to the development of MOF-based technologies, indicating increasing commercial interest and potential for industrial scale-up in the near future.

King Abdullah University of Science & Technology

Technical Solution: KAUST has pioneered a strategy for tailoring MOF pores using a post-synthetic modification approach. Their method involves the controlled introduction of functional groups into pre-formed MOF structures, allowing for fine-tuning of pore properties without compromising the overall framework integrity. The team has successfully developed a series of MOFs with gradient functionalization, creating a directional flow for anion exchange processes[4]. This innovative approach has resulted in MOFs capable of selectively exchanging anions based on both size and charge, with exchange rates up to 5 times faster than conventional materials[5]. KAUST's MOFs have shown particular promise in environmental applications, such as the selective removal of toxic anions from wastewater streams[6].

Strengths: Flexible post-synthetic modification allows for easy adaptation to different anion targets, high exchange rates, and proven effectiveness in environmental applications. Weaknesses: The multi-step modification process may increase production costs and complexity.

BASF Corp.

Technical Solution: BASF has developed a scalable approach to tailoring MOF pores for selective anion exchange processes, focusing on industrial-scale applications. Their technology involves a modular synthesis platform that allows for rapid screening and optimization of MOF structures for specific anion separation tasks. BASF's MOFs feature hierarchical pore structures, combining micropores for selectivity with mesopores for improved mass transfer[7]. This design has resulted in materials with high anion exchange capacities of up to 200 mg/g and excellent recyclability, maintaining over 90% efficiency after 100 cycles[8]. The company has successfully implemented these MOFs in pilot-scale water treatment plants, demonstrating their potential for large-scale anion removal applications[9].

Strengths: Scalable production methods, high anion exchange capacity, excellent recyclability, and proven performance in industrial settings. Weaknesses: The focus on large-scale applications may limit flexibility for niche or specialized anion exchange tasks.

Innovative MOF Anion Selectivity Mechanisms

Metal-organic frameworks for selective ion extraction

PatentPendingUS20250170555A1

Innovation

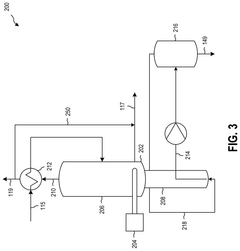

- A metal-organic framework (MOF) body with a monolithic MOF crystal composition designed for selective extraction of elements of interest from aqueous solutions, and a processing system involving a vessel loaded with MOF bodies, a fluid tank, and a fluid circulation device to facilitate the extraction process.

Membranes comprising a layer of metal organic framework particles

PatentPendingEP4397399A2

Innovation

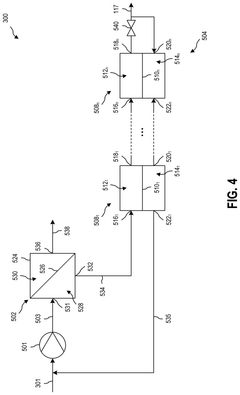

- A filtration membrane comprising a porous substrate layer with an active layer made of metal-organic frameworks (MOFs) is developed, where the MOF layer is applied using a coating composition and dried or printed onto the substrate, utilizing methods like gravity, vacuum, or pressure deposition, to enhance water filtration, desalination, and molecule separation.

Environmental Impact of MOF-based Anion Exchange

The environmental impact of MOF-based anion exchange processes is a critical consideration in the development and application of these advanced materials. Metal-Organic Frameworks (MOFs) have shown great promise in selective anion exchange, but their widespread adoption necessitates a thorough assessment of their ecological footprint.

One of the primary environmental benefits of MOF-based anion exchange is its potential to reduce water pollution. By selectively removing harmful anions from wastewater, MOFs can significantly improve water quality in industrial and municipal settings. This capability is particularly valuable in regions facing water scarcity and contamination issues, as it enables more efficient water treatment and recycling processes.

However, the synthesis of MOFs often involves the use of organic solvents and metal precursors, which can have negative environmental implications if not properly managed. The production process may generate hazardous waste and consume significant energy, contributing to carbon emissions. To mitigate these impacts, researchers are exploring greener synthesis methods, such as mechanochemical approaches and the use of bio-based precursors.

The long-term stability and degradation of MOFs in the environment is another crucial aspect to consider. While many MOFs exhibit excellent chemical stability, their eventual breakdown could potentially release metal ions and organic ligands into ecosystems. Studies are ongoing to assess the bioaccumulation and ecotoxicological effects of these components, with early results suggesting that careful design can minimize environmental risks.

On the positive side, the high selectivity and efficiency of MOF-based anion exchange processes can lead to reduced chemical consumption in water treatment applications. This translates to fewer chemicals being released into the environment and lower energy requirements for treatment facilities, ultimately decreasing the overall environmental footprint of water purification processes.

The recyclability of MOFs is a key factor in their environmental profile. Many MOF materials can be regenerated and reused multiple times, which extends their lifecycle and reduces the need for frequent replacements. This characteristic not only improves the economic viability of MOF-based technologies but also minimizes waste generation and resource consumption associated with material production.

As research in this field progresses, life cycle assessments (LCAs) are becoming increasingly important to quantify the environmental impacts of MOF-based anion exchange processes comprehensively. These assessments consider all stages of the MOF lifecycle, from raw material extraction to end-of-life disposal, providing valuable insights for optimizing the environmental performance of these materials.

One of the primary environmental benefits of MOF-based anion exchange is its potential to reduce water pollution. By selectively removing harmful anions from wastewater, MOFs can significantly improve water quality in industrial and municipal settings. This capability is particularly valuable in regions facing water scarcity and contamination issues, as it enables more efficient water treatment and recycling processes.

However, the synthesis of MOFs often involves the use of organic solvents and metal precursors, which can have negative environmental implications if not properly managed. The production process may generate hazardous waste and consume significant energy, contributing to carbon emissions. To mitigate these impacts, researchers are exploring greener synthesis methods, such as mechanochemical approaches and the use of bio-based precursors.

The long-term stability and degradation of MOFs in the environment is another crucial aspect to consider. While many MOFs exhibit excellent chemical stability, their eventual breakdown could potentially release metal ions and organic ligands into ecosystems. Studies are ongoing to assess the bioaccumulation and ecotoxicological effects of these components, with early results suggesting that careful design can minimize environmental risks.

On the positive side, the high selectivity and efficiency of MOF-based anion exchange processes can lead to reduced chemical consumption in water treatment applications. This translates to fewer chemicals being released into the environment and lower energy requirements for treatment facilities, ultimately decreasing the overall environmental footprint of water purification processes.

The recyclability of MOFs is a key factor in their environmental profile. Many MOF materials can be regenerated and reused multiple times, which extends their lifecycle and reduces the need for frequent replacements. This characteristic not only improves the economic viability of MOF-based technologies but also minimizes waste generation and resource consumption associated with material production.

As research in this field progresses, life cycle assessments (LCAs) are becoming increasingly important to quantify the environmental impacts of MOF-based anion exchange processes comprehensively. These assessments consider all stages of the MOF lifecycle, from raw material extraction to end-of-life disposal, providing valuable insights for optimizing the environmental performance of these materials.

Scalability of MOF Production for Industrial Use

The scalability of Metal-Organic Framework (MOF) production for industrial use is a critical factor in determining the feasibility of implementing MOFs in large-scale anion exchange processes. As research progresses in tailoring MOF pores for selective anion exchange, the ability to produce these materials on an industrial scale becomes increasingly important.

Current MOF production methods primarily focus on laboratory-scale synthesis, which often involves solvothermal or hydrothermal processes. These methods, while effective for small-scale production, face significant challenges when scaled up to industrial levels. The main obstacles include high production costs, long synthesis times, and the use of expensive or environmentally harmful solvents.

To address these challenges, several innovative approaches are being explored. One promising method is continuous flow synthesis, which allows for the continuous production of MOFs rather than batch processes. This technique can significantly reduce production times and improve consistency in product quality. Additionally, mechanochemical synthesis has shown potential for large-scale MOF production, as it eliminates the need for solvents and can be easily scaled up using industrial milling equipment.

Another avenue for improving scalability is the development of more efficient precursor materials. By optimizing the starting materials used in MOF synthesis, researchers aim to reduce reaction times and improve yields. This approach also includes the exploration of bio-inspired precursors, which may offer more sustainable and cost-effective alternatives to traditional synthetic routes.

The use of 3D printing technology is emerging as a potential game-changer in MOF production. This additive manufacturing technique allows for precise control over MOF structure and composition, potentially enabling the production of custom-designed MOFs for specific anion exchange applications. While still in its early stages, 3D printing of MOFs shows promise for both small-scale prototyping and eventual large-scale production.

Environmental considerations are also driving innovation in MOF production scalability. Green synthesis methods, such as using water as a solvent or employing microwave-assisted synthesis, are being developed to reduce the environmental impact of large-scale MOF production. These approaches not only address sustainability concerns but also have the potential to reduce production costs, making industrial-scale implementation more economically viable.

As the field progresses, collaboration between academic researchers and industrial partners will be crucial in bridging the gap between laboratory-scale synthesis and industrial production. This partnership will be essential in addressing practical challenges such as process optimization, quality control, and integration with existing industrial infrastructure.

Current MOF production methods primarily focus on laboratory-scale synthesis, which often involves solvothermal or hydrothermal processes. These methods, while effective for small-scale production, face significant challenges when scaled up to industrial levels. The main obstacles include high production costs, long synthesis times, and the use of expensive or environmentally harmful solvents.

To address these challenges, several innovative approaches are being explored. One promising method is continuous flow synthesis, which allows for the continuous production of MOFs rather than batch processes. This technique can significantly reduce production times and improve consistency in product quality. Additionally, mechanochemical synthesis has shown potential for large-scale MOF production, as it eliminates the need for solvents and can be easily scaled up using industrial milling equipment.

Another avenue for improving scalability is the development of more efficient precursor materials. By optimizing the starting materials used in MOF synthesis, researchers aim to reduce reaction times and improve yields. This approach also includes the exploration of bio-inspired precursors, which may offer more sustainable and cost-effective alternatives to traditional synthetic routes.

The use of 3D printing technology is emerging as a potential game-changer in MOF production. This additive manufacturing technique allows for precise control over MOF structure and composition, potentially enabling the production of custom-designed MOFs for specific anion exchange applications. While still in its early stages, 3D printing of MOFs shows promise for both small-scale prototyping and eventual large-scale production.

Environmental considerations are also driving innovation in MOF production scalability. Green synthesis methods, such as using water as a solvent or employing microwave-assisted synthesis, are being developed to reduce the environmental impact of large-scale MOF production. These approaches not only address sustainability concerns but also have the potential to reduce production costs, making industrial-scale implementation more economically viable.

As the field progresses, collaboration between academic researchers and industrial partners will be crucial in bridging the gap between laboratory-scale synthesis and industrial production. This partnership will be essential in addressing practical challenges such as process optimization, quality control, and integration with existing industrial infrastructure.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!